Wheel Spinner Torque settings

29 posts

• Page 1 of 2 • 1, 2

I've been following the various threads on here regarding the torque settings when refitting knock-on wheels and it has got me thinking have I been doing it all wrong for the last 40 years with my Elan. I fit the wheels and tighten them with the provided lead hammer and I'm sure they're nothing like the 200+ lbs torque that's been mentioned. As yet they have never come off! even when doing Hillclimbs.

With this in mind I sent the Technical Dept of Lotus Cars an email asking for their advice and below is copy of email.

' Hi,

Could you please give me a bit of advice regarding the wheels on my 1971 Elan Sprint. I have owned the car for over 41 years and have always used the supplied lead hammer for removing and refitting the wheels however, I am now hearing that the three eared spinners should be torqued down to at least 200 pound/feet could this be right? I'm sure there's no way I could possibly hit the spinners hard enough to achieve this amount of torque.

Your advice would be most welcome'.

Reply from Lotus

The advice in the service notes states that the wheels nuts should be checked 5-10 miles after initial fitting.

There after every week or after 1000 miles whichever occurs first.

No torque figures are mentioned.

After owning the car for over 41 years, in which time I am sure you have removed and refitted the wheels, the wheels have not come off, so I would think you are tightening them sufficiently.

I hope this helps.

With this reply can someone tell me where the high torque settings have come from.

Thanks

Ian

With this in mind I sent the Technical Dept of Lotus Cars an email asking for their advice and below is copy of email.

' Hi,

Could you please give me a bit of advice regarding the wheels on my 1971 Elan Sprint. I have owned the car for over 41 years and have always used the supplied lead hammer for removing and refitting the wheels however, I am now hearing that the three eared spinners should be torqued down to at least 200 pound/feet could this be right? I'm sure there's no way I could possibly hit the spinners hard enough to achieve this amount of torque.

Your advice would be most welcome'.

Reply from Lotus

The advice in the service notes states that the wheels nuts should be checked 5-10 miles after initial fitting.

There after every week or after 1000 miles whichever occurs first.

No torque figures are mentioned.

After owning the car for over 41 years, in which time I am sure you have removed and refitted the wheels, the wheels have not come off, so I would think you are tightening them sufficiently.

I hope this helps.

With this reply can someone tell me where the high torque settings have come from.

Thanks

Ian

- silverlink

- Second Gear

- Posts: 143

- Joined: 24 Aug 2012

Lotus' non-reply sounds like, "If what you've been doing has worked for you, keep doing it". At this point in time, that's probably the best knowledge and advice they've got. Keep in mind that the person who designed the wheel & nut probably retired long ago, and the fellow who answered your inquiry was probably born after your car was built. And much after the last time any engineering thought was put into the design of the center-lock wheel and nut.

I don't have a direct answer for you, but you'll probably get more results asking the old duffers at a track day or vintage race.

Regards,

Tim Engel

I don't have a direct answer for you, but you'll probably get more results asking the old duffers at a track day or vintage race.

Regards,

Tim Engel

- Esprit2

- Third Gear

- Posts: 354

- Joined: 02 Apr 2008

Hi Tim,

Thanks for your input and perhaps you are right about the 'tech' at Lotus been younger than the car. Regarding the 'old duffers' I think perhaps I could be one of them. Last competition I took part in was in 1976 at Cadwell Park where I was lucky enough to win my class in my Elan. As I say in my original post every time I've put wheels back on the car it was the old lead hammer I used furthermore, mechanics who worked on the car also used the same method. I'm just waiting for one of these special adaptors for putting the spinners on using socket & torque wrench but I don't think I'll be torqueing to the levels some are using.

Ian

Thanks for your input and perhaps you are right about the 'tech' at Lotus been younger than the car. Regarding the 'old duffers' I think perhaps I could be one of them. Last competition I took part in was in 1976 at Cadwell Park where I was lucky enough to win my class in my Elan. As I say in my original post every time I've put wheels back on the car it was the old lead hammer I used furthermore, mechanics who worked on the car also used the same method. I'm just waiting for one of these special adaptors for putting the spinners on using socket & torque wrench but I don't think I'll be torqueing to the levels some are using.

