vexing brake pedal travel problem

26 posts

• Page 2 of 2 • 1, 2

Another easy but sometimes effective method of improving the situation from pad pull-back is to jam the brake pedal down with a piece of wood back to the seat frame and leave overnight, it tends to flex the seals into a better position to reduce pull-back.

- AussieJohn

- Third Gear

- Posts: 440

- Joined: 10 Jun 2007

Hello,

i narrowed down the problem to air trapped in the front circuit. Most likely in the master cylinder or maybe the servo system. Let me explain.

a) I purged the circuit several times. Twice with the pedal/purge screw method and twice with my custom air pressure system, applying 2-2.5 bar on the brake fluid reservoir and pushing the fluid through the circuit(s). I have not seen any bubble and I must have purged 1.5 liter in all! No change in pedal travel, and no change in the feel. Still a long free travel and comfortable firm pedal at the end of it.

b) the rear brakes are not activated until the firm pedal appears. After which they really brake.

c) the front brakes are activated as soon as I touch the brake pedal. However, the torque is minimal. I can turn the wheel by hand. The braking torque steadily increases as the pedal is pressed further in the free travel range, but it remains modest (I can turn the wheel by hand).

I have purged the front callipers both in the nominal position and "at an angle" like was suggested. Seems to me they must be free of air bubbles. That sounds to me like a lot of air is trapped upstream of the callipers.

Could it be that I should purge the master cylinder the other way around by disconnecting the brake line at the servo input side and injecting fluid towards the M/C with a syringe? If a bubble is trapped in upper part of the M/C , this way I could expel it through the hole to the reservoir...

Thanks for your time

Fran?ois

i narrowed down the problem to air trapped in the front circuit. Most likely in the master cylinder or maybe the servo system. Let me explain.

a) I purged the circuit several times. Twice with the pedal/purge screw method and twice with my custom air pressure system, applying 2-2.5 bar on the brake fluid reservoir and pushing the fluid through the circuit(s). I have not seen any bubble and I must have purged 1.5 liter in all! No change in pedal travel, and no change in the feel. Still a long free travel and comfortable firm pedal at the end of it.

b) the rear brakes are not activated until the firm pedal appears. After which they really brake.

c) the front brakes are activated as soon as I touch the brake pedal. However, the torque is minimal. I can turn the wheel by hand. The braking torque steadily increases as the pedal is pressed further in the free travel range, but it remains modest (I can turn the wheel by hand).

I have purged the front callipers both in the nominal position and "at an angle" like was suggested. Seems to me they must be free of air bubbles. That sounds to me like a lot of air is trapped upstream of the callipers.

Could it be that I should purge the master cylinder the other way around by disconnecting the brake line at the servo input side and injecting fluid towards the M/C with a syringe? If a bubble is trapped in upper part of the M/C , this way I could expel it through the hole to the reservoir...

Thanks for your time

Fran?ois

Fran?ois

Lotus Elan Plus 2 130S Big Valves

Lotus Elan Plus 2 130S Big Valves

-

LotusEngineeringBuff - Second Gear

- Posts: 55

- Joined: 17 Nov 2016

Hi Fran?ois,

thank you for following up, I'll have to do some tandem purging myself in a couple weeks and this helps to visualize the possible issues. Here are my 2 c:

It is always possible that air gets trapped in several locations (one may need to purge them one at a time).

At rest air goes up : that can be in lines (swan necks, that one can reasonably easily identify), or in braking elements (cast corners inside calipers...).

When "fast" purging (with a young helper or air pressure) one relies on the viscosity of the incoming fluid to push the bubble(s) away : I would think that this works well for inline bubbles (swan necks) where the incoming pressure is homogeneous and the flow straight and fast, but it may not be the same for braking elements (e.g. calipers upper corners opposed to the purge side, depending on caliper design : if the caliper has a dead corner where the incoming flow does not come straight enough to push the bubble into the line, I would try to purge at an angle with enough pitch and roll to get the bubble towards the next line inlet or the purge outlet first, depending on the purging direction).

