Oversteer on corners

I'm puzzled about this washer on front of the ball-joint discussion. Where does it go? The Ball joint is held to the upper arms by two fore-aft bolts. Putting washers there would have no effect on the suspension geometry.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4405

- Joined: 19 Apr 2008

Another approach would be to soak the spindle to chassis interface with de-oxidiser.

Something with hydrochloric and phosphoric acids in it will "eat" the rust, hopefully penetrating far enough to loosen the spindle. I've used this method on rusted and sheared bolts before, and treating them daily for a week using a syringe was enough to loosen them off.

Obviously you need to observe all the safety precautions of the de-oxidiser manufacturer!

There are also de-oxidisers on the market now which aren't acid based, but I don't have any experience of those.

Something with hydrochloric and phosphoric acids in it will "eat" the rust, hopefully penetrating far enough to loosen the spindle. I've used this method on rusted and sheared bolts before, and treating them daily for a week using a syringe was enough to loosen them off.

Obviously you need to observe all the safety precautions of the de-oxidiser manufacturer!

There are also de-oxidisers on the market now which aren't acid based, but I don't have any experience of those.

Ron '68 +2, '92 M100

-

RonR - First Gear

- Posts: 43

- Joined: 13 Sep 2003

Certainly those knackered bushes won't have helped the handing and may explain why the geometry moved about when being tested.

It's a bit disappointing that the technician didn't notice movement when he was adjusting the toe in.

I agree with Craven about applying some torque back and forth perhaps with a pair of stillsons to the spindle to help ease it out.

Combined with some impact (from both ends if possible) release agent, heat and patience it should eventually move.

There may be some advantage in drilling into the cut off end to enable a sunken punch to induce necking rather than swelling.

The pita is that the spindle could be rusted all the way through the tube if it wasn't copaslipped when installed.

If you have an impact wrench then winding on a couple of nuts and hammering away might give the shock load needed to break the rust.

Let's hope you can shift it and avoid a trailer trip to Spyder.

Are any of the other spindles moving?

It's a bit disappointing that the technician didn't notice movement when he was adjusting the toe in.

I agree with Craven about applying some torque back and forth perhaps with a pair of stillsons to the spindle to help ease it out.

Combined with some impact (from both ends if possible) release agent, heat and patience it should eventually move.

There may be some advantage in drilling into the cut off end to enable a sunken punch to induce necking rather than swelling.

The pita is that the spindle could be rusted all the way through the tube if it wasn't copaslipped when installed.

If you have an impact wrench then winding on a couple of nuts and hammering away might give the shock load needed to break the rust.

Let's hope you can shift it and avoid a trailer trip to Spyder.

Are any of the other spindles moving?

Last edited by MarkDa on Wed Feb 14, 2018 9:29 pm, edited 1 time in total.

- MarkDa

- Coveted Fifth Gear

- Posts: 1113

- Joined: 15 Apr 2017

MarkDa wrote:If you have an impact wrench then winding on a couple of nuts and hammering away might give the shock load needed to break the rust.

+1 on that method. Lots of smaller impacts work more efficiently than fewer large ones in those situations and do less damage.

Bud

1970 +2S Fed 0053N

"Winnemucca - says it all really!!"

1970 +2S Fed 0053N

"Winnemucca - says it all really!!"

- Bud English

- Fourth Gear

- Posts: 938

- Joined: 05 Nov 2011

Jon et all

Wicks (no afiliation) have a clearance sale. Impact drill ?50 and its Makita too.

Jon.

Looking at those bushes im suprised you couldn't feel that when driving. Im more suprised that it wasnt pick up getting aligned. Why were you warned off on poly bushes, what was the reasoning?

Wicks (no afiliation) have a clearance sale. Impact drill ?50 and its Makita too.

Jon.

Looking at those bushes im suprised you couldn't feel that when driving. Im more suprised that it wasnt pick up getting aligned. Why were you warned off on poly bushes, what was the reasoning?

Kick the tyres and light them fires...!!!!!!!

- pauljones

- Fourth Gear

- Posts: 825

- Joined: 09 Feb 2008

billwill wrote:I'm puzzled about this washer on front of the ball-joint discussion. Where does it go? The Ball joint is held to the upper arms by two fore-aft bolts. Putting washers there would have no effect on the suspension geometry.

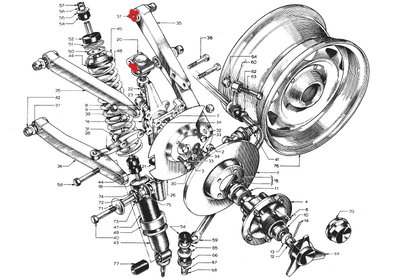

Yes, it will. Consider this:

If you fit equal thickness spacers (eg, washers) where marked in red, the result will be to move the top joint back by the width of the spacers, thus increasing the castor angle. I was worrying about kingpin stress, then realised with it as it is, the KPs are already stressed. Bit like me at the moment!

Last edited by JonB on Wed Feb 14, 2018 5:38 pm, edited 1 time in total.

-

JonB - Coveted Fifth Gear

- Posts: 2371

- Joined: 14 Nov 2017

pauljones wrote:Looking at those bushes I'm surprised you couldn't feel that when driving. I'm more surprised that it wasn't picked up getting aligned. Why were you warned off on poly bushes, what was the reasoning?

