My take on the "old geezer's method" for steering alignment

37 posts

• Page 1 of 3 • 1, 2, 3

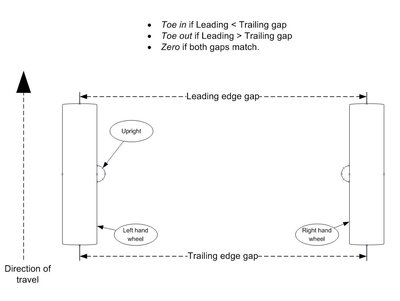

The Plus 2 workshop manual says that the front wheels should have between zero and 3/16" (4.76mm) toe-in. This is the difference between the measurement between the same point at hub height on the tyre tread at the trailing edge of the tyre and the same at the leading edge.

Put another way:

So, we are looking for a means to measure the two gaps (leading / trailing) at hub level on the front wheels.

This method - http://www.lotusowners.com/RepairsUpgra ... /index.htm - uses a long nail driven into a piece of wood as a zero point, then a second nail taped to the wood at the measurement point. I've built a refinement to this approach that I want to share with you.

Put another way:

So, we are looking for a means to measure the two gaps (leading / trailing) at hub level on the front wheels.

This method - http://www.lotusowners.com/RepairsUpgra ... /index.htm - uses a long nail driven into a piece of wood as a zero point, then a second nail taped to the wood at the measurement point. I've built a refinement to this approach that I want to share with you.

-

JonB - Coveted Fifth Gear

- Posts: 2357

- Joined: 14 Nov 2017

The first thing we need is a nice straight bit of wood. I used a tanalised roofing batten, which is about 1.5 x 4.0 cm and just wider than the car.

Next, we need to make up a pair of pointers which replace the nails in the "old geezer" approach. To do this, I used aluminium straight bar and some aluminium right angle bar. The straight bar is about 10mm across and the angle bar is about 3cm on each side. It's scrap I had lying around and it is easily bought from your local DIY store (mine came from B&Q in the UK).

Measure the distance between the centre of the front wheel hub and the ground. Cut a piece of straight bar so that it is the same length, then grind a point at one end. Now attach to the outside of the angle bar using pop rivets so that the pointed end is away from the angle bar and the edge of the angle bar is aligned with the base of the straight bar. Drill and put one rivet in place, then - using a set square - move the bar so that it is perpendicular to the angle bar and carefully drill and put in a second rivet to hold it securely in place. The rivets should face outwards, that is we want to have the low profile rivet heads inside the 90 degree angle bar. When complete, put in some more rivets the same way round as the first two rivets - these are to ensure we have a consistent point of contact when we attach the pointer to the wood.

Make a second one of these tools. When done, they should look like this:

As you can see, mine are not the same width but that is unimportant. What is important is the length of the pointer and the 90 degree angle between the pointer and the right angled base.

I think you can see where this is going... next, prepare the wood. All you need to do is take one of the pointers and clamp it to the batten at one side. Mark up where the pointer bar is if (like me) you're not going to permanently attach the pointer to the batten. This means you can easily take it apart to put away, and reassemble later as needed.

At the other end of the batten, we need to create a reference point from where we will take measurements. Take a rough measurement of the distance between the tyres at the same point on each tyre using a tape measure and deduct 6 inches. Now measure from the point between the two marks at the end of the batten where the first pointer was clamped and drive a small nail into the batten on the same face that distance away from the measurement start point. This doesn't need to be terribly accurate.

Now, we are ready to take a measurement.

Next, we need to make up a pair of pointers which replace the nails in the "old geezer" approach. To do this, I used aluminium straight bar and some aluminium right angle bar. The straight bar is about 10mm across and the angle bar is about 3cm on each side. It's scrap I had lying around and it is easily bought from your local DIY store (mine came from B&Q in the UK).

