Tightening Spinners

11 posts

• Page 1 of 1

Hi

I have a 1971 Elan and I am doing a track day next weekend

To make sure my wheels stay on before, during and after I have purchased one of those wheel widget things

So my question is what setting do I need to set the torque wrench at? I've only had the car for a month and I'm new to all things Elan!

Many thanks

I have a 1971 Elan and I am doing a track day next weekend

To make sure my wheels stay on before, during and after I have purchased one of those wheel widget things

So my question is what setting do I need to set the torque wrench at? I've only had the car for a month and I'm new to all things Elan!

Many thanks

- lotus98

- New-tral

- Posts: 1

- Joined: 12 Aug 2018

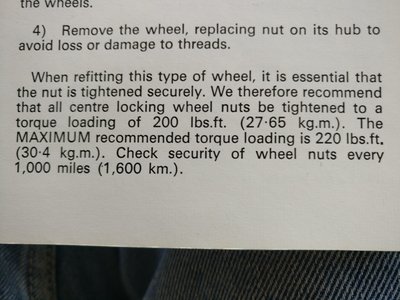

I just purchased a tool from knockoffspinnertool.com. The instructions state that an early Lotus manual recommends 160-180 ft/lb while a later edition shows 200-220 ft/lb for the octagon (earless) spinners. His recommendation is to compromise at 190 ft/lb.

-John

-John

-

JohnCh - Second Gear

- Posts: 95

- Joined: 31 May 2018

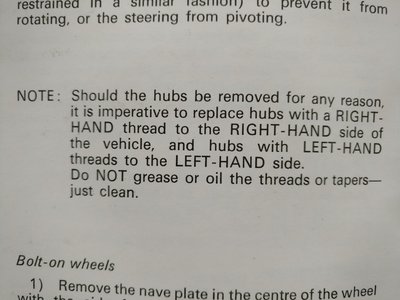

Make sure the threads are clean with no trace of grease , you need good friction on the threads

Steve

Steve

- Concrete-crusher

- Third Gear

- Posts: 386

- Joined: 09 Jun 2013

Andy8421 wrote:Generally tightening torques are quoted for lubricated components.

Does it say in the manual that the threads should be dry?

Yes it is stated in the manual and in the S4 driver's handbook which also states that the tapers should by dry. The handbook also gives the higher torque figure of 200 -220 lb ft.

Roger

S4 DHC

S4 DHC

- oldelanman

- Coveted Fifth Gear

- Posts: 1930

- Joined: 02 Jan 2008

Roger,

Thank you for this. I'll be out washing the copaslip off my spinners this afternoon.

Interesting that the recommendation is to check the spinners every 1000 miles.

Thank you for this. I'll be out washing the copaslip off my spinners this afternoon.

Interesting that the recommendation is to check the spinners every 1000 miles.

68 Elan S3 HSCC Roadsports spec

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

- Andy8421

- Coveted Fifth Gear

- Posts: 1227

- Joined: 27 Mar 2011

No, I disagree. Torque specs generally presume clean, dry threads unless otherwise specified. Some special applications, like rod, main bearing and head bolts/ studs, are always oiled before being torqued. But for a generic engineering table of fastener torques, or for the general torque values given at the end of a Lotus manual's Technical Data Section, the torque values presume clean, dry threads unless otherwise stated. Some engineering tables will give two values, clearly stating which is for dry, and which is for lubed (and 'how' lubed). But if only one value is given with no special clarification, then it presumes clean, dry threads,Andy8421 wrote:Generally tightening torques are quoted for lubricated components.

I'm a mechanical engineer, and that's what I was taught. However, just to be sure something isn't lost in Brit-American translation, I contacted Lotus and asked about their torque specs. The engineer confirmed that the hardware torque values given in Lotus manuals presume clean, dry threads... unless otherwise stated in the assembly instructions. He also noted that while the engine assembly instructions say nothing about the rod, main bearing and cylinder head bolts/ studs, those fasteners are torqued with oiled threads.

Regards,

Tim Engel

- Esprit2

- Third Gear

- Posts: 355

- Joined: 02 Apr 2008

Tim,

Thanks.

I was aware that head bolts/stud torque was quoted lubricated, I thought that applied to all fastenings.

I have always lubricated everything on the grounds I would probably be the next one to undo it. I would guess very few Lotus owners assemble nuts and bolts dry.

Thanks.

I was aware that head bolts/stud torque was quoted lubricated, I thought that applied to all fastenings.

I have always lubricated everything on the grounds I would probably be the next one to undo it. I would guess very few Lotus owners assemble nuts and bolts dry.

68 Elan S3 HSCC Roadsports spec

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

- Andy8421

- Coveted Fifth Gear

- Posts: 1227

- Joined: 27 Mar 2011

I hope that's not the case. The friction varies with the type of surface treatment on the fasteners (zinc, chrome, black oxide, etc), but in general something on the order of 50% of the applied torque goes to overcoming friction in the threads and under the head. Only the balance goes to tensioning the fastener. If the threads are lubricated (oil, anti-seize, threadlocker, anything...), then much more of the applied torque goes to tensioning the fastener and can over-stress it, even to the point of yield.Andy8421 wrote:I would guess very few Lotus owners assemble nuts and bolts dry.

For a lot of general nuts & bolts that you just snug-up without measuring the torque, a little anti-seize isn't a bad thing. But for critical fasteners that you bother to tighten to spec with a torque wrench, read the assembly instructions and be very specific about what you do or don't apply to the threads before torquing.

Beyond the obvious critical fasteners in engines, transmissions and final drives, the most commonly abused fasteners are the bolts/ studs for bolt-on wheels. People tend to slather them up with anti-seize, then torque them to full spec. That's asking for trouble.

Regards,

Tim Engel

- Esprit2

- Third Gear

- Posts: 355

- Joined: 02 Apr 2008

11 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 33 guests