recommendations for wood rim wheel renovation

13 posts

• Page 1 of 1

I've acquired a wood rim wheel for my S2 and want recommendations for products to apply to the wood, I think it has been refurbushed but it has nothing on the wood.

I am not a fan of woodwork so have not a clue what to apply ....wood stain? varnish? French polish? .......give me some metal and I'll weld it but wood nah!

.......give me some metal and I'll weld it but wood nah!

I am not a fan of woodwork so have not a clue what to apply ....wood stain? varnish? French polish?

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3403

- Joined: 11 Sep 2003

Hi Brian, I've done several, and if the wood is clean and bare, you need to choose what colour you want , which can only be done by trial and error I'm afraid. You need woodstain in the colour you choose, and then I just spray several, (5 or 6) thin coats of laquer, with a day in between each to let each coat harden off properly. A good polish afterwards and it come up like glass. the only problem is that you really need to test the colour on the wheel itself, in a very small area, just in case you don't like it ! then if thats the case you'll need to rub it out again, which is easier said than done. Unfortunately if you test it on a different type / age of wood, then you may get a different colour than if you'd put it on your steering wheel....

If there is any laquer left on the wheel currently, I find the best product to take it off is Scotchbrite, either the grey or maroon version.

It's annoyingly difficult to get what you're wanting, rather than physically demanding.

Good Luck

Steve

elans3

If there is any laquer left on the wheel currently, I find the best product to take it off is Scotchbrite, either the grey or maroon version.

It's annoyingly difficult to get what you're wanting, rather than physically demanding.

Good Luck

Steve

elans3

- elans3

- Fourth Gear

- Posts: 530

- Joined: 12 Sep 2003

Thanks for the replys guys,...... O.K. you both say apply a wood stain first so that seems to be the way to go then elans3 says laquer (clear I presume) and cab says urathane (also clear I suppose).......is there a differance between the two or basically is it the same thing........  sorry if its a stupid question but as I said I know little of such things

sorry if its a stupid question but as I said I know little of such things

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3403

- Joined: 11 Sep 2003

If you want to get a good durable finish that will last for ages and be impervious to the weather I would follow the following varnishing method I was taught whilst working on some Germand Yachts using a good quality marine varnish:

i) clean wood down with thinners

ii) 20% varnish to 80% thinners light coat thereof

iii) once fully dry, usually next day, light sanding with finest sandpaper you can find then wipe down with small amount of thinners to remove dust

iv) 40% varnish to 60% thinners light coat thereof

v) once fully dry, usually next day, light sanding with finest sandpaper you can find then wipe down with small amount of thinners to remove dust

vi) 80% varnish to 20% thinners light coat thereof

vii) once fully dry, usually next day, light sanding with finest sandpaper you can find then wipe down with small amount of thinners to remove dust

viii) 100% varnish light coat thereof

ix) once fully dry, usually next day, light sanding with finest sandpaper you can find then wipe down with small amount of thinners to remove dust

x) 100% varnish light coat therefore

leave to fully harden and then lightly buff. You will get a solid coating that will last for years. The whole point of the thinend down coats to begin with is to allow the varnish to soak into the wood thus giving it a good key so that it lasts for years. Rather akin to making sure the weld melts into the metal and doesnt just sit on top of it if you want a good joint.

Personally I would go for a yacht varnish rather than a ployurethane as more resitant to moisture etc.

From Wikipedia (http://en.wikipedia.org/wiki/Polyurethane):

"Polyurethane materials are commonly formulated as paints and varnishes for finishing coats to protect or seal wood. This use results in a hard, abrasion-resistant, and durable coating that is popular for hardwood floors, but considered by some to be difficult or unsuitable for finishing furniture or other detailed pieces. Relative to oil or shellac varnishes, polyurethane varnish forms a harder film which tends to de-laminate if subjected to heat or shock, fracturing the film and leaving white patches. This tendency increases when it is applied over softer woods like pine. This is also in part due to polyurethane's lesser penetration into the wood. "

Hence why I would go for a yacht varnish that can penetrate wood, particularly if you use the method above and is designed to be flexible as boat hulls and deck fittings are constantly moving.

