Rear Caliper

16 posts

• Page 1 of 2 • 1, 2

Hi Guys a couple of questions

Rebuilding the rear calipers, they have been split, I have read on the forum that I should use new bolts, and I have the following suggested torque settings

7/16 bolts - 55 - 70 ibf -

3/8 - 40 - 50 ibf

5/16 - 20 - 25 ibf

The bolts that I am looking at look like they have a full tread, does that matter the existing bolts are only part threaded and would you use socket head caps?

The bigger question the bolts mounting the calipers through the rear upright, again this is part threaded i would not call it a shoulder bolt but again can I use a full thread bolt of should this be un threaded were it goes through the ally upright. I can not find anyone listing them as spares and the ones I can find for M16 front caliper seem to have an un threaded section that is more than the thickness of the upright, I guess I could use some washers

Any comments on bolts but also on rebuilding rear calipers would be welcome

Thanks

Rebuilding the rear calipers, they have been split, I have read on the forum that I should use new bolts, and I have the following suggested torque settings

7/16 bolts - 55 - 70 ibf -

3/8 - 40 - 50 ibf

5/16 - 20 - 25 ibf

The bolts that I am looking at look like they have a full tread, does that matter the existing bolts are only part threaded and would you use socket head caps?

The bigger question the bolts mounting the calipers through the rear upright, again this is part threaded i would not call it a shoulder bolt but again can I use a full thread bolt of should this be un threaded were it goes through the ally upright. I can not find anyone listing them as spares and the ones I can find for M16 front caliper seem to have an un threaded section that is more than the thickness of the upright, I guess I could use some washers

Any comments on bolts but also on rebuilding rear calipers would be welcome

Thanks

Andrew

Lotus Elan+2S 1969

Lotus Elan+2S 1969

- BullAndrew

- First Gear

- Posts: 41

- Joined: 23 May 2014

Hi,

A well-known UK caliper reconditioner replace with cap/socket head bolts IMHO the best are

http://www.unbrako.com/images/downloads/engguide.pdf

Fixing bolts must be the correct length with correct shoulder and they are also drilled for lock wire.

Ron.

A well-known UK caliper reconditioner replace with cap/socket head bolts IMHO the best are

http://www.unbrako.com/images/downloads/engguide.pdf

Fixing bolts must be the correct length with correct shoulder and they are also drilled for lock wire.

Ron.

- Craven

- Coveted Fifth Gear

- Posts: 1624

- Joined: 14 Sep 2013

Have owned S2 elan for 35 years, have pulled apart/reconditioned both front and rear calipers three or four times in that period and have never replaced caliper bolts... close inspection is required though, check threads are OK, check that there is NO corrosion along the shank, clean bolt threads with rotary wire buff, degrease and carefully check items again.

Very rare to have a caliper bolt/s fail.

And if you read the lotus workshop manual they'll say "DO NOT" split the caliper bodies... why not you might ask? The most likely reason is that some absent minded DIY mechanic just might forget to renew/replace the small O ring seal between the caliper halves.

Most important also to torque the bolts to the correct torque during re-assembly. But alas, the workshop manual does not provide torque figures for the caliper body bolts, but they are just humble HT 7/16" UNF, and to save you the search, the torque loading is 40-45 ft lbs.

Generally, I think people get a bit too pedantic about bolt replacement due to the brainwashing that goes on out there. I built my twin cam engine 35 years ago, and reused the original HT conrod bolts, at the time I had no idea how many re-torquing/stretch cycles the bolts had been through prior to that.... so, have I ever had any trouble, NO, But I will admit that the engine has never been taken beyond the redline, but all the same the engine has been given a good workout over the years.

But the next rebuild will see the old "well cycled" conrod bolts replaced with ARP, because as we all know, it is peace of mind when it comes to an engine rebuild, isn't it.

But getting back to caliper bolts.

The breaking strength of a HT 7/16" UNF bolt ranges from 7850 lbs to 17800 lbs depending on the grade.

How much pressure can one apply to a brake pedal? Not enough to break a caliper bolt, not even one that has been re-used two or three/four times.

Very rare to have a caliper bolt/s fail.

And if you read the lotus workshop manual they'll say "DO NOT" split the caliper bodies... why not you might ask? The most likely reason is that some absent minded DIY mechanic just might forget to renew/replace the small O ring seal between the caliper halves.

Most important also to torque the bolts to the correct torque during re-assembly. But alas, the workshop manual does not provide torque figures for the caliper body bolts, but they are just humble HT 7/16" UNF, and to save you the search, the torque loading is 40-45 ft lbs.

Generally, I think people get a bit too pedantic about bolt replacement due to the brainwashing that goes on out there. I built my twin cam engine 35 years ago, and reused the original HT conrod bolts, at the time I had no idea how many re-torquing/stretch cycles the bolts had been through prior to that.... so, have I ever had any trouble, NO, But I will admit that the engine has never been taken beyond the redline, but all the same the engine has been given a good workout over the years.

