Misbehaving Weber?

69 posts

• Page 4 of 5 • 1, 2, 3, 4, 5

Hi John.

I think the safeness of a particular AFR depends primarily on the engine load, the load duration, CR, timing, and the fuel type.

From a performance perspective, it may make sense to tune for a rich mixture on a relatively underpowered vehicle like the 308. If one tunes for best power under the most conditions, I think one would pay the price of heavy fuel consumption. If one tunes for economy and cruising, you will likely leave performance on the table.

Are you really seeing 16.7 AFR at cruise? What fuel are you using?

From the data I posted above, you will see I exceed 15 AFR quite often too, way above stoichiometric for E10, but these events generally occur when I am off the throttle, so therefore no real engine load. Cruise for me is usually a light load condition, so it's probably safe to run very lean under this condition, as long as you go richer when you increase load. The other thing to keep in mind is we are looking at an averaged mixture condition for all cylinders. Some cylinders will be richer or leaner than others, and it's the lean ones that would be of more concern. Of course fuel injection can be much more precise, so this and other technology, enables modern engines to run much leaner.

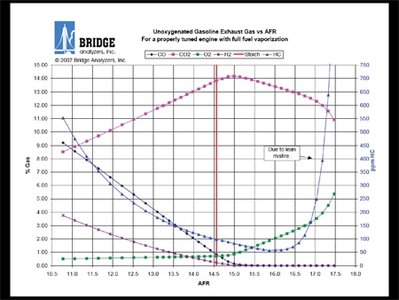

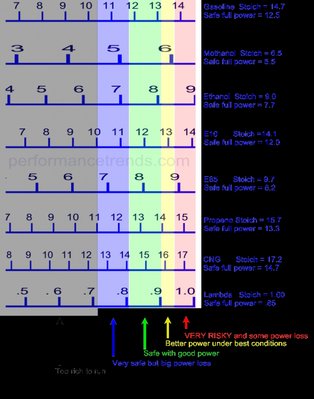

The two references I have been using are shown below. It could be that folks like Innovate could provide better reference material and guidance but I have not found them to be particularly helpful, especially with their legacy products. There is little in the LM-1, LMA-3, and I suspect the LM-2 documentation, that I have found to date, that provides definitive guidance on what the tuning targets should be for various operating conditions, especially with respect to non pure gas fuels.

I don't have all the answers. Additional references and insight sought.

Bill

I think the safeness of a particular AFR depends primarily on the engine load, the load duration, CR, timing, and the fuel type.

From a performance perspective, it may make sense to tune for a rich mixture on a relatively underpowered vehicle like the 308. If one tunes for best power under the most conditions, I think one would pay the price of heavy fuel consumption. If one tunes for economy and cruising, you will likely leave performance on the table.

Are you really seeing 16.7 AFR at cruise? What fuel are you using?

From the data I posted above, you will see I exceed 15 AFR quite often too, way above stoichiometric for E10, but these events generally occur when I am off the throttle, so therefore no real engine load. Cruise for me is usually a light load condition, so it's probably safe to run very lean under this condition, as long as you go richer when you increase load. The other thing to keep in mind is we are looking at an averaged mixture condition for all cylinders. Some cylinders will be richer or leaner than others, and it's the lean ones that would be of more concern. Of course fuel injection can be much more precise, so this and other technology, enables modern engines to run much leaner.

The two references I have been using are shown below. It could be that folks like Innovate could provide better reference material and guidance but I have not found them to be particularly helpful, especially with their legacy products. There is little in the LM-1, LMA-3, and I suspect the LM-2 documentation, that I have found to date, that provides definitive guidance on what the tuning targets should be for various operating conditions, especially with respect to non pure gas fuels.

I don't have all the answers. Additional references and insight sought.

