Misbehaving Weber?

69 posts

• Page 3 of 5 • 1, 2, 3, 4, 5

I think 1 to 2 m is the ideal distance for the sensor to prevent it overheating if its to close to the engine. If its to close to the exhaust pipe end then the issue is air leakage back down the pipe affecting the reading. I think at the end of the Y piece to the tail pipe or the inlet to the rear muffler should be OK.

Innovate do sell and adapter to fit down the tail pipe but warn that it is inaccurate at low rpm due to air leakage.

cheers

Rohan

Innovate do sell and adapter to fit down the tail pipe but warn that it is inaccurate at low rpm due to air leakage.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8415

- Joined: 22 Sep 2003

Get yourself a spare Y-piece,mine's been good for years..you can leave the sensor in when not in use....

John

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

Wouldn't a Wideband on a weber dcoe car be next to use less? I have data loggers on both race cars and thats great being fuel injected but all it would tell you on a Weber car is the mixture is out (not which cylinder is out) i get you change the jets in sets but from past experience you rarely get all four cylinders with exactly the same parameters.

The only guy i know who still races on carbs has four bosses welded into his exhaust manifold just for setting up but he doesn't run with the sensors still in for obvious reasons.

The only guy i know who still races on carbs has four bosses welded into his exhaust manifold just for setting up but he doesn't run with the sensors still in for obvious reasons.

Chris

-

Grizzly - Coveted Fifth Gear

- Posts: 1862

- Joined: 13 Jun 2010

Grizzly wrote:Wouldn't a Wideband on a weber dcoe car be next to use less? I have data loggers on both race cars and thats great being fuel injected but all it would tell you on a Weber car is the mixture is out (not which cylinder is out) i get you change the jets in sets but from past experience you rarely get all four cylinders with exactly the same parameters.

The only guy i know who still races on carbs has four bosses welded into his exhaust manifold just for setting up but he doesn't run with the sensors still in for obvious reasons.

Not useful when competing but certainly useful for setting up your carbs.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8415

- Joined: 22 Sep 2003

Sorry, I didn't explain my aims well. I want to be able to set my carbs up well. I can use the colortune and synchrometer to get balance between cylinders, so if I'm not missing anything, I should be able to use the AFR gauge to identify the correct jets to run, and also, if needed, to support any fine adjustments to float levels later on.

While I'd love to have a go, I don't quite have the time to take up racing, so the gauge has no ongoing purpose in the Elan once setup is complete, other than future diagnostic efforts.

Over the last year or so I have got into programming Arduino based microcontroller devices - off and on over the last 20 years I have been programming PICs, so with the ease of access in Arduino, I think it would be reasonably easy and inexpensive to put together a logger that can record throttle position, rpm and AFR and to write these to a SD card for review in Excel or something like that. I reckon that would give me really good information on which to understand how my carbs are operating. The two 'interesting' bits will be to pick up RPM reliably and to measure throttle position in a way that doesn't leave parts attached to the carb afterwards, or necessitate dismantling or risk changing settings after a successful setup.

I can't split the thread, but I'm happy for a moderator to do so as I agree we have a couple of topics here now. All relevant to my fun though.

Ian.

While I'd love to have a go, I don't quite have the time to take up racing, so the gauge has no ongoing purpose in the Elan once setup is complete, other than future diagnostic efforts.

Over the last year or so I have got into programming Arduino based microcontroller devices - off and on over the last 20 years I have been programming PICs, so with the ease of access in Arduino, I think it would be reasonably easy and inexpensive to put together a logger that can record throttle position, rpm and AFR and to write these to a SD card for review in Excel or something like that. I reckon that would give me really good information on which to understand how my carbs are operating. The two 'interesting' bits will be to pick up RPM reliably and to measure throttle position in a way that doesn't leave parts attached to the carb afterwards, or necessitate dismantling or risk changing settings after a successful setup.

