Bolt on wheel lug nut torque specs

35 posts

• Page 2 of 3 • 1, 2, 3

Craven wrote:I think the speculation that someone has had purpose made studs ( see pic ) to a different lower steel grade is taking thing just too far. With the cost regime of Lotus at the time they specified and had fitted to a bought in mass produced item a different grade stud is risible.

Past unknown history of stress undergone by these studs even in normal roadside spare wheel change, is more than likely a reason for breakage later in its service life.

I dont know what grade the wheel studs were originally made to do you ? i would be surprised if they were Grade 8. They appear softer to me than a typical modern Grade 8 stud. Maybe i should do some hardness and tensile testing on one

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8408

- Joined: 22 Sep 2003

I presume your Triumph data is accurate - what was posted was not original Triumph manual information as far as I could see . However assuming it is accurate it means either a grade 8 stud within the normal range of friction assumptions or a very high friction level and a grade 5 stud.

Thus you need to determine what studs are fitted to your hubs and what friction levels are happening on your hubs and wheels to nut interface. Get the assumption wrong and you maybe break the studs. Then you say the studs are to small and you fit larger one as others do.

All I am trying to highlight is that the 3/8 studs in either grade 5 or grade 8 are plenty big enough to hold your wheels on provide you don't over torque them..... The challenge is to find a torque that holds them on and does not over stress the studs. For me 25 ft -lbs works on alloy wheels with hardened washers and smooth studs and nut thread ( unlubricated) in full race conditions for 40 years with sticky tyres. Depending on the wheel / nut / stud combination and usage you have you may need more than I do. Going to 45 ft-lbs risks stretching breaking a grade 5 stud in average friction level situations and it failing.

Just my simplistic engineering approach, your mileage may vary.

In the end do up the wheel nuts as hard as you like as its your decision and I hope you have 40 years of engineering bolting analysis to back up that decision as the wheels may fall off if you get it wrong. Relying on a listing from a Triumph manual from 50 years ago based on bolting assumptions that may not apply to your situation is just guessing.

cheers

Rohan

Thus you need to determine what studs are fitted to your hubs and what friction levels are happening on your hubs and wheels to nut interface. Get the assumption wrong and you maybe break the studs. Then you say the studs are to small and you fit larger one as others do.

All I am trying to highlight is that the 3/8 studs in either grade 5 or grade 8 are plenty big enough to hold your wheels on provide you don't over torque them..... The challenge is to find a torque that holds them on and does not over stress the studs. For me 25 ft -lbs works on alloy wheels with hardened washers and smooth studs and nut thread ( unlubricated) in full race conditions for 40 years with sticky tyres. Depending on the wheel / nut / stud combination and usage you have you may need more than I do. Going to 45 ft-lbs risks stretching breaking a grade 5 stud in average friction level situations and it failing.

Just my simplistic engineering approach, your mileage may vary.

In the end do up the wheel nuts as hard as you like as its your decision and I hope you have 40 years of engineering bolting analysis to back up that decision as the wheels may fall off if you get it wrong. Relying on a listing from a Triumph manual from 50 years ago based on bolting assumptions that may not apply to your situation is just guessing.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8408

- Joined: 22 Sep 2003

One has to believe the design engineers knew what they were doing, it?s quite possible their practical figures took into consideration the very high friction ( surface area ) of the dry cup and cone of wheel and nut.

Past history of any critical fastener on a 50 year old car is of concern, your solution don?t use recommended torque settings.

Past history of any critical fastener on a 50 year old car is of concern, your solution don?t use recommended torque settings.

- Craven

- Coveted Fifth Gear

- Posts: 1625

- Joined: 14 Sep 2013

Craven wrote:One has to believe the design engineers knew what they were doing, it?s quite possible their practical figures took into consideration the very high friction ( surface area ) of the dry cup and cone of wheel and nut.

Past history of any critical fastener on a 50 year old car is of concern, your solution don?t use recommended torque settings.