Bill

- bill308

- Fourth Gear

- Posts: 736

- Joined: 27 May 2004

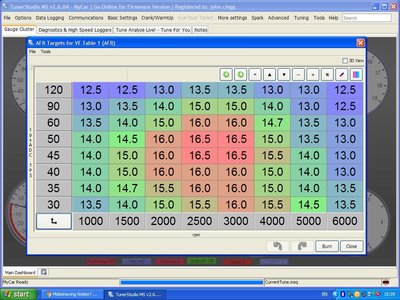

My AFR map.. just cruisin' , as they say

John

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

Hi John.

Thanks for the feedback.

Interesting fuel map. Are you using electronic, port fuel injection, with an O2 sensor in the exhaust pipe for feedback.?

Are you running on pure gasoline?

I understand the horizontal rpm scale. What are the units for TPS on the vertical scale, mV?

So in general, it appears you are tuning for max fuel economy at cruise, yet revert to much richer mixtures at wide open throttle. I think this is a sound strategy, especially if the cost of fuel is relatively high.

What final drive ratio and tire size are you running? Interstate traffic in my area averages about 75 mph and if you want to go out of town, interstates are the most efficient routes. So at 80 mph, I don't think I'd want to run in the 15+ range with a 3.55:1 final drive ratio, even with pure gas.

Bill

Thanks for the feedback.

Interesting fuel map. Are you using electronic, port fuel injection, with an O2 sensor in the exhaust pipe for feedback.?

Are you running on pure gasoline?

I understand the horizontal rpm scale. What are the units for TPS on the vertical scale, mV?

So in general, it appears you are tuning for max fuel economy at cruise, yet revert to much richer mixtures at wide open throttle. I think this is a sound strategy, especially if the cost of fuel is relatively high.

What final drive ratio and tire size are you running? Interstate traffic in my area averages about 75 mph and if you want to go out of town, interstates are the most efficient routes. So at 80 mph, I don't think I'd want to run in the 15+ range with a 3.55:1 final drive ratio, even with pure gas.

Bill

- bill308

- Fourth Gear

- Posts: 736

- Joined: 27 May 2004

Bill

Interesting fuel map. Are you using electronic, port fuel injection, with an O2 sensor in the exhaust pipe for feedback.?

Running Megasquirt Ms1 V3,port injection using GPZ 1000 throttle bodies and WBO2 sensor in the Y-piece

Are you running on pure gasoline?

Running on Supermarket Slop

I understand the horizontal rpm scale. What are the units for TPS on the vertical scale, mV?

TPS ADC ( 0-5v converted to digital )

So in general, it appears you are tuning for max fuel economy at cruise, yet revert to much richer mixtures at wide open throttle. I think this is a sound strategy, especially if the cost of fuel is relatively high.

Lean when it's not needed,Rich when it is.

What final drive ratio and tire size are you running? Interstate traffic in my area averages about 75 mph and if you want to go out of town, interstates are the most efficient routes. So at 80 mph, I don't think I'd want to run in the 15+ range with a 3.55:1 final drive ratio, even with pure gas.

3.77, 175/70.13 Cruising at 75mph ( can't remember exactly at the moment ) approx 3000rpm ( Lotus 5 speed box )

Overall 40mpg

John

Interesting fuel map. Are you using electronic, port fuel injection, with an O2 sensor in the exhaust pipe for feedback.?

Running Megasquirt Ms1 V3,port injection using GPZ 1000 throttle bodies and WBO2 sensor in the Y-piece

Are you running on pure gasoline?

Running on Supermarket Slop

I understand the horizontal rpm scale. What are the units for TPS on the vertical scale, mV?

TPS ADC ( 0-5v converted to digital )

So in general, it appears you are tuning for max fuel economy at cruise, yet revert to much richer mixtures at wide open throttle. I think this is a sound strategy, especially if the cost of fuel is relatively high.

Lean when it's not needed,Rich when it is.

What final drive ratio and tire size are you running? Interstate traffic in my area averages about 75 mph and if you want to go out of town, interstates are the most efficient routes. So at 80 mph, I don't think I'd want to run in the 15+ range with a 3.55:1 final drive ratio, even with pure gas.

