Dellorto Tick Over system.

27 posts

• Page 2 of 2 • 1, 2

I also had this or a similar problem with my Webers when I returned my +2 to the road after a period of storage. I had them ultrasonically cleaned three times by three different places, I poked & prodded, blew them through, soaked them in all sorts of solvents & would have sworn they were completely clear. I almost went down the fuel injection route, but with funds a bit tight, decided instead to invest in a new set of 151's. Completely transformed the car. Sweet tick over, no flat spots, great performance & best of all, fundamentally improved fuel economy, massively better than it had ever been, & I'd never considered it that bad.

It shouldn't be too difficult to re-set the throttle spindles, just a gentle twist & a bit of trial & error. The proverbial 'fag paper' makes a good feeler gauge for this, if you can just pull a piece of thin paper from between the butterfly & the body with similar resistance but without it tearing, you pretty close.

Regards, Tim

It shouldn't be too difficult to re-set the throttle spindles, just a gentle twist & a bit of trial & error. The proverbial 'fag paper' makes a good feeler gauge for this, if you can just pull a piece of thin paper from between the butterfly & the body with similar resistance but without it tearing, you pretty close.

Regards, Tim

- Orsom Weels

- Third Gear

- Posts: 409

- Joined: 31 Oct 2011

Orsom Weels wrote:It shouldn't be too difficult to re-set the throttle spindles, just a gentle twist & a bit of trial & error. The proverbial 'fag paper' makes a good feeler gauge for this, if you can just pull a piece of thin paper from between the butterfly & the body with similar resistance but without it tearing, you pretty close.

Regards, Tim

I've given a small tweak but the spindle is tougher than I thought. I cannot see how using spanners on the nuts would work as one would simply undo. It is nearly there! 1/2 a progression hole difference.

ncm wrote:Hi, have you considered swopping the idle jets over between cylinders 1 and 2 to see if the problem remains on 1 or moves to 2?

Brian.

The problem seems to be lack of air flow. No1 butterfly is effectively shut and has not moved enough to expose the 1st progression hole. That's the theory anyway.

- vincereynard

- Coveted Fifth Gear

- Posts: 1071

- Joined: 12 Jan 2015

Notion of twisting the spindle I believe came about in the early days of Weber?s, these had a brass type material for the spindle. It was quite possible, in normal use, for this type to become slightly twisted being a fairly malleable material. Later carbs were fitted with steel spindles easily identified by a blue/back colour and are much more robust, not suffering the in use distortion of the former brass type.

- Craven

- Coveted Fifth Gear

- Posts: 1624

- Joined: 14 Sep 2013

Vince, I had a look at the carb book but couldn't find any method to balance butterflies in the same carb body. So I tried a Google search and found this that you might like to try before twisting the spindle:

If you had a synchronometer (air flow meter, hand held) you'd be able to measure each intake individually. They are not expensive to buy..

- unscrew the two butterfly screws half a turn then snap shut the throttle several times to see if that would settle it down - Ref: https://www.tr-register.co.uk/forums/in ... djustment/

If you had a synchronometer (air flow meter, hand held) you'd be able to measure each intake individually. They are not expensive to buy..

-

JonB - Coveted Fifth Gear

- Posts: 2358

- Joined: 14 Nov 2017

Craven wrote: Later carbs were fitted with steel spindles easily identified by a blue/back colour and are much more robust, not suffering the in use distortion of the former brass type.

That would explain it. Thanks. It would have taken more force than I was prepared to attempt!

JonB wrote:There is a caveat - a chance the butterfly could be damaged, but if you're careful it may work. I guess the order of the day would be not to undo the screws too much so the butterfly flaps about. Also, check the butterfly in question is not bent already, maybe that's the root cause?

If you had a synchronometer (air flow meter, hand held) you'd be able to measure each intake individually. They are not expensive to buy..

The problem with that is that the screws are pretty firmly fixed, the ends being crimped in place. Any attempt to loosen would probably ruin the screws and / or the thread in the spindle.

As it happens I have got it close to within a fraction of the progression hole. No2 still opens "slightly" first but it is very small. (Third of a mm?) AND NOW No1 and No2 are pulling equally and suffer virtually the same revs drop.

Hurrah! So to celebrate No3's dropped off a bit!

I have a CarTune syncromiser but if 1/2 are fixed and 3/4 are fixed it does not seem much point checking all 4.

