Original Engine Mounts - Converted To Urethane Bushings.

17 posts

• Page 1 of 2 • 1, 2

Hi Guys, hope you have a few spare minutes, got

something here you might want to see.

A twin cam engine mount conversion project...

another job completed while rebuilding the S2 elan.

The engine mounts were due for replacement especially

the broken engine mount on the exhaust side.

I get a bit tired of replacing these old mounts. So it was time for

a rethink, the first thoughts were to dismantle the mounts,

remove all of the old rubber, and prepare the old mounts, before

setting them up in a special holding jig in order to pour urethane

into the cavity where the old rubber resided.

Then we decided to go in another direction.

Why not use the outer metal shell of the old mounts, and

re-manufacture the rest of the mount to suit.

During the project, we took some photos, but then decided

to shoot some video as well, now the video is nothing fancy,

it was shot on my old Nokia mobile phone, so there?s a bit

of hand held shake, and a bit of roll with the footage, but I reckon

you'll get the gist of what it's about, and there's some voice

over audio to help explain things.

I hope you'll enjoy watching how the project evolved.

We can?t yet vouch for how good or bad the new urethane

engine mounts are going to be, because the S2 elan wont be

on the road for a few months yet. But if they don't work, we

still have two old original mounts as a back up.

Please note: We are ?Not marketing? these mounts,

this was strictly an "in house trial project" to see if this idea

will work, and we thought we would share this with you.

If you have enough nous, i.e. (Engineering tools & skills) you

should be able to carry out the same kind of project, but

only if you know what you are doing, as there is a bit

of tricky work involved in the project, it's a job that is best

done with the body off the chassis, as in during a rebuild/restoration.

The vids have been shot on the go, they are short, and to

the point and provided as general information for the twin

Cam - lotus elan owner...

These videos have already been widely seen by the guys

on our private lotus list, and many reckon it's a great idea,

my guess is the vids are bound to produce some lively

discussion here.

You may agree, or disagree with the project, but I'm willing

to experiment to find more reliable solutions to the component

failures that occur on these older cars.

Let the show begin:

Part 1.

http://youtu.be/ajrg1ylXKUU

Part 2.

http://www.youtube.com/watch?v=k4qMLOR_qCw

Part 3.

http://www.youtube.com/watch?v=PE-9B-Ed2es

Enjoy.

Ceejay

something here you might want to see.

A twin cam engine mount conversion project...

another job completed while rebuilding the S2 elan.

The engine mounts were due for replacement especially

the broken engine mount on the exhaust side.

I get a bit tired of replacing these old mounts. So it was time for

a rethink, the first thoughts were to dismantle the mounts,

remove all of the old rubber, and prepare the old mounts, before

setting them up in a special holding jig in order to pour urethane

into the cavity where the old rubber resided.

Then we decided to go in another direction.

Why not use the outer metal shell of the old mounts, and

re-manufacture the rest of the mount to suit.

During the project, we took some photos, but then decided

to shoot some video as well, now the video is nothing fancy,

it was shot on my old Nokia mobile phone, so there?s a bit

of hand held shake, and a bit of roll with the footage, but I reckon

you'll get the gist of what it's about, and there's some voice

over audio to help explain things.

I hope you'll enjoy watching how the project evolved.

We can?t yet vouch for how good or bad the new urethane

engine mounts are going to be, because the S2 elan wont be

on the road for a few months yet. But if they don't work, we

still have two old original mounts as a back up.

Please note: We are ?Not marketing? these mounts,

this was strictly an "in house trial project" to see if this idea

will work, and we thought we would share this with you.

If you have enough nous, i.e. (Engineering tools & skills) you

should be able to carry out the same kind of project, but

only if you know what you are doing, as there is a bit

of tricky work involved in the project, it's a job that is best

done with the body off the chassis, as in during a rebuild/restoration.

The vids have been shot on the go, they are short, and to

the point and provided as general information for the twin

Cam - lotus elan owner...

These videos have already been widely seen by the guys

on our private lotus list, and many reckon it's a great idea,

my guess is the vids are bound to produce some lively

discussion here.

You may agree, or disagree with the project, but I'm willing

to experiment to find more reliable solutions to the component

failures that occur on these older cars.

Let the show begin:

Part 1.

http://youtu.be/ajrg1ylXKUU

Part 2.

http://www.youtube.com/watch?v=k4qMLOR_qCw

Part 3.

http://www.youtube.com/watch?v=PE-9B-Ed2es

Enjoy.