I can't split the thread, but I'm happy for a moderator to do so as I agree we have a couple of topics here now. All relevant to my fun though.

Ian.

1968 +2 (50/1167) in French Blue on Webers

-

Ian T - First Gear

- Posts: 35

- Joined: 04 Jul 2016

rgh0 wrote:

Not useful when competing but certainly useful for setting up your carbs.

cheers

Rohan

Don't you set them up on the rollers? i've had an MTX-L fitted to my road car for quite a while and frankly i never look at it because it moves around so much when i'm driving it's hard to follow. A logger is better but even then it's designed to be used with an EMS so much of the important data is missing.

Chris

-

Grizzly - Coveted Fifth Gear

- Posts: 1862

- Joined: 13 Jun 2010

You can buy tps specifically for the dcoe. Think it just fastens to end of the throttle shaft.

I should get a bung added to my y piece while it's not too much hassle.

Wouldn't have thought it should be too hard to hook up to a mbed type system or maybe even bbc micro to log data. Even add things like map our mass air flow sensors not sure they'd be that useful for just tuning thou.

I should get a bung added to my y piece while it's not too much hassle.

Wouldn't have thought it should be too hard to hook up to a mbed type system or maybe even bbc micro to log data. Even add things like map our mass air flow sensors not sure they'd be that useful for just tuning thou.

'73 +2 130/5 RHD, now on the road and very slowly rolling though a "restoration"

- mbell

- Coveted Fifth Gear

- Posts: 2643

- Joined: 07 Jun 2013

mbell wrote:You can buy tps specifically for the dcoe. Think it just fastens to end of the throttle shaft.

I should get a bung added to my y piece while it's not too much hassle.

Wouldn't have thought it should be too hard to hook up to a mbed type system or maybe even bbc micro to log data. Even add things like map our mass air flow sensors not sure they'd be that useful for just tuning thou.

Thanks, I found the TPS parts while looking at a spares listing. Looking at the rearmost end of the rear carburettor, I think it would be (almost) trivial to add a simple variable resistor TPS to it using an arm and rod attached by a nyloc nut on the free threads on the end of the shaft.

Having erroneously bought an AFM for my daily driver (running lean and I didn't spot the g/sec unit instead of kg/h I was more familiar with before condemning it) I did consider using the now spare AFM as an electronic synchrometer before buying the STE one. I agree that without metering the fuel going in the reading of air is pretty meaningless and it would be much better to evaluate it in the exhaust.

The Arduino board I'm thinking of is about 30mm long by about 15mm wide and 6mm deep with a micro SD connected, and consumes less than 100mA at full chat. It would be practical to have the whole thing including a power supply inside a matchbox that only needs TPS, tacho and AFR measurements to be useful. I wasn't rich enough to own a BBC B, but instead had (and still have) a Sinclair Spectrum. The idea of using that would be fun, but sadly take far longer to implement and in the end be less capable.

As far as fitting a sensor goes, I'd currently favour just before the tailpipe silencer - looking at the Y piece, I can't help but feel there's not much distance after combination of the two headers to mix the gases and the sensor might predominantly read one over the other. I'm probably wrong there, but there also isn't much room that's not used up by the sleeved joints either.

I'll go with the compression test as you suggested earlier and colortune to see if it helps me to clean up no4. If at that point everything is behaving and I have a nice, tractable engine with 'OK' plug indications and a sensible CO reading on the Crypton, I may conclude it's all good. I love test equipment though!

Ian.

1968 +2 (50/1167) in French Blue on Webers

-

Ian T - First Gear

- Posts: 35

- Joined: 04 Jul 2016

BBC Micros ?

Hey guys, get with the times... Use a Raspberry Pi !

Incidentally they go well with an Arduino.

https://www.raspberrypi.org/

Hey guys, get with the times... Use a Raspberry Pi !

Incidentally they go well with an Arduino.

https://www.raspberrypi.org/

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

billwill wrote:BBC Micros ?

