Clutch Slave Cylinder take it out

38 posts

• Page 1 of 3 • 1, 2, 3

Hi everyone,

I'm new here and I'm french so, sorry for my English.

I start to rebuild my old lotus elan +2.

I've a problem to take out the slave cylinder (clutch).

He's stuck and I don't think so there we have a piston pin.

Don't understand what blocked out the slave.

Any tips to take it out ?

Best regards,

Elio

I'm new here and I'm french so, sorry for my English.

I start to rebuild my old lotus elan +2.

I've a problem to take out the slave cylinder (clutch).

He's stuck and I don't think so there we have a piston pin.

Don't understand what blocked out the slave.

Any tips to take it out ?

Best regards,

Elio

- Helio_s

- First Gear

- Posts: 15

- Joined: 26 Aug 2019

Hi Elio,

There is a snap ring (circlip). The opening might be out of sight when you are under the car.

Also the previous owner/mechanic may have used loctite on the cylinder. VERY careful use of heat and a large hammer may work. The cylinder will probably be junk at the end.

I removed mine recently. No loctite but the clip was a real pain. I hope it helps.

Regards,

There is a snap ring (circlip). The opening might be out of sight when you are under the car.

Also the previous owner/mechanic may have used loctite on the cylinder. VERY careful use of heat and a large hammer may work. The cylinder will probably be junk at the end.

I removed mine recently. No loctite but the clip was a real pain. I hope it helps.

Regards,

Pete

1970 S4 DHC

1971 S2 Europa

1968 +2

1970 S4 DHC

1971 S2 Europa

1968 +2

- Bombay Racing Green

- Second Gear

- Posts: 221

- Joined: 05 Sep 2012

I recently took mine out. The clip is not a normal circlip with pin holes for a pair of circlip pliers. I had to use a screwdriver with a small hammer to rotate it to a suitable position, then it was straightforward to get off. Once removed, corrosion was holding the cylinder in place, so I drifted it out with a piece of wood and the hammer. It survived, but I may need a new clip.

http://www.lotuselan.net/wiki/QA_-_Clutch_%2B2

Item 26 on the diagram is the clip you need to remove.

http://www.lotuselan.net/wiki/QA_-_Clutch_%2B2

Item 26 on the diagram is the clip you need to remove.

-

JonB - Coveted Fifth Gear

- Posts: 2371

- Joined: 14 Nov 2017

More posts with in this post regarding the circlip and the cylinder.

viewtopic.php?f=37&t=20000

viewtopic.php?f=37&t=20000

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3402

- Joined: 11 Sep 2003

in replacing my ring clip, i used a pair of standard circlips (required 2 to stop the slave moving). is there any reason this is a bad idea ?

1968 Elan plus 2 - project

2007 Elise S2 [modified with a Hethel 70th sticker (yellow)]

2000 Elise S1 - Sold

2007 Elise S2 [modified with a Hethel 70th sticker (yellow)]

2000 Elise S1 - Sold

- wotsisname

- Third Gear

- Posts: 452

- Joined: 24 Jun 2015

I used ordinary circlips as well, and they were in stock at my local engineers supplies shop; some years ago now.

Eric in Burnley

1967 S3SE DHC

Eric in Burnley

1967 S3SE DHC

- ericbushby

- Coveted Fifth Gear

- Posts: 1362

- Joined: 13 Jun 2011

jono wrote:If I recall correctly, the cylinder needs a small amount of 'float' such that it's able to move slightly in the bellhousing hole before reacting against the clutch lever

Mine does have a small amount of float but I've always assumed it was 'good enough' with off the shelf parts - ie a bespoke set up wouldn't have the end float. Now you've got me thinking about whether the end float is there for a reason, and if it is, what is the reason?

Stuart Holding

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

- 69S4

- Coveted Fifth Gear

- Posts: 1124

- Joined: 23 Sep 2004

I have removed a couple of these. On both once the ring was out it was impossible to remove the slave cylinder due to corrosion. On the first after many attempts, in frustration I just whacked the slave cylinder with a cold chisel around the outside of the ring groove. It fell apart and came out in bits. The second i did the same, 2 minutes max to remove and they're not expensive to replace.

Dave

Dave

Elan +2

Elise mk 1

Elise mk 1

- Donels

- Fourth Gear

- Posts: 711

- Joined: 10 Sep 2016

The clip ring has a gap in it and it is made of spring steel.

