Carbs meant to be mounted 'loose'?

19 posts

• Page 1 of 2 • 1, 2

A classic car enthusiast was pouring over my Plus 2 recently and he pointed out that the carbs were fitted too tightly. He said that there's a Thackwray washer in place so that the carbs can be mounted in such a way as to allow a little 'give'. If you push on my carbs, it moves the whole engine block (ie, there's no give).

What's the correct fixing please?

What's the correct fixing please?

- Steve S2

- First Gear

- Posts: 33

- Joined: 14 Jul 2011

Hi SteveS2,

Nuts on carbs should only be tightened to give a 1mm gap in between the coils of the thackray washers,as stated in workshop manual, so as to allow the carbs to float rather than being rigid, but not all engines that use Webers & Dellorto's mount them in that way.

Regards

John

Nuts on carbs should only be tightened to give a 1mm gap in between the coils of the thackray washers,as stated in workshop manual, so as to allow the carbs to float rather than being rigid, but not all engines that use Webers & Dellorto's mount them in that way.

Regards

John

- Kerryt333

- Second Gear

- Posts: 69

- Joined: 30 Nov 2009

Kerryt333 beat me to it

There should be a little movement, but not so much that there's an air leak.

You'll notice if there's an air leak if, when idling you pust up in the carbs the car's idle speed changes noticably.

The 1mm gap in the thack's is a good guide for correct tightness.

If the carbs are tightened fast against the mainfold you run the risk of cracking the manifold.

Take care,

Peter

There should be a little movement, but not so much that there's an air leak.

You'll notice if there's an air leak if, when idling you pust up in the carbs the car's idle speed changes noticably.

The 1mm gap in the thack's is a good guide for correct tightness.

If the carbs are tightened fast against the mainfold you run the risk of cracking the manifold.

Take care,

Peter

I is an Inginear....please excuse my speeling!

'73 +2S 130/5

Scimitar GTE for the lazy days, 3008, Some bicycles, Wife, Kids, Cats, Dogs....chickens....cluck cluck...one duck...the others flew away!

'73 +2S 130/5

Scimitar GTE for the lazy days, 3008, Some bicycles, Wife, Kids, Cats, Dogs....chickens....cluck cluck...one duck...the others flew away!

-

peterako - Fourth Gear

- Posts: 681

- Joined: 02 Mar 2006

peterako wrote:

If the carbs are tightened fast against the mainfold you run the risk of cracking the manifold.

Take care,

Peter

Yes I've seen it happen

John

No longer active on here, I value my privacy.

No longer active on here, I value my privacy.

-

nebogipfel - Coveted Fifth Gear

- Posts: 1275

- Joined: 25 Sep 2003

Note that for the carbs to be mounted "loose" there should be a "soft mount" between the carb body and the inlet manifold. Typically this mount is in the form of an aluminum or nylon spacer about 6mm thick with a fat O-ring on each side. If there is no such "soft mount" then loosening up the mounting nuts will simply result in an air leak.

Steve

Elan S1 1963-Bourne bodied

Elan S3 1967 FHC pre airflow

Formerly:

Elan S1 1964

Elan S3 1966 FHC pre airflow

Elan S3 1967 FHC airflow

Elan S4 1969 FHC

Europa S2 1970

Esprit S2 1979

Elan S1 1963-Bourne bodied

Elan S3 1967 FHC pre airflow

Formerly:

Elan S1 1964

Elan S3 1966 FHC pre airflow

Elan S3 1967 FHC airflow

Elan S4 1969 FHC

Europa S2 1970

Esprit S2 1979

- bitsobrits

- Third Gear

- Posts: 418

- Joined: 27 Apr 2011

peterako wrote:Kerryt333 beat me to it

There should be a little movement, but not so much that there's an air leak.

You'll notice if there's an air leak if, when idling you pust up in the carbs the car's idle speed changes noticably.

The 1mm gap in the thack's is a good guide for correct tightness.

If the carbs are tightened fast against the mainfold you run the risk of cracking the manifold.

Take care,

Peter

While the risk of cracking may an issue for a Lotus, compliant mountings are used in many Weber applications. This was apparently to stop engine vibrations being transferred to the carbs causing the fuel to froth in the float chambers. Frothing upset the effective fuel level, changing the metering and causing the engine to run rough.

68 Elan S3 HSCC Roadsports spec

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

- Andy8421

- Coveted Fifth Gear

- Posts: 1223

- Joined: 27 Mar 2011

Steve...I think that you need a workshop manual, and Brian Bucklands superb book.