Ceejay

Live your dream-wear your passion.

http://elantrikbits.com/lotus-elan-blog/

http://elantrikbits.com/lotus-elan-blog/

- ceejay

- Fourth Gear

- Posts: 558

- Joined: 27 Mar 2007

Interesting and clever solution CeeJay. The original mounts (especially the exhaust side) were simply 105E Anglia mounts that were for a 39HP application. No doubt they are not suitable and especially on the loaded mountings on Europas. They just don't last on a well driven Elan, especially with headers. The easy and available solution is the upgraded mounts supplied that have no void between the blade and the cradle that mounts to the engine block. They work fine on all these applications including racing use. They are available from us and a number of sources in the UK, USA and Japan. After replacing several exhaust side mounts and one intake side on my well enjoyed S2 in rather short order we redesigned the standard mountings to be truly up to the intended use we expect and they've done the job.

- Jeff@Jae

- Second Gear

- Posts: 196

- Joined: 29 Sep 2003

Jeff, maybe it might have been a good idea to also post a picture

of your uprated engine mounts.

This engine mount conversion project was something I have been

thinking about for quite some time, it is a doable project for the

skilled metal fabricator owner, and I have no doubt that the

urethane bushing material will be far superior to what appears to

be a front suspension metalastic bush, (In the photo supplied

by other poster) as they are quite hard, and have very little flex

when applied to an engine mount situation.... the NVH might be

more than you'd want to know about.

You see, I also posted this project because of all the current

forum chatter about acquiring lathes, mills, drills, welders etc

for maintaining classic cars, I for one, would encourage any elan

owner to build their mechanical/fabricating skills in all areas, but

you need a comprehensive understanding of all of the things

associated with these skills.

I have spent a lifetime learning, building & refining mechanical,

fabricating, welding, machining skills because I gain huge

personal rewards and much satisfaction from constructing and

fabricating special things for my lotus... it's lucky that the elan

is the type of car which lends itself to these applications.

You only have to read between the lines of some of the postings

on this forum to see that some people struggle with elan

ownership, while they are a fairly basic car, they also

have complexities that are difficult to understand in some areas.

Thanks for your reply.

Ceejay

of your uprated engine mounts.

This engine mount conversion project was something I have been

thinking about for quite some time, it is a doable project for the

skilled metal fabricator owner, and I have no doubt that the

urethane bushing material will be far superior to what appears to

be a front suspension metalastic bush, (In the photo supplied

by other poster) as they are quite hard, and have very little flex

when applied to an engine mount situation.... the NVH might be

more than you'd want to know about.

You see, I also posted this project because of all the current

forum chatter about acquiring lathes, mills, drills, welders etc

for maintaining classic cars, I for one, would encourage any elan

owner to build their mechanical/fabricating skills in all areas, but

you need a comprehensive understanding of all of the things

associated with these skills.

I have spent a lifetime learning, building & refining mechanical,

fabricating, welding, machining skills because I gain huge

personal rewards and much satisfaction from constructing and

fabricating special things for my lotus... it's lucky that the elan

is the type of car which lends itself to these applications.

You only have to read between the lines of some of the postings

on this forum to see that some people struggle with elan

ownership, while they are a fairly basic car, they also

have complexities that are difficult to understand in some areas.

Thanks for your reply.

Ceejay

- ceejay

- Fourth Gear

- Posts: 558

- Joined: 27 Mar 2007

Interesting video Ceejay, a very practical approach, I like tales like that. I was put off initially by the "need a lathe" because I haven't got one, but looking at the video it's all do-able without albeit a longer and slower job.

I hope you'll post again with comments about vibration/harshness when the car is up & running, it would be interesting to hear if it's acceptable for a road car. And as I've also got a Europa which loads the engine mounts much more than the Elan, I have an added interest !

Brian

I hope you'll post again with comments about vibration/harshness when the car is up & running, it would be interesting to hear if it's acceptable for a road car. And as I've also got a Europa which loads the engine mounts much more than the Elan, I have an added interest !

Brian

-

UAB807F - Fourth Gear

- Posts: 604

- Joined: 20 Dec 2010

Watch this space Brian, I am as keen as you are to find out if this has

been a good move or not, I feel pretty confident, but as they say, the proof

is in the eating of the cake, and yes, I will definitely post the outcome,

both the good & the bad.

