laser alignment check?

13 posts

• Page 1 of 1

Hi Guys,

Talking about driving the Elan and the enjoy factor of 5/5..Got me thinking! Does the panel think it will be worth the effort / Time / cost etc, to have the car set up on the laser/computer system?

Anyone done this and seen a remarkable difference on a car they thought was good as was?

Talking about driving the Elan and the enjoy factor of 5/5..Got me thinking! Does the panel think it will be worth the effort / Time / cost etc, to have the car set up on the laser/computer system?

Anyone done this and seen a remarkable difference on a car they thought was good as was?

Alex Black.

Now Sprintless!!

Now Sprintless!!

-

alexblack13 - Coveted Fifth Gear

- Posts: 2072

- Joined: 17 Oct 2007

Alex, Getting the car on an alignment rack to me, is worth the trouble if, the car can get on the rack (clearance). You should have an alignment person that is willing to take the time to do something different. Ask for a true four wheel alignment with thrust angle. You will have to take the specifications to the alignment shop, special parts (washers) and tools (files) and explain how adjustments can be made. I don't want to start an on-line war but, the front end of the elan (Europa and early Esprits also) can be adjusted for caster, camber and toe. A quick explanation. Caster can be adjusted by spacing the inner control arms with washers and the upper ball joint with washers also. I use the thin and thick AN washers. Camber, the outer arm where the ball joint bolts to arm holes, can be elongated for some camber adjustment. Both Spyder and the Elan Factory in Australia have adjustable upper arms for camber adjustment. Nothing much can be done to the rear unless, the adjustable for toe, rear arms are on the car. Much has been written about making them on the list, Spyder sells them. No one seems to know about adjusting camber in the rear. There is more to it than what I have written, but it can be done. If you do decide to do it, put what ever load you drive with, in the car, that means you! The first time on the rack you might want to see how far off or on the car is, before you start. Will it make a difference in the way the car drives? I would say yes but, I have driven cars that pull to one side, that the operator is happy with. That is a hard one to answer but, there is a reason for those specifications Lotus gives us. Once again no war, just what I have been doing over the years, and it does work for me. Let me know if you need more help. I am in the process of writing an article for Lotus ReMarque, on making Elan/Europa adjustable front upper arms and doing alignments.

Good luck, Steve V. In Arizona

Good luck, Steve V. In Arizona

- mr.vman

- Second Gear

- Posts: 80

- Joined: 22 Apr 2004

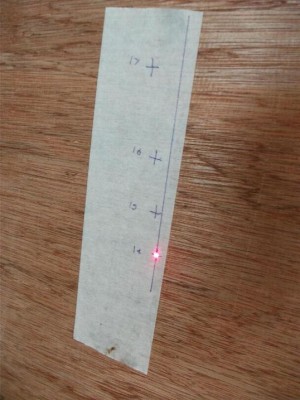

I was putting a new set of front shocks on my Plus 2, so I decided to check the bump steer while I was at it.

Spent some time studying the archives here, but when I got the system working it was so simple. I got a ?3 laser pen on Ebay, an 8" x 6" mirror taped to the back plate (hubs removed), and a board to mount strips of 2" masking tape on which to trace the points, and a spirit level to mark of the deflections.

Original shims supplied with the Spyder chassis were 3.8 and 3.55mm. Minium bump was acheived with 2.1 and 2.4mm.

As the rack ball joints are 26" apart while the rack mounts are only 12", I used the ratio to calculate the actual change at the balljoint, which made a lot of trial and error unecessary.

The car steers like a Kart now, great improvement

Spent some time studying the archives here, but when I got the system working it was so simple. I got a ?3 laser pen on Ebay, an 8" x 6" mirror taped to the back plate (hubs removed), and a board to mount strips of 2" masking tape on which to trace the points, and a spirit level to mark of the deflections.

Original shims supplied with the Spyder chassis were 3.8 and 3.55mm. Minium bump was acheived with 2.1 and 2.4mm.

As the rack ball joints are 26" apart while the rack mounts are only 12", I used the ratio to calculate the actual change at the balljoint, which made a lot of trial and error unecessary.

The car steers like a Kart now, great improvement

alexblack13 wrote:Hi Guys,

Talking about driving the Elan and the enjoy factor of 5/5..Got me thinking! Does the panel think it will be worth the effort / Time / cost etc, to have the car set up on the laser/computer system?

Anyone done this and seen a remarkable difference on a car they thought was good as was?

68 Elan +2, 70 Elan +2s

-

Foxie - Coveted Fifth Gear

- Posts: 1210

- Joined: 20 Sep 2003

In recent days, because the technology has advanced, and completely changed the traditional alignment laser is in use. In reality, these systems are designed so that they can actually provide a faster and more accurate.

Laser Pointers

Laser Pointers

Last edited by laserpointershop on Sat Mar 12, 2011 5:54 am, edited 1 time in total.