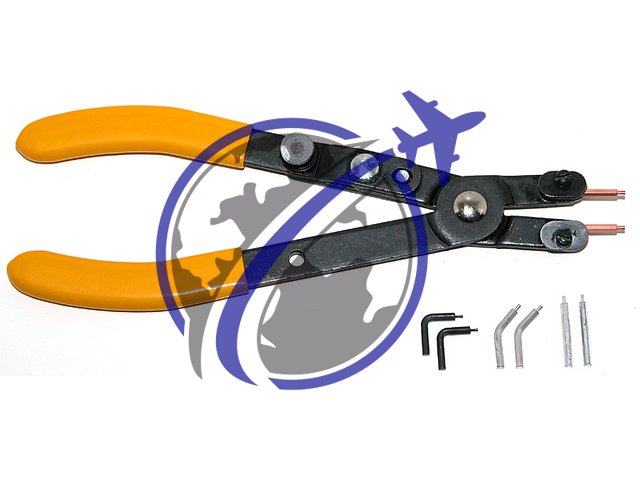

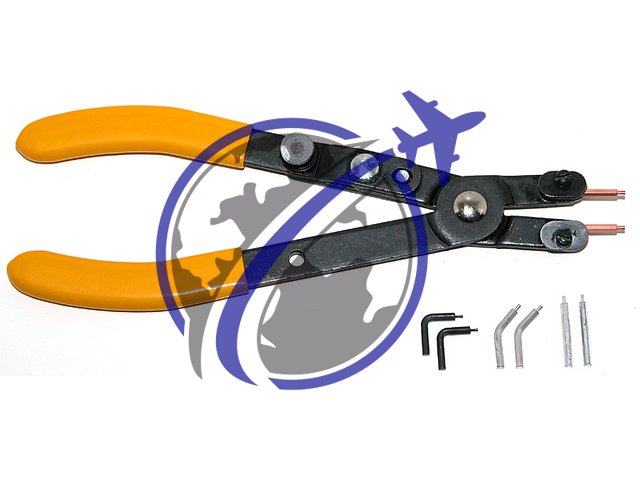

Item 27 in the diagram below. It is fairly tight against the back edge of the tubular hole in the bell housing. It surrounds the slave cylinder sitting in a groove.

The ends of the gap are squared off and so to remove it you ideally need a circlip pliers fitted with flattenned pins. Rotate the ring around the slave with a pipe grip or tap it with a chisel drift rod, until you get easy access to the gap in the ring.

Get the ends on the circliip pliers into the gap and squeeze gently to expand the ring. You should then be able to wiggle it out of its groove and onto the larger diameter portion of the slave cylinder. Do not expand it more than necessary or you will snap it or weaken it.

Tap it along with a drift until it pushes the rubber cap off the end of the slave and you should then be able to get it and the pushrod and adjusting screw off.

Removing the hydraulic pipes and tapping the open end of the slave cylinder with a piece of wood in between it and a small hammer should then get the slave out of the bell housing.

Getting it back on is the reverse of this procedure

Item 27 in the diagram below. It is fairly tight against the back edge of the tubular hole in the bell housing. It surrounds the slave cylinder sitting in a groove.

The ends of the gap are squared off and so to remove it you ideally need a circlip pliers fitted with flattenned pins. Rotate the ring around the slave with a pipe grip or tap it with a chisel drift rod, until you get easy access to the gap in the ring.

Get the ends on the circliip pliers into the gap and squeeze gently to expand the ring. You should then be able to wiggle it out of its groove and onto the larger diameter portion of the slave cylinder. Do not expand it more than necessary or you will snap it or weaken it.

Tap it along with a drift until it pushes the rubber cap off the end of the slave and you should then be able to get it and the pushrod and adjusting screw off.

Removing the hydraulic pipes and tapping the open end of the slave cylinder with a piece of wood in between it and a small hammer should then get the slave out of the bell housing.

Getting it back on is the reverse of this procedure

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4405

- Joined: 19 Apr 2008

Elio,

I bought the type of pliers that Bill describes from Snap On. A Google search found a few alternatives, but they were all American, I did not find a European manufacturer. As the gearbox and slave cylinder were Ford parts that might explain the use of this type of circlip/snap ring.

Good luck getting it apart.

Richard Hawkins

I bought the type of pliers that Bill describes from Snap On. A Google search found a few alternatives, but they were all American, I did not find a European manufacturer. As the gearbox and slave cylinder were Ford parts that might explain the use of this type of circlip/snap ring.

Good luck getting it apart.

Richard Hawkins

- RichardHawkins

- Coveted Fifth Gear

- Posts: 1280

- Joined: 05 Jul 2008

Mine are like these, they have little clamps on the ends so that you can fabricate weird points for the pliers from old nails etc.

https://www.lasaero.com/products/article/A011YSSUT

https://www.lasaero.com/products/article/A011YSSUT

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4405

- Joined: 19 Apr 2008

38 posts

• Page 1 of 3 • 1, 2, 3

Total Online:

Users browsing this forum: No registered users and 17 guests