Spinner spanner

53 posts

• Page 3 of 4 • 1, 2, 3, 4

pereirac wrote:I am a bit worried about..."Wheel arch damage virtually eliminated". I would prefer to eliminate it completely...

I would guess he means that wheel arch damage shouldn't occur ....... but if you are really ham fisted with the torque wrench............?

Let's be honest, if you swing the wheel hammer like a maniac you can hit the bodywork ......... you shouldn't .........but you can

I like the fact that it is not a metal device and is therefore less likely to cause marks and scratches.

John

No longer active on here, I value my privacy.

No longer active on here, I value my privacy.

-

nebogipfel - Coveted Fifth Gear

- Posts: 1275

- Joined: 25 Sep 2003

Hi Thor,

Glad you got the replacement leathers. The leather is cheap except I had to purchase a whole hide. I have the dies to make the cuts. If any one needs them, let me know.

I am just starting a new run for the lotus spinners tools and I want to grind it down so that when the tool is pressed hard on your type of alloys the leather should be the only thing the touches the wheel. My hope is that all lotus wheels can fit my tool.

There was only one other lotus buyer who used it on his steel wheels and it worked fine. He had another car that used the lotus alloy type wheel and it hit his wheel trying to finish the torque. His alloy had a thinner shim and needed much more removed than you had suggested. Apparently That type of alloy wheel has different size shims that can make the spinner sit very close to the spinner. Other post had said that thicker shims were available. Unless they are cheap, it does not seem worth it. I am going to shave a little off in anycase with the new run.

If you can find the time and a grinder let me know how much needs to be made to your tool and I'll send you a new one, chromed. Or I can remove as much as is safe on a unchromed one and have you try it. Let me know if that is better for you. If the shims are too thin it may not work on that setup or thicker shims would have to be put on.

I only used my steel wheels and the panasports to design my tool. I have not been able to find the alloy type to measure.

If all that is true the other tool that is now being offered may have more of a problem than mine as it appears more of his tool goes past the spinner to grip the ears and hold it on and will also hit before fully torqued. Ask him if he has tried the alloys with the different shim sizes. The more moving parts the more it will cost.

Mine has no moving parts to set and is smaller. I like that there are inventive minds out there working on thing that are better than a hammer. The Swiss one has to be more expensive the way it is casted and polished. I would like to see one up close, except it would cost me US $331.00 + shipping.

Let's stay in touch, Sarto

Glad you got the replacement leathers. The leather is cheap except I had to purchase a whole hide. I have the dies to make the cuts. If any one needs them, let me know.

I am just starting a new run for the lotus spinners tools and I want to grind it down so that when the tool is pressed hard on your type of alloys the leather should be the only thing the touches the wheel. My hope is that all lotus wheels can fit my tool.

There was only one other lotus buyer who used it on his steel wheels and it worked fine. He had another car that used the lotus alloy type wheel and it hit his wheel trying to finish the torque. His alloy had a thinner shim and needed much more removed than you had suggested. Apparently That type of alloy wheel has different size shims that can make the spinner sit very close to the spinner. Other post had said that thicker shims were available. Unless they are cheap, it does not seem worth it. I am going to shave a little off in anycase with the new run.

If you can find the time and a grinder let me know how much needs to be made to your tool and I'll send you a new one, chromed. Or I can remove as much as is safe on a unchromed one and have you try it. Let me know if that is better for you. If the shims are too thin it may not work on that setup or thicker shims would have to be put on.

I only used my steel wheels and the panasports to design my tool. I have not been able to find the alloy type to measure.

If all that is true the other tool that is now being offered may have more of a problem than mine as it appears more of his tool goes past the spinner to grip the ears and hold it on and will also hit before fully torqued. Ask him if he has tried the alloys with the different shim sizes. The more moving parts the more it will cost.

Mine has no moving parts to set and is smaller. I like that there are inventive minds out there working on thing that are better than a hammer. The Swiss one has to be more expensive the way it is casted and polished. I would like to see one up close, except it would cost me US $331.00 + shipping.