If the air is (was) "only" trapped in the master cylinder, I would think the issue would be relatively easily solved, as the ports are nicely on the top of the cylinder : at worse, a bit of yaw should be enough to get the air away (raising the front, then the rear of the car)

good luck !

thank you for following up, I'll have to do some tandem purging myself in a couple weeks and this helps to visualize the possible issues. Here are my 2 c:

It is always possible that air gets trapped in several locations (one may need to purge them one at a time).

At rest air goes up : that can be in lines (swan necks, that one can reasonably easily identify), or in braking elements (cast corners inside calipers...).

When "fast" purging (with a young helper or air pressure) one relies on the viscosity of the incoming fluid to push the bubble(s) away : I would think that this works well for inline bubbles (swan necks) where the incoming pressure is homogeneous and the flow straight and fast, but it may not be the same for braking elements (e.g. calipers upper corners opposed to the purge side, depending on caliper design : if the caliper has a dead corner where the incoming flow does not come straight enough to push the bubble into the line, I would try to purge at an angle with enough pitch and roll to get the bubble towards the next line inlet or the purge outlet first, depending on the purging direction).

If the air is (was) "only" trapped in the master cylinder, I would think the issue would be relatively easily solved, as the ports are nicely on the top of the cylinder : at worse, a bit of yaw should be enough to get the air away (raising the front, then the rear of the car)

good luck !

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 2006

- Joined: 02 Sep 2013

If air is trapped in the calipers ( or the clutch slave cylinder) wedging the pedal down so the system is under pressure overnight helps. I believe this is due to the smaller air molecules slowly leaking past the cylinder seals when under pressure while the larger fluid molecules dont leak past the seals.

Get air out of the servo internal circuits is harder and can sometimes take a lot of bleeding.

cheers

Rohan

Get air out of the servo internal circuits is harder and can sometimes take a lot of bleeding.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8407

- Joined: 22 Sep 2003

Progress report. At last success in bleeding the brakes

Fist let me tell you what I have tried but has not worked:

a) I purged (bled?) the front brake circuit some more using the air pressure system. No change in pedal travel

b) Instead of bleeding with positive air pressure, I figured it might help to purge under vacuum to suck the bubbles of air instead of pushing them out. So I connected the bleeding screw of both from calipers to the headlamps vacuum connection on the inlet manifold and ran the engine. That did not help (since the vacuum is only 250mm Hg at idle, I was activating the pedal to bleed faster). Did not improve

c) I thought maybe I have bubbles in the master cylinder that need to be bled. So I connected my vacuum line to the pressure inlet of the home-made clamped cover and ran the fluid in reverse by pressing one caliper piston at a time did not help

d) I also tried leaving the pedal pressed down for a few days by a block of wood jammed between pedal and driver's seat. To no avail.

I was enraged. I decided to let it be for a couple of days.

Today, I was back at work.

a) I decided to try to see where the darn bubbles are located. I made a servo bypass line with two female adapters. I purged the circuit. Of course it produced a lot of bubbles 'cause the line was empty when I connected it. But after bleeding the necessary quantity IT WORKED. It did start braking seriously as soon as I was touching the pedal

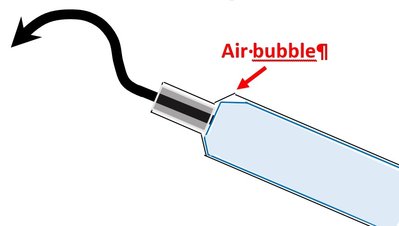

b) Of course I had to put the servo back in the circuit and I knew that in all likelihood it would cause problems. That's when I decided that to put all odds on my side I should try to bleed with the servo as vertical as possible so that the bubbles would be pushed into the brake line towards the calipers. I unbolted the servo, tilted it to the max (see photos) and bled the circuit in this configuration. AND IT WORKED. HAVING THE SERVO ALMOST VERTICAL FLOATED THE BUBBLES TO THE TOP THE SERVO CYLINDER AND INTO THE BRAKE LINE.

and I knew that in all likelihood it would cause problems. That's when I decided that to put all odds on my side I should try to bleed with the servo as vertical as possible so that the bubbles would be pushed into the brake line towards the calipers. I unbolted the servo, tilted it to the max (see photos) and bled the circuit in this configuration. AND IT WORKED. HAVING THE SERVO ALMOST VERTICAL FLOATED THE BUBBLES TO THE TOP THE SERVO CYLINDER AND INTO THE BRAKE LINE.

