Rack solid mounts

15 posts

• Page 1 of 1

Hi Shaun,

I like your thought process & the execution looks great! Yes, may not be a major issue, but why not use the empty gap to support any potential lateral loads? Looks like first class work.

1. Have you driven yet to assess actual steering feel? [the pics do look like you are still in construction.]

2. Are the screws only to fasten the halves of the nylon together, not to screw the nylon into the rack frame? [In one pic it appears that one of the screws extends down to the frame support.]

Jay

______________________________________________________________

I like your thought process & the execution looks great! Yes, may not be a major issue, but why not use the empty gap to support any potential lateral loads? Looks like first class work.

1. Have you driven yet to assess actual steering feel? [the pics do look like you are still in construction.]

2. Are the screws only to fasten the halves of the nylon together, not to screw the nylon into the rack frame? [In one pic it appears that one of the screws extends down to the frame support.]

Jay

______________________________________________________________

just looking for clues at the scene....

- S2Jay

- Second Gear

- Posts: 154

- Joined: 21 Dec 2010

Agreed, very sensible mod. A nylon "top hat" bush in the top of the steering column inside the horn ring relieves some of the stress on the rubbish column bushes and makes the steering feel much more positive too.

1970 S4SE/1760cc big valve/SA-AX block, L2s, 45DCOEs, 1978 Jensen GT, 1962 AH Sprite, Alfa-Romeo 159, 1966 Bristol Bus, 1947 AEC Regal bus.

- nigelrbfurness

- Third Gear

- Posts: 373

- Joined: 04 Apr 2008

Nigel,

Reference the rubbish steering column bushes, I find this sort of thing so frustrating. I bought from several suppliers, and they all seem the same, ie slack. I don't believe that the original bush as used by Triumph would have been this slack, and please don't mention the steering column coupling. In the end I had my steering column hard chrome plated and ground down to fit the bush.

Richard Hawkins

Reference the rubbish steering column bushes, I find this sort of thing so frustrating. I bought from several suppliers, and they all seem the same, ie slack. I don't believe that the original bush as used by Triumph would have been this slack, and please don't mention the steering column coupling. In the end I had my steering column hard chrome plated and ground down to fit the bush.

Richard Hawkins

- RichardHawkins

- Coveted Fifth Gear

- Posts: 1268

- Joined: 05 Jul 2008

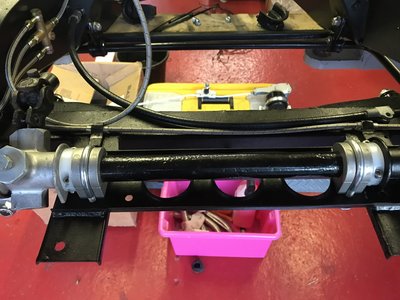

shaun wrote:Having fitted solid mounts I was a bit concerned about rack movement as the mounts only rely on the clamping force . Milled some nylon split blocks to take up the gaps on the rack , am I being a bit over cautious

Hi Shaun,

Did you start with the poly bush used with the old-style mounts? I've seen those on eBay for Spitfires.

I'm assuming same width on both sides? I don't have the body on the chassis, so I'd like to get the rack placement correct so the steering shaft will line up with the pinion. First time I'm doing this for my Elan.

Finally, do you think that shims will be necessary with the solid mounts?

Best,

Tony

Tony

1967 Elan S3 SE

Northeast US

1967 Elan S3 SE

Northeast US

- Tmac897

- Second Gear

- Posts: 190

- Joined: 01 Aug 2019

Tony,

the rack height is critical for minimising bump steer and the shims provide this adjustment.

Assuming that the nylon blocks are machined to the exact height for the particular car, shims would be superfluous.

the rack height is critical for minimising bump steer and the shims provide this adjustment.

Assuming that the nylon blocks are machined to the exact height for the particular car, shims would be superfluous.

- mikealdren

- Coveted Fifth Gear

- Posts: 1194

- Joined: 26 Aug 2006

mikealdren wrote:Tony,

the rack height is critical for minimising bump steer and the shims provide this adjustment.

Hi Mike,

Yes, I'm learning that as I read through the many and detailed posts about it. I am of course familiar with the term, and the effects of, bump steer; but I never knew it's cause and remedy. So that's been helpful. However, since it has to be measured under load, and my Elan is just a frame and suspension right now, I'm at leat a couple of months away from having to deal with that.