Let's stay in touch, Sarto

lotus elan 1966 S3 FHC

36/5785

LHD

36/5785

LHD

-

mac5777 - Fourth Gear

- Posts: 503

- Joined: 05 Jul 2004

Hi Carl,

I also like the look of the Swiss tool that you posted. It looks like something I would put on my coffee table as a art piece or ask guest what do they think it does for a prize. It has to be much larger than mine as it looks like it only grabs the ends of the ears making it a larger tool. I assume that they will not be making the tool for our lotuses, but for cars where there is a larger market as the set up tooling dies etc. etc. will cost more than they could recoup for a profit with the limited number of our lotuses. The market for the Aston Martin spinners is much larger then our lotuses. Each change requires a different set of tooling. It does look like a Swiss watch made item. I do know to machine a piece like that is very very expensive.

Thanks for the three eared post for the Aston Martin,

Sarto

I also like the look of the Swiss tool that you posted. It looks like something I would put on my coffee table as a art piece or ask guest what do they think it does for a prize. It has to be much larger than mine as it looks like it only grabs the ends of the ears making it a larger tool. I assume that they will not be making the tool for our lotuses, but for cars where there is a larger market as the set up tooling dies etc. etc. will cost more than they could recoup for a profit with the limited number of our lotuses. The market for the Aston Martin spinners is much larger then our lotuses. Each change requires a different set of tooling. It does look like a Swiss watch made item. I do know to machine a piece like that is very very expensive.

Thanks for the three eared post for the Aston Martin,

Sarto

lotus elan 1966 S3 FHC

36/5785

LHD

36/5785

LHD

-

mac5777 - Fourth Gear

- Posts: 503

- Joined: 05 Jul 2004

Hi Sarto,

They do have one for our Lotuses only they did not have a picture of one yet so they said it looks like the Aston Martin one... As soon as I get a photo I will post it up here.

I agree it looks more like a piece of modern art than a garage tool and is a beautiful piece of machining...

Nice to hear from you (your Elan look great)

Carl

(I sent then details of your tool so you never know they may contact you..)

They do have one for our Lotuses only they did not have a picture of one yet so they said it looks like the Aston Martin one... As soon as I get a photo I will post it up here.

I agree it looks more like a piece of modern art than a garage tool and is a beautiful piece of machining...

Nice to hear from you (your Elan look great)

Carl

(I sent then details of your tool so you never know they may contact you..)

-

pereirac - Fourth Gear

- Posts: 957

- Joined: 01 Oct 2003

Carl and Stuart,

If the Swiss are making the tool for all types of auto spinners and it is made of a soft metal so it does not mark the chrome spinners, does not chip the wheels and locks on the spinners ears so that it does not slip off, I am impressed!!

I can only offer my tool at a much lower price as my engineering design cut the manufacturing cost. I had other designs and one that looks like the Swiss one but the cost to produce it was way to much. With enough money anything can be made. Maybe they have Government funding?? uumm

Mine was laser cut out, pressed into shape and welded once. Finished it with chrome plating and leather that is cheap to replace if ever needed.

Oh ya, Carl, nobody has called me yet.

thanks again for your post, Sarto

Here is a more recent tool photo

If the Swiss are making the tool for all types of auto spinners and it is made of a soft metal so it does not mark the chrome spinners, does not chip the wheels and locks on the spinners ears so that it does not slip off, I am impressed!!

I can only offer my tool at a much lower price as my engineering design cut the manufacturing cost. I had other designs and one that looks like the Swiss one but the cost to produce it was way to much. With enough money anything can be made. Maybe they have Government funding?? uumm

Mine was laser cut out, pressed into shape and welded once. Finished it with chrome plating and leather that is cheap to replace if ever needed.

