Tightening a Knock Off Spinner/Wheel?

43 posts

• Page 2 of 3 • 1, 2, 3

Hi

If you have stripped/changed parts of the hubs it may be worth ensuring that your tight spinner is actually resulting in a tight wheel, i.e the spinners are not bottoming on the hub threads before they exert the intended clamping force on the wheel centre. Two of my spinners have different depths of thread, this together with the different thread lengths from the wheel centres between the front and back hubs requires that care is taken not to swop the spinners on each side.

Rather than use a simple torque figure as a guide for tightening the spinner using an angular measurement would appear to be of more value. This would require the spinner to be tightened by hand until it contacts the wheel centre, removing discernable play in wheel, and then further tighten the spinner a further set number of degrees by which ever method you prefer. Of course failure to achieve the set number of degrees would indicate that your spinner may be bottoming and not clamping the wheel correctly.

Unfortunately, my +2 is still up on axle stands so I do not have the means to determine what the angle should be yet. However, measuring the angle that 180lbft of torque will turn the spinner should be fairly straightforward. I suspect that maybe the angle will be different between steel wheels and alloy wheels, possibly different makes of alloy wheels will also be different.

A further advantage of making the measurement would be that if you ensured your wheels were replaced on the same pegs each time (paint?) you have the option to make a small mark on the wheel that lines up with a similarly marked spinner ear. Visual confirmation at the roadside of the tightness of the spinner by checking the marks may give a level of reassurance.

Hope this helps,

Mike

If you have stripped/changed parts of the hubs it may be worth ensuring that your tight spinner is actually resulting in a tight wheel, i.e the spinners are not bottoming on the hub threads before they exert the intended clamping force on the wheel centre. Two of my spinners have different depths of thread, this together with the different thread lengths from the wheel centres between the front and back hubs requires that care is taken not to swop the spinners on each side.

Rather than use a simple torque figure as a guide for tightening the spinner using an angular measurement would appear to be of more value. This would require the spinner to be tightened by hand until it contacts the wheel centre, removing discernable play in wheel, and then further tighten the spinner a further set number of degrees by which ever method you prefer. Of course failure to achieve the set number of degrees would indicate that your spinner may be bottoming and not clamping the wheel correctly.

Unfortunately, my +2 is still up on axle stands so I do not have the means to determine what the angle should be yet. However, measuring the angle that 180lbft of torque will turn the spinner should be fairly straightforward. I suspect that maybe the angle will be different between steel wheels and alloy wheels, possibly different makes of alloy wheels will also be different.

A further advantage of making the measurement would be that if you ensured your wheels were replaced on the same pegs each time (paint?) you have the option to make a small mark on the wheel that lines up with a similarly marked spinner ear. Visual confirmation at the roadside of the tightness of the spinner by checking the marks may give a level of reassurance.

Hope this helps,

Mike

- Washer

- First Gear

- Posts: 27

- Joined: 28 Jan 2013

One other point not mentioned, have you painted the hubs recently? On my car, the PO had used a rather thick coat of paint on the hubs. This prevented the wheel from being tightened completely against the hub. After a spirited drive down a steep grade, the front KO's became a bit loose. I noticed this because of a clicking sound I heard after pulling away from a stop sign at the bottom of the grade. It took several whacks with the hammer to get everything tight again. After getting home, I pulled the front wheels and saw that the paint had been displaced at the point of contact between the wheel and the hub. Pulled the other two 2 off the rear and found the same pattern. Scraped off the remaining paint and only applied a fog coat of paint to the hub. I regularly drive a mountain course that requires heavy braking on some very sharp turns. Since making the above change, I have never had the wheels come loose again.