Measure the distance between the centre of the front wheel hub and the ground. Cut a piece of straight bar so that it is the same length, then grind a point at one end. Now attach to the outside of the angle bar using pop rivets so that the pointed end is away from the angle bar and the edge of the angle bar is aligned with the base of the straight bar. Drill and put one rivet in place, then - using a set square - move the bar so that it is perpendicular to the angle bar and carefully drill and put in a second rivet to hold it securely in place. The rivets should face outwards, that is we want to have the low profile rivet heads inside the 90 degree angle bar. When complete, put in some more rivets the same way round as the first two rivets - these are to ensure we have a consistent point of contact when we attach the pointer to the wood.

Make a second one of these tools. When done, they should look like this:

As you can see, mine are not the same width but that is unimportant. What is important is the length of the pointer and the 90 degree angle between the pointer and the right angled base.

I think you can see where this is going... next, prepare the wood. All you need to do is take one of the pointers and clamp it to the batten at one side. Mark up where the pointer bar is if (like me) you're not going to permanently attach the pointer to the batten. This means you can easily take it apart to put away, and reassemble later as needed.

At the other end of the batten, we need to create a reference point from where we will take measurements. Take a rough measurement of the distance between the tyres at the same point on each tyre using a tape measure and deduct 6 inches. Now measure from the point between the two marks at the end of the batten where the first pointer was clamped and drive a small nail into the batten on the same face that distance away from the measurement start point. This doesn't need to be terribly accurate.

Now, we are ready to take a measurement.

Last edited by JonB on Mon Jan 01, 2018 6:07 pm, edited 1 time in total.

-

JonB - Coveted Fifth Gear

- Posts: 2357

- Joined: 14 Nov 2017

To measure leading gap, first affix one pointer to the left hand side of the batten as before, ensuring the pointer upright is aligned with the marks we already drew on the batten. Slide the batten under the car, in front of the wheels taking care not to knock the pointer upright, because we want it to remain square.

At this point, I am going to deviate a little from the old geezer method, because my Kumho tyres have a straight groove going all round their circumference in the middle of the tread, so I do not need to make any pencil marks on my tyres. But let's call it the "reference mark". So, line the tip of the pointer up against the reference mark by carefully sliding the batten left / right. Set the pointer so it is roughly vertical (it should do this anyway).

Now, go to the other side of the car and carefully slide the second pointer under the batten without moving it left or right; in other words, without disturbing the first pointer. Line the second pointer up with the reference mark on the tyre as before.

Now take a ruler and slide it along the top of the batten until it hits the little nail.

Finally, read off the gap between the nail and the middle of the second pointer.

Take note of the value (169mm in this case, which we will call the "leading edge gap value"), then remove the second pointer and reposition the batten so it is behind the front wheels. Repeat the process to measure the "trailing edge gap value". These values are relative to the position of the nail, but if you want an absolute value, just add the distance between the nail and the fixed pointer.

Finally, deduct the leading edge gap value from the trailing edge gap value and the result is the toe setting. If it is positive, the wheels have toe-in. If negative, they have toe out. If they are the same.. well you get the gist.

At this point, I am going to deviate a little from the old geezer method, because my Kumho tyres have a straight groove going all round their circumference in the middle of the tread, so I do not need to make any pencil marks on my tyres. But let's call it the "reference mark". So, line the tip of the pointer up against the reference mark by carefully sliding the batten left / right. Set the pointer so it is roughly vertical (it should do this anyway).

Now, go to the other side of the car and carefully slide the second pointer under the batten without moving it left or right; in other words, without disturbing the first pointer. Line the second pointer up with the reference mark on the tyre as before.

Now take a ruler and slide it along the top of the batten until it hits the little nail.

Finally, read off the gap between the nail and the middle of the second pointer.

Take note of the value (169mm in this case, which we will call the "leading edge gap value"), then remove the second pointer and reposition the batten so it is behind the front wheels. Repeat the process to measure the "trailing edge gap value". These values are relative to the position of the nail, but if you want an absolute value, just add the distance between the nail and the fixed pointer.