Hey guys, get with the times...

I am with the times, the new bbc micro bit ~13 quid with Bluetooth and good number if a to d converters. Expecting to be getting one in the near future, that I might play with.

'73 +2 130/5 RHD, now on the road and very slowly rolling though a "restoration"

- mbell

- Coveted Fifth Gear

- Posts: 2643

- Joined: 07 Jun 2013

rgh0 wrote:I think 1 to 2 m is the ideal distance for the sensor to prevent it overheating if its to close to the engine. If its to close to the exhaust pipe end then the issue is air leakage back down the pipe affecting the reading. I think at the end of the Y piece to the tail pipe or the inlet to the rear muffler should be OK.

Innovate do sell and adapter to fit down the tail pipe but warn that it is inaccurate at low rpm due to air leakage.

cheers

Rohan

I had read somewhere (Innovate site?) that the optimum distance from the head was about 80cm (30") for gas temperature reasons, so I welded one bung on each of the first Y where they could fit protected from the ground and with reasonably access. I tried both sides and for my use they appear interchangeable.

I have tried the rear muffler adapter, and if it may be convenient to help out a friend to get started, the signal is way more unstable which I found of little use for tuning (lambda values under load on the road, I would not trust the clamp to hold for very long on our bumpy roads).

Regarding the Innovate LM2 readout box, it took me a while to get the RPM input to work, probably because the nature of the electronic ignition I had fitted early during the restoration, but eventually Innovate pointed me to a solution that got me to workable results (from memory using differential input with a local ground, via the blue and black wires, and with a potentiometer to attenuate the signal to where it would just pick up, since it seems that the low overshoot of some electronic ignitions is what would confuse the readout input).

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 2000

- Joined: 02 Sep 2013

This is an interesting discussion.

When they first came out, I was intent on buying a dual channel LM-2 based upon the LM-1's reputation. A little research, especially on the Innovate forum of the time, strongly suggested users of the LM-2 had a problem acquiring a good rpm signal. So the purchase was put off and I began looking for an earlier LM-1.

Last year I found a good used LM-1 with all the cables and a Bosch O2 wide band sensor. I also found a good price on a new LMA-3, auxiliary box which plugs into the LM-1 and provides rpm, two g-sensors, MAP, and provision for a generic 0-5 VDC sensor among other possibilities.

So I installed a couple of sensor bungs just before the muffler on my 1978 308 GTS and came up to speed on the instrument's use. The sensor location on my 308 roughly corresponds to just down stream of the Y-pipe on and Elan and indeed that is likely where I will position it on my 26S project. The 308 has a bung corresponding to each cylinder bank, but until now, I've only looked at the front bank.

I am acquiring AFR, RPM, 2-axes of acceleration, and MAP at this time. I would like to get TPS, but I needed to get up to speed on the built in sensors before moving on to tps, which requires an external sensor.

For MAP, I use a standard GM sensor that I wired into, but am not currently using with my Electromotive xdi-2, programmable ignition system. I am using this same system on my 26S project, as it has proven to be bullet proof. The xdi-2 can accommodate a MAP signal for load control of ignition timing. The signal is collected from the 8-intake manifold vacuum taps I also use for synchronization purposes, with an 8-bank manometer. For a MAP signal, all hose barbs are connected together with an 8 to 4 to 2 to 1 soft plumbing manifold, so the consolidated MAP signal is very steady. Looking at the data, this should work well with the ignition system for advanced spark control under light throttle, or cruise conditions. Certainly there will be lots of data to look at.

At idle, I'm seeing 9-10 psia on the Innovate data and this corresponds well with the 26 cm Hg column I see at idle when doing a synchronization. At wide open throttle I see about 14.5 psia which makes sense as standard pressure at sea level is 14.7 psia. Lowest pressure (highest vacuum) is seen when coasting down from high rpm in gear and pressures as low as 4 psia were seen. MAP is a really good signal to have as it is a measure of engine load. High pressure, high load, low pressure low load. As such it is a reasonable substitute for tps without the added complication of an external sensor and power source. I would still like to have tps so when someone works it out for DCOE's let me know. I think Webcon Weber has a tps that will work for a reasonable cost, but right now I don't need it to make sense of the data.