Rob Walker

26-4889

50-0315N

1964 Sabra GT

1964 Elva Mk4T Coupe (awaiting restoration)

1965 Ford Falcon Ranchero, 302,AOD,9",rack and pinion,disc,etc,etc,etc

1954 Nash Healey LeMans Coupe

Owning a Lotus will get you off the couch

26-4889

50-0315N

1964 Sabra GT

1964 Elva Mk4T Coupe (awaiting restoration)

1965 Ford Falcon Ranchero, 302,AOD,9",rack and pinion,disc,etc,etc,etc

1954 Nash Healey LeMans Coupe

Owning a Lotus will get you off the couch

- prezoom

- Coveted Fifth Gear

- Posts: 1194

- Joined: 16 Mar 2009

I've been using a plsatic deadblow hammer which doesn't mark the wheels when I occasionally miss

I remember reading an article ages ago that recommended hitting hard enough for it to be a solid whack without knocking the dried manure off the bottom of the car

I remember reading an article ages ago that recommended hitting hard enough for it to be a solid whack without knocking the dried manure off the bottom of the car

Chris

Elan +2 #0245

Exige S2 Supercharged

Elan +2 #0245

Exige S2 Supercharged

- Chrispy

- Third Gear

- Posts: 308

- Joined: 29 Oct 2017

George,

Interesting point about the Hub being on the right way.

The left side Spinners (From the Drivers Seat) Loosen Clockwise and the

Right Side Loosen Anti Clockwise on mine, which I assume to be correct

as it means the "Undo" is in opposition to Wheel travel whilst the Car is in a Forward Motion.

Even if they were round the wrong way though, would the Wheel Loosen if it were Torqued correctly?

Bearing in mind, here in the Uk, most of the old British Cars had the same Wheel Nuts both sides.

Ian

Interesting point about the Hub being on the right way.

The left side Spinners (From the Drivers Seat) Loosen Clockwise and the

Right Side Loosen Anti Clockwise on mine, which I assume to be correct

as it means the "Undo" is in opposition to Wheel travel whilst the Car is in a Forward Motion.

Even if they were round the wrong way though, would the Wheel Loosen if it were Torqued correctly?

Bearing in mind, here in the Uk, most of the old British Cars had the same Wheel Nuts both sides.

Ian

Lotus Elan +2S 130

Jensen Healey

Jensen Healey

- Classic-BSC

- First Gear

- Posts: 32

- Joined: 22 Jun 2016

George,

Yes, as you thought, your hubs and wheels are correct.

Eric in Burnley

Yes, as you thought, your hubs and wheels are correct.

Eric in Burnley

- ericbushby

- Coveted Fifth Gear

- Posts: 1362

- Joined: 13 Jun 2011

As an update.

I ordered a Three Eared Spinner Tool from Lionel and it arrived today.

45 GBP which I think is good value. It is very well made.

Polished and Shiny. Almost seems a shame to use it!

Haven't tried it on the Car yet, I think I might like to add a piece of Leather

or something similar to avoid Metal to Metal Contact.

Ian

I ordered a Three Eared Spinner Tool from Lionel and it arrived today.

45 GBP which I think is good value. It is very well made.

Polished and Shiny. Almost seems a shame to use it!

Haven't tried it on the Car yet, I think I might like to add a piece of Leather

or something similar to avoid Metal to Metal Contact.

Ian

Lotus Elan +2S 130

Jensen Healey

Jensen Healey

- Classic-BSC

- First Gear

- Posts: 32

- Joined: 22 Jun 2016

I had trouble with wheels coming loose at Thruxton last weekend,

I have a spin off tool and have previously torqued them to 190 ft/lbs, raced at Donnington and Snetterton without issue. Testing at Thruxton and the rear nearside came off, luckily at low speed. Re torqued all wheels up to 220ft/lbs and the rear off side wheel came loose. Talked to the team next to me and they torque their Elan wheels up to 350ft/lbs, same as their GT40 and F2 cars so tried that for the race with added triple lock wire. Wheels stayed on this time. Other teams said its better to tighten up with a mallet rather than a wrench.