Finally, deduct the leading edge gap value from the trailing edge gap value and the result is the toe setting. If it is positive, the wheels have toe-in. If negative, they have toe out. If they are the same.. well you get the gist.

Last edited by JonB on Mon Jan 01, 2018 6:10 pm, edited 2 times in total.

-

JonB - Coveted Fifth Gear

- Posts: 2357

- Joined: 14 Nov 2017

To adjust the steering alignment, it is a fairly simple matter of rotating the track rod arms on either side of the car so that they screw into / out of the track rod ends to achieve the desired amount of toe-in. A good idea to help the wheels turn easily is to put some engine oil in a pair of thick plastic bags and place one under each front wheel. The other thing to do is to lock the steering wheel with a jack on the front seat in the straight ahead position and adjust each track rod an equal amount; this ensures your steering wheel stays straight.

Lotus say that tracking should be set with the bottom chassis closing plate 6.5" from the ground which implies a certain loading when tracking measurement / adjustment takes place. Probably equivalent to two adults sat in the front seats. However, as I have a Spyder chassis, I am not sure what the corresponding clearance should be.

Lotus say that tracking should be set with the bottom chassis closing plate 6.5" from the ground which implies a certain loading when tracking measurement / adjustment takes place. Probably equivalent to two adults sat in the front seats. However, as I have a Spyder chassis, I am not sure what the corresponding clearance should be.

-

JonB - Coveted Fifth Gear

- Posts: 2357

- Joined: 14 Nov 2017

Jon

You have been busy!

There's a lot of talk about wheel alignment on the forum.

I gained the impression that alignment is measured at the rim rather than tyre tread.

I'd say that the spyder chassis should have same geometry as standard chassis so some sand bags in footwell or on top of engine are on order to be bang on.

Mark

You have been busy!

There's a lot of talk about wheel alignment on the forum.

I gained the impression that alignment is measured at the rim rather than tyre tread.

I'd say that the spyder chassis should have same geometry as standard chassis so some sand bags in footwell or on top of engine are on order to be bang on.

Mark

- MarkDa

- Coveted Fifth Gear

- Posts: 1116

- Joined: 15 Apr 2017

Re: rim vs tread. If you read the description at the end of the second page on the link I posted, the author says he'd used this method to set tracking then got it professionally checked. He said it was spot on, but maybe he got lucky.

The problem is that rim measurement is tricky without specialised equipment and really we need a proper specification (degrees of angle rather than front / back measurement). Otherwise you'd get different results for different wheel sizes. Come to think of it, this is unavoidable thanks to tyre variance and that perhaps explains why Lotus gave a range (0 - 4.76mm toe-in).

The Workshop Manual says:

That is a little imprecise as it doesn't say where on the wheel you should measure. The procedure that follows that quote mentions using a "suitable checking gauge" and casts no more light on the matter.

I reckon that if I went to Kwik-Fit or some other tyre depot and asked them to check it, they wouldn't be able to do it without a proper toe-in angle. I haven't actually set mine but when I first measured it I had 6mm toe-in. Then I spent time freeing up the track rod end and extension nuts and seem to have added another 5mm. Oops. I reset the steering wheel on the rack so it is nearly straight, and now need to adjust tracking and centre position accordingly. That's today's job, then I might go see Miles for a chat, if he's around.

The problem is that rim measurement is tricky without specialised equipment and really we need a proper specification (degrees of angle rather than front / back measurement). Otherwise you'd get different results for different wheel sizes. Come to think of it, this is unavoidable thanks to tyre variance and that perhaps explains why Lotus gave a range (0 - 4.76mm toe-in).

The Workshop Manual says:

The front wheels are considered to toe-in when the setting of the front wheels is such that the distance between the front of the wheels is less than that at the rear of the wheels when measured in the same plane.

That is a little imprecise as it doesn't say where on the wheel you should measure. The procedure that follows that quote mentions using a "suitable checking gauge" and casts no more light on the matter.

