What did you do to your Lotus today...

Yesterday I solved an electrical issue in the dashboard that's been making me tear my hair out as I inch closer to re-installing the dash.

Everything was working properly except the telltales for the turn idicators and for the main beam. When the indicators were activated, their telltale and the one for the main beam with both blink faintly, while when the main beam was activated its telltale would not light at all. Worse, the lamps that illuminate the faces of all gauges except the two on the passenger side would blink as well! Some careful poring over the diagrams showed no electrical relation between the two telltales other than the earth, which made no sense...or did it? I did all the due diligence, making sure that nothing was cross-connected and such, then finally came to my senses and questioned the earths.

The dashboard seems like the most thoroughly-earthed part of the car, so I had assumed it was good. It turns out that the wire that earths all the problem items didn't connect to the big main earth for the dashboard! In fact, the only thing it did connect to was the earth for the driver-side window motor! I'm not sure why that is, as there was no apparent loose end anywhere, but I rectified it quickly with about fifteen inches of black wire with a ring-terminal on each end, one end under the thumbscrew one the back of one of the blinking gauges and the other end under a thumbscrew on the back of one of the non-blinking gauges. Works a treat now!

Also I made more progress with the rear suspension- cleaned-up the wishbones a little, enough to notice that the outer sleeves for the bushes didn't come out with the rubber when I had a friend press-out the old bushes. No problem, run a hacksaw through the hole, notch the sleeve, then drift it out with a few taps of the hammer and an old screwdriver as a drift.

Everything was working properly except the telltales for the turn idicators and for the main beam. When the indicators were activated, their telltale and the one for the main beam with both blink faintly, while when the main beam was activated its telltale would not light at all. Worse, the lamps that illuminate the faces of all gauges except the two on the passenger side would blink as well! Some careful poring over the diagrams showed no electrical relation between the two telltales other than the earth, which made no sense...or did it? I did all the due diligence, making sure that nothing was cross-connected and such, then finally came to my senses and questioned the earths.

The dashboard seems like the most thoroughly-earthed part of the car, so I had assumed it was good. It turns out that the wire that earths all the problem items didn't connect to the big main earth for the dashboard! In fact, the only thing it did connect to was the earth for the driver-side window motor! I'm not sure why that is, as there was no apparent loose end anywhere, but I rectified it quickly with about fifteen inches of black wire with a ring-terminal on each end, one end under the thumbscrew one the back of one of the blinking gauges and the other end under a thumbscrew on the back of one of the non-blinking gauges. Works a treat now!

Also I made more progress with the rear suspension- cleaned-up the wishbones a little, enough to notice that the outer sleeves for the bushes didn't come out with the rubber when I had a friend press-out the old bushes. No problem, run a hacksaw through the hole, notch the sleeve, then drift it out with a few taps of the hammer and an old screwdriver as a drift.

1970 Elan Plus 2 (not S) 50/2036

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

-

The Veg - Coveted Fifth Gear

- Posts: 2185

- Joined: 16 Nov 2015

Currently fighting locking ring install on the slave cylinder. Managed to bend one out of shape with expanding pliers trying to get it expanded enough to go over the cylinder. I have 1 more on hand, any tips on expanding the ring enough without damaging it?

Henry

69 Elan S4

65 Seven S2

69 Elan S4

65 Seven S2

- SENC

- Coveted Fifth Gear

- Posts: 1015

- Joined: 30 Dec 2015

SENC wrote:Currently fighting locking ring install on the slave cylinder. Managed to bend one out of shape with expanding pliers trying to get it expanded enough to go over the cylinder. I have 1 more on hand, any tips on expanding the ring enough without damaging it?

Have you seen this thread: lotus-gearbox-f37/clutch-slave-cylinder-replacement-t35788.html

If you haven't got the right ring pliers don't waste your time trying to fit the ring. I'm sure people here have managed to do it but I gave up and used a standard circlip with eyes and circlip pliers. That worked fine until I found a pair of ring pliers. Life's too short.....

Nick

-

elanner - Fourth Gear

- Posts: 546

- Joined: 14 Sep 2010

Thanks Nick, yes, I have the right pliers. I think I was too ham-fisted with the first one, or perhaps it was a bit less pliant and resilient. I managed to get the 2nd one on successfully. Added a remote bleed screw (using the pegasus parts recommended) and got the system bled. Have some cleanup and reorganization to do, then can finally get rebuilt carbs reinstalled.