Regards

Andy

I have a spin off tool and have previously torqued them to 190 ft/lbs, raced at Donnington and Snetterton without issue. Testing at Thruxton and the rear nearside came off, luckily at low speed. Re torqued all wheels up to 220ft/lbs and the rear off side wheel came loose. Talked to the team next to me and they torque their Elan wheels up to 350ft/lbs, same as their GT40 and F2 cars so tried that for the race with added triple lock wire. Wheels stayed on this time. Other teams said its better to tighten up with a mallet rather than a wrench.

Regards

Andy

- batfish

- Third Gear

- Posts: 300

- Joined: 09 Oct 2003

In my book there is a world of difference between a constant turning force and a nut tightened by flogging. Instantaneous compressive force causes inward distortion of the wheel centre creating in effect a spring loaded holding force on the spinner.

Flogging technique is not pretty but very effective.

FWIW

Flogging technique is not pretty but very effective.

FWIW

- Craven

- Coveted Fifth Gear

- Posts: 1625

- Joined: 14 Sep 2013

The left side Spinners (From the Drivers Seat) Loosen Clockwise and the

Right Side Loosen Anti Clockwise on mine, which I assume to be correct

as it means the "Undo" is in opposition to Wheel travel whilst the Car is in a Forward Motion

Not to put the cat among the pigeons . . . . but I've always believed that this would be the incorrect way. With all of the centre-lock race cars I've owned the mantra is always "put the wheels BACK on" meaning they should tighten when turned toward the back of the car. The logic is that more force is applied to the rotating mass under braking than under acceleration. Therefore, braking action tends to tighten the assembly. I seriously doubt our street cars can generate enough rotational force under the hardest acceleration to loosen even a poorly tightened wheel. However, heavy braking force will apply much more rotational force and can easily loosen a poorly torqued wheel.

YMMV

Right Side Loosen Anti Clockwise on mine, which I assume to be correct

as it means the "Undo" is in opposition to Wheel travel whilst the Car is in a Forward Motion

Not to put the cat among the pigeons . . . . but I've always believed that this would be the incorrect way. With all of the centre-lock race cars I've owned the mantra is always "put the wheels BACK on" meaning they should tighten when turned toward the back of the car. The logic is that more force is applied to the rotating mass under braking than under acceleration. Therefore, braking action tends to tighten the assembly. I seriously doubt our street cars can generate enough rotational force under the hardest acceleration to loosen even a poorly tightened wheel. However, heavy braking force will apply much more rotational force and can easily loosen a poorly torqued wheel.

YMMV

Charlie Warner

Fatto Gatto Racing

Fatto Gatto Racing

-

fattogatto - Third Gear

- Posts: 251

- Joined: 23 Sep 2015

On most, if not all other cars with centre lock wheels like MG, Jag Triumph etc, they are fitted right hand thread to left side of car & visa versa, whereas Lotus fit Right hand thread to right hand side & visa versa & both will undo in use if fitted to the wrong sides. Many years ago, a colleague who was used to working on MG's insisted on fitting a set of Lotus hubs as he would an MG's & they just wouldn't stay tight, they'd loosen off in just a few miles no matter how hard he tried to hammer them up. I eventually persuaded him to try them the other way round, & hey presto, they stayed tight. This made both of us curious as to why they should be different. If you look at each of them, on the Lotus, the male part of the tapered cone is on the spinner & tightens into the female part on the wheel, whereas on the MG etc, the male part of the cone is on the wheel & the female part is inside the spinner & tightens over the wheel. Don't ask me why, or even if this makes such a difference, as the torsional & rotational forces are the same in both systems, but it was the only thing we could come up with. Maybe someone can explain or come up with another reason ?

Regards, Tim

Regards, Tim

- Orsom Weels

- Third Gear

- Posts: 409

- Joined: 31 Oct 2011

Hello All, Its been awhile. I have to congratulate those who have made tools that eliminate the need for a hammer. They all exert equal force to all ears rather than one at a time using a hammer. Which could distort the spinner and make it harder to remove with some of the aluminum type spinners.

