stromberg head conversion

21 posts

• Page 1 of 2 • 1, 2

have now carried out stromberg head conversion, to fit webbers or delortos, , if any one is interested in this service , the head has been converted and has a removeable inlet manifold , the head i am doing for my own car is at the stage of fitting hardened valve seats , with 42mm inlet valves and 38mm exhaust , , , using serria cosworth valve guides, ,iam more than happy just doing the basic conversion, should anyone want it price would start at ?400 +manifold at ?150. , also do a adapter manifold for a single 45 webber conversion with excellent results at knockhill , cheers

800bhp escort cosworth, 1000bhp nissan skyline , rs200, ,rs 500 ,lotus europa twin cam ,lotus elan s4 rolling road , ecu remaps, powder coating ,like making things that work, do all my own engine work ,worked for cosworth,lotus , porsche, aston martin

- del@ace

- First Gear

- Posts: 24

- Joined: 09 Jun 2008

Hi Del

This may or may not be a repeat of your last post on the single weber. You may want to get some photos posted soon as that is what folks are going to want to see.

Gary

p.s. - take a look at

http://www.omnitech-engineering.com/auto/strom.asp

short article from Lotus Limited newsletter

http://www.omnitech-engineering.com/ima ... rque_2.pdf

This may or may not be a repeat of your last post on the single weber. You may want to get some photos posted soon as that is what folks are going to want to see.

Gary

p.s. - take a look at

http://www.omnitech-engineering.com/auto/strom.asp

short article from Lotus Limited newsletter

http://www.omnitech-engineering.com/ima ... rque_2.pdf

-

garyeanderson - Coveted Fifth Gear

- Posts: 2634

- Joined: 12 Sep 2003

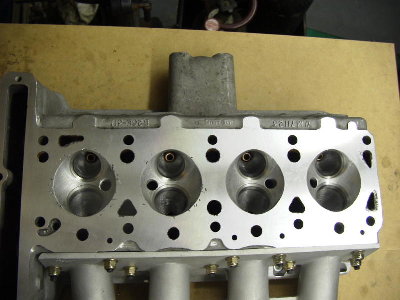

here is some pics conversion with removable manifold can be removed complete with carbs attached

800bhp escort cosworth, 1000bhp nissan skyline , rs200, ,rs 500 ,lotus europa twin cam ,lotus elan s4 rolling road , ecu remaps, powder coating ,like making things that work, do all my own engine work ,worked for cosworth,lotus , porsche, aston martin

- del@ace

- First Gear

- Posts: 24

- Joined: 09 Jun 2008

I agree with Steve, from your photo's the work looks great.

What do you use for a gasket between the manifold & cylinder head?

Cheers

John

What do you use for a gasket between the manifold & cylinder head?

Cheers

John

Beware of the Illuminati

Editor: On Sunday morning, February 8th 2015, Derek "John" Pelly AKA GrumpyBodger passed away genuinely peacefully at Weston Hospicecare, Weston Super Mare. He will be missed.

Editor: On Sunday morning, February 8th 2015, Derek "John" Pelly AKA GrumpyBodger passed away genuinely peacefully at Weston Hospicecare, Weston Super Mare. He will be missed.

-

GrUmPyBoDgEr - Coveted Fifth Gear

- Posts: 2346

- Joined: 29 Oct 2004

no problem with the gasket , could use paper or in the middle of getting cometic to make as needed, this is why i have posted this conversion , i know omnitec do a conversion i have changed it only thought it could be improved on , i think what they do is excellent , , any way just trying to workout or gauge interest, turnaround would start at around a week for the basic machinig and fitting adapter plate , then porting would take longer also do a longer inlet manifold for more torque which means carbs are further away from head or the short manifold for high revs, i will be trying both manifold on the rolling road to do a back to back test but i am a few weeks away from that at the moment, but if there is a bit of interest i will press on , thanks for looking

800bhp escort cosworth, 1000bhp nissan skyline , rs200, ,rs 500 ,lotus europa twin cam ,lotus elan s4 rolling road , ecu remaps, powder coating ,like making things that work, do all my own engine work ,worked for cosworth,lotus , porsche, aston martin

- del@ace

- First Gear

- Posts: 24

- Joined: 09 Jun 2008

no problem with the gasket , could use paper or in the middle of getting cometic to make as needed, this is why i have posted this conversion , i know omnitec do a conversion i have changed it only thought it could be improved on , i think what they do is excellent , , any way just trying to workout or gauge interest, turnaround would start at around a week for the basic machinig and fitting adapter plate , then porting would take longer also do a longer inlet manifold for more torque which means carbs are further away from head or the short manifold for high revs, i will be trying both manifold on the rolling road to do a back to back test but i am a few weeks away from that at the moment, but if there is a bit of interest i will press on , thanks for looking