Henry

69 Elan S4

65 Seven S2

69 Elan S4

65 Seven S2

- SENC

- Coveted Fifth Gear

- Posts: 1015

- Joined: 30 Dec 2015

SENC wrote:Currently fighting locking ring install on the slave cylinder. Managed to bend one out of shape with expanding pliers trying to get it expanded enough to go over the cylinder. I have 1 more on hand, any tips on expanding the ring enough without damaging it?

You expand it while off the back of the slave cylinder, expand only the diameter by increasing the gap. Do not twist it.

When it is bigger than the slave cylinder, slide it forwards until nearly at the groove, release the pliers and then gently tap the ring forwards into the groove using and old screwdriver or similar.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

Purchased a ' Synchrometer' from eBay. Took all of 5 minutes to balance the twin dellorto on my 130/5. Is now easier to start and the idle is much smoother. I have always previously used the piece of hose method but my ear is obviously not as good as I thought,

Mick

Mick

- Mick6186

- Second Gear

- Posts: 216

- Joined: 11 Mar 2014

Did not drive or work on my Lotus this weekend. The Elan is ready for the next race meeting. However I stuffed up my accommodation booking and did it for Feb rather than March which I only discovered when I got notification I was due to arrive next weekend !!!!... a $300 lesson in paying attention to the month when you book on line as I had to re-book at a much higher cost for accommodation on the right weekend as that was all that was left.

But I did spend the weekend replacing a rear wheel bearing on my sons 2004 Golf R32 with his help. An interesting exercise that demonstrated 2 things

1. The Lotus workshop manual is an order of magnitude more accurate than the factory VW golf R32 manual. And on line help is useless compared to this forum to learn the real issues in the change

2. The suspension and wheel bearing design of a Lotus Elan is an order of magnitude better from a service viewpoint. The number of special tools and the amount of disassembly needed for a VW R32 rear wheel bearing change is ridiculous and made worse as they replaced a ball joint in the rear suspension control arms with a rubber bush that are not aligned and have to be twisted to install after the 2003 model If I was not such a believer in corporate good intent I would think its about maximising service revenue. It took a fair amount of thought and suggestions from my creative son and engineering expertise to figure out how to get the rear suspension reassembled after the bearing change without a host of even more special tools and a full dismantle and rebuild from scratch.

If I was not such a believer in corporate good intent I would think its about maximising service revenue. It took a fair amount of thought and suggestions from my creative son and engineering expertise to figure out how to get the rear suspension reassembled after the bearing change without a host of even more special tools and a full dismantle and rebuild from scratch.

Now i could tell the VW service people how to save 8 hours on this exercise if I need to do it again but it requires a couple of extra special tools called a crow bar and ratchet strap

but it requires a couple of extra special tools called a crow bar and ratchet strap  you live and learn every day

you live and learn every day

cheers

Rohan

But I did spend the weekend replacing a rear wheel bearing on my sons 2004 Golf R32 with his help. An interesting exercise that demonstrated 2 things

1. The Lotus workshop manual is an order of magnitude more accurate than the factory VW golf R32 manual. And on line help is useless compared to this forum to learn the real issues in the change

2. The suspension and wheel bearing design of a Lotus Elan is an order of magnitude better from a service viewpoint. The number of special tools and the amount of disassembly needed for a VW R32 rear wheel bearing change is ridiculous and made worse as they replaced a ball joint in the rear suspension control arms with a rubber bush that are not aligned and have to be twisted to install after the 2003 model

Now i could tell the VW service people how to save 8 hours on this exercise if I need to do it again

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8409

- Joined: 22 Sep 2003

rgh0 wrote:.... made worse as they replaced a ball joint in the rear suspension control arms with a rubber bush that are not aligned and have to be twisted to install after the 2003 model

I get frustrated by this a lot working on modern cars - I had the same issue just the other day on a Volvo. There doesn't seem to be a single position in the suspension travel where things just fit together. And when you need to use a lot more force on things, you run the risk of injuring yourself or damaging something. And it's harder to assess the condition of the rubber bushes because they're always under stress, so failures don't result in play in the drooped position. And you can't press the bush out - you have to replace the arm. etc etc

Paddy

1963 Elan S1

-

paddy - Coveted Fifth Gear

- Posts: 1036

- Joined: 27 Oct 2008

paddy wrote:rgh0 wrote:.... made worse as they replaced a ball joint in the rear suspension control arms with a rubber bush that are not aligned and have to be twisted to install after the 2003 model

I get frustrated by this a lot working on modern cars - I had the same issue just the other day on a Volvo. There doesn't seem to be a single position in the suspension travel where things just fit together. And when you need to use a lot more force on things, you run the risk of injuring yourself or damaging something. And it's harder to assess the condition of the rubber bushes because they're always under stress, so failures don't result in play in the drooped position. And you can't press the bush out - you have to replace the arm. etc etc

Paddy

Was it the rear suspension on a Haldex 4WD Volvo like i struggled with on the Golf R32?