3.77, 175/70.13 Cruising at 75mph ( can't remember exactly at the moment ) approx 3000rpm ( Lotus 5 speed box )

Overall 40mpg

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

Hi John.

Sorry to be a pest, but I am curious why you are successful running the lean mixtures in your map. Was this sorted out on the dyno, on the road, or a combination of both?

Is there ethanol mixed into your Supermarket Slop fuel by the oil supplier? In the USA, the gas pumps are required to display the alcohol type and content with a sticker on the pump. Typically, the sticker says "May contain up to 10% ethanol", for all grades in my area. This is the most common type of fuel. Other locations may use E15 and I believe they are also looking at E85. E10 seems to be tolerated reasonably well by most cars, but any fuel with more alcohol content should only be used in vehicles that expressly state they are designed for these fuels.

With regard to the ADC units, I now assume these are Analog-to-Digital Counts (ADC) and it appears 30 corresponds to a throttle opening at idle and 120 corresponds to wide open throttle. Is this correct?

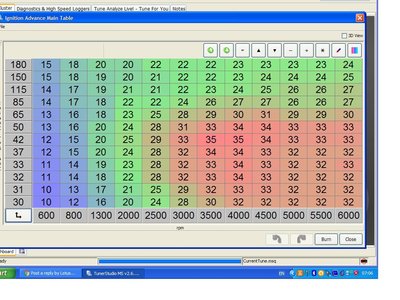

What does your ignition timing curve look like?

Bill

Sorry to be a pest, but I am curious why you are successful running the lean mixtures in your map. Was this sorted out on the dyno, on the road, or a combination of both?

Is there ethanol mixed into your Supermarket Slop fuel by the oil supplier? In the USA, the gas pumps are required to display the alcohol type and content with a sticker on the pump. Typically, the sticker says "May contain up to 10% ethanol", for all grades in my area. This is the most common type of fuel. Other locations may use E15 and I believe they are also looking at E85. E10 seems to be tolerated reasonably well by most cars, but any fuel with more alcohol content should only be used in vehicles that expressly state they are designed for these fuels.

With regard to the ADC units, I now assume these are Analog-to-Digital Counts (ADC) and it appears 30 corresponds to a throttle opening at idle and 120 corresponds to wide open throttle. Is this correct?

What does your ignition timing curve look like?

Bill

- bill308

- Fourth Gear

- Posts: 736

- Joined: 27 May 2004

Bill

Don't worry about being a pest,all the settings have " matured " over the years,since January 2009,gleaning bits from here and there and pushing the boundaries little by little,no dyno time yet as I am planning to run single plenum shortly ( have done before ,it was good before it backfired on me )

As for "Supermarket Slop" , all it says at the pump is "cheap" , my mother hails from Scotland and my father a Yorkshireman....

As for the ADC,yes nearly,28 closed throttle 200 ( approx ) wide open.

Spark Map

When all is done I look forward to doing some fine tuning on the road with someone who is computer literate and knows about fuelling...it's not easy , even downright dangerous trying to look at a laptop screen while driving...

Then when I'm satisfied maybe a dyno session, but dyno shops are not that keen on Megasquirt as it's a build it yourself thing..

John

Don't worry about being a pest,all the settings have " matured " over the years,since January 2009,gleaning bits from here and there and pushing the boundaries little by little,no dyno time yet as I am planning to run single plenum shortly ( have done before ,it was good before it backfired on me )

As for "Supermarket Slop" , all it says at the pump is "cheap" , my mother hails from Scotland and my father a Yorkshireman....

As for the ADC,yes nearly,28 closed throttle 200 ( approx ) wide open.

Spark Map

When all is done I look forward to doing some fine tuning on the road with someone who is computer literate and knows about fuelling...it's not easy , even downright dangerous trying to look at a laptop screen while driving...

Then when I'm satisfied maybe a dyno session, but dyno shops are not that keen on Megasquirt as it's a build it yourself thing..

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

Interestingly, I am still working on this.