I am happy as anyone can be I hope this post help future bleeders.

I hope this post help future bleeders.

Fran?ois

Fist let me tell you what I have tried but has not worked:

a) I purged (bled?) the front brake circuit some more using the air pressure system. No change in pedal travel

b) Instead of bleeding with positive air pressure, I figured it might help to purge under vacuum to suck the bubbles of air instead of pushing them out. So I connected the bleeding screw of both from calipers to the headlamps vacuum connection on the inlet manifold and ran the engine. That did not help (since the vacuum is only 250mm Hg at idle, I was activating the pedal to bleed faster). Did not improve

c) I thought maybe I have bubbles in the master cylinder that need to be bled. So I connected my vacuum line to the pressure inlet of the home-made clamped cover and ran the fluid in reverse by pressing one caliper piston at a time did not help

d) I also tried leaving the pedal pressed down for a few days by a block of wood jammed between pedal and driver's seat. To no avail.

I was enraged. I decided to let it be for a couple of days.

Today, I was back at work.

a) I decided to try to see where the darn bubbles are located. I made a servo bypass line with two female adapters. I purged the circuit. Of course it produced a lot of bubbles 'cause the line was empty when I connected it. But after bleeding the necessary quantity IT WORKED. It did start braking seriously as soon as I was touching the pedal

b) Of course I had to put the servo back in the circuit

I am happy as anyone can be

Fran?ois

- Attachments

Last edited by LotusEngineeringBuff on Mon Sep 11, 2017 9:08 am, edited 1 time in total.

Fran?ois

Lotus Elan Plus 2 130S Big Valves

Lotus Elan Plus 2 130S Big Valves

-

LotusEngineeringBuff - Second Gear

- Posts: 55

- Joined: 17 Nov 2016

I'm glad it worked out for you eventually, bleeding can be quite vexing at times... esp. when only a small bubble remains but appears to be very comfortably stuck (I suspect I still have one of these to get rid of this week).

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 2006

- Joined: 02 Sep 2013

The boosters you have are Lockheed units, not the original Girling ones. There are a number of issues with these around their mounting angle and a spring in the air valve system so it does not surprise me you have some problems. Always worth posting photos of what you have as people make assumptions Worth researching in previous posts how to get the Lockheed unit to work properly

cheers

Rohan

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8407

- Joined: 22 Sep 2003

rgh0 wrote:The boosters you have are Lockheed units, not the original Girling ones. There are a number of issues with these around their mounting angle and a spring in the air valve system so it does not surprise me you have some problems. Always worth posting photos of what you have as people make assumptions Worth researching in previous posts how to get the Lockheed unit to work properly

cheers

Rohan

Indeed. The car has been modified to dual brake circuit when it was imported in Switzerland in 2008. I still have the single circuit servo. But... only one of course

Cheers

Fran?ois

Fran?ois

Lotus Elan Plus 2 130S Big Valves

Lotus Elan Plus 2 130S Big Valves

-

LotusEngineeringBuff - Second Gear

- Posts: 55

- Joined: 17 Nov 2016

Foxie wrote:The nose of the servo is the highest point in the brake hydraulic system. That's where any air bubbles will collect. That's why I fitted an additional bleed nipple there

That's smart, but after the problem I had, and the way I solved it, I suspect that withing the servo cylinder, there is a location where a bubble can sit without being bled (see schematics attached) unless the angle at which the servo sits is increased towards the vertical.

Fran?ois

Fran?ois

Lotus Elan Plus 2 130S Big Valves

Lotus Elan Plus 2 130S Big Valves

-

LotusEngineeringBuff - Second Gear

- Posts: 55

- Joined: 17 Nov 2016

26 posts

• Page 2 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 15 guests