Clutch Release Bearing

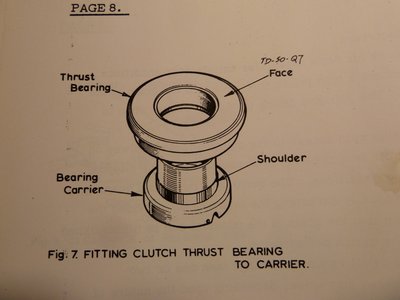

More mystery - this time, the bearing carrier. The used one I have sourced has hardly any wear, and is stamped FoMoCo, so I presume is a genuine unit for the 4 speed - I pulled it from a low mileage +2 many years ago. Slightly different to the one that was in the car which was probably a pattern one. The FoMoCo one has a very thin shoulder compared to that shown in the manual (artistic licence?). Other dimensional differences between the two will alter the clutch arm angle on actuation. The original will require less throw. Now I am aware of the shoulder (which I had overlooked), the bearing does fit more snugly, but I wouldn't call it a press fit!

I do wonder what the effect of all these slight differences make in the action and longevity of the parts..

Jeremy

I do wonder what the effect of all these slight differences make in the action and longevity of the parts..

Jeremy

-

JJDraper - Fourth Gear

- Posts: 923

- Joined: 17 Oct 2004

So I'm about to pull my engine and gearbox to fit a new water pump and attend to various oil leaks. I estimate that they were last out about 15 years ago, so perhaps 20,000-25,000 miles. I plan to change the clutch centre plate as a matter of course and assumed I would also renew the release bearing and, if needed, the bearing carrier.

But this thread has got me thinking that, assuming they are branded and look ok, I should leave the bearing & carrier alone, given that they are not causing any trouble (if it ain't broke, don't fix it).

How long should a decent quality bearing & carrier last? Are they close enough to end-of-life that I should replace them anyway? One wrinkle is that I can't be 100% sure they were renewed during the last engine removal.

Nick

But this thread has got me thinking that, assuming they are branded and look ok, I should leave the bearing & carrier alone, given that they are not causing any trouble (if it ain't broke, don't fix it).

How long should a decent quality bearing & carrier last? Are they close enough to end-of-life that I should replace them anyway? One wrinkle is that I can't be 100% sure they were renewed during the last engine removal.

Nick

-

elanner - Fourth Gear

- Posts: 547

- Joined: 14 Sep 2010

I would expect a good quality bearing in a Lotus to last 50k to 100k miles of road use depending on how much you rest your foot on the clutch pedal and whether you keep it adjusted right so its not spinning when your foots off the pedal. The one in my Plus 2 has gone 60k miles and will be replaced when I put the engine back in the car during its current extended restoration The one in my Landcruiser has lasted so far 440k km's

cheers

Rohan

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8407

- Joined: 22 Sep 2003

Hi All,

Have purchased recently clutch release bearing from "123 Bearing". Part number: 408504FX-SKF. Cost: Euro 46.51

The bearing is marked: 408504, GT BRITAIN, CTLC, SKF.

Width: .6".

ID: 1 3/8" (1.375")

Inner sleeve is brass.

https://www.123bearing.eu/bearing-408504FX-SKF.php

Please note: have not fitted this bearing, so cannot comment on it's efficacy.

Cheers,

Colin.

Have purchased recently clutch release bearing from "123 Bearing". Part number: 408504FX-SKF. Cost: Euro 46.51

The bearing is marked: 408504, GT BRITAIN, CTLC, SKF.

Width: .6".

ID: 1 3/8" (1.375")

Inner sleeve is brass.

https://www.123bearing.eu/bearing-408504FX-SKF.php

Please note: have not fitted this bearing, so cannot comment on it's efficacy.

Cheers,

Colin.

'68 S4 DHC

- fatboyoz

- Fourth Gear

- Posts: 627

- Joined: 04 Oct 2003

I am about to fit an aluminum bellhousing from a Pinto to my Elan and a concentric slave cylinder would seem to be the best answer to the throw out bearing difference. Question-which year Saab 900 throw out bearing do I need?