My solution is based on my wheels, nuts, hubs and my engineering analysis as I have highlighted. Anyone else solution's needs to be based on their current set up of wheels, nuts, studs. If its close to the original triumph one then maybe the original triumph torque spec is maybe OK - If its wrong you will know eventually

Personally I would start low at maybe 30 to 35 ft lbs for a standard steel wheel and nut combination and check often and increase it if it comes loose.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8408

- Joined: 22 Sep 2003

Bringing this thread up again not just around torque specs but also because it could have the most relevance for replacing a stud.

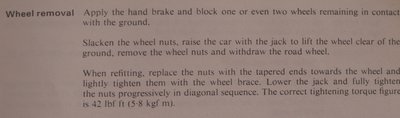

I recently had a lug nut and stud shear off my S1 (rescued by the hub cap) and could have been because of too high a torque. Confident that it the nuts would have been torqued according to Buckland considering how much the guide was used as reference. In speaking to Dave Bean Eng however the 35 lbs/ft was suggested.

Not really my question though - any advice on removing a sheared off stud to replace it?

Thanks!

I recently had a lug nut and stud shear off my S1 (rescued by the hub cap) and could have been because of too high a torque. Confident that it the nuts would have been torqued according to Buckland considering how much the guide was used as reference. In speaking to Dave Bean Eng however the 35 lbs/ft was suggested.

Not really my question though - any advice on removing a sheared off stud to replace it?

Thanks!

- Wolfman

- First Gear

- Posts: 23

- Joined: 30 Nov 2021

I would remove the Hub and replace all 4 Studs.

Going off subject i don't like the way someone "wirelocked" the Brake Caliper Bolts

Alan

Going off subject i don't like the way someone "wirelocked" the Brake Caliper Bolts

Alan

Alan.b Brittany 1972 elan sprint fhc Lagoon Blue 0460E

- alan.barker

- Coveted Fifth Gear

- Posts: 3763

- Joined: 06 Dec 2008

Wheel studs can also break because someone has fitted aftermarket wheels with more negative offset than the standard ones. This will increase the bending stress on the bolts, wheel bearings, etc.

1970 Ford Escort Twin Cam

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

- 2cams70

- Coveted Fifth Gear

- Posts: 2170

- Joined: 10 Jun 2015

+1 "boy racer " + extra low profile sticky Tyres

Alan

Alan

Alan.b Brittany 1972 elan sprint fhc Lagoon Blue 0460E

- alan.barker

- Coveted Fifth Gear

- Posts: 3763

- Joined: 06 Dec 2008

Try gently tapping the studs out from the front using a copper hammer. Do not persist if they are too stubborn because as you correctly pointed out you risk damage to parts such as bearings.

The best tool for the job would be screw type press tool. You may be able to adapt something for the job such as a screw operated ball joint separator.

Failing that yes - it's best to remove the hub before attempting to remove them.

By the way - looking at the length of thread extending past the wheel nut are you sure the studs are original and that the car has always had standard steel wheels and no wheel spacers? They look too long to me but then again it's a Lotus.

The best tool for the job would be screw type press tool. You may be able to adapt something for the job such as a screw operated ball joint separator.

Failing that yes - it's best to remove the hub before attempting to remove them.

By the way - looking at the length of thread extending past the wheel nut are you sure the studs are original and that the car has always had standard steel wheels and no wheel spacers? They look too long to me but then again it's a Lotus.

1970 Ford Escort Twin Cam

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

- 2cams70

- Coveted Fifth Gear

- Posts: 2170

- Joined: 10 Jun 2015

The use of longer wheel studs was something the racing boys did a few year's back (do they still do it?), the reason being that if a nut came loose it took longer to come off the stud and gave a longer warning that something was not right and prevented the nut from flying off and causing damage to someone or something.

- tonyabacus

- Third Gear

- Posts: 449

- Joined: 16 Sep 2003

35 posts

• Page 2 of 3 • 1, 2, 3

Total Online:

Users browsing this forum: No registered users and 4 guests