Rear Brake Caliper Rebuild-Restoration.

29 posts

• Page 1 of 2 • 1, 2

Image # 1.

The rear brake caliper looks pretty sad after more than twenty years

of service, they should be serviced at more regular intervals, but like

many things automotive... if it ain?t broke ...don't fix it.

So we want to go from a very grungy looking old caliper...

Image # 2:

To this... a completely rebuilt & restored near perfect

rear brake caliper.

Image # 3:

The dismantling can reveal many things, you live in hope that the

internal piston cylinder bore of the caliper has not been wrecked

by corrosion, before a close inspection was made, this bore

looked like it was not in very good condition.

But after a degrease and hot wash blast and then a quick dry

with compressed air it looked OK.

The pistons were sods to remove, but after a soak with WD 40

and a large amount of air pressure from the workshop compressor

they finally moved upwards and were popped out (Careful here,

they can come out like missiles? cover with a large rag.

The next step was to take

all the calliper components to a mate?s workshop to bead blast

to strip every bit of paint and rust back to bare metal.

This sure beats most forms of metal cleaning, but the parts must be

cleaned afterwards with compressed air, the outside of caliper housings

must be painted within an hour or so to prevent oxidation

on the cast iron occurring. The special paint used on the calipers

was 3M-brake caliper paint (Spray can)... about 4 to 5 coats

were applied along with a hot air quick drying process

(Hair dryer) was used between coats.

The hand brake mechanism on both calipers was checked &

rebuilt with new pins etc to get rid of the wear that occurs over a long period

of service, the parts were then sent to the electroplaters to be gold

zinc passivated for protection.

Image # 4:

The scourge of brake calipers, old hard chromed pistons that

succumb to moisture and corrosion, there's only one place for

pistons in this bad state, and that is the rubbish bin.

We bought some free machining stainless bar and machined up

a set of four new stainless steel pistons, what a difference

they make.

Image # 5:

You might think that painting the calipers is a tricky job?

Well it could be if you are not careful, the biggest worry

is preventing any paint getting into the piston bore.

We solved that problem by machining up a wooden plug

that simply slipped into the bore recess, a long wood

screw was then inserted to make insertion and removal

a simple job; note the shape of the plug.

We wanted to get some paint into the first groove where the

rubber dust/moisture cover seal rim is inserted, but a very

small amount of colour mist did find it's way into the bore,

but was easily removed with a cotton swab saturated with

paint thinners.

The mating faces of each caliper was masked off with

tape and trimmed with a sharp knife.

Image # 6:

The Lotus workshop manual says "On no account should

you dismantle the caliper halves" Why not?

They make it sound like re-assembly is some deep dark secret known

only to a few select people.... are they afraid that the calipers

will be mixed with another and end up being a badly matched

pair... difficult to do if you only have two calipers to work with!

Or maybe they think that someone will assemble the two halves

minus the small O-ring that provides the seal between the transfer

gallery from one caliper to the other.... but you'd have to be a complete

idiot to do that. And yes, it is important to understand what you are

about if you delve into brake calipers, the workshop manual

also does not provide any torque figures for the 3/8" and 5/16" UNF bolts

that hold the callipers together.... but 33-38 foot-pounds is about right

for the 3/8? & 14 -19 foot pounds for the smaller bolts... too easy.

Another great advantage of splitting the calipers is that it makes

the rebuilding job very easy, it is such a simple job to insert the piston

seals, and quite simple to place the dust cover lip correctly into the

groove before carefully the pistons are inserted, I've tried this

with the calipers assembled and it drives you nuts trying to

get the seal, dust cover & piston in.

Image # 7:

Now before you embark on the caliper rebuilt project spend

A couple of hours building a brake caliper bench vice holding

Tool, this will make the job a whole lot more enjoyable.

The tool is designed to rotate 360Deg on the base, so

Whatever it is you have to access, the tool will allow that.

Image # 8:

The caliper jig or holding tool, simple in design and simple

To make, well worth the effort to have this tool in your workshop,

sure, you are not going top use it much, but I have a whole bunch

of tools that make servicing and working on the elan so much easier.

So there you have it, the hand brake rods will be attached at later date,

as will the drive shafts, but that will down the road a bit yet.