I wondered if one of these would fit/work?

https://www.ebay.com/itm/New-Saab-900-9 ... 0005.m1851

Thanks all.

I wondered if one of these would fit/work?

https://www.ebay.com/itm/New-Saab-900-9 ... 0005.m1851

Thanks all.

'65 S2 4844

- Davidb

- Fourth Gear

- Posts: 886

- Joined: 02 Jul 2009

I removed/re fitted engine without removing manifold studs taking full engine mounting off completely and moving engine to one side.

Also let me throw this into the ring.

Many years ago I had a screaming thrust (ball bearing type) and managed to use a length of hard plastic tube squashed to a slit on pointing end concocted to extend a spray grease aerosol pushing the pipe through the bell housing where clutch arm protrudes, the pipe being rigid managed to point it against the inner and outer tiny gaps of the roller bearing, not easy on a Mk6 Bentley but it worked and never heard it again over 15 years of not a lot of miles, maybe worth an hour of fiddling to save engine out stress, worth a go !!!

Also let me throw this into the ring.

Many years ago I had a screaming thrust (ball bearing type) and managed to use a length of hard plastic tube squashed to a slit on pointing end concocted to extend a spray grease aerosol pushing the pipe through the bell housing where clutch arm protrudes, the pipe being rigid managed to point it against the inner and outer tiny gaps of the roller bearing, not easy on a Mk6 Bentley but it worked and never heard it again over 15 years of not a lot of miles, maybe worth an hour of fiddling to save engine out stress, worth a go !!!

- weddingcarclive

- First Gear

- Posts: 40

- Joined: 16 Jul 2014

My turn to join in.. been following this thread with interest and ages.

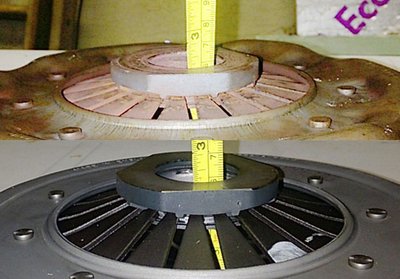

Brain is getting dodgey these days so dates are approximate. 2014 put a close ratio g/box in with new clutch plate and thrust bearing. Couldn?t get a good adjustment and always seemed too near the floor. 2016 started to get very very noisy so took engine out and changed clutch cover and plate bearing (theory was that the clutch fingers had weakened and causing the crap adjustment). Lovely adjustment, nice feel, nice and quiet (not gearbox! Whine, whine) This year (2019?... just checking) drove to France and bearing failed again! Engine out again! Bearing is knackered. It sounded like the bearing was spinning on the carrier but on inspection it doesn?t look like it. The bearing face is blued and looks overheated. The adjustment was good, probably 3-4 mm. Bearing came from a reputable dealer.

I?m inclined to to put the original semi close g/box back in, get a super heavy duty bearing and carrier from Mr Thompson.

Sorry about the long post- but long story.

Suggestions please, I don?t really want to take the engine out every couple of years.

Thanks.

Brain is getting dodgey these days so dates are approximate. 2014 put a close ratio g/box in with new clutch plate and thrust bearing. Couldn?t get a good adjustment and always seemed too near the floor. 2016 started to get very very noisy so took engine out and changed clutch cover and plate bearing (theory was that the clutch fingers had weakened and causing the crap adjustment). Lovely adjustment, nice feel, nice and quiet (not gearbox! Whine, whine) This year (2019?... just checking) drove to France and bearing failed again! Engine out again! Bearing is knackered. It sounded like the bearing was spinning on the carrier but on inspection it doesn?t look like it. The bearing face is blued and looks overheated. The adjustment was good, probably 3-4 mm. Bearing came from a reputable dealer.

I?m inclined to to put the original semi close g/box back in, get a super heavy duty bearing and carrier from Mr Thompson.