Because I am currently refurbishing the elan it was a great opportunity

to do something different with the mounts, and the cost was virtually nothing

but my time as I had all of the materials on hand, including four totally stuffed

old engine mounts, which provided the base for the project.

Glad you and several other elan owners have enjoyed the show.

Col

been a good move or not, I feel pretty confident, but as they say, the proof

is in the eating of the cake, and yes, I will definitely post the outcome,

both the good & the bad.

Because I am currently refurbishing the elan it was a great opportunity

to do something different with the mounts, and the cost was virtually nothing

but my time as I had all of the materials on hand, including four totally stuffed

old engine mounts, which provided the base for the project.

Glad you and several other elan owners have enjoyed the show.

Col

- ceejay

- Fourth Gear

- Posts: 558

- Joined: 27 Mar 2007

ceejay wrote:Watch this space Brian, I am as keen as you are to find out if this has

been a good move or not, I feel pretty confident, but as they say, the proof

is in the eating of the cake, and yes, I will definitely post the outcome,

both the good & the bad.

Because I am currently refurbishing the elan it was a great opportunity

to do something different with the mounts, and the cost was virtually nothing

but my time as I had all of the materials on hand, including four totally stuffed

old engine mounts, which provided the base for the project.

Glad you and several other elan owners have enjoyed the show.

Col

Ceejay,

I, too, enjoyed the show and thanks for making the effort to share. One question...have you strengthened the frame where they fit to? (wrt known cracking on std frames in that area)

Now, if you can turn your hand to *urethane rotoflexes!

(*Some while back I asked about these on here. I understood that someone in Oz had made some for Honda S600 driveline application)

- ardee_selby

- Coveted Fifth Gear

- Posts: 1090

- Joined: 30 Sep 2003

Chassis or frame mounting brackets were strengthened years

ago so no dramas in that dept.

Urethane rotoflexes, that is anew one on me... i guess

anything is possible these days, there would be considerable

amount of work in building a holding jig, and if reusing

old rotoflex segments etc I would not like the job

of cleaning old rubber off the metal parts.

Then you have the worry of whether the urethane

is going to bond correctly to each metal component, it's a

nice thought....But, I think I'll stick to CVs

ago so no dramas in that dept.

Urethane rotoflexes, that is anew one on me... i guess

anything is possible these days, there would be considerable

amount of work in building a holding jig, and if reusing

old rotoflex segments etc I would not like the job

of cleaning old rubber off the metal parts.

Then you have the worry of whether the urethane

is going to bond correctly to each metal component, it's a

nice thought....But, I think I'll stick to CVs

- ceejay

- Fourth Gear

- Posts: 558

- Joined: 27 Mar 2007

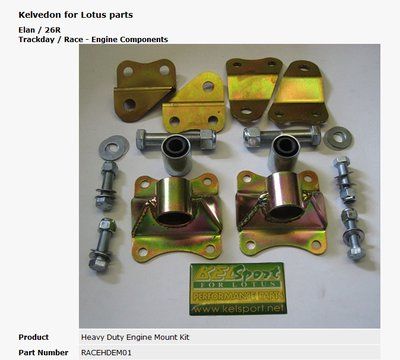

Pic att'd of the TTR engine mounts as used by many for competition use. 65 GBP plus Vat

cheers

dave

cheers

dave

Dave Hughes

S2 26R

Elan DHC Sprint

Shapecraft Honda powered S1(in progress)

Turbocharged 26R clone (also in progress)

Evora 400 development car ex Lotus Factory

S2 26R

Elan DHC Sprint

Shapecraft Honda powered S1(in progress)

Turbocharged 26R clone (also in progress)

Evora 400 development car ex Lotus Factory

-

bigvalvehead - Third Gear

- Posts: 394

- Joined: 11 Sep 2003

Dave,

how long have TTR been using Urethane bushes in their mounts?

Oh & can they be retro-fitted?

Mine fitted about 8 years ago have "metallastic" (rubber) bushes I think.

The mounts in your photo appear to have more squishy material & are probably more compliant than the ones I have in my car.

Cheers

John

how long have TTR been using Urethane bushes in their mounts?

Oh & can they be retro-fitted?

Mine fitted about 8 years ago have "metallastic" (rubber) bushes I think.

The mounts in your photo appear to have more squishy material & are probably more compliant than the ones I have in my car.

Cheers

John

Beware of the Illuminati

Editor: On Sunday morning, February 8th 2015, Derek "John" Pelly AKA GrumpyBodger passed away genuinely peacefully at Weston Hospicecare, Weston Super Mare. He will be missed.