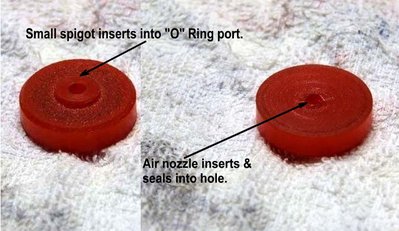

Image # 9:

There are only two ways to remove caliper pistons that are

seized in the bores, you may need to use a penetrating compound,

Don?t worry, this can be removed later during restoration.

Now, the first and best way I believe is to force them out

with air pressure,as you can?t lever them out. Take a look at

Image # 9. This is small bung machined from urethane, yes the

same stuff that suspension bushes are made from, it has

a small hole drilled through the bung, note also the small

spigot on one side of the bung?refer to image seven

and you will notice the O ring recess or port, place the

spigot of the bung into the recess, holding the bung in one hand,

take the air compressor airline nozzle in the other, place the

nozzle into the hole in the bung, and pull the trigger on the air

nozzle and hold it tight, also place a heavy rag over the

caliper piston, as when the piston ejects, it will come out

with considerable force.

This method will 95% of the time, remove stubborn pistons,

Depending how badly seized they are, and if they are totally

seized, then new calipers may be required.

Have fun, and work carefully.

CeeJay

The rear brake caliper looks pretty sad after more than twenty years

of service, they should be serviced at more regular intervals, but like

many things automotive... if it ain?t broke ...don't fix it.

So we want to go from a very grungy looking old caliper...

Image # 2:

To this... a completely rebuilt & restored near perfect

rear brake caliper.

Image # 3:

The dismantling can reveal many things, you live in hope that the

internal piston cylinder bore of the caliper has not been wrecked

by corrosion, before a close inspection was made, this bore

looked like it was not in very good condition.

But after a degrease and hot wash blast and then a quick dry

with compressed air it looked OK.

The pistons were sods to remove, but after a soak with WD 40

and a large amount of air pressure from the workshop compressor

they finally moved upwards and were popped out (Careful here,

they can come out like missiles? cover with a large rag.

The next step was to take

all the calliper components to a mate?s workshop to bead blast

to strip every bit of paint and rust back to bare metal.

This sure beats most forms of metal cleaning, but the parts must be

cleaned afterwards with compressed air, the outside of caliper housings

must be painted within an hour or so to prevent oxidation

on the cast iron occurring. The special paint used on the calipers

was 3M-brake caliper paint (Spray can)... about 4 to 5 coats

were applied along with a hot air quick drying process

(Hair dryer) was used between coats.

The hand brake mechanism on both calipers was checked &

rebuilt with new pins etc to get rid of the wear that occurs over a long period

of service, the parts were then sent to the electroplaters to be gold

zinc passivated for protection.

Image # 4:

The scourge of brake calipers, old hard chromed pistons that

succumb to moisture and corrosion, there's only one place for

pistons in this bad state, and that is the rubbish bin.

We bought some free machining stainless bar and machined up

a set of four new stainless steel pistons, what a difference

they make.

Image # 5:

You might think that painting the calipers is a tricky job?

Well it could be if you are not careful, the biggest worry

is preventing any paint getting into the piston bore.

We solved that problem by machining up a wooden plug

that simply slipped into the bore recess, a long wood

screw was then inserted to make insertion and removal

a simple job; note the shape of the plug.

We wanted to get some paint into the first groove where the

rubber dust/moisture cover seal rim is inserted, but a very

small amount of colour mist did find it's way into the bore,

but was easily removed with a cotton swab saturated with

paint thinners.

The mating faces of each caliper was masked off with

tape and trimmed with a sharp knife.

Image # 6:

The Lotus workshop manual says "On no account should

you dismantle the caliper halves" Why not?

They make it sound like re-assembly is some deep dark secret known

only to a few select people.... are they afraid that the calipers

will be mixed with another and end up being a badly matched

pair... difficult to do if you only have two calipers to work with!

Or maybe they think that someone will assemble the two halves

minus the small O-ring that provides the seal between the transfer

gallery from one caliper to the other.... but you'd have to be a complete

idiot to do that. And yes, it is important to understand what you are

about if you delve into brake calipers, the workshop manual

also does not provide any torque figures for the 3/8" and 5/16" UNF bolts

that hold the callipers together.... but 33-38 foot-pounds is about right

for the 3/8? & 14 -19 foot pounds for the smaller bolts... too easy.

