Adjusting the "squirt" on dellortos

27 posts

• Page 1 of 2 • 1, 2

Hi all,

A couple of months ago I was discussing a problem I am having with my DHLA40 carbs on one fo the other forums and would like to revisit it..

I am very happy with the carbs (theyre on a lotus elan +2) as they seem work really well in general use with no obvious flat spots..

The trouble I have is when I floor it at low engine speed (particularly in the lower gears).

Under these conditions the car bogs badly. Now obviously getting a wide band sensor to look at the transient change in mixture would be the ideal situation. Unfortunately I don;t have the cash free at the moment as I have had to shell out for a fancy preengaged starter!

The outcome of the previous discussions was that the accelerator pump was running too rich..

I dropped 5 in the jet size and it seemed to help a little..

However one of the guys mentioned that you could also change the pump stroke by altering the adustable rod under the carbs..

I was loathed to do this as I was using the car daily and it ment taking the airbox and potentially the carbs off the car to fashion an adjustment.

However now I find myself in just that situation after a small loom meltdown

The questions are

Should I launch into adjusting via this route?

Has any in the forum done it successfully?

Which way do I wind the adjusting nuts to lean out the mixture?

Thanks for any help

tim

A couple of months ago I was discussing a problem I am having with my DHLA40 carbs on one fo the other forums and would like to revisit it..

I am very happy with the carbs (theyre on a lotus elan +2) as they seem work really well in general use with no obvious flat spots..

The trouble I have is when I floor it at low engine speed (particularly in the lower gears).

Under these conditions the car bogs badly. Now obviously getting a wide band sensor to look at the transient change in mixture would be the ideal situation. Unfortunately I don;t have the cash free at the moment as I have had to shell out for a fancy preengaged starter!

The outcome of the previous discussions was that the accelerator pump was running too rich..

I dropped 5 in the jet size and it seemed to help a little..

However one of the guys mentioned that you could also change the pump stroke by altering the adustable rod under the carbs..

I was loathed to do this as I was using the car daily and it ment taking the airbox and potentially the carbs off the car to fashion an adjustment.

However now I find myself in just that situation after a small loom meltdown

The questions are

Should I launch into adjusting via this route?

Has any in the forum done it successfully?

Which way do I wind the adjusting nuts to lean out the mixture?

Thanks for any help

tim

-

tdafforn - Fourth Gear

- Posts: 744

- Joined: 12 Sep 2003

TIM I think it might have been me who mentioned this, was it around the time Kieth left this forum?.

To quickly recap what I said.

1) The jet size controls the duration of the squirt, not the amount

2) The pump stroke controls the amount of fuel

To sort your problem I would suggest you remove your carbs and set the jets back to the recommended size. Then set the rod lengths equally to give you 3mm (from memory, will check and get back if wrong) of thread protruding below the lock nuts. If you then fill the float chamber with fuel and operate the throttle while squirting the fuel from the jet into a jar and also making a mental note of how many seconds it takes. Do the other carb and you should achieve a similar duration & amount. If you dont chack the pump diaphragm.

By reducing your pump jet you have increased the duration which may have been too much for the engine.

The setting should not be too critical in terms of performance but it's worth fiddling with in terms of economy.

Hope this helps

Regards

Dave

To quickly recap what I said.

1) The jet size controls the duration of the squirt, not the amount

2) The pump stroke controls the amount of fuel

To sort your problem I would suggest you remove your carbs and set the jets back to the recommended size. Then set the rod lengths equally to give you 3mm (from memory, will check and get back if wrong) of thread protruding below the lock nuts. If you then fill the float chamber with fuel and operate the throttle while squirting the fuel from the jet into a jar and also making a mental note of how many seconds it takes. Do the other carb and you should achieve a similar duration & amount. If you dont chack the pump diaphragm.

By reducing your pump jet you have increased the duration which may have been too much for the engine.

The setting should not be too critical in terms of performance but it's worth fiddling with in terms of economy.

Hope this helps

Regards

Dave

1970 plus2s & Rochdale Olympic & Rochdale GT

- Dave-M

- Second Gear

- Posts: 175

- Joined: 11 Jun 2005

If you've ever looked at a Dellorto you might have noticed they have one of the most obscure linkages ever devised fitted on the pump circuit.

A few years back a guy who knows webers quite well and I studied the Dellorto manual with the carb in our hands and after a few sessions over lunch still didn't understand how the pump circuit works.

The reason being there is no positive operation of the pump lever, it is biased back to one state by the internal spring and all the throttle lever does is compress a couple of very weak external springs and leave the linkage to the pump circuit rather slack.

The conclusion was the only way the pump can operating is with a convenient hand pulling on the pump lever arm. Adjustment of the tiny adjustment nuts or removal completely with an axe would make as much difference to carb operation as sticking a packet of polo mints in the glovebox.

I've a spare carb kicking around and will try and show what I mean (if I can fit it on my scannner - no digital camera!)

