Short block long stroke engine

I've been on and off this forum for many years, having bought a basket case S3 FHC in about 2008 or so. Jobs, family and building a house have been getting in the way, but recently I got access to a garage relatively near my house for the first time in many years so am trying to re-energize the project again.

There are some great engine build threads on this forum and so many knowledgeable people - it is really inspirational. I'm hoping to use this thread to document my engine re-re-build, inspired by some of Rohan's and Naury's posts. Hopefully it may be use to others in a similar position.

I had originally rebuilt the engine to approximately Sprint spec (Q360 cams, big valve, head done by Paul Exon) but my uncle died earlier in the year and left me a bit of money, and he was a car nut, so it felt like he'd probably appreciate me spending it on pushing the project along, and building a more exciting engine, rather than something dull like the mortgage.

There are some great engine build threads on this forum and so many knowledgeable people - it is really inspirational. I'm hoping to use this thread to document my engine re-re-build, inspired by some of Rohan's and Naury's posts. Hopefully it may be use to others in a similar position.

I had originally rebuilt the engine to approximately Sprint spec (Q360 cams, big valve, head done by Paul Exon) but my uncle died earlier in the year and left me a bit of money, and he was a car nut, so it felt like he'd probably appreciate me spending it on pushing the project along, and building a more exciting engine, rather than something dull like the mortgage.

- ill_will

- Third Gear

- Posts: 264

- Joined: 18 Apr 2008

Skip forward a couple of years, and I had a rolling chassis. I hadn't ever had the engine running so at this point, due to budget constraints, I decided to rebuild the front cover, replace the gaskets and seals and fire it up, to see what the oil pressure was like, and do a compression test.

This wasn't a total disaster but it was smoking a bit and oil pressure was at the low end of acceptable, so I bit the bullet and sent the head to Paul Exon.

This wasn't a total disaster but it was smoking a bit and oil pressure was at the low end of acceptable, so I bit the bullet and sent the head to Paul Exon.

- ill_will

- Third Gear

- Posts: 264

- Joined: 18 Apr 2008

Welcome back, I'm sure you're right about your Uncle's wishes and I look forward to hearing more,

I bought a simple Workmate like yours, at £30 the best tool investment I ever made!

I bought a simple Workmate like yours, at £30 the best tool investment I ever made!

Meg

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

-

Quart Meg Miles - Coveted Fifth Gear

- Posts: 1170

- Joined: 03 Oct 2012

Another few years later the head was back from Exon after a complete refresh with new guides, seats, follower sleeves, valves, followers, studs and Q360 cams and then mated with the bottom end which had new bearings and rings. Cylinders were honed as they were ok but at the larger end of the range. Pistons were ok size-wise but a non-matched set, and I didn't check balance.

This is effectively the starting point for the re-re-build. Since the head is now more or less as-new I will probably source another for this phase and keep this one as a spare/sell it (it has been built up but never run.)

This is effectively the starting point for the re-re-build. Since the head is now more or less as-new I will probably source another for this phase and keep this one as a spare/sell it (it has been built up but never run.)

- ill_will

- Third Gear

- Posts: 264

- Joined: 18 Apr 2008

Looks good Will. What are you going to do about the body? I'm at the same stage (and in south London) and still undecided.

- mikealdren

- Coveted Fifth Gear

- Posts: 1194

- Joined: 26 Aug 2006

great story... I would think the most time and possibly money is spent on the body for such a project, even if doing a lot oneself, so that is where your uncle may allow for a decisive move to keep the ball rolling.

keep it on the road!

keep it on the road!