My fuel level in the carbs has increased by itself to approx 24mm and while I have a good idle when the engine is cold, it goes a little lumpy when warm. I now have two symptoms, that I think I have caused for myself.

Firstly (and most importantly as it is a safety issue) I have a dribble of fuel from one or other carb about 20 seconds after switch off when warm. Looking at the threads here it seems like there are two options, most likely the fuel level is just too high, expands and overflows into the mains, or a leak allowing a hidden chamber to fill with fuel due to vacuum that leaks out between the venturi and bore (I'm much less sure I understand this). I can't detect a rise in the carb bowl fuel level after switch off using the optical level measurement method, but I'm thinking float level is the culprit.

Secondly, looking at the colortune at idle, I have a predominantly blue/green combustion on all cylinders, but with the car very slightly nose down on my driveway I find the rear barrel of each carb has a stable combustion and the front has occasional single yellow flashes accompanied by a misfire. That behaviour continues up to around 2000rpm and probably further. If the occasional drop of fuel made it over the top of the drilling into the main, that would account for it perhaps.

I guess my hunch is worth following and I should reduce the fuel level.

The main difference between the last posts and this one is that I filled the car with Shell Nitro (or whatever their "no ethanol" fuel is called) and the car has had perhaps 100 miles of running, which will have purged the stale fuel from the carbs. Perhaps that altered the weight of the fuel in the carb and accounts for my raised fuel level now.

I have also bought new 45F8 idle jets rather than trust that my originals were successfully cleaned. Fitting them and tuning resulted in a CO level of around 5% which is nearer to my 4% target.

Unless someone here has a flash of inspiration, I will correct the fuel level and see if it rectifies the idle miss and the dribble of fuel after running, which apart from being dangerous is earning the car no gold stars from my better half, who doesn't much like the smell either.

Keith Franck suggests that balance between barrels within a carb should not be corrected by twisting the butterfly spindle but I reckon I will have to give this a try to get my balance right overall. The step I think I am missing out on is a full carb strip down, rebuild with new bits and setup from scratch. Maybe that's a job for this winter when I am less busy driving it...

I'll report back, thanks for all the advice thus far.

Ian.

My fuel level in the carbs has increased by itself to approx 24mm and while I have a good idle when the engine is cold, it goes a little lumpy when warm. I now have two symptoms, that I think I have caused for myself.

Firstly (and most importantly as it is a safety issue) I have a dribble of fuel from one or other carb about 20 seconds after switch off when warm. Looking at the threads here it seems like there are two options, most likely the fuel level is just too high, expands and overflows into the mains, or a leak allowing a hidden chamber to fill with fuel due to vacuum that leaks out between the venturi and bore (I'm much less sure I understand this). I can't detect a rise in the carb bowl fuel level after switch off using the optical level measurement method, but I'm thinking float level is the culprit.

Secondly, looking at the colortune at idle, I have a predominantly blue/green combustion on all cylinders, but with the car very slightly nose down on my driveway I find the rear barrel of each carb has a stable combustion and the front has occasional single yellow flashes accompanied by a misfire. That behaviour continues up to around 2000rpm and probably further. If the occasional drop of fuel made it over the top of the drilling into the main, that would account for it perhaps.

I guess my hunch is worth following and I should reduce the fuel level.

The main difference between the last posts and this one is that I filled the car with Shell Nitro (or whatever their "no ethanol" fuel is called) and the car has had perhaps 100 miles of running, which will have purged the stale fuel from the carbs. Perhaps that altered the weight of the fuel in the carb and accounts for my raised fuel level now.

I have also bought new 45F8 idle jets rather than trust that my originals were successfully cleaned. Fitting them and tuning resulted in a CO level of around 5% which is nearer to my 4% target.

Unless someone here has a flash of inspiration, I will correct the fuel level and see if it rectifies the idle miss and the dribble of fuel after running, which apart from being dangerous is earning the car no gold stars from my better half, who doesn't much like the smell either.