I reckon that if I went to Kwik-Fit or some other tyre depot and asked them to check it, they wouldn't be able to do it without a proper toe-in angle. I haven't actually set mine but when I first measured it I had 6mm toe-in. Then I spent time freeing up the track rod end and extension nuts and seem to have added another 5mm. Oops. I reset the steering wheel on the rack so it is nearly straight, and now need to adjust tracking and centre position accordingly. That's today's job, then I might go see Miles for a chat, if he's around.

-

JonB - Coveted Fifth Gear

- Posts: 2357

- Joined: 14 Nov 2017

Jon

Alignment machines do use degrees an so work regardless of rim or tyre size.

When I took my sprint in recently I was rather surprised that the machines database included 70s Elan.

The angle range was bang on for toe in at rim when I calculated it back.

However the rear angle they used was 'combined' rather than individual.

Assuming that eventually you will spring for a computerised 4 wheel check then I'd work on upper end of range using your system as a starting point.

It'll be interesting to hear what Miles has to say on the subject.

Mark

Alignment machines do use degrees an so work regardless of rim or tyre size.

When I took my sprint in recently I was rather surprised that the machines database included 70s Elan.

The angle range was bang on for toe in at rim when I calculated it back.

However the rear angle they used was 'combined' rather than individual.

Assuming that eventually you will spring for a computerised 4 wheel check then I'd work on upper end of range using your system as a starting point.

It'll be interesting to hear what Miles has to say on the subject.

Mark

- MarkDa

- Coveted Fifth Gear

- Posts: 1116

- Joined: 15 Apr 2017

Jon

Here's a useful thread including a view from the factory.

lotus-suspension-f42/rear-wheel-alignment-t19472.html

Mark

Here's a useful thread including a view from the factory.

lotus-suspension-f42/rear-wheel-alignment-t19472.html

Mark

- MarkDa

- Coveted Fifth Gear

- Posts: 1116

- Joined: 15 Apr 2017

Yes the above post series is the best information I have. Never seen any better data and the vagueness is unfortunately reality in true Lotus tradition

Personally I use the string method for wheel alignment as they are by definition straight !

cheers

Rohan

Personally I use the string method for wheel alignment as they are by definition straight !

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8409

- Joined: 22 Sep 2003

That's an interesting thread, that starts out saying you measure on the rim but also refers to "the American method", which is what I have done (measure on the tyre). I am none the wiser, and no one seems to have come up with a definitive answer as to where the measurement should be taken.

It also talks about rear toe in which is interesting, but I do not see how you adjust this without adjustable wishbones.

Back to the front wheels: I set them to 3mm toe-in as measured at the tyre and the steering feels a little better. I suppose the thing to do would be a little trigonometry to determine the difference between a measurement taken at the tyre and rim, to see if the distance is in the range 0 - 4.76mm. And when we are talking about the wheel "rim", are we referring to the raised lip that the tyre presses against or the flat bit behind the raised lip? I would guess the lip.

I'm pretty sure I can modify my rig to measure rim to rim. All it needs is a pair of nails fixed at right angles at the top of the pointer.

It also talks about rear toe in which is interesting, but I do not see how you adjust this without adjustable wishbones.

Back to the front wheels: I set them to 3mm toe-in as measured at the tyre and the steering feels a little better. I suppose the thing to do would be a little trigonometry to determine the difference between a measurement taken at the tyre and rim, to see if the distance is in the range 0 - 4.76mm. And when we are talking about the wheel "rim", are we referring to the raised lip that the tyre presses against or the flat bit behind the raised lip? I would guess the lip.

I'm pretty sure I can modify my rig to measure rim to rim. All it needs is a pair of nails fixed at right angles at the top of the pointer.