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 1998

- Joined: 02 Sep 2013

I, too, am storing a freshly rebuilt, 40 years ago, head. I knew it was going in storage at the time so every

valve got greased up from the seat to the tip of the stem. No springs or cam followers are installed. I didn't

want any corrosion on any mating surfaces. Still looks good today,

valve got greased up from the seat to the tip of the stem. No springs or cam followers are installed. I didn't

want any corrosion on any mating surfaces. Still looks good today,

Greg Z

45/0243K Sprint

45/7286 S3 SE DHC

45/0243K Sprint

45/7286 S3 SE DHC

-

gjz30075 - Coveted Fifth Gear

- Posts: 3020

- Joined: 12 Sep 2003

mikealdren wrote:Looks good Will. What are you going to do about the body? I'm at the same stage (and in south London) and still undecided.

Thanks Mike. I got as far as getting some quotes a few years back, but I want to do a few more bits and pieces (for example, check the exhaust silencer doesn't need a bigger tunnel) before biting the bullet. I think I'm leaning towards SMS as they seem to get good feedback but aren't as expensive as someone like Option 1.

I've done most of the structural stuff and a bit of the tissuing but don't have the skill or patience to do the epoxy primer, flatting etc. Getting the paint off was a big undertaking and not very enjoyable!

- ill_will

- Third Gear

- Posts: 264

- Joined: 18 Apr 2008

After stripping the block down it became apparent that it had been sleeved at some point. As mentioned above, the bores were at the bigger end of the range and since I plan to use the longer throw 77.6mm crank in this engine, and it will need new pistons anyway, a rebore or resleeve+bore was on the cards.

The block is a LB graded one, which according to the Miles Wilkins book:

'min wall thickness 0.100" ...

LB to be used for 1558cc only, unsuitable for 83.5mm rebore'

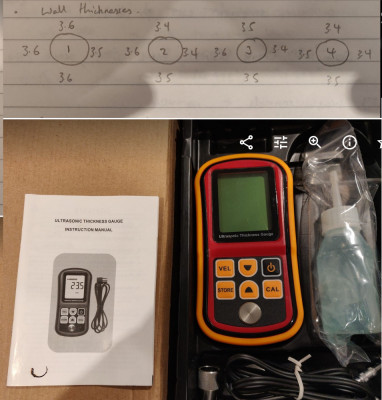

There has been discussion on here that with careful measurement and offset boring it might be possible to get away with 83.5mm in a 'LB' block. To take some measurements I bought a secondhand ultrasonic tester on ebay and did my best to take a set of 'worst case' readings. This was a bit tricky, probably caused by the liner/block interface, but after a bit of trial and error it looked like the liners are fairly well centered, and worst case thickness was 3.4mm, on the existing bore size of a touch over 82.5mm. Allowing for 0.5mm a side (targeting 83.5mm) that leaves 2.9mm, so a shade over the 0.1" recommended.

At this point I test-fitted the new long stoke crank, rods and old pistons using an old set of bearings and used a Dremel to open a couple of areas to give 0.060" clearance. You can see a couple of areas in the photo. There was also an area on the back of the engine mount lugs. It was a bit fiddly getting the feeler gauge in but I found that tying a bit of wire through the loop at the end enabled it to be dangled in and moved to the right spots.

Annoyingly I realised later that I had forgotten to check the jackshaft, so will need to do this later on. I have cut the jackshaft down to just two bearings, and faced off the end in the lathe to clean it up. It might be necessary to grind off some of the old push rod cam profiles.

The block is a LB graded one, which according to the Miles Wilkins book:

'min wall thickness 0.100" ...

LB to be used for 1558cc only, unsuitable for 83.5mm rebore'

There has been discussion on here that with careful measurement and offset boring it might be possible to get away with 83.5mm in a 'LB' block. To take some measurements I bought a secondhand ultrasonic tester on ebay and did my best to take a set of 'worst case' readings. This was a bit tricky, probably caused by the liner/block interface, but after a bit of trial and error it looked like the liners are fairly well centered, and worst case thickness was 3.4mm, on the existing bore size of a touch over 82.5mm. Allowing for 0.5mm a side (targeting 83.5mm) that leaves 2.9mm, so a shade over the 0.1" recommended.

