Hand brake tree,

14 posts

• Page 1 of 1

Good afternoon,

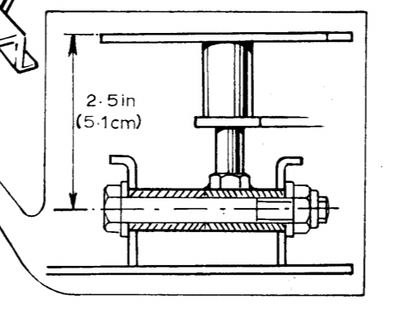

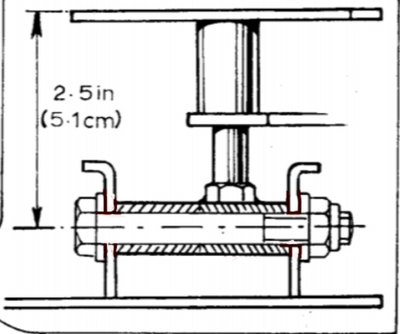

I am just assembling a hand brake tree on a Spyder chassis. The lotus manual shows the hand break tree pivoting on the chassis. Why is this? I would have thought it would be more robust and less resulting wear on the location holes if boss and spacer were sandwiched between the plates and pivoted on the bolt, or am I missing something? Maybe they were concerned the bolt could be over tightened, squashing the boss and stopping movement?

I am sure someone can point out why it is not designed like this.

Cheers.

David

I am just assembling a hand brake tree on a Spyder chassis. The lotus manual shows the hand break tree pivoting on the chassis. Why is this? I would have thought it would be more robust and less resulting wear on the location holes if boss and spacer were sandwiched between the plates and pivoted on the bolt, or am I missing something? Maybe they were concerned the bolt could be over tightened, squashing the boss and stopping movement?

I am sure someone can point out why it is not designed like this.

Cheers.

David

- davidj

- Third Gear

- Posts: 451

- Joined: 09 Apr 2008

I think it is to allow for suspension movement.

In addition, I took advantage of the lower pivot to lean the tree to the rhs so that I would have just a little more rotation available before impinging the diff cover. My new tree is oriented at 90 deg, whereas in your pick it looks like one with the upper arms rotated a bit clockwise, which should also offer more rotation. That early design seems like it should be better than the current replacement.

Also, with that suspension travel idea in mind I made sure to cinch up the nuts for the rod ends loose so they can pivot a bit at the upper tree arms.

John

In addition, I took advantage of the lower pivot to lean the tree to the rhs so that I would have just a little more rotation available before impinging the diff cover. My new tree is oriented at 90 deg, whereas in your pick it looks like one with the upper arms rotated a bit clockwise, which should also offer more rotation. That early design seems like it should be better than the current replacement.

Also, with that suspension travel idea in mind I made sure to cinch up the nuts for the rod ends loose so they can pivot a bit at the upper tree arms.

John

- baileyman

- Third Gear

- Posts: 348

- Joined: 17 Aug 2017

The tree has to be able to move left/right to allow for difference in the actuation rod travel. If say the left adjuster were a little slacker than the right when the brake is applied one rod would move more than the other so the tree would be able to "tilt" to the right as well as rotate...

- vxah

- Third Gear

- Posts: 380

- Joined: 08 Nov 2012

vxah wrote:The tree has to be able to move left/right to allow for difference in the actuation rod travel. If say the left adjuster were a little slacker than the right when the brake is applied one rod would move more than the other so the tree would be able to "tilt" to the right as well as rotate...

Correct! The tree self-centres between the hubs and ensures that both caliper levers get the same pull.

The pull of the cable has to be resisted by the chassis holes but provided these and all the pivot pins are well greased wear is not a problem.

If your tree is off the car, then I would recommend redrilling all the pivot holes inline with the cable and rod ends to closely fit new pins (which you may have to make or purchase specially). Smother everything in grease. I drove 100,000 miles without a working handbrake before redrilling the tree, and 120,000 with it working perfectly since, merely adjusting the calipers for pad wear.