Ian

- silverlink

- Second Gear

- Posts: 143

- Joined: 24 Aug 2012

I have seen the figure of 200lb torque quoted....on this site !!! In the dim & distant past someone posted a scan of a US spec owners manual, where it was stated.

Can't remember who though!

Can't remember who though!

Richard

'72 Sprint

'72 Sprint

- richardcox_lotus

- Coveted Fifth Gear

- Posts: 1097

- Joined: 11 Jul 2004

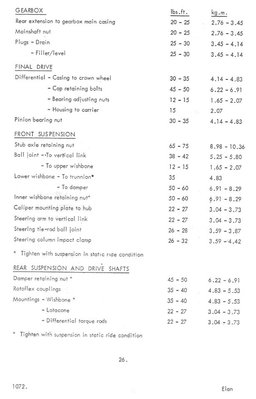

Page 27 of section 0 (Introduction) of the Elan workshop manual gives the wheel torque as 200-220 lbft.

Sarto (the inventor of the Knock Off Spinner tool) told me that Mike Ostrov (of CA Elite fame) & he did some "research" with Sarto measuring the torque that Mike put on the 3 eared spinners with the lead hammer. Apparently the torque was consistently within that range.

Sarto (the inventor of the Knock Off Spinner tool) told me that Mike Ostrov (of CA Elite fame) & he did some "research" with Sarto measuring the torque that Mike put on the 3 eared spinners with the lead hammer. Apparently the torque was consistently within that range.

- Attachments

-

ElanWSMSection0p27.pdf

ElanWSMSection0p27.pdf- (141.37 KiB) Downloaded 678 times

Phil Harrison

1972 Elan Sprint 0260K

1972 Elan Sprint 0260K

-

pharriso - Coveted Fifth Gear

- Posts: 3194

- Joined: 15 Sep 2010

Torque specs are listed in the last pages of the Technical Data Section at the front of the manual. I have two Workshop Manuals, and they don't agree on the torque spec for the Octagon hub nut.

Workshop Manual 36 T 327 dated 03/70

Technical Data Section, pg 27, dated 10/74 (not the same date as manual's title page)

Wheel nuts (octagonal) ... 200 - 220 lbs-ft ... 27.65 - 30.42 kg-m

Workshop Manual X036T0327Z dated 10/72

Technical Data Section, pg 27

Wheel nuts (octagonal) ... 160 - 180 lbs-ft ... 22.12 - 24.88 kg-m

Regards,

Tim Engel

Workshop Manual 36 T 327 dated 03/70

Technical Data Section, pg 27, dated 10/74 (not the same date as manual's title page)

Wheel nuts (octagonal) ... 200 - 220 lbs-ft ... 27.65 - 30.42 kg-m

Workshop Manual X036T0327Z dated 10/72

Technical Data Section, pg 27

Wheel nuts (octagonal) ... 160 - 180 lbs-ft ... 22.12 - 24.88 kg-m

Regards,

Tim Engel

- Esprit2

- Third Gear

- Posts: 354

- Joined: 02 Apr 2008

Having read the last couple of posts I got out my British Workshop Manual (from Hethel) and nowhere does it mention any torque settings for the wheels just the bit I got as a reply from Lotus.

Ian

Ian

- silverlink

- Second Gear

- Posts: 143

- Joined: 24 Aug 2012

Are you looking in the Technical Data Section. It's sometimes identified as being part of the "Introduction", but in my two manuals, the Tech Data section starts on page 9, at the front of the manual. It's normal Lotus format for all the torque specs to be listed in the last pages of the Tech Data, and in my manuals, that's pages 25, 26 & 27. "HUBS" appears at the top of page 27, and a torque spec is given for the Wheel Nut (Octagon).

Regards,

Tim Engel

See the attachments:

Regards,

Tim Engel

See the attachments:

- Attachments

Last edited by Esprit2 on Wed Apr 16, 2014 2:33 pm, edited 1 time in total.