Mark

Mark

-

Elanintheforest - Coveted Fifth Gear

- Posts: 2496

- Joined: 04 Oct 2005

The "Soft Mount" is the sandwich plate that is installed between the carb's mounting flange and the manifold. It?s a necessary part and should always be used. Dellortos/ Webers/ Solex/ Mikuni carbs have the same flange geometry and share a common soft mount style. SU and Zenith Strombergs each have their own variations on the soft mount.

There are several styles of Dellorto/ Weber soft mount. Lotus' unique mount was die-cast metal and had a tapered, funnel-shaped bore which extended slightly to one side, forming a lip. The mount is to be installed with the funnel pointing toward the engine (large diameter toward carb / small diameter toward engine). There are some strange, complicated flow dynamics inside an intake manifold, including reverse flow. The lip is a dam meant to inhibit a reversion wave from reaching the carb and messing with the calibration. The funnel & lip may look restrictive to the eye, but the net result is really an improvement in flow and mixture control. It was a Lotus innovation.

*~*~*

Many similar aftermarket soft mounts are the same in overall shape and thickness, but molded in plastic and without the funnel bore & lip reversion dam... they have a simple straight bore and can be installed facing either way.

Both of above styles have circular grooves cut concentric with, and outside of the center bore, which accept large O-rings. The O-rings both seal the joint, and provide a flexible mount to keep engine vibrations from reaching the carbs.

The width of the gap on either side of the soft mount will vary by brand, and more specifically with the thickness of the O-ring used. If the vintage Lotus OEM metal soft mount is used, the gaps should be .040" (1 mm), +/? ? more specifically, 0.35 - 0.50 inch (0.89 ? 1.27 mm). But various plastic soft mounts on the market each use different thickness O-rings and gaps, so read the instructions. Even the later Lotus OEM soft mount used in the carbureted Turbo 910 engine used much thicker O-rings that required a 0.080" (2 mm) gap. Use good judgment. If it appears you are crushing the crap out of the O-rings? then don't. You'll just ruin them, or they will squirt out of the joint, and cause air leaks and poor running.

The Nyloc mounting nuts are to be tightened until the gaps on either side of the soft mount are to spec. If Thackeray washers (springs) are used, also limit nut adjustment to maintain a minimum gap between the spring coils of 0.030".

*~*~*

A newer type of soft mount consists of a thin, stamped metal plate with an integrally molded rubber "O-ring" around the center bore. It's a one piece part instead of the O-ring / plate / O-ring assembly. It's easier to handle, but thinner than the standard sandwich plate. Using one effectively shortens the inlet's overall length, changing the "tuned" effect. It's a small difference, but a difference none the less if you're fussy about such things.

Instructions for those soft mounts don't specify a gap for either side, they just say to tighten the nuts...

1) Thackeray washer: until there's a 0.35 - 0.50 inch (0.89 ? 1.27 mm) gap between the coils, or...

2) Rubber Grommet: until all slack is taken up between the nut, cup washer and rubber grommet (ie, the stack just goes solid), then tighten the nut another 1 1/2 turns, ensuring that the "V" in all grommets is equal. Since the M8 nuts have a 1.25 pitch thread, 1 1/2 turns is equivalent to 1.88mm (0.074") of crush/ pre-load... or roughtly 2 mm (0.08")

*~*~*

On all of the above styles, the O-rings both seal the joint, and provide a flexible mount to keep engine vibrations from reaching the carbs. The carbs are not so much rigidly mounted to the engine as free-floating alongside of it. That provides a harmonic barrier that prevents engine vibrations from reaching the carburetor causing the fuel to froth, and complicating mixture control.

Never install the carbs without the soft mounts. Regardless of the type of soft mount used, NEVER tighten the nuts until the joint is solid. To do so would crush the O-ring and extrude it out of the joint in places, creating air leaks and killing the intended vibration damping quality.

*~*~*

Thackeray washers experience metal fatigue due to the vibrations, and break. The upper ones are more prone to failure, while the lower ones have little load on them and last forever.

The rubber grommets are fuel resistant, but not fuel proof; so fuel leakage will eventually attack them. Since stuff runs down hill, the lower grommets tend to fail first, while the upper ones see little fuel and last forever.

The best compromise solution is to use Thackeray washers on the bottom and grommets on the top for optimum soft mount life.