Most spinners are labeled UNDO or OFF with a directional arrow for Right or Left side for reverse threads.

We are lucky as our Lotus Elans and Cobra / GT40s are pin drives.

Most other spinner like MGs, Triumphs, early wire wheel Cobras, Morgans, Lotus Elites type 14 and the larger Jaguars are all spline driven wheels. They have to be watched as the splines can wear and bend to a dangerous shape. If they are over tightened it can weaken the threads. Pin drive wheels also have to be watched as the wheel holes can elongated and cause the wheel to move on the hub.

The other danger is that the hubs are installed incorrectly on the wrong side.

The biggest complaint I get is from the Cobra guys is that they can not get the spinners off.

The only torque settings and I mean the only one is in the Lotus Elan's manual which states 160 to 180 torque and in a later manual 200 to 220 ft/lbs. All of the other car and wheel manufacturers, just said to use a lead hammer and beat on them until you think they are tight enough.

I welcome any corrections to my thinking. PM me for info on the attached photo

Sarto

[email protected]" target="_blank

Most spinners are labeled UNDO or OFF with a directional arrow for Right or Left side for reverse threads.

We are lucky as our Lotus Elans and Cobra / GT40s are pin drives.

Most other spinner like MGs, Triumphs, early wire wheel Cobras, Morgans, Lotus Elites type 14 and the larger Jaguars are all spline driven wheels. They have to be watched as the splines can wear and bend to a dangerous shape. If they are over tightened it can weaken the threads. Pin drive wheels also have to be watched as the wheel holes can elongated and cause the wheel to move on the hub.

The other danger is that the hubs are installed incorrectly on the wrong side.

The biggest complaint I get is from the Cobra guys is that they can not get the spinners off.

The only torque settings and I mean the only one is in the Lotus Elan's manual which states 160 to 180 torque and in a later manual 200 to 220 ft/lbs. All of the other car and wheel manufacturers, just said to use a lead hammer and beat on them until you think they are tight enough.

I welcome any corrections to my thinking. PM me for info on the attached photo

Sarto

[email protected]" target="_blank

lotus elan 1966 S3 FHC

36/5785

LHD

36/5785

LHD

-

mac5777 - Fourth Gear

- Posts: 501

- Joined: 05 Jul 2004

I don?t think any even slightly astute owner would flog a wheel spinner on just one ear, wheel spinners should never be tightened with the weight of the car on the wheel allowing the wheel to be rotated.

There lots of chat about whether the pegs are for drive or just location.

There lots of chat about whether the pegs are for drive or just location.

- Craven

- Coveted Fifth Gear

- Posts: 1625

- Joined: 14 Sep 2013

I would point out that Sarto?s unit clearly shows that you indeed do tighten the wheel nuts towards the rear of the car. Standard threads on the left side and left handed threads for the right side.

Charlie Warner

Fatto Gatto Racing

Fatto Gatto Racing

-

fattogatto - Third Gear

- Posts: 251

- Joined: 23 Sep 2015

Perhaps the tool Sarto shows is not for the Elan ?

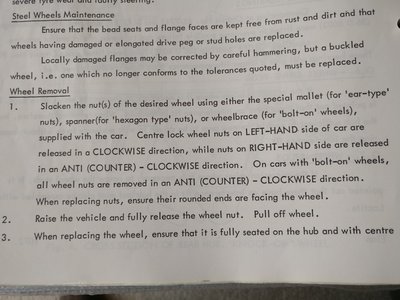

From the Elan Workshop Manual......

From the Elan Workshop Manual......

Roger

S4 DHC

S4 DHC

- oldelanman

- Coveted Fifth Gear

- Posts: 1927

- Joined: 02 Jan 2008

43 posts

• Page 2 of 3 • 1, 2, 3

Total Online:

Users browsing this forum: No registered users and 26 guests