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8409

- Joined: 22 Sep 2003

"And on line help is useless compared to this forum to learn the real issues in the change."

Indeed! I find that for modern cars, the only useful information you can get from car-specific fora is information that is relevant to boy-racer performance mods. Most rational people, unfortunately, pay somebody else to do the work.

Indeed! I find that for modern cars, the only useful information you can get from car-specific fora is information that is relevant to boy-racer performance mods. Most rational people, unfortunately, pay somebody else to do the work.

1970 Elan Plus 2 (not S) 50/2036

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

-

The Veg - Coveted Fifth Gear

- Posts: 2185

- Joined: 16 Nov 2015

Got the dashboard back in! Well, mostly anyway. There are still some details to work out, but two screws are holding it and all the circuits that can be tested at the moment are functioning correctly.

1970 Elan Plus 2 (not S) 50/2036

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

-

The Veg - Coveted Fifth Gear

- Posts: 2185

- Joined: 16 Nov 2015

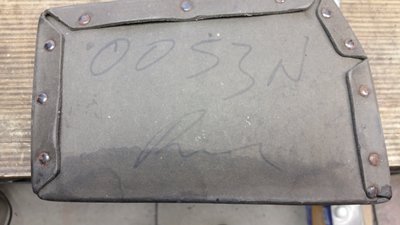

I refurbished my misshapen glove box. The bottom had sagged to the point that it wasn't flat anymore. It even had a high-water mark from being stored outside with the passenger window down.

By saturating the cardboard with waterproof wood glue and clamping the distorted surfaces between 1/4" steel plates, I was able to get the top and bottom surfaces flat and hard again. I used the same method to restore the mounting flanges. I painted the inside with black Rust-Oleum enamel and flocked it with nylon flocking. Just waiting for the paint to dry. Little projects between big projects.

By saturating the cardboard with waterproof wood glue and clamping the distorted surfaces between 1/4" steel plates, I was able to get the top and bottom surfaces flat and hard again. I used the same method to restore the mounting flanges. I painted the inside with black Rust-Oleum enamel and flocked it with nylon flocking. Just waiting for the paint to dry. Little projects between big projects.

Bud

1970 +2S Fed 0053N

"Winnemucca - says it all really!!"

1970 +2S Fed 0053N

"Winnemucca - says it all really!!"

- Bud English

- Fourth Gear

- Posts: 940

- Joined: 05 Nov 2011

Today I changed the fluld in my clutch, and it was far easier than I thought. I was all ready with my one man brake and clutch bleeding kit (which is a bit fiddly to use) when I thought of just letting the fluid drip out of the slave cylinder into a tray by slackening the bleed nipple a bit. Then I could just keep topping up the master. Once the system was flushed through I just tightened the bleed nipple again. No air entered the system!

Spent the rest of the day dealing with continuing trouble with the engine revs dropping to 200-300rpm when returning to idle after opening the throttle suddenly (Strombergs with low balance pipe). The revs then pick up to a normal idle after a second or two. If the throttle is opened more slowly it does not happen. I thought I has fixed it by replacing the fuel pump but it is back. I have tried everything obvious (air filter, fuel pump, float level, float valve sticking, air piston sticking, timing, syncronisation, air leaks, ATF fluid in the dampers, split diaphragms and needle mixture setting). Still not quite right. It behaves as if the mixture is lean but it isn't. Anyone else had this?

I have tried everything obvious (air filter, fuel pump, float level, float valve sticking, air piston sticking, timing, syncronisation, air leaks, ATF fluid in the dampers, split diaphragms and needle mixture setting). Still not quite right. It behaves as if the mixture is lean but it isn't. Anyone else had this?

Dave Chapman.

Spent the rest of the day dealing with continuing trouble with the engine revs dropping to 200-300rpm when returning to idle after opening the throttle suddenly (Strombergs with low balance pipe). The revs then pick up to a normal idle after a second or two. If the throttle is opened more slowly it does not happen. I thought I has fixed it by replacing the fuel pump but it is back.

Dave Chapman.

- david.g.chapman

- Fourth Gear

- Posts: 780

- Joined: 26 Nov 2003

Total Online:

Users browsing this forum: No registered users and 27 guests