Hmm, I can feel it, if you mean a perceived looseness in the steering or the tendency to dive into corners.

Regarding poly bushes, according to the fellow I spoke to who was showing me his lovely Plus 2, they didn't last very long. Rubber bushes should be fine; after all, the reputation of the Elan's handling was not gained through the use of poly bushes.

-

JonB - Coveted Fifth Gear

- Posts: 2371

- Joined: 14 Nov 2017

JonB wrote:billwill wrote:I'm puzzled about this washer on front of the ball-joint discussion. Where does it go? The Ball joint is held to the upper arms by two fore-aft bolts. Putting washers there would have no effect on the suspension geometry.

Yes, it will. Consider this:

If you fit equal thickness spacers (eg, washers) where marked in red, the result will be to move the top joint back by the width of the spacers, thus increasing the castor angle. I was worrying about kingpin stress, then realised with it as it is, the KPs are already stressed. Bit like me at the moment!

I agree with your methodologyand have been experimenting with the same method on the dry run fitting to my chassis.

I found that an AN washer thickness of rearward movement of the ball joint increases caster by about 0.42 degrees. AN washers from memory are 1.36 mm. Don't run vital calculations on this. Mine is a dry run with some varibles I have yet to make consistent.

You don't really know where you are with your 'king pin stress' as you've got a bent spindle. Ordinarily the trunnion will point the vertical link directly in the middle of the gap between the top wishbones and as Bill points out, if you move the ball joint away from this central postion, the inflexible kingpin junction is stressed.

However TTR and Mike Laughlin have no worries in 'stealing some caster'. In the rose joint set up, the top wishbones are naturally wider spaced and there are 4 AN washers ( or as many as you want if you put washers on the spindles to widen the rose joints further) in the gap between the outer ends of the front wishbones. All of these can be placed at the front(ie moving the ball joint back by 2 AN washers).

Mine started at 3.6 degrees. I'll aim for about 4.5 degrees. I have a plan to deal with the trunnion.

Some race teams are re welding the whole spindle jig on the front suspension to give " considerably more than 3 degrees"

I'm really worried that your original data is inaccurate

Get the spindle sorted , bushes done, get mobile and get it re looked at by someone who builds these cars

Graeme

S4 SE

S2 GTS

Caterham 420R

Sold - Peterson JPS Exige

S4 SE

S2 GTS

Caterham 420R

Sold - Peterson JPS Exige

-

661 - Coveted Fifth Gear

- Posts: 1192

- Joined: 29 Mar 2012

Hi Graeme

I agree with what you said - my point is that with my castor reading so low the KPs are already stressed, in theory, because they're being pushed forward. That said, I am not going to consider fitting spacers unless the all new bush + spindle setup doesn't improve the castor. I consider this highly unlikely given the poor state of the bushes, especially the O/S lowers, which had completely disintegrated. I was able to remove the arms and leave the bush crush tubes in situ!

Cheers

JonB

I agree with what you said - my point is that with my castor reading so low the KPs are already stressed, in theory, because they're being pushed forward. That said, I am not going to consider fitting spacers unless the all new bush + spindle setup doesn't improve the castor. I consider this highly unlikely given the poor state of the bushes, especially the O/S lowers, which had completely disintegrated. I was able to remove the arms and leave the bush crush tubes in situ!

Cheers

JonB

-

JonB - Coveted Fifth Gear

- Posts: 2371

- Joined: 14 Nov 2017

JonB wrote:Hi Graeme

I agree with what you said - my point is that with my castor reading so low the KPs are already stressed, in theory, because they're being pushed forward. That said, I am not going to consider fitting spacers unless the all new bush + spindle setup doesn't improve the castor. I consider this highly unlikely given the poor state of the bushes, especially the O/S lowers, which had completely disintegrated. I was able to remove the arms and leave the bush crush tubes in situ!

Cheers

JonB

With the castor measured as it was ( if accurate) the kingpins would only be stressed if all the other variables were as intended by their good maker, ie chassis jigged to 3 degrees and all bushes and spindles where they should be.

That later point was obviously not the case. I suspect your vertical links may well have flopped into that castor position and , as said, I'm surprised that wasn't picked up when driving.

Get everything that's worn replaced and see where you are with the front. The rear is another matter!

Perhaps of interest to some, I use poles strings and gauges from these guys:

http://www.bg-racing.co.uk/index.php?ro ... h=1603_796

Graeme

S4 SE

S2 GTS

Caterham 420R

Sold - Peterson JPS Exige

S4 SE

S2 GTS

Caterham 420R

Sold - Peterson JPS Exige

-

661 - Coveted Fifth Gear

- Posts: 1192

- Joined: 29 Mar 2012

Speaking of which, a new S/S spindle arrived from Spyder today. Total cost ?30 which is more than double what they quoted. ?7.95 + VAT carriage seemed rather excessive. Oh well.

Meanwhile, I am still applying penetrating oil and tapping the ends of the old rod, at least twice daily. No movement so far.

Meanwhile, I am still applying penetrating oil and tapping the ends of the old rod, at least twice daily. No movement so far.

-

JonB - Coveted Fifth Gear

- Posts: 2371

- Joined: 14 Nov 2017

Total Online:

Users browsing this forum: No registered users and 16 guests