Another great advantage of splitting the calipers is that it makes

the rebuilding job very easy, it is such a simple job to insert the piston

seals, and quite simple to place the dust cover lip correctly into the

groove before carefully the pistons are inserted, I've tried this

with the calipers assembled and it drives you nuts trying to

get the seal, dust cover & piston in.

Image # 7:

Now before you embark on the caliper rebuilt project spend

A couple of hours building a brake caliper bench vice holding

Tool, this will make the job a whole lot more enjoyable.

The tool is designed to rotate 360Deg on the base, so

Whatever it is you have to access, the tool will allow that.

Image # 8:

The caliper jig or holding tool, simple in design and simple

To make, well worth the effort to have this tool in your workshop,

sure, you are not going top use it much, but I have a whole bunch

of tools that make servicing and working on the elan so much easier.

So there you have it, the hand brake rods will be attached at later date,

as will the drive shafts, but that will down the road a bit yet.

Image # 9:

There are only two ways to remove caliper pistons that are

seized in the bores, you may need to use a penetrating compound,

Don?t worry, this can be removed later during restoration.

Now, the first and best way I believe is to force them out

with air pressure,as you can?t lever them out. Take a look at

Image # 9. This is small bung machined from urethane, yes the

same stuff that suspension bushes are made from, it has

a small hole drilled through the bung, note also the small

spigot on one side of the bung?refer to image seven

and you will notice the O ring recess or port, place the

spigot of the bung into the recess, holding the bung in one hand,

take the air compressor airline nozzle in the other, place the

nozzle into the hole in the bung, and pull the trigger on the air

nozzle and hold it tight, also place a heavy rag over the

caliper piston, as when the piston ejects, it will come out

with considerable force.

This method will 95% of the time, remove stubborn pistons,

Depending how badly seized they are, and if they are totally

seized, then new calipers may be required.

Have fun, and work carefully.

CeeJay

- ceejay

- Fourth Gear

- Posts: 558

- Joined: 27 Mar 2007

Ceejay, big thanks for the description of your organised and meticulous approach to the rear caliper overhaul/rebuild.

I agree that the prohibition on caliper dismantling is a bit silly. When I did mine, I got the new square section seals from a UK brake supplier and then also went to the trouble of replacing the through fasteners with Capscrews (the only fasteners I could source with a high yield rating).

The groove for the dust boot and piston seal does appear to be a high corrosion point. Ideally a sacrificial zinc coating would be helpful here.

SJ Sportcars provide new pins for the handbrake assembly in stainless. J Farrell (USA) can provide SS pistons for those unable to machine their own.

By the way, the entire caliper/handbrake assembly is Common to the Plus 2 as well.

Regards

Gerry

I agree that the prohibition on caliper dismantling is a bit silly. When I did mine, I got the new square section seals from a UK brake supplier and then also went to the trouble of replacing the through fasteners with Capscrews (the only fasteners I could source with a high yield rating).

The groove for the dust boot and piston seal does appear to be a high corrosion point. Ideally a sacrificial zinc coating would be helpful here.

SJ Sportcars provide new pins for the handbrake assembly in stainless. J Farrell (USA) can provide SS pistons for those unable to machine their own.

By the way, the entire caliper/handbrake assembly is Common to the Plus 2 as well.

Regards

Gerry

Last edited by gerrym on Tue Jun 21, 2011 4:14 pm, edited 1 time in total.

- gerrym

- Fourth Gear

- Posts: 882

- Joined: 25 Jun 2006

Classicar automotive brakes in Cheshire now recast/make the hand brake bits that dangle. Last time I was in for parts they told me that restoration of original, at a fixed cost, was not possible due to a lot of the hand brake parts being worn beyond reclamation. This is handy to know as I have been lucky up to now with the 3 set I have done in the last 12 years.

Mike

Mike

Mike

Elan S4 Zetec

Suzuki Hustler T250

Suzuki TC120R trailcat

Yamaha YR5

Suzuki Vstrom 650XT

Suzuki TS185K

Elan S4 Zetec

Suzuki Hustler T250

Suzuki TC120R trailcat

Yamaha YR5

Suzuki Vstrom 650XT

Suzuki TS185K

-

miked - Coveted Fifth Gear

- Posts: 1192

- Joined: 29 Sep 2003

Thanks Gerry for your kind words. If you have the skills & the tools you can

save heaps of time & money on mechanical rebuilds.