Oh ya, Carl, nobody has called me yet.

thanks again for your post, Sarto

Here is a more recent tool photo

lotus elan 1966 S3 FHC

36/5785

LHD

36/5785

LHD

-

mac5777 - Fourth Gear

- Posts: 503

- Joined: 05 Jul 2004

Sarto, will try to get time to grind mine... Other than that, I'm actually looking to buy steel/chrome 5.5" wheels to replace the alloys, as I love the look of the deep dish chrome, and they're easier to keep looking nice...

Other than the scrapes, your tool is an invaluable help in the garage. The tool stays firmly clamped and gets the torque down, but I've already broken one torque wrench.... "non reversible" it said on the label...

"non reversible" it said on the label...

Other than the scrapes, your tool is an invaluable help in the garage. The tool stays firmly clamped and gets the torque down, but I've already broken one torque wrench....

- thor

- Third Gear

- Posts: 482

- Joined: 12 May 2005

Thor, I will have the new run done soon and I will send you one that has been adjusted and hopefully fit your type alloys. The new chrome wheels that you are going to use sounds like a good looking set up. You have to post a picture when they are installed.

I also broke a torque wrench for the same reason. I now have a 250 ft/lb, ratcheted and reversible so I can torque in either direction, left and right side wheels. I dial it up when I loosen the spinners. 200fi/lbs on and 225 ft/lbs off seems to work for me. A breaker bar with an extension also work just fine.

Regards, Sarto

I also broke a torque wrench for the same reason. I now have a 250 ft/lb, ratcheted and reversible so I can torque in either direction, left and right side wheels. I dial it up when I loosen the spinners. 200fi/lbs on and 225 ft/lbs off seems to work for me. A breaker bar with an extension also work just fine.

Regards, Sarto

lotus elan 1966 S3 FHC

36/5785

LHD

36/5785

LHD

-

mac5777 - Fourth Gear

- Posts: 503

- Joined: 05 Jul 2004

".......... well I for one have never worked out why our excellent UK based suppliers haven't pushed the USA market !!! "

Some years ago I contacted a well known and respected supplier by phone from Canada to purchase poly bushes, only available at that time from UK. He was too busy having tea and put his wife on to take my call!! Too busy for business?

Some years ago I contacted a well known and respected supplier by phone from Canada to purchase poly bushes, only available at that time from UK. He was too busy having tea and put his wife on to take my call!! Too busy for business?

- lotusbc

- First Gear

- Posts: 24

- Joined: 11 Feb 2007

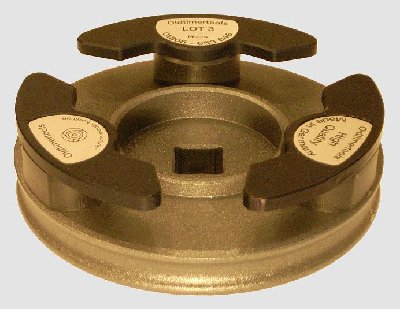

Photo of the Swiss spanner as promised

Intesetingly enough, now that I see the photo magnified, compared to the Swiss website, I have just noticed it says "Made in Germany" on it....

They appear to come from http://www.oldtimertools.de but they are still expensive compared to the alternatives (?249 +)

Carl

Intesetingly enough, now that I see the photo magnified, compared to the Swiss website, I have just noticed it says "Made in Germany" on it....

They appear to come from http://www.oldtimertools.de but they are still expensive compared to the alternatives (?249 +)

Carl

-

pereirac - Fourth Gear

- Posts: 957

- Joined: 01 Oct 2003

Lovely lovely tool for a Ferrari 250SWB with spinners on the Borranis, and an appropriately stiff price......

- thor

- Third Gear

- Posts: 482

- Joined: 12 May 2005

Hi Carl,

Had some time to look at the German made tool site (what a selection of tools!!) and the picture you posted on their elan tool. Looking at your last enlarged picture, I have a couple of observations.

1. Unlike my leather protection, the spinner's face sits down on the hard surface of their tool's base and under full torque may damage the front of the spinner's chrome. Unless the material that the base is made of is softer then the chrome.

2. Having a square 1/2 inch hole to attach the breaker bar means that there is only three positions the attach the bar. The fourth position is always in the mud. That will leave you in ockward leverage positions as you are trying to tighen the spinner. Like a vertical angle near the wheel wells.

