Wednesday Spyder Bodge Report.

19 posts

• Page 1 of 2 • 1, 2

Timing the cams has been delayed by further evidence of incompetence.

Before any timing I, naturally, had to check the valve clearances.

Remember this engine has done maybe 500 miles since "rebuild."

IN EXT

1 .006 .007 (!)

2 .004 .012

3 .004 .011

4 .005 .009

1 correct another 2 just on limits. So now I'll have to honk the cams out and check all the shims.

I was pretty cheesed off that, despite having had to remove the gearbox, they did not bother with the lever ball that was about to disintegrate, did not bother to give it a cursory clean or even change the oil.

Now I'm grateful.

Before any timing I, naturally, had to check the valve clearances.

Remember this engine has done maybe 500 miles since "rebuild."

IN EXT

1 .006 .007 (!)

2 .004 .012

3 .004 .011

4 .005 .009

1 correct another 2 just on limits. So now I'll have to honk the cams out and check all the shims.

I was pretty cheesed off that, despite having had to remove the gearbox, they did not bother with the lever ball that was about to disintegrate, did not bother to give it a cursory clean or even change the oil.

Now I'm grateful.

- vincereynard

- Coveted Fifth Gear

- Posts: 1071

- Joined: 12 Jan 2015

I had same issue with my number 1 ex clearance. I think I remember reading on here that no 1 tends to closer up when the head is torqued down.

I suspect mine was set in correct range with the head off but changed when head was fitted. I've been in and adjusted the clearance and that if a few others.

I suspect mine was set in correct range with the head off but changed when head was fitted. I've been in and adjusted the clearance and that if a few others.

'73 +2 130/5 RHD, now on the road and very slowly rolling though a "restoration"

- mbell

- Coveted Fifth Gear

- Posts: 2643

- Joined: 07 Jun 2013

Nick,

The numbers you quote mean absolutely nothing to me, what is the prognosis of the engine, will it go pop if not seen to?

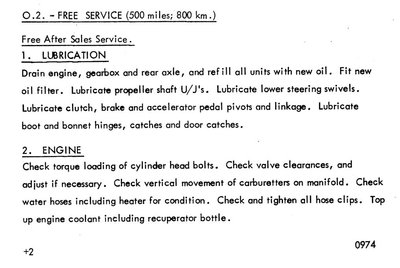

I seem to remember that the first 500 mile service for a twincam involves checking and adjusting valve clearances?

The numbers you quote mean absolutely nothing to me, what is the prognosis of the engine, will it go pop if not seen to?

I seem to remember that the first 500 mile service for a twincam involves checking and adjusting valve clearances?

Kindest regards

Alan Thomas

Alan Thomas

-

Spyder fan - Coveted Fifth Gear

- Posts: 2022

- Joined: 11 Jun 2009

While clearances can move over the first 500 kms and should be checked and reset, to be that far wrong is another issue.

When the head is torqued down the cam clearances will change and they need to be checked and reset. It is quick and easy to set the clearance with the head off during a rebuild and lots of builders do not check and adjust once the head is bolted down resulting in unacceptable clearances when it is next checked

measure twice, cut ( or adjust) once is the best advice

cheers

Rohan

When the head is torqued down the cam clearances will change and they need to be checked and reset. It is quick and easy to set the clearance with the head off during a rebuild and lots of builders do not check and adjust once the head is bolted down resulting in unacceptable clearances when it is next checked

measure twice, cut ( or adjust) once is the best advice

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8417

- Joined: 22 Sep 2003

Alan - I'll PM you somewhere else.

Rohan -

"While clearances can move over the first 500 kms and should be checked and reset, to be that far wrong is another issue."

Layers of Trouble - Usually Spyder?

"When the head is torqued down the cam clearances will change and they need to be checked and reset. It is quick and easy to set the clearance with the head off during a rebuild and lots of builders do not check and adjust once the head is bolted down resulting in unacceptable clearances when it is next checked"

I've always thought it a bit pointless doing in on a bench for that reason. It will probably have to be redone anyway.

Could be shaping up to a head off job for peace of mind.

Rohan -

"While clearances can move over the first 500 kms and should be checked and reset, to be that far wrong is another issue."

Layers of Trouble - Usually Spyder?