Regards,

Tim Engel

Lotus Owners Oftha North (LOON)

There are several styles of Dellorto/ Weber soft mount. Lotus' unique mount was die-cast metal and had a tapered, funnel-shaped bore which extended slightly to one side, forming a lip. The mount is to be installed with the funnel pointing toward the engine (large diameter toward carb / small diameter toward engine). There are some strange, complicated flow dynamics inside an intake manifold, including reverse flow. The lip is a dam meant to inhibit a reversion wave from reaching the carb and messing with the calibration. The funnel & lip may look restrictive to the eye, but the net result is really an improvement in flow and mixture control. It was a Lotus innovation.

*~*~*

Many similar aftermarket soft mounts are the same in overall shape and thickness, but molded in plastic and without the funnel bore & lip reversion dam... they have a simple straight bore and can be installed facing either way.

Both of above styles have circular grooves cut concentric with, and outside of the center bore, which accept large O-rings. The O-rings both seal the joint, and provide a flexible mount to keep engine vibrations from reaching the carbs.

The width of the gap on either side of the soft mount will vary by brand, and more specifically with the thickness of the O-ring used. If the vintage Lotus OEM metal soft mount is used, the gaps should be .040" (1 mm), +/? ? more specifically, 0.35 - 0.50 inch (0.89 ? 1.27 mm). But various plastic soft mounts on the market each use different thickness O-rings and gaps, so read the instructions. Even the later Lotus OEM soft mount used in the carbureted Turbo 910 engine used much thicker O-rings that required a 0.080" (2 mm) gap. Use good judgment. If it appears you are crushing the crap out of the O-rings? then don't. You'll just ruin them, or they will squirt out of the joint, and cause air leaks and poor running.

The Nyloc mounting nuts are to be tightened until the gaps on either side of the soft mount are to spec. If Thackeray washers (springs) are used, also limit nut adjustment to maintain a minimum gap between the spring coils of 0.030".

*~*~*

A newer type of soft mount consists of a thin, stamped metal plate with an integrally molded rubber "O-ring" around the center bore. It's a one piece part instead of the O-ring / plate / O-ring assembly. It's easier to handle, but thinner than the standard sandwich plate. Using one effectively shortens the inlet's overall length, changing the "tuned" effect. It's a small difference, but a difference none the less if you're fussy about such things.

Instructions for those soft mounts don't specify a gap for either side, they just say to tighten the nuts...

1) Thackeray washer: until there's a 0.35 - 0.50 inch (0.89 ? 1.27 mm) gap between the coils, or...

2) Rubber Grommet: until all slack is taken up between the nut, cup washer and rubber grommet (ie, the stack just goes solid), then tighten the nut another 1 1/2 turns, ensuring that the "V" in all grommets is equal. Since the M8 nuts have a 1.25 pitch thread, 1 1/2 turns is equivalent to 1.88mm (0.074") of crush/ pre-load... or roughtly 2 mm (0.08")

*~*~*

On all of the above styles, the O-rings both seal the joint, and provide a flexible mount to keep engine vibrations from reaching the carbs. The carbs are not so much rigidly mounted to the engine as free-floating alongside of it. That provides a harmonic barrier that prevents engine vibrations from reaching the carburetor causing the fuel to froth, and complicating mixture control.

Never install the carbs without the soft mounts. Regardless of the type of soft mount used, NEVER tighten the nuts until the joint is solid. To do so would crush the O-ring and extrude it out of the joint in places, creating air leaks and killing the intended vibration damping quality.

*~*~*

Thackeray washers experience metal fatigue due to the vibrations, and break. The upper ones are more prone to failure, while the lower ones have little load on them and last forever.

The rubber grommets are fuel resistant, but not fuel proof; so fuel leakage will eventually attack them. Since stuff runs down hill, the lower grommets tend to fail first, while the upper ones see little fuel and last forever.

The best compromise solution is to use Thackeray washers on the bottom and grommets on the top for optimum soft mount life.

Regards,

Tim Engel

Lotus Owners Oftha North (LOON)

- Esprit2

- Third Gear

- Posts: 355

- Joined: 02 Apr 2008

Tim wrote, "Lotus' unique mount was die-cast metal and had a tapered, funnel-shaped bore which extended slightly to one side, forming a lip."

Well that's News to me after 37 years of driving Loti. I thought they are just a spacer to carry "O" rings and can be fitted either way.