I had the same idea but decided to use a 1 inch hex shaft on my knockoff tool, It added the need for a 1 inch, 12 point socket with the 1/2 inch drive, but most tool boxes have one.

It allows us to keep the lever in a 2:00 or a 10:00 o:clock position as we torque on the spinner. In that position we minimize the body wheel well damage, have more control of the torque by just using our weight pushing down. Just reset the socket and finish the torque.

If you are not using a torque wrench you will need to get the feel for the 200ft/lbs of torque using a breaker bar. It is easier from the 2:00 or the 10:00 o:clock position only pushing down with your own weight. That positon keeps you balanced and in control of the torque. No pushing from vertical or pulling or lifting the lever.

If you are going to use a torque wrench here are some suggestions.

Use a 250ft/lbs of torque with a 1/2 inch drive, It should be ratcheted and reversible. Some torque wrenches only torque in one direction and when removing a spinner it takes more to break it loose and can damage the torque wrench. If you can afford a torque wrench, it is easier. The German company does offer a ratcheted breaker bar as an add-on to cost.

I use 200ft/lbs for on and to take it off I dial it up to 225 plus ft/lbs. That has worked for me.

And last, my knockoff tool is engineered to cost much less.

Thanks again, Sarto.

Had some time to look at the German made tool site (what a selection of tools!!) and the picture you posted on their elan tool. Looking at your last enlarged picture, I have a couple of observations.

1. Unlike my leather protection, the spinner's face sits down on the hard surface of their tool's base and under full torque may damage the front of the spinner's chrome. Unless the material that the base is made of is softer then the chrome.

2. Having a square 1/2 inch hole to attach the breaker bar means that there is only three positions the attach the bar. The fourth position is always in the mud. That will leave you in ockward leverage positions as you are trying to tighen the spinner. Like a vertical angle near the wheel wells.

I had the same idea but decided to use a 1 inch hex shaft on my knockoff tool, It added the need for a 1 inch, 12 point socket with the 1/2 inch drive, but most tool boxes have one.

It allows us to keep the lever in a 2:00 or a 10:00 o:clock position as we torque on the spinner. In that position we minimize the body wheel well damage, have more control of the torque by just using our weight pushing down. Just reset the socket and finish the torque.

If you are not using a torque wrench you will need to get the feel for the 200ft/lbs of torque using a breaker bar. It is easier from the 2:00 or the 10:00 o:clock position only pushing down with your own weight. That positon keeps you balanced and in control of the torque. No pushing from vertical or pulling or lifting the lever.

If you are going to use a torque wrench here are some suggestions.

Use a 250ft/lbs of torque with a 1/2 inch drive, It should be ratcheted and reversible. Some torque wrenches only torque in one direction and when removing a spinner it takes more to break it loose and can damage the torque wrench. If you can afford a torque wrench, it is easier. The German company does offer a ratcheted breaker bar as an add-on to cost.

I use 200ft/lbs for on and to take it off I dial it up to 225 plus ft/lbs. That has worked for me.

And last, my knockoff tool is engineered to cost much less.

Thanks again, Sarto.

Last edited by mac5777 on Thu Feb 22, 2007 8:35 pm, edited 2 times in total.

lotus elan 1966 S3 FHC

36/5785

LHD

36/5785

LHD

-

mac5777 - Fourth Gear

- Posts: 503

- Joined: 05 Jul 2004

Hi guys

I saw this on ebay recently for ?95, I don't know if it is any good? It looks simple enough

http://www.spinitoff.com/

Jason

I saw this on ebay recently for ?95, I don't know if it is any good? It looks simple enough

http://www.spinitoff.com/

Jason

-

Jason1 - Coveted Fifth Gear

- Posts: 1349

- Joined: 03 Nov 2005

53 posts

• Page 3 of 4 • 1, 2, 3, 4

Total Online:

Users browsing this forum: No registered users and 7 guests