A few years back a guy who knows webers quite well and I studied the Dellorto manual with the carb in our hands and after a few sessions over lunch still didn't understand how the pump circuit works.

The reason being there is no positive operation of the pump lever, it is biased back to one state by the internal spring and all the throttle lever does is compress a couple of very weak external springs and leave the linkage to the pump circuit rather slack.

The conclusion was the only way the pump can operating is with a convenient hand pulling on the pump lever arm. Adjustment of the tiny adjustment nuts or removal completely with an axe would make as much difference to carb operation as sticking a packet of polo mints in the glovebox.

I've a spare carb kicking around and will try and show what I mean (if I can fit it on my scannner - no digital camera!)

Martin

72 Sprint DHC

72 Sprint DHC

-

M100 - Third Gear

- Posts: 450

- Joined: 16 Sep 2003

Dave-M wrote:,

1) The jet size controls the duration of the squirt, not the amount

2) The pump stroke controls the amount of fuel

Dave

This is what I have always understood to be the way they work but ................

M100 Wrote Quote

"Adjustment of the tiny adjustment nuts or removal completely with an axe would make as much difference to carb operation as sticking a packet of polo mints in the glovebox."

and I tend to agree as the small adjusting nuts "fell off" one carb on my Europa, I only saw it by accident and when I replaced them it made no difference (that I could detect) weather the nuts were screwed all in or all out, I just set it the same as the other one and it was fine.

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3407

- Joined: 11 Sep 2003

Tim, It most certainly does. I think previous comments regarding the link system are wrong.

The operating system is infinatly adjustable and adjusts the start position (ie stroke length) of the diaphragm to govern the amount of fuel to be injected.

If you look at your carbs you will see that by adjusting the nuts at the bottom of the rod the lever is raised or lowered (with respect to the rod)at the rest position giving more or less fuel respectivley. So there you have it up with the nuts for more and down for less.

This link system is in principle the same as weber DCOM carbs and is similar to DCOE'S in as much as it relys on spring pressure and not a driect mechanical link. The DCOE using different rod lengths to achieve the required amount of fuel by altering the piston stroke.

To Rohan & M100. If you imagine the spring, diaphragm lever and nut interface as just an easy way to account for the angular movement of the rod as the operating arm on the throttle spindle moves it while maintaining a slop free joint. Much the same as a rose joint would, then imagine the effect of moving the rose joint up and down the shaft.

Let us know how you get on Tim

Regards

Dave

The operating system is infinatly adjustable and adjusts the start position (ie stroke length) of the diaphragm to govern the amount of fuel to be injected.

If you look at your carbs you will see that by adjusting the nuts at the bottom of the rod the lever is raised or lowered (with respect to the rod)at the rest position giving more or less fuel respectivley. So there you have it up with the nuts for more and down for less.

This link system is in principle the same as weber DCOM carbs and is similar to DCOE'S in as much as it relys on spring pressure and not a driect mechanical link. The DCOE using different rod lengths to achieve the required amount of fuel by altering the piston stroke.

To Rohan & M100. If you imagine the spring, diaphragm lever and nut interface as just an easy way to account for the angular movement of the rod as the operating arm on the throttle spindle moves it while maintaining a slop free joint. Much the same as a rose joint would, then imagine the effect of moving the rose joint up and down the shaft.

Let us know how you get on Tim

Regards

Dave

- Dave-M

- Second Gear

- Posts: 175

- Joined: 11 Jun 2005

just been out to look at the linkages and they are set at between 3 and 4 mm

(bottom of nut to bottom of thread) is that as you'd expect for a pair of unmolested DHLAs (baring im mind most problems seem to be linked to DPO fiddling)

So if I am getting this right I should remove the carbs replace the old jets, check that each jet is giving the same lenght shot of gas. Then in my case where I think it running rich its down with the nuts (ooer!)..

Any ideas as to how much as a first shot?

Tim

(bottom of nut to bottom of thread) is that as you'd expect for a pair of unmolested DHLAs (baring im mind most problems seem to be linked to DPO fiddling)

So if I am getting this right I should remove the carbs replace the old jets, check that each jet is giving the same lenght shot of gas. Then in my case where I think it running rich its down with the nuts (ooer!)..

Any ideas as to how much as a first shot?

Tim

-

tdafforn - Fourth Gear

- Posts: 744

- Joined: 12 Sep 2003

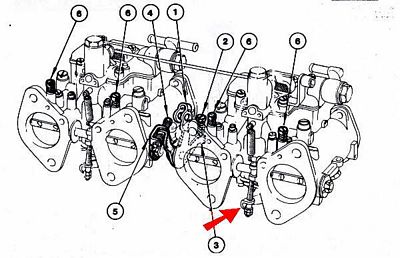

Looking at the linkage with the throttles closed the pump lever can physically move around 10mm upwards towards the throttle spindles when assisted by hand

When the throttle is wide open the strong internal spring biases the pump lever downwards.