800bhp escort cosworth, 1000bhp nissan skyline , rs200, ,rs 500 ,lotus europa twin cam ,lotus elan s4 rolling road , ecu remaps, powder coating ,like making things that work, do all my own engine work ,worked for cosworth,lotus , porsche, aston martin

- del@ace

- First Gear

- Posts: 24

- Joined: 09 Jun 2008

Hi Del

From the photos it looks like you weld a mounting plate onto the side of the head after machining off the Stromberg inlets. I presume you do this to get sufficient metal in the areas where you have located the manifold mounting studs. Have you had to line bore the cam tunnels and face the head after this welding?

cheers

Rohan

From the photos it looks like you weld a mounting plate onto the side of the head after machining off the Stromberg inlets. I presume you do this to get sufficient metal in the areas where you have located the manifold mounting studs. Have you had to line bore the cam tunnels and face the head after this welding?

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8409

- Joined: 22 Sep 2003

hi no problem with cam tunnels no need to line bore , yes the head will need refaced but havent shown that because im in the middle of doing valve seat inserts, will put pics up when i feel im happy with it , cheers del

800bhp escort cosworth, 1000bhp nissan skyline , rs200, ,rs 500 ,lotus europa twin cam ,lotus elan s4 rolling road , ecu remaps, powder coating ,like making things that work, do all my own engine work ,worked for cosworth,lotus , porsche, aston martin

- del@ace

- First Gear

- Posts: 24

- Joined: 09 Jun 2008

I sent off the link to the topic at hand to John McCoy who has been doing these conversion for a number of years.

http://www.omnitech-engineering.com/auto/strom.asp

I first heard of the project from my Friend Kenny Duclos back in 1996 or so, he had a prototype for fitting and testing I believe. I didn't meet John until last year when I was attending the Monterey Hiistorics in August. John was there Tending to Rawlson Can-Am car that was racing that weekend

http://www.omnitech-engineering.com/aut ... on2001.asp

We had about 20 minutes to talk engines, LoCorts and the like.

So John has done a few Stomberg head conversions and he offered the the following

"Hi Gary;

Well, unfortunately, this fellow is probably in for a tuff, possibly expensive learning curve, depending on how many people bite. My first attempt at this conversion was to do exactly what he has done, however, after several dyno pulls, the manifold loosened, and hair line cracks appeared in stress areas under the cam tappets. If you look at an original Weber head, the inlet ports aid in supporting the heads structure & stiffness, this is derived from the vent box, and some ribs, if you don?t re-establish this support, the head will stress relive under load, and you will have problems.

So, I designed a manifold which mounts on a 3D CNC machined surface, and a mirror of the surface on the manifold, I designed into this mounting plain a large fillet under the tappet intersection, and angle studded the manifold into the fillet, thus establishing support from the side loads from the tappets.

I made the mistake one time to sell a manifold to someone to mount, I amplified the above, however, I think because he was using a manual mill, and wasn?t able to machine the necessary fillet, and mirror fit to the manifold precisely, it also cracked, and the manifold loosened.

There have been those whom have welded on ports, this method creates so much heat, the head is done after the ports are welded.

So, I guess the moral of the story is, there is allot more than meets the eye, tan?t as simple as it looks.

Perhaps, since you?re a neutral party, you might be able to enlighten the readers as to what I discovered in my development, or perhaps, just elude to the point that the conversion is a bit more technical than it appears.

Merry Christmas

John"

Rohan posted these photos a while back on another forum and I guess they might as wall get posted here. Take a look at how John has done it, may save you some time effort and lastly aggrevation.

Gary

http://www.omnitech-engineering.com/auto/strom.asp

I first heard of the project from my Friend Kenny Duclos back in 1996 or so, he had a prototype for fitting and testing I believe. I didn't meet John until last year when I was attending the Monterey Hiistorics in August. John was there Tending to Rawlson Can-Am car that was racing that weekend

http://www.omnitech-engineering.com/aut ... on2001.asp

We had about 20 minutes to talk engines, LoCorts and the like.