Keith Franck suggests that balance between barrels within a carb should not be corrected by twisting the butterfly spindle but I reckon I will have to give this a try to get my balance right overall. The step I think I am missing out on is a full carb strip down, rebuild with new bits and setup from scratch. Maybe that's a job for this winter when I am less busy driving it...

I'll report back, thanks for all the advice thus far.

Ian.

Last edited by Ian T on Sun Aug 21, 2016 3:18 am, edited 2 times in total.

1968 +2 (50/1167) in French Blue on Webers

-

Ian T - First Gear

- Posts: 35

- Joined: 04 Jul 2016

Hi Ian.

You might want to take a measurement on your fuel pressure.

Also, it may be that your float valves are leaking. It might make sense to get a rebuild kit and at least change out the float valves and reset the float levels to the book value.

Twisting the throttle shaft on a DCOE to do an inter carb balance is tricky, but can be done. However, if you are going to keep the car, maybe it's time to step up and get a new set of Spanish made 151's. I believe they have an internal balance circuit and provision for vacuum taps, both desirable features that can make life much easier.

Bill

You might want to take a measurement on your fuel pressure.

Also, it may be that your float valves are leaking. It might make sense to get a rebuild kit and at least change out the float valves and reset the float levels to the book value.

Twisting the throttle shaft on a DCOE to do an inter carb balance is tricky, but can be done. However, if you are going to keep the car, maybe it's time to step up and get a new set of Spanish made 151's. I believe they have an internal balance circuit and provision for vacuum taps, both desirable features that can make life much easier.

Bill

- bill308

- Fourth Gear

- Posts: 736

- Joined: 27 May 2004

Hi John.

Thanks for bearing with me.

I believe your tuning process is a reasonable one. I suspect your fuel does not contain alcohol, so I would assume a stoichiometric value for pure gas of 14.7 for your case.

Is your TPS a rotary or linear device and how is it mounted and powered?

I note your ignition timing advances quite a bit when you are running lean. I believe this is correct. My understanding is that the fastest burn rates are at the max power AFR's, the low 12's for gasoline. AFR's above and below this point should burn slower, so should also benefit from additional timing advance.

Bill

Thanks for bearing with me.

I believe your tuning process is a reasonable one. I suspect your fuel does not contain alcohol, so I would assume a stoichiometric value for pure gas of 14.7 for your case.

Is your TPS a rotary or linear device and how is it mounted and powered?

I note your ignition timing advances quite a bit when you are running lean. I believe this is correct. My understanding is that the fastest burn rates are at the max power AFR's, the low 12's for gasoline. AFR's above and below this point should burn slower, so should also benefit from additional timing advance.

Bill

- bill308

- Fourth Gear

- Posts: 736

- Joined: 27 May 2004

Bill

Thanks,the throttle sensor is a rotary pot. off a Ford Mondeo with a home made mounting plate and is fed off the 5V from the Megasquirt.

John

Thanks,the throttle sensor is a rotary pot. off a Ford Mondeo with a home made mounting plate and is fed off the 5V from the Megasquirt.

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

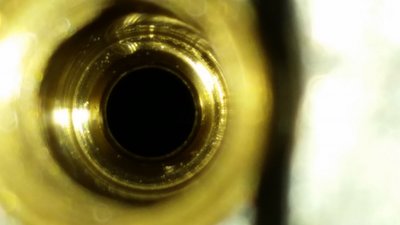

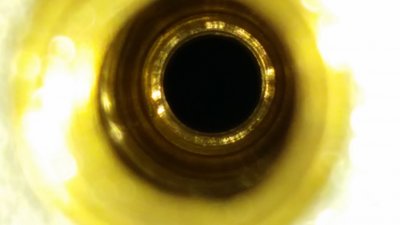

I have found the source of the leak from the carbs after switch off and taken a video...

Now I need to understand what it is and why it is leaking. All four barrels were leaking just the same. Obviously the video is rotated, but I am sure it is obvious.

https://youtu.be/IdcUtny69MQ

Cheers,

Ian.