But the next rebuild will see the old "well cycled" conrod bolts replaced with ARP, because as we all know, it is peace of mind when it comes to an engine rebuild, isn't it.

But getting back to caliper bolts.

The breaking strength of a HT 7/16" UNF bolt ranges from 7850 lbs to 17800 lbs depending on the grade.

How much pressure can one apply to a brake pedal? Not enough to break a caliper bolt, not even one that has been re-used two or three/four times.

- ceejay

- Fourth Gear

- Posts: 558

- Joined: 27 Mar 2007

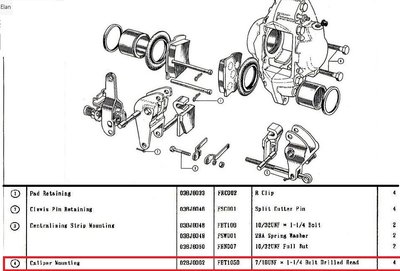

What is the length of the 7/16" bolt used to mount the rear calipers to the hubs? Mine seem to have gone missing, and the RDent parts manual just specifies a Lotus P/N. Diagram also does not show lock washers, but they are specified for the fronts. Any reason for this?

Thanks,

Tony

Thanks,

Tony

Tony

1967 Elan S3 SE

Northeast US

1967 Elan S3 SE

Northeast US

- Tmac897

- Second Gear

- Posts: 190

- Joined: 01 Aug 2019

Hi,

I happen to have a new set of rear caliper mounting bolts with the lockwire drilling. I got them from SJSportscars, and they only took a year to arrive I'm willing to wait again for replacements so I'm happy to pass on the ones I have if that helps you out.

I'm willing to wait again for replacements so I'm happy to pass on the ones I have if that helps you out.

Paddy

I happen to have a new set of rear caliper mounting bolts with the lockwire drilling. I got them from SJSportscars, and they only took a year to arrive

Paddy

1963 Elan S1

-

paddy - Coveted Fifth Gear

- Posts: 1036

- Joined: 27 Oct 2008

paddy wrote:Hi,

I happen to have a new set of rear caliper mounting bolts with the lockwire drilling. I got them from SJSportscars, and they only took a year to arriveI'm willing to wait again for replacements so I'm happy to pass on the ones I have if that helps you out.

Paddy

Hi Paddy,

That's a very generous offer, and if I was a rear caliper mount, a wash, and a blow dry away from putting my Elan back on the road, I would likely take you up on it. But I'm an engine rebuild, a complete interior replacement, and a new paint job away. I'm sure I will be able to scare up a couple of bolts in that amount of time, even if I have to pay $5 bucks each from Dave Bean Engineering.

By the way, I didn't know this, but I found out recently that DBE has a sister company that manufactures aircraft bolts. I just bought a complete set of Rotoflex coupling bolts, and the thin head, rear wishbone attachment bolts from them, and it only took a couple of days. Not cheap, but availability coupled with the knowledge of the particular Elan requirements made things very easy.

Best,

Tony

Tony

1967 Elan S3 SE

Northeast US

1967 Elan S3 SE

Northeast US

- Tmac897

- Second Gear

- Posts: 190

- Joined: 01 Aug 2019

Tmac897 wrote:

...

By the way, I didn't know this, but I found out recently that DBE has a sister company that manufactures aircraft bolts. ...

Best,

Tony

Sometimes I feel like a bolt manufacturer, too, shortening threaded lengths, turning down heads and nuts, drilling for wire, turning crazy conical diff stay washers, et al.

JOhn

- baileyman

- Third Gear

- Posts: 348

- Joined: 17 Aug 2017

Tony,

I happened to be visiting DBE (Dave Bean Engineering) approximately two weeks ago and saw the thin head rear A-Arm bolts and the others you are talking about. They are a thing of beauty.

Congratulations! Smart Buy!

Frank

I happened to be visiting DBE (Dave Bean Engineering) approximately two weeks ago and saw the thin head rear A-Arm bolts and the others you are talking about. They are a thing of beauty.

Congratulations! Smart Buy!

Frank

Famous Frank

67 Elan Coupe

66 Elan S2 SE

65 Elan S2

65 Elan 26R

69 S2 Europa

06 Elise

67 Barracuda

67 Elan Coupe

66 Elan S2 SE

65 Elan S2

65 Elan 26R

69 S2 Europa

06 Elise

67 Barracuda

-

Famous Frank - Fourth Gear

- Posts: 556

- Joined: 29 Apr 2004

Famous Frank wrote:Tony,

I happened to be visiting DBE (Dave Bean Engineering) approximately two weeks ago and saw the thin head rear A-Arm bolts and the others you are talking about. They are a thing of beauty.

Frank

Yes, they even come with individual red rubber thread protectors! Almost too pretty to install.

Tony

Tony

1967 Elan S3 SE

Northeast US

1967 Elan S3 SE

Northeast US

- Tmac897

- Second Gear

- Posts: 190

- Joined: 01 Aug 2019

16 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 9 guests