The xdi-2 provides a tach output signal, a clean 0-12V square wave. For the car's tach, I use an MSD tach amplifier box to boost the signal, but the LM-1 reads this signal directly and it provides very clean data. I would think the LM-2 would also read this signal without issue, but I just don't know.

So the bottom line is the LM-1/LMA-3 system works well and will store 45-minutes of data before having to be down loaded to a laptop using a serial port and cable. The LM-2 can use USM or memory cards which is really nice and they work with modern laptops. I have an old dedicated laptop that works ok for this purpose. Once data is down loaded from the LM-1 using Innovate's LogWorks3, I export the data set as a Comma Separated Variable (CSV) file type that I can open directly with MS Excel, where I can post process and plot with a lot of flexibility.

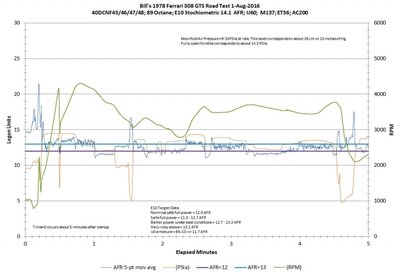

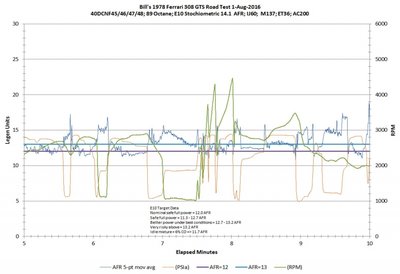

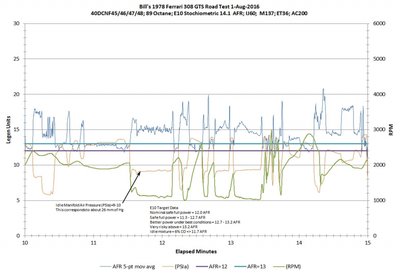

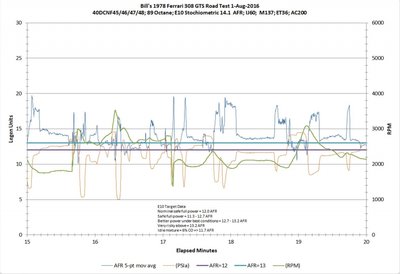

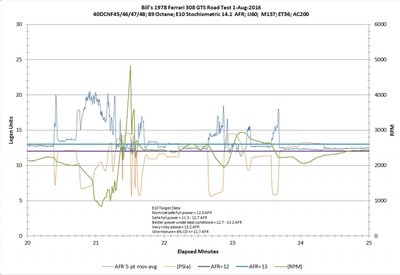

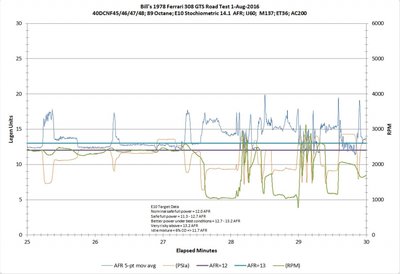

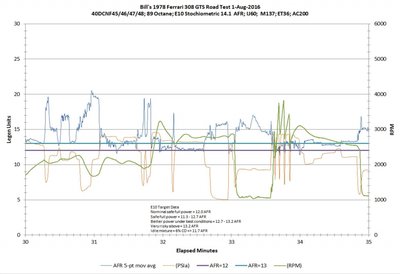

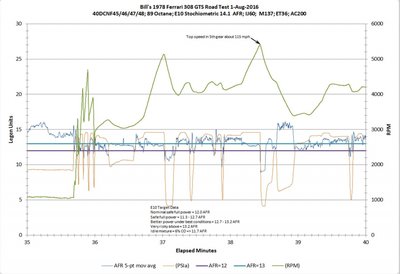

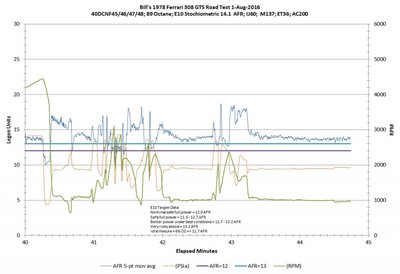

I first convert the elapsed time to minutes for plotting purposes. I find the AFR data bounces around a lot so part of my post processing is to use a 5-point moving average to smooth out this signal. This technique takes the previous 2 AFR readings, the current reading, and then the following 2 AFR readings, adds them up, then divides by 5. Each data point is treated the same way and the signal is smoothed out with no coherence (advance/retard in time domain) distortion. The sample rate is every 0.08192 seconds. AFR and MAP are plotted on the primary Y-axis and RPM is plotted on the secondary Y-axis. I find 5-minutes of data on a plot to be reasonable for analysis, so the entire run is broken down onto nine, 5-minute plots. Please see the following images.

Based upon early data, I decreased the AC from 220 to 200. The data showed high rpm was now richer without noticeably affecting anything else. Very cool, just what I expected. So, next change is to increase main jet size from 137 to 140, which is now done, but not yet tested. This should slightly richen everything up above about 3500 rpm. I will also change the idle jet size from 60 to 65 but I'm waiting on delivery of these jets. This change should richen up mixtures from 1200 to 3500 rpm.