===

Mike, it is good to see that the handbrake mechanism parts are also

available, but I reclaimed the parts by drilling out where the pins

go through and machining small bushes (under size) and brazing

them in so that the new pins and holes could be reamed and

matched perfectly.

Yes, the parts will wear again in the long term, but for now

they are fine.

ceejay

save heaps of time & money on mechanical rebuilds.

===

Mike, it is good to see that the handbrake mechanism parts are also

available, but I reclaimed the parts by drilling out where the pins

go through and machining small bushes (under size) and brazing

them in so that the new pins and holes could be reamed and

matched perfectly.

Yes, the parts will wear again in the long term, but for now

they are fine.

ceejay

- ceejay

- Fourth Gear

- Posts: 558

- Joined: 27 Mar 2007

Just a comment.... on the REALLLY stuck brake pistons... when the compressed air does not pop them out... I use a grease gun with a fitting made to screw into the bleeder hole. It does waste a lot of grease and makes a real mess but it has never failed me.....

- zog

- Second Gear

- Posts: 200

- Joined: 15 Nov 2003

A foot pump is another option for piston removal if you don't have a compressor. The adaptor is made from a bleed nipple and a tyre valve. The pry bar stops one piston popping right out before the other moves.

This method is also useful when assembling the caliper to check that the pistons are moving freely. A little bit of pressure in the caliper acts as an air spring and you can "bounce" the pistons on that to check they are moving freely before you refit the caliper to the car.

This method is also useful when assembling the caliper to check that the pistons are moving freely. A little bit of pressure in the caliper acts as an air spring and you can "bounce" the pistons on that to check they are moving freely before you refit the caliper to the car.

Roger

S4 DHC

S4 DHC

- oldelanman

- Coveted Fifth Gear

- Posts: 1926

- Joined: 02 Jan 2008

Roger - is that bleed nipple / tyre valve gadget something you bought or did you make it? If it's the latter, your welding is a bit better than mine! The one I made works well enough but looks like something the Time Team dug up

Stuart Holding

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

- 69S4

- Coveted Fifth Gear

- Posts: 1124

- Joined: 23 Sep 2004

69S4 wrote:Roger - is that bleed nipple / tyre valve gadget something you bought or did you make it? If it's the latter, your welding is a bit better than mine! The one I made works well enough but looks like something the Time Team dug up

Yes I made it. The tyre valve bit is brass so I must have brazed or soldered it together - can't remember now. I also find that painting helps fill in the blow holes

Roger

S4 DHC

S4 DHC

- oldelanman

- Coveted Fifth Gear

- Posts: 1926

- Joined: 02 Jan 2008

Dear All

....is the sincerest form of flattery,mine is silver soldered and is now interchangeable with the grease gun AND metric and imperial connectors...

John

Thanks Roger

....is the sincerest form of flattery,mine is silver soldered and is now interchangeable with the grease gun AND metric and imperial connectors...

John

Thanks Roger

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

I made a little adaptor that screws into the bleed nipple hole. A plug screwed into the hose connection to blank off, and a grease gun with liquid grease and the pistons just slowly pump out.

Splitting the two halves is fine but you must keep everything spotless. ... Granny/eggs/ sucking?? I know, I know... Replace the o rings without fail.

Another example of the brilliant knowledge to be found on this forum. Well done lads. Great job CeeJay...

I also made some new pins for the handbrake lever pivots / parts. Stainless. secured with 'r' clips. Drilled out the worn holes to round, & made the pins to suit.

Al' .......

Splitting the two halves is fine but you must keep everything spotless. ... Granny/eggs/ sucking?? I know, I know... Replace the o rings without fail.

Another example of the brilliant knowledge to be found on this forum. Well done lads. Great job CeeJay...

I also made some new pins for the handbrake lever pivots / parts. Stainless. secured with 'r' clips. Drilled out the worn holes to round, & made the pins to suit.

Al' .......

Alex Black.

Now Sprintless!!

Now Sprintless!!

-

alexblack13 - Coveted Fifth Gear

- Posts: 2076

- Joined: 17 Oct 2007

29 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: shynsy and 23 guests