Sorry about the long post- but long story.

Suggestions please, I don?t really want to take the engine out every couple of years.

Thanks.

- Attachments

-

- 51ebb474-1cda-43e5-bfb9-4d067a7aa018.jpeg (74.63 KiB) Viewed 2299 times

-

SADLOTUS - Fourth Gear

- Posts: 517

- Joined: 19 Oct 2003

If the bearing is as you say knackered and the face of the bearing is worn and blue it would suggest that it has been in constant contact with the fingers on the clutch pressure plate and that it is why it has worn out.

So my suggestion would be that either you have the adjustment too fine or maybe something hydraulic, master or slave cylinder, is causing the constant thrust bearing to pressure plate contact.

I can't see that just replacing the bearing is going to solve your problem, something else is going on.

So my suggestion would be that either you have the adjustment too fine or maybe something hydraulic, master or slave cylinder, is causing the constant thrust bearing to pressure plate contact.

I can't see that just replacing the bearing is going to solve your problem, something else is going on.

Alan

Currently:-

1971 +2 S130/ 5speed Type 9.

1960 MGA 1600 Mk1 Coupe. 5speed type 9.

Currently:-

1971 +2 S130/ 5speed Type 9.

1960 MGA 1600 Mk1 Coupe. 5speed type 9.

- alanr

- Coveted Fifth Gear

- Posts: 1047

- Joined: 14 Sep 2018

Davidb wrote:I am about to fit an aluminum bellhousing from a Pinto to my Elan and a concentric slave cylinder would seem to be the best answer to the throw out bearing difference. Question-which year Saab 900 throw out bearing do I need?

I did a similar mod some time ago according to the Hollnagel paper, iirc just picked up a new "Saab 900" slave (not sure if later models like Saab 9.3 would be the same, but there is plenty supply under Saab 900 spare parts) to see how it would adapt and fit since it was cheap enough (less than 50), though I suppose other parts would do:

http://images.lotuselan.net/lel/34300/0 ... linder.jpg

It ended up as the final version, I kept the bearing that came with it, too.

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 2006

- Joined: 02 Sep 2013

Alanr... yes I agree on all of that. How can I check clearances when the g/box is attached to the engine?

Also, I did wonder if that first bearing failure caused the second bearing to rotate on the carrier (more/a little/occasionally), causing misalignment and constant contact.

Or.... that the slave magically went out of adjustment..... how? (other than magic).

https://www.youtube.com/watch?v=i1pyMANBI8I

https://www.youtube.com/watch?v=uhHBFXt7Oz4

Also, I did wonder if that first bearing failure caused the second bearing to rotate on the carrier (more/a little/occasionally), causing misalignment and constant contact.

Or.... that the slave magically went out of adjustment..... how? (other than magic).

https://www.youtube.com/watch?v=i1pyMANBI8I

https://www.youtube.com/watch?v=uhHBFXt7Oz4

-

SADLOTUS - Fourth Gear

- Posts: 517

- Joined: 19 Oct 2003

Well the Thrust bearings in your utube links are well and truly shot, no doubt about that!

Another thought whilst you have the engine out I would check the crankshaft end float ( worn crank thrust washers) which could also cause you to have varying clutch clearance.

Assuming the above all ok..

You will obviously you have to replace the current bearing and maybe carrier if you think it is maybe turning on it. Then confirm with it all reassembled your 3-4mm clearance at the slave cylinder pushrod/thrust arm. Either pul back on the arm or remove the return spring to check it. The clearance is checked at this arm and not the pedal!

Test the car and see after running if the clearance you have has changed. If after testing you have no clearance then I would suggest and suspect master cylinder piston or slave cylinder piston sticking.

Just my two pennyworth!

Alan

Another thought whilst you have the engine out I would check the crankshaft end float ( worn crank thrust washers) which could also cause you to have varying clutch clearance.

Assuming the above all ok..

