Wheel Nut

12 posts

• Page 1 of 1

Sorry to ask such a basic question but will someone please advise me how to correctly tighten the road wheel retaining nut. I have a mallet in the kit for this purpose. The workshop manual says that I should check that they are tight every 1000 miles but does not appear to tell me how to do this or how to tighten them in the first instance.

Many thanks,

Bob

Many thanks,

Bob

- bobm3142

- First Gear

- Posts: 47

- Joined: 17 Aug 2011

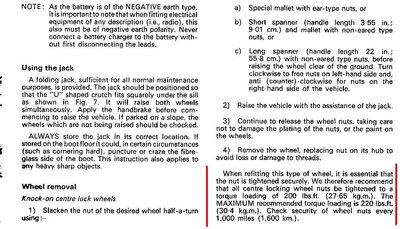

Here's what the Driver's handbook says.........

Or you might want to consider one of Sartos tools to do the job with a torque wrench......Search for "spinner tool" or "sarto" in the Tool Talk section

Or you might want to consider one of Sartos tools to do the job with a torque wrench......Search for "spinner tool" or "sarto" in the Tool Talk section

Roger

S4 DHC

S4 DHC

- oldelanman

- Coveted Fifth Gear

- Posts: 1927

- Joined: 02 Jan 2008

Hello Roger,

Thanks for the info. It is just what I needed. It doesn't seem very scientific but I guess it's worked successfully for years and years.

I have a Lotus workshop manual but not a handbook for my S3. I'll look out for one (perhaps a reproduced one).

Many thanks,

Bob

Thanks for the info. It is just what I needed. It doesn't seem very scientific but I guess it's worked successfully for years and years.

I have a Lotus workshop manual but not a handbook for my S3. I'll look out for one (perhaps a reproduced one).

Many thanks,

Bob

- bobm3142

- First Gear

- Posts: 47

- Joined: 17 Aug 2011

I second the motion for the Sarto tool. Along with a good torque wrench (or a piece of pipe, a knowledge of your weight, and the ability to measure), it makes for a better, more consistent fitting.

Art

Art

Art Frederick

S2 Roadster, built in 1965, registered in 1966, No. 26/4934

Nothing else of interest at present

S2 Roadster, built in 1965, registered in 1966, No. 26/4934

Nothing else of interest at present

-

frearther - Third Gear

- Posts: 373

- Joined: 23 Sep 2003

Eeek....

"We would point out however, that if the nut(s) are overtightened by a very heavy, strong person, ther is a possibility of splitting the wheel in the area adjacent to the wheel nut."

I'm heavy (100kg+)....relatively strong...and use a wheel spanner with a 3'+ lever......I'm worried now.......

Peter

"We would point out however, that if the nut(s) are overtightened by a very heavy, strong person, ther is a possibility of splitting the wheel in the area adjacent to the wheel nut."

I'm heavy (100kg+)....relatively strong...and use a wheel spanner with a 3'+ lever......I'm worried now.......

Peter

I is an Inginear....please excuse my speeling!

'73 +2S 130/5

Scimitar GTE for the lazy days, 3008, Some bicycles, Wife, Kids, Cats, Dogs....chickens....cluck cluck...one duck...the others flew away!

'73 +2S 130/5

Scimitar GTE for the lazy days, 3008, Some bicycles, Wife, Kids, Cats, Dogs....chickens....cluck cluck...one duck...the others flew away!

-

peterako - Fourth Gear

- Posts: 681

- Joined: 02 Mar 2006

Hi Peter,

I don't know what kind of an Inginear you is (elec., mech., etc), but if you're mechanical and you look at the wheel arrangement you will see that there is a real danger of splitiing the wheel. When I have more time I will calculate how much talk is needed to split the wheel and what effect dynamic loading through road bumps, etc. might have. The info in the handbook (kindly copied above for me) states that the aim is a torque of 200lbsf.ft with a maximum recommended value of 220lbsf.ft. There is very little difference in these (just 20lbsf.ft) so some care is needed, especially when you consider that friction in the threads could easily account for 20lbsf.ft. At 3ft you need to pull about 70 lbsf. (66.7 to 73.3). I recon a decent torque wrench is the answer. Do clean the threads but do NOT lubricate them and do check that they are tight at regular intervals and after a short distance when you first tighten them.