- laserpointershop

- New-tral

- Posts: 1

- Joined: 11 Mar 2011

laserpointershop wrote:In recent days, because the technology has advanced, and completely changed the traditional alignment laser is in use. In reality, these systems are designed so that they can actually provide a faster and more accurate.

Beware of the Illuminati

Editor: On Sunday morning, February 8th 2015, Derek "John" Pelly AKA GrumpyBodger passed away genuinely peacefully at Weston Hospicecare, Weston Super Mare. He will be missed.

Editor: On Sunday morning, February 8th 2015, Derek "John" Pelly AKA GrumpyBodger passed away genuinely peacefully at Weston Hospicecare, Weston Super Mare. He will be missed.

-

GrUmPyBoDgEr - Coveted Fifth Gear

- Posts: 2340

- Joined: 29 Oct 2004

I still use the string system .It's good enough for fast race cars and slow ox carts ...and it keeps the neighbors guessing

Ed

Ed

dont close your eyes --you will miss the crash

Editor: On June 12, 2020, Edward Law, AKA TwinCamMan, passed away; his obituary can be read at https://www.friscolanti.com/obituary/edward-law. He will be missed.

Editor: On June 12, 2020, Edward Law, AKA TwinCamMan, passed away; his obituary can be read at https://www.friscolanti.com/obituary/edward-law. He will be missed.

-

twincamman - Coveted Fifth Gear

- Posts: 2453

- Joined: 02 Oct 2003

Pat Thomas is great, but for those of us who live at the other end of the country it's not so practical. Hence a certain amount of DIY is required. Regarding Sean's post on the Bump Steer, most of the cost here is the time or labour of un-bolting the rack and inserting/removing shims so DIY should be definitely the way to go.

I'm going to redo my bump steer using two off Wixey angle gauges (one on each wheel). These should enable me to measure bump steer directly off the gauge (ie without plotting) down to 0.3mm - much better than the geometry allows.

Does anyone have the thread form for the knock-on hubs to hand. I'll machine up a flat faced cap that screws on to the hub thread, then the Wixey gauge will attached to the cap. flat faced caps can also be used for conveniently mounting laser "string"

Regards

Gerry

I'm going to redo my bump steer using two off Wixey angle gauges (one on each wheel). These should enable me to measure bump steer directly off the gauge (ie without plotting) down to 0.3mm - much better than the geometry allows.

Does anyone have the thread form for the knock-on hubs to hand. I'll machine up a flat faced cap that screws on to the hub thread, then the Wixey gauge will attached to the cap. flat faced caps can also be used for conveniently mounting laser "string"

Regards

Gerry

- gerrym

- Fourth Gear

- Posts: 882

- Joined: 25 Jun 2006

I've heard a whisper that "Miked" has just done the bump steer on his +2 using an incredibly simple & accurate method.

I don't know if he's ready to post the solution on here yet but I think he's planning to.

Are you out there Mike?

Cheers

John

P.S. Has anyone fathomed out what the original post on this thread is about?

I don't know if he's ready to post the solution on here yet but I think he's planning to.

Are you out there Mike?

Cheers

John

P.S. Has anyone fathomed out what the original post on this thread is about?

Beware of the Illuminati

Editor: On Sunday morning, February 8th 2015, Derek "John" Pelly AKA GrumpyBodger passed away genuinely peacefully at Weston Hospicecare, Weston Super Mare. He will be missed.

Editor: On Sunday morning, February 8th 2015, Derek "John" Pelly AKA GrumpyBodger passed away genuinely peacefully at Weston Hospicecare, Weston Super Mare. He will be missed.

-

GrUmPyBoDgEr - Coveted Fifth Gear

- Posts: 2340

- Joined: 29 Oct 2004

"If you do decide to do it, put what ever load you drive with, in the car, that means you!"

Note maximum of 450 lbs

Cheers - Richard

Note maximum of 450 lbs

Cheers - Richard

- Attachments

-

- trpressuredecal.jpg (25.67 KiB) Viewed 2342 times

- ardee_selby

- Coveted Fifth Gear

- Posts: 1090

- Joined: 30 Sep 2003

this will help --easy to make ed

dont close your eyes --you will miss the crash

Editor: On June 12, 2020, Edward Law, AKA TwinCamMan, passed away; his obituary can be read at https://www.friscolanti.com/obituary/edward-law. He will be missed.

Editor: On June 12, 2020, Edward Law, AKA TwinCamMan, passed away; his obituary can be read at https://www.friscolanti.com/obituary/edward-law. He will be missed.

-

twincamman - Coveted Fifth Gear

- Posts: 2453

- Joined: 02 Oct 2003

Hi John,

Here it is. Just one side (I made one for each side). I just did a quick set up for the photos. The springs are now back on with the wheels drooping. Yes, it is rough but it works and only took me and 1 1/4 hours to knock up

Some:

Chipboard shelf.

Shock Chord.

Cup hooks

?1.50 Spirit level.