So John has done a few Stomberg head conversions and he offered the the following

"Hi Gary;

Well, unfortunately, this fellow is probably in for a tuff, possibly expensive learning curve, depending on how many people bite. My first attempt at this conversion was to do exactly what he has done, however, after several dyno pulls, the manifold loosened, and hair line cracks appeared in stress areas under the cam tappets. If you look at an original Weber head, the inlet ports aid in supporting the heads structure & stiffness, this is derived from the vent box, and some ribs, if you don?t re-establish this support, the head will stress relive under load, and you will have problems.

So, I designed a manifold which mounts on a 3D CNC machined surface, and a mirror of the surface on the manifold, I designed into this mounting plain a large fillet under the tappet intersection, and angle studded the manifold into the fillet, thus establishing support from the side loads from the tappets.

I made the mistake one time to sell a manifold to someone to mount, I amplified the above, however, I think because he was using a manual mill, and wasn?t able to machine the necessary fillet, and mirror fit to the manifold precisely, it also cracked, and the manifold loosened.

There have been those whom have welded on ports, this method creates so much heat, the head is done after the ports are welded.

So, I guess the moral of the story is, there is allot more than meets the eye, tan?t as simple as it looks.

Perhaps, since you?re a neutral party, you might be able to enlighten the readers as to what I discovered in my development, or perhaps, just elude to the point that the conversion is a bit more technical than it appears.

Merry Christmas

John"

Rohan posted these photos a while back on another forum and I guess they might as wall get posted here. Take a look at how John has done it, may save you some time effort and lastly aggrevation.

Gary

-

garyeanderson - Coveted Fifth Gear

- Posts: 2634

- Joined: 12 Sep 2003

i suppose a new kid on the block is always going to get a hard time , almost treading on toes , cheers del

800bhp escort cosworth, 1000bhp nissan skyline , rs200, ,rs 500 ,lotus europa twin cam ,lotus elan s4 rolling road , ecu remaps, powder coating ,like making things that work, do all my own engine work ,worked for cosworth,lotus , porsche, aston martin

- del@ace

- First Gear

- Posts: 24

- Joined: 09 Jun 2008

Del, Gary has taken the time and trouble to point out , with the help of someone who's been doing this for years, where your ideas may be improved. His words..."Take a look at how John has done it, may save you some time effort and lastly aggrevation".

If you are so arrogant that you think that this is giving you a hard time....you ain't seen nothing yet.

Mark

If you are so arrogant that you think that this is giving you a hard time....you ain't seen nothing yet.

Mark

-

Elanintheforest - Coveted Fifth Gear

- Posts: 2496

- Joined: 04 Oct 2005

Hi Del

The mouniting plate you have welded on the machined face may achieve the needed reinforcement for the cam tunnels and manifold mounting bolts that John describes as critical to avoid problems overtime.

Keep on with the development - love to see the dyno results when you have finished - especially the differences between the short and long inlet runners. Lotus orginally started with signficantly long runners on their first development engines and then shortened the runners for the production engines to enable then to fit in the Lotus Cortina engine bay.

cheers

Rohan

The mouniting plate you have welded on the machined face may achieve the needed reinforcement for the cam tunnels and manifold mounting bolts that John describes as critical to avoid problems overtime.

Keep on with the development - love to see the dyno results when you have finished - especially the differences between the short and long inlet runners. Lotus orginally started with signficantly long runners on their first development engines and then shortened the runners for the production engines to enable then to fit in the Lotus Cortina engine bay.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8409

- Joined: 22 Sep 2003

One "feature" common to both John McCoy's and del@ace's conversions are that the standard crankcase vent with oil drop out box are cut away from the cylinder head. Therefore the crankcase needs to be vented from somewhere else, most commonly the front of the cam cover. Nothing fatal, just another task in completing the conversion. I have to add that nobody is trying to step on del@ace's toes. I applaud his initiative and skill. However John McCoy has learned quite a bit from many, many computer simulations, flow bench and dyno runs. I have to admit some bias here as I have just gotten my original Stromberg head back from John after conversion. I am just starting on the build-up of a 1700cc long stroke engine based on this cylinder head. The goal is lots of torque between 2500 and 5000 rpm to suit my road-use-only +2S. I will start a separate thread to document this project. A final note about inlet tract length. John McCoy deliberately retained the standard inlet tract geometry in hopes to make his conversions acceptable to the FIA for historic racing. I believe he has been successful. Change the geometry and the FIA frowns sternly.

Russ Newton

Elan +2S (1971)

Elite S2 (1962)

Elan +2S (1971)

Elite S2 (1962)

-

CBUEB1771 - Coveted Fifth Gear

- Posts: 1546

- Joined: 09 Nov 2006

21 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 9 guests