The other thing to mention is the role fuel type plays. My 308 is only 8.8:1 CR, so I run it on 89 octane (R+M)/2 fuel. My pump gas is E10, which means it can have UP TO10% ethanol, but one really never knows for sure what it actually is. References I found indicate E10 stoichiometric AFR is 14.1 AFR, verses 14.7 for pure gasoline. My LM-1 is programmed with this value (14.1) so the AFR data reflects this refinement. Other sources suggest AFR target ranges as shown on the plot text boxes. Bottom line is E10 requires richer tuning. Let me know if anyone is able to come up with better fuel information.

Bill

When they first came out, I was intent on buying a dual channel LM-2 based upon the LM-1's reputation. A little research, especially on the Innovate forum of the time, strongly suggested users of the LM-2 had a problem acquiring a good rpm signal. So the purchase was put off and I began looking for an earlier LM-1.

Last year I found a good used LM-1 with all the cables and a Bosch O2 wide band sensor. I also found a good price on a new LMA-3, auxiliary box which plugs into the LM-1 and provides rpm, two g-sensors, MAP, and provision for a generic 0-5 VDC sensor among other possibilities.

So I installed a couple of sensor bungs just before the muffler on my 1978 308 GTS and came up to speed on the instrument's use. The sensor location on my 308 roughly corresponds to just down stream of the Y-pipe on and Elan and indeed that is likely where I will position it on my 26S project. The 308 has a bung corresponding to each cylinder bank, but until now, I've only looked at the front bank.

I am acquiring AFR, RPM, 2-axes of acceleration, and MAP at this time. I would like to get TPS, but I needed to get up to speed on the built in sensors before moving on to tps, which requires an external sensor.

For MAP, I use a standard GM sensor that I wired into, but am not currently using with my Electromotive xdi-2, programmable ignition system. I am using this same system on my 26S project, as it has proven to be bullet proof. The xdi-2 can accommodate a MAP signal for load control of ignition timing. The signal is collected from the 8-intake manifold vacuum taps I also use for synchronization purposes, with an 8-bank manometer. For a MAP signal, all hose barbs are connected together with an 8 to 4 to 2 to 1 soft plumbing manifold, so the consolidated MAP signal is very steady. Looking at the data, this should work well with the ignition system for advanced spark control under light throttle, or cruise conditions. Certainly there will be lots of data to look at.