I was told by a race mechanic that he just lays a board up against the wheel and runs through droop to bump with his foot at the bottom. That got me thinking.

The vertical piece was set out at 3.5 inches from the perpendicular. It does not move on the rubber mat. Then jack up and down using the marks to read your gaps. I set a scale from ride height to 2.5 inch droop and 1.5 inch bump. I only used the 2 inch and 1 inch marks for checks (3 inch travel). The only problem I had was my trolley jacks at either side. The travel from bump to droop is quite significant and sometimes the jack would pop out with the acute angle of the bottom bone on full droop.

When I carry out finer checks I will make a small clevis to pivot on the bottom shocker hole. I may attach it to an old track rod and ball joint and fit it to the jack so it will pivot at the ball end.

Unless I am missing something, if the ?toe in? is set up and this is carried out, you will dial out bump. My garage floor is not flat enough for mega accuracy. I will be going to a place with good floor to repeat it all. String line for "toe in" of front and rear and then recheck of bump. I am pretty dam near now though.

You can shine a light under the gap of the wood to enhance the visibility of the gap.

Whilst the proper manufactured ones use 1 or 2 DTI?s, I think this is an improvment over the old businesses about measuring from the top of pivot points to the rack top. I would estimate that you can get to within 10 thou with the wood. I drilled a hole in the centre of the wood to centre the wood over the wheel. Near enough, rack of the eye!

I know chipboard may warp but this is not and my garage is dry. It can be improved. First shot!

Mike

Here it is. Just one side (I made one for each side). I just did a quick set up for the photos. The springs are now back on with the wheels drooping. Yes, it is rough but it works and only took me and 1 1/4 hours to knock up

Some:

Chipboard shelf.

Shock Chord.

Cup hooks

?1.50 Spirit level.

I was told by a race mechanic that he just lays a board up against the wheel and runs through droop to bump with his foot at the bottom. That got me thinking.

The vertical piece was set out at 3.5 inches from the perpendicular. It does not move on the rubber mat. Then jack up and down using the marks to read your gaps. I set a scale from ride height to 2.5 inch droop and 1.5 inch bump. I only used the 2 inch and 1 inch marks for checks (3 inch travel). The only problem I had was my trolley jacks at either side. The travel from bump to droop is quite significant and sometimes the jack would pop out with the acute angle of the bottom bone on full droop.

When I carry out finer checks I will make a small clevis to pivot on the bottom shocker hole. I may attach it to an old track rod and ball joint and fit it to the jack so it will pivot at the ball end.

Unless I am missing something, if the ?toe in? is set up and this is carried out, you will dial out bump. My garage floor is not flat enough for mega accuracy. I will be going to a place with good floor to repeat it all. String line for "toe in" of front and rear and then recheck of bump. I am pretty dam near now though.

You can shine a light under the gap of the wood to enhance the visibility of the gap.

Whilst the proper manufactured ones use 1 or 2 DTI?s, I think this is an improvment over the old businesses about measuring from the top of pivot points to the rack top. I would estimate that you can get to within 10 thou with the wood. I drilled a hole in the centre of the wood to centre the wood over the wheel. Near enough, rack of the eye!

I know chipboard may warp but this is not and my garage is dry. It can be improved. First shot!

Mike

Last edited by miked on Wed Jul 31, 2013 7:07 am, edited 1 time in total.

Mike

Elan S4 Zetec

Suzuki Hustler T250

Suzuki TC120R trailcat

Yamaha YR5

Suzuki Vstrom 650XT

Suzuki TS185K

Elan S4 Zetec

Suzuki Hustler T250

Suzuki TC120R trailcat

Yamaha YR5

Suzuki Vstrom 650XT

Suzuki TS185K

-

miked - Coveted Fifth Gear

- Posts: 1191

- Joined: 29 Sep 2003

To compensate for tire load [ the tire patch deforms when stuck on the concrete] get 4 metal pie plates and put grease between them [one on top of the other] so the tire wont stick on the concrete it will swivel on the pie plates [-and Martha Stewart will send you an award ]--so you have some string --4 pie plates and a tape measure and a home made degree device ---cost about 20 bucks -Highly portable in a plastic bag -reusable and dead accurate .With this system you can set caster camber and toe in , or you can spend 1000 bucks for a whim whammy laser outfit ----- are there no Scots out there????? think of the Fosters or Speckled Hen Ale you can buy for the remaining 980 bucks ,,, Granny always said [' were no cheap, were canny']  -ed

-ed

dont close your eyes --you will miss the crash

Editor: On June 12, 2020, Edward Law, AKA TwinCamMan, passed away; his obituary can be read at https://www.friscolanti.com/obituary/edward-law. He will be missed.

Editor: On June 12, 2020, Edward Law, AKA TwinCamMan, passed away; his obituary can be read at https://www.friscolanti.com/obituary/edward-law. He will be missed.

-

twincamman - Coveted Fifth Gear

- Posts: 2453

- Joined: 02 Oct 2003

13 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 12 guests