Now I need to understand what it is and why it is leaking. All four barrels were leaking just the same. Obviously the video is rotated, but I am sure it is obvious.

https://youtu.be/IdcUtny69MQ

Cheers,

Ian.

1968 +2 (50/1167) in French Blue on Webers

-

Ian T - First Gear

- Posts: 35

- Joined: 04 Jul 2016

I believe that the pump jet. Have you checked that the ball bearing and weight are present in your carbs?

They are located under one of the screw caps you can access with the lid removed on the engine end of the carbs.

They are located under one of the screw caps you can access with the lid removed on the engine end of the carbs.

'73 +2 130/5 RHD, now on the road and very slowly rolling though a "restoration"

- mbell

- Coveted Fifth Gear

- Posts: 2643

- Joined: 07 Jun 2013

Thanks Mark, I will take a look. Tomorrow I am heading out to the Lotus Festival so I would like it to be right if at all possible. Obviously (?) It doesn't leak out of the carbs when the engine is running so I believe it is safe enough to drive, but I don't like the few drops coming out after switch off.

I suppose that the ball bearings that are supposed to seal are potentially dirty.

Thanks again,

Ian.

I suppose that the ball bearings that are supposed to seal are potentially dirty.

Thanks again,

Ian.

1968 +2 (50/1167) in French Blue on Webers

-

Ian T - First Gear

- Posts: 35

- Joined: 04 Jul 2016

I thought there is a mod to stop leak/dribble after switching off. The blanking plate on the back of webers between the chokes you drill a small hole at a higher level than the securing screws. This stops a vacuum being caused behind blanking plate when running. When you stop engine vacuum is still there and sucks fuel from carb body which then dribbles.

Have a look at past posts on the subject for more details.

Alan

Have a look at past posts on the subject for more details.

Alan

Alan.b Brittany 1972 elan sprint fhc Lagoon Blue 0460E

- alan.barker

- Coveted Fifth Gear

- Posts: 3756

- Joined: 06 Dec 2008

Well, I have been quiet mainly due to having to work for a living, but over the last weekend I bit the bullet and took the carbs off the car to investigate the leak.

Indeed it was the pump jets. I searched here and Google but couldn't find any solutions, although several references to the pump jets leaking, so I thought I would investigate and then come back here for advice. As it turned out, when I removed my carbs from the car, they had barely 10mm of fuel in the bowls and simply putting them on the bench, filling the bowls to the 25mm-down point and then actuating the accelerator pump a few times until fuel came from the pump jets, I re-created the leak.

So with that, I took the opportunity to clean them out pretty thoroughly and then removed the caps, weights and balls from both demand valves. I also removed the spill valve screwed into the bottom of the bowls and had a look down the bores. They looked dull and dirty, so I simply put some Brasso (brass cleaner) on a cotton bud (Q-Tip for those across the pond) and spun it in the bores to clean the seats. A quick blast with carb cleaner and a good look down the bores confirmed why these valves were leaking.

Essentially, when the throttle is opened, the balls are lifted by the fuel being pumped through and the fuel escapes through the drilling to the pump jets. All good, unless the seats that the balls settle onto are pitted and there's no seal, which is how mine are. The pump jets are well below the fuel level in the carb bowls and the balls are there to stop fuel from syphoning out of the bowl into the barrel.

With no solutions on the net to be found, I thought about how to fix it. A drill bit rotated by hand simply skipped and would have left grooves, so I had to make something more suitable. I went with the idea that something blunt and flat faced in combination with a cutting compound would do the job and turned down a length of bright steel rod with the following dimensions:

Tip: 2.6mm diameter, approx 6mm long

Shank: 5.9mm diameter, approx 40mm long

Shaft: 7mm diameter, 100mm long

The transition from the tip to the shank has a small inside radius to a flat end, so the idea is the tool self-centres in the inner hole and then spins (in an electric drill), wearing very slowly away at the seat where the ball sits. I used both Autosol and Brasso as cutting compound and only very light pressure with the drill.