At idle, I'm seeing 9-10 psia on the Innovate data and this corresponds well with the 26 cm Hg column I see at idle when doing a synchronization. At wide open throttle I see about 14.5 psia which makes sense as standard pressure at sea level is 14.7 psia. Lowest pressure (highest vacuum) is seen when coasting down from high rpm in gear and pressures as low as 4 psia were seen. MAP is a really good signal to have as it is a measure of engine load. High pressure, high load, low pressure low load. As such it is a reasonable substitute for tps without the added complication of an external sensor and power source. I would still like to have tps so when someone works it out for DCOE's let me know. I think Webcon Weber has a tps that will work for a reasonable cost, but right now I don't need it to make sense of the data.

The xdi-2 provides a tach output signal, a clean 0-12V square wave. For the car's tach, I use an MSD tach amplifier box to boost the signal, but the LM-1 reads this signal directly and it provides very clean data. I would think the LM-2 would also read this signal without issue, but I just don't know.

So the bottom line is the LM-1/LMA-3 system works well and will store 45-minutes of data before having to be down loaded to a laptop using a serial port and cable. The LM-2 can use USM or memory cards which is really nice and they work with modern laptops. I have an old dedicated laptop that works ok for this purpose. Once data is down loaded from the LM-1 using Innovate's LogWorks3, I export the data set as a Comma Separated Variable (CSV) file type that I can open directly with MS Excel, where I can post process and plot with a lot of flexibility.

I first convert the elapsed time to minutes for plotting purposes. I find the AFR data bounces around a lot so part of my post processing is to use a 5-point moving average to smooth out this signal. This technique takes the previous 2 AFR readings, the current reading, and then the following 2 AFR readings, adds them up, then divides by 5. Each data point is treated the same way and the signal is smoothed out with no coherence (advance/retard in time domain) distortion. The sample rate is every 0.08192 seconds. AFR and MAP are plotted on the primary Y-axis and RPM is plotted on the secondary Y-axis. I find 5-minutes of data on a plot to be reasonable for analysis, so the entire run is broken down onto nine, 5-minute plots. Please see the following images.

Based upon early data, I decreased the AC from 220 to 200. The data showed high rpm was now richer without noticeably affecting anything else. Very cool, just what I expected. So, next change is to increase main jet size from 137 to 140, which is now done, but not yet tested. This should slightly richen everything up above about 3500 rpm. I will also change the idle jet size from 60 to 65 but I'm waiting on delivery of these jets. This change should richen up mixtures from 1200 to 3500 rpm.

The other thing to mention is the role fuel type plays. My 308 is only 8.8:1 CR, so I run it on 89 octane (R+M)/2 fuel. My pump gas is E10, which means it can have UP TO10% ethanol, but one really never knows for sure what it actually is. References I found indicate E10 stoichiometric AFR is 14.1 AFR, verses 14.7 for pure gasoline. My LM-1 is programmed with this value (14.1) so the AFR data reflects this refinement. Other sources suggest AFR target ranges as shown on the plot text boxes. Bottom line is E10 requires richer tuning. Let me know if anyone is able to come up with better fuel information.

Bill

- bill308

- Fourth Gear

- Posts: 736

- Joined: 27 May 2004

Bill

Could you repeat that?

Could you repeat that?

67 Elan Super Safety

67 Elan +2

67 Elan +2

- seniorchristo

- Fourth Gear

- Posts: 590

- Joined: 19 Dec 2013

Bill

I know you have a 308 but is it really " very risky " above 13.8 ?, I often see 16.7 at cruising..

John

I know you have a 308 but is it really " very risky " above 13.8 ?, I often see 16.7 at cruising..

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

69 posts

• Page 3 of 5 • 1, 2, 3, 4, 5

Total Online:

Users browsing this forum: No registered users and 22 guests