French polish is a form of lacquer and my understanding it, althoguh stand to be corrected, that a similar technique to the one outliend above is used to get a good key for the polish and then it is built up in thinned downed layers before top coats of the full strength stuff.

Having seen 55year old pine that is kept outside in Berlin and suffered no rot due to being varnished in the manner above I have always used it since.

Main thing with getting a good finish on wood is to make sure it is immaculately clean, degreased with suitable thinners before you start applying any coats and there is no dust around. Plus use a good quality brush, btu make sure it has been worn in first to remove any loose hairs. A mariner friend of mine told me that as an apprentice they used to use brushes for creosoting on the boats to wear them down and then making sure they were very clean would then use them for varnishing!

Hope this helps.

Andy

i) clean wood down with thinners

ii) 20% varnish to 80% thinners light coat thereof

iii) once fully dry, usually next day, light sanding with finest sandpaper you can find then wipe down with small amount of thinners to remove dust

iv) 40% varnish to 60% thinners light coat thereof

v) once fully dry, usually next day, light sanding with finest sandpaper you can find then wipe down with small amount of thinners to remove dust

vi) 80% varnish to 20% thinners light coat thereof

vii) once fully dry, usually next day, light sanding with finest sandpaper you can find then wipe down with small amount of thinners to remove dust

viii) 100% varnish light coat thereof

ix) once fully dry, usually next day, light sanding with finest sandpaper you can find then wipe down with small amount of thinners to remove dust

x) 100% varnish light coat therefore

leave to fully harden and then lightly buff. You will get a solid coating that will last for years. The whole point of the thinend down coats to begin with is to allow the varnish to soak into the wood thus giving it a good key so that it lasts for years. Rather akin to making sure the weld melts into the metal and doesnt just sit on top of it if you want a good joint.

Personally I would go for a yacht varnish rather than a ployurethane as more resitant to moisture etc.

From Wikipedia (http://en.wikipedia.org/wiki/Polyurethane):

"Polyurethane materials are commonly formulated as paints and varnishes for finishing coats to protect or seal wood. This use results in a hard, abrasion-resistant, and durable coating that is popular for hardwood floors, but considered by some to be difficult or unsuitable for finishing furniture or other detailed pieces. Relative to oil or shellac varnishes, polyurethane varnish forms a harder film which tends to de-laminate if subjected to heat or shock, fracturing the film and leaving white patches. This tendency increases when it is applied over softer woods like pine. This is also in part due to polyurethane's lesser penetration into the wood. "

Hence why I would go for a yacht varnish that can penetrate wood, particularly if you use the method above and is designed to be flexible as boat hulls and deck fittings are constantly moving.

French polish is a form of lacquer and my understanding it, althoguh stand to be corrected, that a similar technique to the one outliend above is used to get a good key for the polish and then it is built up in thinned downed layers before top coats of the full strength stuff.

Having seen 55year old pine that is kept outside in Berlin and suffered no rot due to being varnished in the manner above I have always used it since.

Main thing with getting a good finish on wood is to make sure it is immaculately clean, degreased with suitable thinners before you start applying any coats and there is no dust around. Plus use a good quality brush, btu make sure it has been worn in first to remove any loose hairs. A mariner friend of mine told me that as an apprentice they used to use brushes for creosoting on the boats to wear them down and then making sure they were very clean would then use them for varnishing!

Hope this helps.

Andy

Live life to the fullest - that's why I own a Lotus

- handi_andi

- Third Gear

- Posts: 392

- Joined: 04 Feb 2006

Brian,

Why not talk to the tech bloke at Moto Lita? I found him to be really helpful, even though he knew I was not buying anything.

Pete.