Editor: On Sunday morning, February 8th 2015, Derek "John" Pelly AKA GrumpyBodger passed away genuinely peacefully at Weston Hospicecare, Weston Super Mare. He will be missed.

-

GrUmPyBoDgEr - Coveted Fifth Gear

- Posts: 2346

- Joined: 29 Oct 2004

alan71 wrote:If you don't have the tools to do it yourself you could try these.

Alan.

Has anyone used the Kelvedon competition engine mounts in a road car? I wonder if they are not sufficiently compliant for road use.

Russ Newton

Elan +2S (1971)

Elite S2 (1962)

Elan +2S (1971)

Elite S2 (1962)

-

CBUEB1771 - Coveted Fifth Gear

- Posts: 1546

- Joined: 09 Nov 2006

This is a fast road version of the Kelvedon engine mount with bigger rubber bushings. I am trying to eliminate a dashboard vibration which I think is engine related. I am wondering if these mounts would be worth trying. Has anybody used these mounts and would they be acceptable with a 711M tall block?

Thanks

Chris

https://kelvedonlotus.co.uk/product/ela ... ne-mounts/

Thanks

Chris

https://kelvedonlotus.co.uk/product/ela ... ne-mounts/

67 Elan Super Safety

67 Elan +2

67 Elan +2

- seniorchristo

- Fourth Gear

- Posts: 590

- Joined: 19 Dec 2013

An old thread resurrected, the videos no longer play, does anyone know whether I am guessing cold poured urethane mounts actually worked?

If they relied on a rubber to metal bond to remain attached then I already know the answer

When I was a jig and tool draughtsman I had to design a fixture to mould a urethane coating on chuck jaws to grip cast impellor housings for centrifugal pumps, the first trial cure resulted in all the urethane pouring out all over the toolroom floor

If they relied on a rubber to metal bond to remain attached then I already know the answer

When I was a jig and tool draughtsman I had to design a fixture to mould a urethane coating on chuck jaws to grip cast impellor housings for centrifugal pumps, the first trial cure resulted in all the urethane pouring out all over the toolroom floor

- Chancer

- Coveted Fifth Gear

- Posts: 1133

- Joined: 20 Mar 2012

Hi all... just swinging by here while reading other posts on the forum, and noticed the chatter about converting orig mounts to urethane.... am not sure if I ever got back on this one.

Well, long story short, we have reverted to original heavy duty elan engine mounts, for one simple reason.

And that is the excessive amount of engine vibrations transmitted back through the chassis with the urethan bushes.

In order for these mounts to work, they require a very large block of urethane, because compliance and flex are still very important for engine mounts.

They might be OK in a race car over ten laps around a circuit, but on a long road, they would be come unbearable. I have no doubt the urethane mounts would last a lot longer than the old rubber types...but for peace and quiet, and far better NVH, I'll be sticking to the old type for now... and put up with the occasional replacement... as much of a chore it is to do.

It is great to try out new methods and or convert existing things over to more modern materials, but they require a lot of trial and error before you get them right.

Well, long story short, we have reverted to original heavy duty elan engine mounts, for one simple reason.

And that is the excessive amount of engine vibrations transmitted back through the chassis with the urethan bushes.

In order for these mounts to work, they require a very large block of urethane, because compliance and flex are still very important for engine mounts.

They might be OK in a race car over ten laps around a circuit, but on a long road, they would be come unbearable. I have no doubt the urethane mounts would last a lot longer than the old rubber types...but for peace and quiet, and far better NVH, I'll be sticking to the old type for now... and put up with the occasional replacement... as much of a chore it is to do.

It is great to try out new methods and or convert existing things over to more modern materials, but they require a lot of trial and error before you get them right.

Live your dream-wear your passion.

http://elantrikbits.com/lotus-elan-blog/

http://elantrikbits.com/lotus-elan-blog/

- ceejay

- Fourth Gear

- Posts: 558

- Joined: 27 Mar 2007

Hi All,

Another very old thread resurected.

Any clue what happened to the You tube videos?

My exhaust side engine mount has just collapsed, so looking to alternatives!

Regards

Jeff

Another very old thread resurected.

Any clue what happened to the You tube videos?

My exhaust side engine mount has just collapsed, so looking to alternatives!

Regards

Jeff

-

jeff jackson - Third Gear

- Posts: 365

- Joined: 31 May 2004

17 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 33 guests