In order to talk them a spinner tool is needed and from what I can make out (from the leads kindly given to me, above) they are manufactured in the USA and cost about ?100. These look well made and worth the money, however, I want something right now so I going to produce my own design (using what materials I have in my garage). I will use the same principle of a hex. drive in the centre so that I can use a standard torque wrench and a socket. Mine will be made in mild steel, with PTFE contact sleeves, and I calculate that the largest hex. bar I have (0.8" across the flats) is just sufficient to take the torque.

Thanks Peter,

Regards,

Bob

I don't know what kind of an Inginear you is (elec., mech., etc), but if you're mechanical and you look at the wheel arrangement you will see that there is a real danger of splitiing the wheel. When I have more time I will calculate how much talk is needed to split the wheel and what effect dynamic loading through road bumps, etc. might have. The info in the handbook (kindly copied above for me) states that the aim is a torque of 200lbsf.ft with a maximum recommended value of 220lbsf.ft. There is very little difference in these (just 20lbsf.ft) so some care is needed, especially when you consider that friction in the threads could easily account for 20lbsf.ft. At 3ft you need to pull about 70 lbsf. (66.7 to 73.3). I recon a decent torque wrench is the answer. Do clean the threads but do NOT lubricate them and do check that they are tight at regular intervals and after a short distance when you first tighten them.

In order to talk them a spinner tool is needed and from what I can make out (from the leads kindly given to me, above) they are manufactured in the USA and cost about ?100. These look well made and worth the money, however, I want something right now so I going to produce my own design (using what materials I have in my garage). I will use the same principle of a hex. drive in the centre so that I can use a standard torque wrench and a socket. Mine will be made in mild steel, with PTFE contact sleeves, and I calculate that the largest hex. bar I have (0.8" across the flats) is just sufficient to take the torque.

Thanks Peter,

Regards,

Bob

- bobm3142

- First Gear

- Posts: 47

- Joined: 17 Aug 2011

Bob

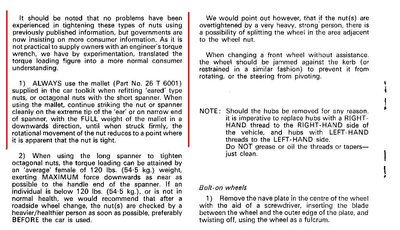

"however, I want something right now so I going to produce my own design (using what materials I have in my garage). I will use the same principle of a hex. drive in the centre so that I can use a standard torque wrench and a socket. Mine will be made in mild steel, with PTFE contact sleeves,"

...had the same thoughts so while looking through an autojumble noticed a nice big box spanner,cost ?2,with a bit of grinding and a bit of welding is now a 1/2" drive spinner socket...

[attachment=0]2011_0817knockon0001.JPG[/attachment]

John

"however, I want something right now so I going to produce my own design (using what materials I have in my garage). I will use the same principle of a hex. drive in the centre so that I can use a standard torque wrench and a socket. Mine will be made in mild steel, with PTFE contact sleeves,"

...had the same thoughts so while looking through an autojumble noticed a nice big box spanner,cost ?2,with a bit of grinding and a bit of welding is now a 1/2" drive spinner socket...

[attachment=0]2011_0817knockon0001.JPG[/attachment]

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4522

- Joined: 21 Sep 2003

bobm3142 wrote:Hi Peter,

When I have more time I will calculate how much talk is needed to split the wheel and what effect dynamic loading through road bumps, etc. might have.

Bob

I know it's a typo but it's April first.

Bud

1970 +2S Fed 0053N

"Winnemucca - says it all really!!"

1970 +2S Fed 0053N

"Winnemucca - says it all really!!"

- Bud English

- Fourth Gear

- Posts: 938

- Joined: 05 Nov 2011

Bud English wrote:bobm3142 wrote:Hi Peter,

When I have more time I will calculate how much talk is needed to split the wheel and what effect dynamic loading through road bumps, etc. might have.

Bob

I know it's a typo but it's April first.I have to point out that there have been some threads, the battery switch thread comes to mind, that had almost that much talk. Properly focused, talk can be a powerful force. Apply it responsibly!

Hey, ease off. Bob may be from Boston!

Mechanical Engineer, happily retired!

'67 S3 SE FHC

See Facebook page: W J Barry Photography

Put your money where your mouse is, click on "Support LotusElan.net" below.

'67 S3 SE FHC

See Facebook page: W J Barry Photography

Put your money where your mouse is, click on "Support LotusElan.net" below.

-

Galwaylotus - Coveted Fifth Gear

- Posts: 1255

- Joined: 01 May 2006

12 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 20 guests