-

JonB - Coveted Fifth Gear

- Posts: 2357

- Joined: 14 Nov 2017

Jon

I now use magnetic sight-tubes attached to the rims , but a piece or string etc would suffice...

lotus-suspension-f42/tracking-t19506.html#p109700

John

I now use magnetic sight-tubes attached to the rims , but a piece or string etc would suffice...

lotus-suspension-f42/tracking-t19506.html#p109700

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

Jon

A British car manufacturer is unlikely to use the American method.

Not much trigonometry needed just measure tyre overall diameter in inches (c23?) and divide by 13 then multiply by toe-in required.

Your rig is best suited for the tyre and I'd say quite good enough when you've decided what number to use.

If measuring at rim one can use either the very edge or the landing just inside. Tyre shops tend to clip on the edge.

Quite right about rear toe-in. I needed one new so bought a pair of adjustable from Spyder. They're not a lot more and very easy to use.

The cars are very sensitive to rear toe-in, so it's worth checking in case the bones or chassis are distorted.

Mark

A British car manufacturer is unlikely to use the American method.

Not much trigonometry needed just measure tyre overall diameter in inches (c23?) and divide by 13 then multiply by toe-in required.

Your rig is best suited for the tyre and I'd say quite good enough when you've decided what number to use.

If measuring at rim one can use either the very edge or the landing just inside. Tyre shops tend to clip on the edge.

Quite right about rear toe-in. I needed one new so bought a pair of adjustable from Spyder. They're not a lot more and very easy to use.

The cars are very sensitive to rear toe-in, so it's worth checking in case the bones or chassis are distorted.

Mark

- MarkDa

- Coveted Fifth Gear

- Posts: 1116

- Joined: 15 Apr 2017

Don't think magnetic wotsits will work on my alloy wheels.

Now if the track is an inch less on the front, as the thread is saying, you have to allow for that when using the string method, right? Because you will not be measuring against a parallel line otherwise.

Also, when working out the tyre diameter, should we be taking account of the fact that the tyre is deformed at the contact patch?

So unnecessarily vague and thus stupid. Why couldn't Lotus have given a toe in angle? (Don't bother answering that, it was rhetorical.)

Now if the track is an inch less on the front, as the thread is saying, you have to allow for that when using the string method, right? Because you will not be measuring against a parallel line otherwise.

Also, when working out the tyre diameter, should we be taking account of the fact that the tyre is deformed at the contact patch?

So unnecessarily vague and thus stupid. Why couldn't Lotus have given a toe in angle? (Don't bother answering that, it was rhetorical.)

-

JonB - Coveted Fifth Gear

- Posts: 2357

- Joined: 14 Nov 2017

With string method you need parallel strings set an equal distance from the centre of the lock off spinners at both the front and rear.

That equal distance will as you say be different at each end!

You needn't worry about tyre distortion as you are measuring at mid height.

And as you are setting within a large range you don't have to worry about second order issues

That equal distance will as you say be different at each end!

You needn't worry about tyre distortion as you are measuring at mid height.

And as you are setting within a large range you don't have to worry about second order issues

- MarkDa

- Coveted Fifth Gear

- Posts: 1116

- Joined: 15 Apr 2017

Ok. I have measured the wheels at 355mm (14?) across the rim and 560mm (22?) across the tyre which gave me a conversion factor of 1.577. With measured toe in at the tyre of 3mm, I calculate that is 1.9mm at the rim which seems to be in tolerance. Should I increase it?

Meanwhile the rear wheels have 7mm toe in at the tyre (4.43 mm at the rim). Perhaps front and rear toe in should be the same?

Meanwhile the rear wheels have 7mm toe in at the tyre (4.43 mm at the rim). Perhaps front and rear toe in should be the same?

Last edited by JonB on Tue Jan 02, 2018 5:35 pm, edited 1 time in total.

-

JonB - Coveted Fifth Gear

- Posts: 2357

- Joined: 14 Nov 2017

37 posts

• Page 1 of 3 • 1, 2, 3

Total Online:

Users browsing this forum: No registered users and 22 guests