With the adjustment nuts at the tightest (i.e maximum thread exposed outboard) and with the throttles opened fully there is approximately 3mm of movement of the pump lever caused by the internal spring in the downward direction.

Adjustment of the nuts towards the end of the linkage would reduce the pump lever travel towards zero.

When the maximum adjustment of the pump linkage is in the order of circa 0-3mm why engineer in 10mm of movement when you are only ever going to be able to use 1/3 of that?

Pic attached to jog memories.

When the throttle is wide open the strong internal spring biases the pump lever downwards.

With the adjustment nuts at the tightest (i.e maximum thread exposed outboard) and with the throttles opened fully there is approximately 3mm of movement of the pump lever caused by the internal spring in the downward direction.

Adjustment of the nuts towards the end of the linkage would reduce the pump lever travel towards zero.

When the maximum adjustment of the pump linkage is in the order of circa 0-3mm why engineer in 10mm of movement when you are only ever going to be able to use 1/3 of that?

Pic attached to jog memories.

Martin

72 Sprint DHC

72 Sprint DHC

-

M100 - Third Gear

- Posts: 450

- Joined: 16 Sep 2003

Martin,

I have attached a couple of images in the hope we can sort this out. On the left is the setup from a weber 40 DCOM and on the right is the Dellorto.

As you say it is possible to push the diaphragm operating lever upwards by 10mm but that is not the way the forces are applied.

As the throttle opend the rod is pushed down and the rod spring is in compression, this presses down on the diaphragm operating arm which then on the other side of the pivot point pushes upwards on the diaphragm plunger, which then pushes the fuel above the diaphragm through the pump jet and into the manifold. The light spring above the diaphragm is there to maintain the diaphragm plunger(below the diaphragm) in contact with the operating arm.

You may looking at the pictures now see how altering the position of the adjusting nuts also alters the length of stroke of the diaphragm which is limited in it's upward travel by the top casting in the picture.

I am not trying to be controversial or argumentative but I make a part of my living by restoring/ refurbishing Weber and Dellorto carbs and I like to think I know what I am talking about.

Regards

Dave

I have attached a couple of images in the hope we can sort this out. On the left is the setup from a weber 40 DCOM and on the right is the Dellorto.

As you say it is possible to push the diaphragm operating lever upwards by 10mm but that is not the way the forces are applied.

As the throttle opend the rod is pushed down and the rod spring is in compression, this presses down on the diaphragm operating arm which then on the other side of the pivot point pushes upwards on the diaphragm plunger, which then pushes the fuel above the diaphragm through the pump jet and into the manifold. The light spring above the diaphragm is there to maintain the diaphragm plunger(below the diaphragm) in contact with the operating arm.

You may looking at the pictures now see how altering the position of the adjusting nuts also alters the length of stroke of the diaphragm which is limited in it's upward travel by the top casting in the picture.

I am not trying to be controversial or argumentative but I make a part of my living by restoring/ refurbishing Weber and Dellorto carbs and I like to think I know what I am talking about.

Regards

Dave

- Dave-M

- Second Gear

- Posts: 175

- Joined: 11 Jun 2005

Martin, Cleaning carb castings is not what this thread is about, Your sarcasm is not appreciated and I don't need to tout for business here and have never done so.

Regards

Dave

Dave, that never was the intention of my posting. Sarcasm never even entered my head at any stage (and even now I fail to see any evidence of it)

I had just been looking a carb again and reading your posting and noticed the movement on the pump arm is from the compression of the spring on the rod, not from the expansion of the internal spring as I had thought from my earlier inspection, That is why I said it's *starting* to make some sense now. But not having had one in bits for a long while and with most of my books (except perversely the weber tuning guide!) that might refresh me on the operating principles still in storage I was trying to remember something that happened probably 10-12 years ago.

Threads sometimes drift off to other areas and the *only* reason I asked about carb cleaning in the first place was you mentioning your experience. I'm not for the brand new out of the factory look, carbs can often take on a reasonable patina with age which to my eye looks better, sometimes like the ones I was handling earlier while looking at the pump linkage, despite being some 3 or 4 years newer than the ones on my car and not being used for around 25 years just look crap. I had (obviously totally incorrectly) thought that you might be able to make some positive suggestions. If not then so be it.

Martin

72 Sprint DHC

72 Sprint DHC

-

M100 - Third Gear

- Posts: 450

- Joined: 16 Sep 2003

Dave,

I'm not disputing the theory or the mechanical actions but the only point I was making is that I could detect no difference in drivability after adjusting the stroke from one extream to the other.

Martin,

I have used "Mag wheel cleaner" to clean the carb bodies with good results (dispite comments that it would damage the carbs)

I'm not disputing the theory or the mechanical actions but the only point I was making is that I could detect no difference in drivability after adjusting the stroke from one extream to the other.

Martin,

I have used "Mag wheel cleaner" to clean the carb bodies with good results (dispite comments that it would damage the carbs)

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3407

- Joined: 11 Sep 2003

27 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 57 guests