- Esprit2

- Third Gear

- Posts: 354

- Joined: 02 Apr 2008

Yes I think that's true. The torque setting for the eared nuts is 3

3 solid whacks

3 solid whacks

- robertverhey

- Fourth Gear

- Posts: 694

- Joined: 20 Feb 2007

Sarto here, Lotus Elan is the only and I mean the only car company the states a torque setting. All others just say to use a hammer and beat on it until you think its good. The biggest complaints I get is trying to remove over tighten spinners.

Mike Ostrov, who has many hours attaching lotus wheels, said "hand tighten the spinner and three good whacks with a lead hammer does it" He also said when using the leverage of an extension bar or a torque wrench, you need to block the wheel because the wheel can spin. I've added a rubber wheel chock that allows one to remove a wheel by jacking the wheel up just so it can spin, place the rubber chock to wedge the wheel for removal or tighten. Now the spinner is perfectly seated to the wheel without the weight of the car on the wheel.

The earlier Lotus manual said 160 to 180. The later manual said 200 to 220. Mike's hammer method was consistent at about 210. I assume it could justified the Lotus torque settings.

http://knockoffspinnertool.com/wheel_wedge_story

http://www.olthoffracing.com/tech-and-how-to-videos?

business-listings-f3/knockoff-socket-wrench-t2268-30.html

Pharriso's link has a better image of the torque setting.

Hope this helps

Sarto

Mike Ostrov, who has many hours attaching lotus wheels, said "hand tighten the spinner and three good whacks with a lead hammer does it" He also said when using the leverage of an extension bar or a torque wrench, you need to block the wheel because the wheel can spin. I've added a rubber wheel chock that allows one to remove a wheel by jacking the wheel up just so it can spin, place the rubber chock to wedge the wheel for removal or tighten. Now the spinner is perfectly seated to the wheel without the weight of the car on the wheel.

The earlier Lotus manual said 160 to 180. The later manual said 200 to 220. Mike's hammer method was consistent at about 210. I assume it could justified the Lotus torque settings.

http://knockoffspinnertool.com/wheel_wedge_story

http://www.olthoffracing.com/tech-and-how-to-videos?

business-listings-f3/knockoff-socket-wrench-t2268-30.html

Pharriso's link has a better image of the torque setting.

Hope this helps

Sarto

lotus elan 1966 S3 FHC

36/5785

LHD

36/5785

LHD

-

mac5777 - Fourth Gear

- Posts: 501

- Joined: 05 Jul 2004

I'd guess that those of us who have been whacking at the spinners with a hammer over the years have a feel for how tight is good enough but when I last painted my wheels the prospect of undoing all the hard work by a misjudged hammer blow had me look at making a Sarto style wheel tool. What I came up with was no work of art and getting to 180lbs/ft took a little thought as my torque wrench doesn't go that high but I was surprised to find although it felt tight leaning on the bar it wasn't as tight as the third hit of the three good whacks method.

Maybe if I'd continued on to 220lbs/ft the two would have matched up but the hammer result surprised me and as it takes up less space in the boot I've gone back to that.

Maybe if I'd continued on to 220lbs/ft the two would have matched up but the hammer result surprised me and as it takes up less space in the boot I've gone back to that.

Stuart Holding

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

- 69S4

- Coveted Fifth Gear

- Posts: 1124

- Joined: 23 Sep 2004

I'm not happy with "three good whacks",is that for Popeye,Bluto or Olive Oyl ?

Whereas 200 ft/lb is 200 ft/lb !

John

Whereas 200 ft/lb is 200 ft/lb !

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4522

- Joined: 21 Sep 2003

Apologies guys,

After reading Esprit2's thread I had another look in my English manual and sure enough on page 27 its stated as 160-180 lb feet (octagonal)

Very interesting about whacking the three eared spinner and getting close to that setting using the good old lead hammer method.

Ian

After reading Esprit2's thread I had another look in my English manual and sure enough on page 27 its stated as 160-180 lb feet (octagonal)

Very interesting about whacking the three eared spinner and getting close to that setting using the good old lead hammer method.

Ian

- silverlink

- Second Gear

- Posts: 143

- Joined: 24 Aug 2012

29 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 18 guests