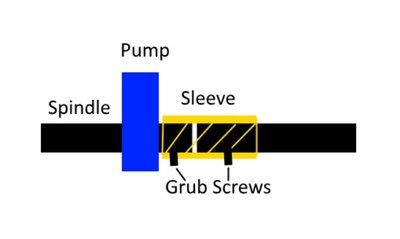

I do have a plan. Cut the spindle in half and join with a close fitting tube complete with locking grub screws. The each could be set individually and no nasty bending required.

Only risk is a ruined spindle.

- vincereynard

- Coveted Fifth Gear

- Posts: 1071

- Joined: 12 Jan 2015

That's pretty radical!

"The book" makes a point about how expensive the spindles are (in the context of removing them, vs. the nuts). It's right too, they cost ?35.95 plus VAT:

http://www.dellorto.co.uk/shop/dellorto ... t-dhla-48/

I'm also wondering whether a grub screw will have enough grip to hold the shaft. And is there space inside the carb body to hold the outer sleeve and grub screws. Plus, will you be able to access it in situ for adjustment?

If you do go to the effort of removing the spindle (to cut it), you have to remove the butterflies anyway. If you then twist it with one side locked in a vice, you might get more precision. However there's a risk of buckling the spindle so that the butterfly will never sit right in the throttle opening.

I assume that there is no play in the spindle bearings and they are clean and moving freely.

"The book" makes a point about how expensive the spindles are (in the context of removing them, vs. the nuts). It's right too, they cost ?35.95 plus VAT:

http://www.dellorto.co.uk/shop/dellorto ... t-dhla-48/

I'm also wondering whether a grub screw will have enough grip to hold the shaft. And is there space inside the carb body to hold the outer sleeve and grub screws. Plus, will you be able to access it in situ for adjustment?

If you do go to the effort of removing the spindle (to cut it), you have to remove the butterflies anyway. If you then twist it with one side locked in a vice, you might get more precision. However there's a risk of buckling the spindle so that the butterfly will never sit right in the throttle opening.

I assume that there is no play in the spindle bearings and they are clean and moving freely.

-

JonB - Coveted Fifth Gear

- Posts: 2358

- Joined: 14 Nov 2017

There?s good reason for crimping or staking the butterfly screws, the area is subject to high frequency/ ultrasonic vibration so any mods need to take this sort of thing into consideration as well.

From someone that has his fair share of changing carb shafts I would leave well along unless it?s really is unavoidable.

From someone that has his fair share of changing carb shafts I would leave well along unless it?s really is unavoidable.

- Craven

- Coveted Fifth Gear

- Posts: 1624

- Joined: 14 Sep 2013

Vince

Bin there , done it , have the T-shirt , for the small amount of "set" required I used two pairs of long-nose locking pliers , one on each butterfly....

John

Bin there , done it , have the T-shirt , for the small amount of "set" required I used two pairs of long-nose locking pliers , one on each butterfly....

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

Craven wrote:There?s good reason for crimping or staking the butterfly screws, the area is subject to high frequency/ ultrasonic vibration so any mods need to take this sort of thing into consideration as well.

From someone that has his fair share of changing carb shafts I would leave well along unless it?s really is unavoidable.

I wasn't intending to do it. It was just a thought about a possible solution. One danger being if the grub screws went AWOL would the effected cylinder suddenly go full bore? That could be awkward.

john.p.clegg wrote:Vince

Bin there , done it , have the T-shirt , for the small amount of "set" required I used two pairs of long-nose locking pliers , one on each butterfly....

John

Spot on! That's what I ended up using. With strips of hard plastic between the jaws for protection.

William2 wrote:Hi Vince, have you considered getting in touch with the guys at Dellorto UK in Reading and sending the carb to them for fitment of a new spindle and setting up. I think that is the avenue I would go down. Regards, Will

They are so close now I don't need to tweak any more. They were, allegedly, rebuilt by the dreaded P.O!

If I was to spend any more on them I suspect I would buy new, complete with the air bypass.

- vincereynard

- Coveted Fifth Gear

- Posts: 1071

- Joined: 12 Jan 2015

Postscript to put this thread away.

Toad now runs far better. A bit spluttery to begin with as it is after a lengthy fiddle.

Starts on the button and much more lively in the initial rev range. Hardly surprising as it was effectively a 1200 cc Twink before!

Thanks for all the help.

Toad now runs far better. A bit spluttery to begin with as it is after a lengthy fiddle.

Starts on the button and much more lively in the initial rev range. Hardly surprising as it was effectively a 1200 cc Twink before!

Thanks for all the help.

- vincereynard

- Coveted Fifth Gear

- Posts: 1071

- Joined: 12 Jan 2015

27 posts

• Page 2 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 32 guests