How to look down the bore? In the end I used my Samsung Galaxy S5 phone and the "Magnifier Plus HD" app, which lets me turn on the LED to provide light as well as something like 10-20x magnification.

I kept polishing each bore until I had a clean ring of flat, shiny brass at the bottom, then used a cotton bud in the drill again, with Autosol and then Brasso to polish the seating area to a bright shine.

A quick test on the bench afterwards showed no leaks, so I put the carbs back together and refitted them to the car. The fuel leak is now gone, taking with it the unpleasant smell of petrol that previously filled my garage and dripped fuel over my ignition components.

I thought I'd post this here as I'm convinced that many owners have the same problem and it doesn't seem to be well known how to fix it. I'm sure that someone in an engineering shop would be able to find a suitable cutting tool off the shelf to improve on my method, but I am very pleased with the results and would do the same again to rectify it in the future.

I'll try posting some photos...

Indeed it was the pump jets. I searched here and Google but couldn't find any solutions, although several references to the pump jets leaking, so I thought I would investigate and then come back here for advice. As it turned out, when I removed my carbs from the car, they had barely 10mm of fuel in the bowls and simply putting them on the bench, filling the bowls to the 25mm-down point and then actuating the accelerator pump a few times until fuel came from the pump jets, I re-created the leak.

So with that, I took the opportunity to clean them out pretty thoroughly and then removed the caps, weights and balls from both demand valves. I also removed the spill valve screwed into the bottom of the bowls and had a look down the bores. They looked dull and dirty, so I simply put some Brasso (brass cleaner) on a cotton bud (Q-Tip for those across the pond) and spun it in the bores to clean the seats. A quick blast with carb cleaner and a good look down the bores confirmed why these valves were leaking.

Essentially, when the throttle is opened, the balls are lifted by the fuel being pumped through and the fuel escapes through the drilling to the pump jets. All good, unless the seats that the balls settle onto are pitted and there's no seal, which is how mine are. The pump jets are well below the fuel level in the carb bowls and the balls are there to stop fuel from syphoning out of the bowl into the barrel.

With no solutions on the net to be found, I thought about how to fix it. A drill bit rotated by hand simply skipped and would have left grooves, so I had to make something more suitable. I went with the idea that something blunt and flat faced in combination with a cutting compound would do the job and turned down a length of bright steel rod with the following dimensions:

Tip: 2.6mm diameter, approx 6mm long

Shank: 5.9mm diameter, approx 40mm long

Shaft: 7mm diameter, 100mm long

The transition from the tip to the shank has a small inside radius to a flat end, so the idea is the tool self-centres in the inner hole and then spins (in an electric drill), wearing very slowly away at the seat where the ball sits. I used both Autosol and Brasso as cutting compound and only very light pressure with the drill.

How to look down the bore? In the end I used my Samsung Galaxy S5 phone and the "Magnifier Plus HD" app, which lets me turn on the LED to provide light as well as something like 10-20x magnification.

I kept polishing each bore until I had a clean ring of flat, shiny brass at the bottom, then used a cotton bud in the drill again, with Autosol and then Brasso to polish the seating area to a bright shine.

A quick test on the bench afterwards showed no leaks, so I put the carbs back together and refitted them to the car. The fuel leak is now gone, taking with it the unpleasant smell of petrol that previously filled my garage and dripped fuel over my ignition components.

I thought I'd post this here as I'm convinced that many owners have the same problem and it doesn't seem to be well known how to fix it. I'm sure that someone in an engineering shop would be able to find a suitable cutting tool off the shelf to improve on my method, but I am very pleased with the results and would do the same again to rectify it in the future.

I'll try posting some photos...

- Attachments

1968 +2 (50/1167) in French Blue on Webers

-

Ian T - First Gear

- Posts: 35

- Joined: 04 Jul 2016

69 posts

• Page 4 of 5 • 1, 2, 3, 4, 5

Total Online:

Users browsing this forum: No registered users and 21 guests