They say your never too old to learn

Alan B

Well that's News to me after 37 years of driving Loti. I thought they are just a spacer to carry "O" rings and can be fitted either way.

They say your never too old to learn

Alan B

Alan.b Brittany 1972 elan sprint fhc Lagoon Blue 0460E

- alan.barker

- Coveted Fifth Gear

- Posts: 3754

- Joined: 06 Dec 2008

Any chance of a pic of one of those Tim? got to admit I have never seen that as the ones I have always seen seem to be just straight through.

I have seen spacers that tapered but they were for fitting 45 DCOE?s to a 40 DCOE manifold as in standard Twin Cam Elan/Europa engines.

Just had a look at some spare spacers I have and they look straight but I don't know where I acquired them so could be aftermarket supplied.

Mybe I have been fitting them the wrong way round so would like to see how much taper they have

I have seen spacers that tapered but they were for fitting 45 DCOE?s to a 40 DCOE manifold as in standard Twin Cam Elan/Europa engines.

Just had a look at some spare spacers I have and they look straight but I don't know where I acquired them so could be aftermarket supplied.

Mybe I have been fitting them the wrong way round so would like to see how much taper they have

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3407

- Joined: 11 Sep 2003

I'll have to scrounge around through some boxes, but I don't think I have any loose spares... certainly not a set. My own engine has plastic spacers for the lack of a full set of metal ones.types26/36 wrote:Any chance of a pic of one of those Tim? got to admit I have never seen that as the ones I have always seen seem to be just straight through.

Regards,

Tim Engel

- Esprit2

- Third Gear

- Posts: 355

- Joined: 02 Apr 2008

ok ---I quit using thackery washers a long time a go ---I now use 2 split or lock washers on each nut ---they dont back off with vibration and are reusable many times -cheaper and easier to find in any hardware store --  -ed

-ed

dont close your eyes --you will miss the crash

Editor: On June 12, 2020, Edward Law, AKA TwinCamMan, passed away; his obituary can be read at https://www.friscolanti.com/obituary/edward-law. He will be missed.

Editor: On June 12, 2020, Edward Law, AKA TwinCamMan, passed away; his obituary can be read at https://www.friscolanti.com/obituary/edward-law. He will be missed.

-

twincamman - Coveted Fifth Gear

- Posts: 2463

- Joined: 02 Oct 2003

But split washers, even two stacked, are much more stiff than a Thackeray washer, and they don't provide the degree of compliance needed to let the soft mount do it's job. The Thackeray washers (or the rubber grommet alternatives) are important to the overall carb mount.twincamman wrote:ok ---I quit using thackery washers a long time a go ---I now use 2 split or lock washers on each nut ---they dont back off with vibration and are reusable many times -cheaper and easier to find in any hardware store ---ed

Regards,

Tim Engel

- Esprit2

- Third Gear

- Posts: 355

- Joined: 02 Apr 2008

what ever !!!!--think about it !!!! --YOU DONT CRANK THEM UP TIGHT  --GEEEEZ you think like a Chevy guy -ed

--GEEEEZ you think like a Chevy guy -ed

dont close your eyes --you will miss the crash

Editor: On June 12, 2020, Edward Law, AKA TwinCamMan, passed away; his obituary can be read at https://www.friscolanti.com/obituary/edward-law. He will be missed.

Editor: On June 12, 2020, Edward Law, AKA TwinCamMan, passed away; his obituary can be read at https://www.friscolanti.com/obituary/edward-law. He will be missed.

-

twincamman - Coveted Fifth Gear

- Posts: 2463

- Joined: 02 Oct 2003

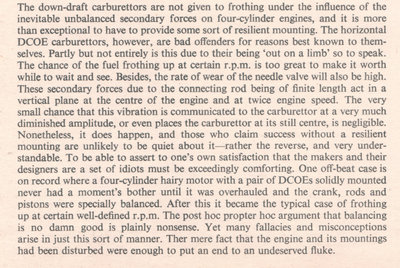

Steve S2 wrote:A classic car enthusiast was pouring over my Plus 2 recently and he pointed out that the carbs were fitted too tightly. He said that there's a Thackwray washer in place so that the carbs can be mounted in such a way as to allow a little 'give'. If you push on my carbs, it moves the whole engine block (ie, there's no give).

What's the correct fixing please?

A snippet from Mr.Passini on why...

Cheers - Richard

- ardee_selby

- Coveted Fifth Gear

- Posts: 1090

- Joined: 30 Sep 2003

19 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 13 guests