Why not talk to the tech bloke at Moto Lita? I found him to be really helpful, even though he knew I was not buying anything.

Pete.

-

elansprint71 - Coveted Fifth Gear

- Posts: 2624

- Joined: 16 Sep 2003

rub the wood with fine steel wool then apply marine varnish ---ed

dont close your eyes --you will miss the crash

Editor: On June 12, 2020, Edward Law, AKA TwinCamMan, passed away; his obituary can be read at https://www.friscolanti.com/obituary/edward-law. He will be missed.

Editor: On June 12, 2020, Edward Law, AKA TwinCamMan, passed away; his obituary can be read at https://www.friscolanti.com/obituary/edward-law. He will be missed.

-

twincamman - Coveted Fifth Gear

- Posts: 2453

- Joined: 02 Oct 2003

I've just restored a lovely wooden rimed steering wheel that a 'yoof' threw away because some varnish was lifting, I used the technique my dear old dad taught me, to get the original varnish off, first i scraped it with a new stanley knife type blade at 90 degrees to the wood, it took several blades as they must remain sharp or damage the wood, I then sanded the wheel till smooth. I stained it down with colron wood dye and left over night. I then varnished it with "Plasticote" exterior varnish, this is in an aerosol can and very thinned down, about 6 light coats gave a smooth and shiny finish. As its sprayed there is no need to rub down brush marks between coats, the varnish is also very thin and soaks in to the wood well. Having got a shiny base, I then gave it a light sand with 1500 grit wet n dry (dry) wiped it down with some acetone to degrease and sprayed 3 final coats on to the wheel, allowing the varnish to tack off between coats.

I have done several wheels and dashboards in the same way with very satisfactory results

Mark

I have done several wheels and dashboards in the same way with very satisfactory results

Mark

- tower of strength

- Third Gear

- Posts: 351

- Joined: 15 Mar 2005

O.K. guys....several choices/methods here  any more pics to see results?

any more pics to see results?

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3403

- Joined: 11 Sep 2003

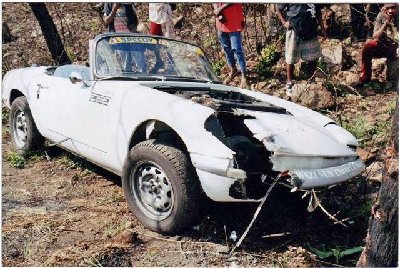

And are we not going to get anyone worried for our health telling us not to do it in case we crash and get splinters?

John

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4521

- Joined: 21 Sep 2003

john.p.clegg wrote:And are we not going to get anyone worried for our health telling us not to do it in case we crash and get splinters?

:

Probably... but been there-done that and lived to tell the tale......

couple of pics of what happens to a woodrim

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3403

- Joined: 11 Sep 2003

Use yacht varnish and you will not be sorry you did. Unless they specifically state formulation for exterior use, polyurethanes are not suitable for it and certainly not as good as a top-notch spar varnish. A car is a fairly severe outdoor application.

Another advantage is that yacht varnishes generally recommend a thinning process, useful to get started and to finish up. Polys generally recommend no thinning and are too thick as supplied.

My Moto-Lita is just gorgeous on the Europa. There are worse ways to die than with a chest packed with splintered wood. At least you'll go down with your Lotus!

Another advantage is that yacht varnishes generally recommend a thinning process, useful to get started and to finish up. Polys generally recommend no thinning and are too thick as supplied.

My Moto-Lita is just gorgeous on the Europa. There are worse ways to die than with a chest packed with splintered wood. At least you'll go down with your Lotus!

- denicholls2

- Fourth Gear

- Posts: 550

- Joined: 23 Jan 2006

Check this out

http://www.rustins.co.uk/

Did mine a few years ago and cannot recommend them highly enough

John

http://www.rustins.co.uk/

Did mine a few years ago and cannot recommend them highly enough

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4521

- Joined: 21 Sep 2003

13 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 23 guests