You will obviously you have to replace the current bearing and maybe carrier if you think it is maybe turning on it. Then confirm with it all reassembled your 3-4mm clearance at the slave cylinder pushrod/thrust arm. Either pul back on the arm or remove the return spring to check it. The clearance is checked at this arm and not the pedal!

Test the car and see after running if the clearance you have has changed. If after testing you have no clearance then I would suggest and suspect master cylinder piston or slave cylinder piston sticking.

Just my two pennyworth!

Alan

Last edited by alanr on Sat Nov 23, 2019 11:05 am, edited 1 time in total.

Alan

Currently:-

1971 +2 S130/ 5speed Type 9.

1960 MGA 1600 Mk1 Coupe. 5speed type 9.

Currently:-

1971 +2 S130/ 5speed Type 9.

1960 MGA 1600 Mk1 Coupe. 5speed type 9.

- alanr

- Coveted Fifth Gear

- Posts: 1047

- Joined: 14 Sep 2018

Just to add to Cravens info, there are 2 thrust carriers available for these cars ( see suppliers listings for thrust bearing carriers) , depending which pressure plate you have fitted, if you only see fingers of metal on the pressure plate you need a carrier which brings the thrust bearing closer to the pressure plate and visa versa if your pressure plate has a flat steel pad that greets the the thrust bearing you use the shorter length carrier, as regards the shoulder at the back end of the carrier, it is only this shoulder which grips the thrust bearing inner race from spinning on the carrier and in my opinion quite a poor design of area of grip and maybe a smear of silicone sealer forward of the shoulder would had a little extra grip between carrier and inner bearing race !

Another point when ever thinking of just replacing the spinning plate which has inevitable wear of friction pads, the new thicker friction pad area can then show up problems on the pressure plate springs (some springs weaker than others) that the worn spinner with its thinner pad hid, possibly resulting in clutch judder ! My advice is always new / refurbished full three piece assembly, engine out once is enough !!!!

Another point when ever thinking of just replacing the spinning plate which has inevitable wear of friction pads, the new thicker friction pad area can then show up problems on the pressure plate springs (some springs weaker than others) that the worn spinner with its thinner pad hid, possibly resulting in clutch judder ! My advice is always new / refurbished full three piece assembly, engine out once is enough !!!!

- weddingcarclive

- First Gear

- Posts: 40

- Joined: 16 Jul 2014

Alanr - liking your twopennyworth. When I checked the adjustment it was at the slave pushrod as per the workshop manual.

Popped the bearing off the carrier today and was still a tight fit.... of course it may have welded itself on with heat but wasn't such a difficult separation.

I'm liking the slave cylinder sticking theory. Never had a problem like that before, and to be honest I'm running out of ideas.

Craven and WeddingcarClive, it's a flat thrust pad on the clutch fingers and a flat faced bearing - always has been. I know there's two different bearings/clutch covers but I thought the difference was four/five speed g/box difference. Also I changed the clutch cover last time thinking the cover had worn but there was no difference in dims I did wonder if the fingers had weakened but it's only when then clutch is depressed that would apply.

Gonna order new carrier and bearing then measure when they get here.

Keep them coming!

Popped the bearing off the carrier today and was still a tight fit.... of course it may have welded itself on with heat but wasn't such a difficult separation.

I'm liking the slave cylinder sticking theory. Never had a problem like that before, and to be honest I'm running out of ideas.

Craven and WeddingcarClive, it's a flat thrust pad on the clutch fingers and a flat faced bearing - always has been. I know there's two different bearings/clutch covers but I thought the difference was four/five speed g/box difference. Also I changed the clutch cover last time thinking the cover had worn but there was no difference in dims I did wonder if the fingers had weakened but it's only when then clutch is depressed that would apply.

Gonna order new carrier and bearing then measure when they get here.

Keep them coming!

-

SADLOTUS - Fourth Gear

- Posts: 517

- Joined: 19 Oct 2003

Total Online:

Users browsing this forum: No registered users and 26 guests