Meg

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

-

Quart Meg Miles - Coveted Fifth Gear

- Posts: 1170

- Joined: 03 Oct 2012

Afternoon,

Sorry, miss leading english on my part; I was not asking why the hand brake tree pivots. I understand it has to pivot to successfully operate both brakes. Rather it was a general question about the design of the assembly, as it pivots on the two chassis holes. I would have thought a simpler design would have sandwiched the tree boss between the two chassis plates and pivot on the 2 1/4 inch bolt.

However, it is a rather academic discussion as my chassis has already been drilled to take the o/d of the tree boss.

Cheers,

David

Sorry, miss leading english on my part; I was not asking why the hand brake tree pivots. I understand it has to pivot to successfully operate both brakes. Rather it was a general question about the design of the assembly, as it pivots on the two chassis holes. I would have thought a simpler design would have sandwiched the tree boss between the two chassis plates and pivot on the 2 1/4 inch bolt.

However, it is a rather academic discussion as my chassis has already been drilled to take the o/d of the tree boss.

Cheers,

David

- davidj

- Third Gear

- Posts: 451

- Joined: 09 Apr 2008

Because the the bolt can be done up tight without deforming the chassis rails (it compresses onto the pivot tube) and hence it cannot be assembled wrongly.

In your modified design, if you were to tighten the bolt too far, it would deform the chassis rails and potentially could lock up the pivot tube so that it could not rotate.

You could do it in a way that pivots on the bolt - either with a shoulder on the bolt to restrict the amount of tightening or with a second tube inside the pivot tube that would be trapped between the rails - leaving the pivot to rotate. Both of these are more complex, more expensive and probably heavier by a few grams - hence the current design.

Richard

In your modified design, if you were to tighten the bolt too far, it would deform the chassis rails and potentially could lock up the pivot tube so that it could not rotate.

You could do it in a way that pivots on the bolt - either with a shoulder on the bolt to restrict the amount of tightening or with a second tube inside the pivot tube that would be trapped between the rails - leaving the pivot to rotate. Both of these are more complex, more expensive and probably heavier by a few grams - hence the current design.

Richard

- Higs

- Second Gear

- Posts: 150

- Joined: 02 Dec 2009

@higs I thought that may be the case as well, see my initial post. However, because of the lip design, the bolt would have to be very tight to deform the chassis rail, and with the existing design, the mounting holes wear as the handbrake operates.

However, water under the bridge now!

However, water under the bridge now!

- davidj

- Third Gear

- Posts: 451

- Joined: 09 Apr 2008

The handbrake tree is a true example of Lotus built in lightness and simplicity based on clever engineering analysis of the stresses involved. The tension in the rods to the brake levers balances the tension in the hand brake cable as the tree tilts forward when loaded . The for / aft and side to side flexibility also accommodates the suspension movement and all of this occurs without additional components or weight or complexity.

A small design challenge back in the early 60's but something that most other manufacturers struggled with then and still do now

cheers

Rohan

A small design challenge back in the early 60's but something that most other manufacturers struggled with then and still do now

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8417

- Joined: 22 Sep 2003

Not a Lotus original design, I think.

The Austin-Healey Sprite, and maybe other BMC cars, has a similar tree but as an aluminium casting. Very nice, but too expensive for Lotus!

The Austin-Healey Sprite, and maybe other BMC cars, has a similar tree but as an aluminium casting. Very nice, but too expensive for Lotus!

-

RogerFrench - Fourth Gear

- Posts: 536

- Joined: 01 Dec 2009

Just a note, the workshop manual includes a drawing for a modified handbrake tree that gives better leverage for the handbrake, depending on the age of your car it may already have it as standard, if not its a worthwhile mod if you have it apart.

Change is inevitable, except from a vending machine!

- Bigbaldybloke

- Fourth Gear

- Posts: 889

- Joined: 16 May 2017

14 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 21 guests