My immediate problem is rack location, preventing side to side movement as you have done, and locating the pinion properly for the steering shaft installation. So I went ahead and bought a pair of new poly bushings for a Spitfire from eBay for $15, which I intend to mill down and install. I'm going to assume equal spacing, unless I can find any measurements in the shop manual. Probably not as big an issue as I originally thought. Since the body has been off the frame for a while, I didn't remember how much access to the steering rack there would be to make any necessary adjustments.

Thanks again for your help.

Best,

Tony

Tony

1967 Elan S3 SE

Northeast US

1967 Elan S3 SE

Northeast US

- Tmac897

- Second Gear

- Posts: 190

- Joined: 01 Aug 2019

The shim thickness is mesured from the top wishbone. Nothing to do with load or weight.

Alan

Alan

Alan.b Brittany 1972 elan sprint fhc Lagoon Blue 0460E

- alan.barker

- Coveted Fifth Gear

- Posts: 3754

- Joined: 06 Dec 2008

Tmac897 wrote:

Yes, I'm learning that as I read through the many and detailed posts about it. I am of course familiar with the term, and the effects of, bump steer; but I never knew it's cause and remedy. So that's been helpful. However, since it has to be measured under load, and my Elan is just a frame and suspension right now, I'm at leat a couple of months away from having to deal with that.

Best,

Tony

Tony, to expand on Alan's point, you have to have the car unloaded and the front springs/shocks removed to measure bump steer. It requires the suspension to be moved through its travel and the change in toe in / out measured and minimised. This can't be done with the suspension loaded. The point at which the car is just frame and suspension is the ideal time to get the bump steer right.

Good luck.

68 Elan S3 HSCC Roadsports spec

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

- Andy8421

- Coveted Fifth Gear

- Posts: 1223

- Joined: 27 Mar 2011

" you have to have the car unloaded and the front springs/shocks removed to measure bump steer. It requires the suspension to be moved through its travel and the change in toe in / out measured and minimised. This can't be done with the suspension loaded. The point at which the car is just frame and suspension is the ideal time to get the bump steer right."

IMHO

The measurements should be taken , measuring up/down from " ride height " , which is not known till the suspension components have settled/bedded in and loaded with the equivalent drivers weight in the drivers seat.... and is best achieved working from those measurements with the springs temporarily removed...

John

IMHO

The measurements should be taken , measuring up/down from " ride height " , which is not known till the suspension components have settled/bedded in and loaded with the equivalent drivers weight in the drivers seat.... and is best achieved working from those measurements with the springs temporarily removed...

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

John,

You are of course correct, you can't get zero bump on the Elan, so best to try and minimise it around normal running height - of course you do need to unload the car and remove the springs after you have figured out what the ride height is to measure the bump.

If you want to do this before building the car, the manual does offer an alternative, suggesting that all suspension geometry should be set at a ride height as follows:

"With the vehicle standing on its wheels, insert wooden blocks beneath each front lower wishbone fulcrum and beneath each rear chassis leg adjacent to the pivot but not touching the pivot. Load the vehicle with weights ... until the blocks are just nipped.... The dimensions of the blocks should be Front 6.125in, Rear 6.00in"

Supporting the frame at this height would allow bump to be minimised at (what presumably) Lotus believed the usual ride height to be.

Andy.

You are of course correct, you can't get zero bump on the Elan, so best to try and minimise it around normal running height - of course you do need to unload the car and remove the springs after you have figured out what the ride height is to measure the bump.

If you want to do this before building the car, the manual does offer an alternative, suggesting that all suspension geometry should be set at a ride height as follows:

"With the vehicle standing on its wheels, insert wooden blocks beneath each front lower wishbone fulcrum and beneath each rear chassis leg adjacent to the pivot but not touching the pivot. Load the vehicle with weights ... until the blocks are just nipped.... The dimensions of the blocks should be Front 6.125in, Rear 6.00in"

Supporting the frame at this height would allow bump to be minimised at (what presumably) Lotus believed the usual ride height to be.

Andy.

68 Elan S3 HSCC Roadsports spec

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

- Andy8421

- Coveted Fifth Gear

- Posts: 1223

- Joined: 27 Mar 2011

.. assuming standard ( original ? ) springs , weights ( engine? diff? gearbox? ) etc. etc.

ie. as it came out of the factory ,or at least off the drawing board ?

John

ie. as it came out of the factory ,or at least off the drawing board ?

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

15 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 25 guests