At this point I test-fitted the new long stoke crank, rods and old pistons using an old set of bearings and used a Dremel to open a couple of areas to give 0.060" clearance. You can see a couple of areas in the photo. There was also an area on the back of the engine mount lugs. It was a bit fiddly getting the feeler gauge in but I found that tying a bit of wire through the loop at the end enabled it to be dangled in and moved to the right spots.

Annoyingly I realised later that I had forgotten to check the jackshaft, so will need to do this later on. I have cut the jackshaft down to just two bearings, and faced off the end in the lathe to clean it up. It might be necessary to grind off some of the old push rod cam profiles.

- ill_will

- Third Gear

- Posts: 264

- Joined: 18 Apr 2008

gjz30075 wrote:I, too, am storing a freshly rebuilt, 40 years ago, head. I knew it was going in storage at the time so every

valve got greased up from the seat to the tip of the stem. No springs or cam followers are installed. I didn't

want any corrosion on any mating surfaces. Still looks good today,

That's a good point - I will remove the springs and followers if I intend to keep it long term!

- ill_will

- Third Gear

- Posts: 264

- Joined: 18 Apr 2008

nmauduit wrote:great story... I would think the most time and possibly money is spent on the body for such a project, even if doing a lot oneself, so that is where your uncle may allow for a decisive move to keep the ball rolling.

keep it on the road!

That is a good point - I've been thinking the same thing. Doing the bodywork is quite unpleasant, and the previous time I tried spraying a car diy-style the finish wasn't great... A lot of orange peel.

- ill_will

- Third Gear

- Posts: 264

- Joined: 18 Apr 2008

ill_will wrote:Doing the bodywork is quite unpleasant, and the previous time I tried spraying a car diy-style the finish wasn't great... A lot of orange peel.

orange peel can be sanded flat and polished (actually quite straightforward with "direct gloss" paints, i.e. not requiring clear coat on top), this is not the worst part, but the preparation of the bodywork to get a good result can be very demanding, depending what you start from ... and the beautiful paint not lasting very long if not done properly...

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 1998

- Joined: 02 Sep 2013

Regarding painting. SMS partner Paul Mason split from the rest of the SMS team and set up on his own as Paul Mason Autospray I believe working at or alongside Spyder Engineering. Paul was the sprayer at SMS who they’ve got now I don’t know, but their reputation was built on his work.

Steve

Silence is Golden; Duct Tape is Silver

Silence is Golden; Duct Tape is Silver

-

elanfan1 - Coveted Fifth Gear

- Posts: 1720

- Joined: 13 Jan 2004

Most Lotus stamped "LB" blocks or standard non lotus 120 E and other blocks will take 83.5 mm bores with offset boring to achieve the best wall thicknesses. Sleeved blocks get a little trickier as you need to consider both the sleeve thickness and the total wall thickness and try to pick up both with the ultrasonic measurement which is not easy with the general type measurement devices.

A lot of blocks were sleeved by Ford from new to recover casting or machining problems. Hard to tell whats Ford original or if its been sleeved later now in many cases.

From your measurements t sounds like your block is Ok for 83.5 for road use for which 2.5mm / 100 thou is generally OK provided the thinnest areas are small and not on the thrust face. I try to have over 3mm / 120 thou for a race engine.

There is a big choice of rod and piston combinations with a long stroke 1600 crank in a 1500 short block but lighter is always better

cheers

Rohan

A lot of blocks were sleeved by Ford from new to recover casting or machining problems. Hard to tell whats Ford original or if its been sleeved later now in many cases.

From your measurements t sounds like your block is Ok for 83.5 for road use for which 2.5mm / 100 thou is generally OK provided the thinnest areas are small and not on the thrust face. I try to have over 3mm / 120 thou for a race engine.

There is a big choice of rod and piston combinations with a long stroke 1600 crank in a 1500 short block but lighter is always better

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8409

- Joined: 22 Sep 2003

Total Online:

Users browsing this forum: No registered users and 17 guests