"When the head is torqued down the cam clearances will change and they need to be checked and reset. It is quick and easy to set the clearance with the head off during a rebuild and lots of builders do not check and adjust once the head is bolted down resulting in unacceptable clearances when it is next checked"

I've always thought it a bit pointless doing in on a bench for that reason. It will probably have to be redone anyway.

Could be shaping up to a head off job for peace of mind.

- vincereynard

- Coveted Fifth Gear

- Posts: 1071

- Joined: 12 Jan 2015

If the head is flat and the block flat and you torque the head down evenly the clearance should only move by 1 or 2 thou from the bench set up. Due to the head bending as its bolted down.More than that clearance change can result and you have a more fundamental issue but it can be corrected by adjusting the valves shims for correct clearance provided then cams are not binding in what are probably non straight cam tunnels

cheers

Rohan

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8417

- Joined: 22 Sep 2003

vincereynard wrote:Alan - I'll PM you somewhere else.

.

No probs,

I wasn't being picky or trying to defend anybody, I really don't know anything about the technicalities of valve clearances and how to set them on a twin cam. But I do read a lot of technical manuals (not much sticks) and remembered the following extract.

Kindest regards

Alan Thomas

Alan Thomas

-

Spyder fan - Coveted Fifth Gear

- Posts: 2022

- Joined: 11 Jun 2009

mbell wrote:I had same issue with my number 1 ex clearance. I think I remember reading on here that no 1 tends to closer up when the head is torqued down.

I suspect mine was set in correct range with the head off but changed when head was fitted. I've been in and adjusted the clearance and that if a few others.

Sorry I have not replied sooner. Bit of a flap on!

Interesting that No1 has a tendency to close. In or Ex?

On mine the In was the only one correct and the exhaust way out.

- vincereynard

- Coveted Fifth Gear

- Posts: 1071

- Joined: 12 Jan 2015

It looks like removing and stripping the head is the only way to discover what other horrors the Peterborough Plonkers may have done so -

Whats the current recommendation for head gaskets? Top end sets in general. I have a2mm sheet of neoprene rubber that I intend to cut for a cam gasket. Just as an experiment to see if that particular item can be improved. (The new one I have is nowhere near a good fit.)

Vince

Whats the current recommendation for head gaskets? Top end sets in general. I have a2mm sheet of neoprene rubber that I intend to cut for a cam gasket. Just as an experiment to see if that particular item can be improved. (The new one I have is nowhere near a good fit.)

Vince

- vincereynard

- Coveted Fifth Gear

- Posts: 1071

- Joined: 12 Jan 2015

Vince

Cutting it to shape will be a pain....as will keeping it in place, I'd go for lightly oiling the head surface and cleaning the cam cover surface and applying a bead of silicon , resting in place and let it go off overnight ( or longer ) before tightening.

John

Cutting it to shape will be a pain....as will keeping it in place, I'd go for lightly oiling the head surface and cleaning the cam cover surface and applying a bead of silicon , resting in place and let it go off overnight ( or longer ) before tightening.

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

John

I've tried that 3 times. First it sunk down and stuck fast. Second I had it propped up with spacers and it seemed went off in places and others stayed sticky. Third - I lined the head with oiled baking paper! The Silicone stuck fast to the paper. 3 attempts with 2 different silicones - I gave up!

I'll report if I have any more success with the rubber sheet!

I've tried that 3 times. First it sunk down and stuck fast. Second I had it propped up with spacers and it seemed went off in places and others stayed sticky. Third - I lined the head with oiled baking paper! The Silicone stuck fast to the paper. 3 attempts with 2 different silicones - I gave up!

I'll report if I have any more success with the rubber sheet!

- vincereynard

- Coveted Fifth Gear

- Posts: 1071

- Joined: 12 Jan 2015

That's odd,mine have been good for the past fifteen years or so.....some silicon took days to go off but am well pleased with mine

John

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

john.p.clegg wrote:That's odd,mine have been good for the past fifteen years or so.....some silicon took days to go off but am well pleased with mine

John

Hello John

In the late 80's, I've done it like you.

Then, in a few of sleepless nights, I've generated a new solution:

Only once changed in 24 Years. Greetings Urs

-

ElanDNA - Second Gear

- Posts: 119

- Joined: 31 Jan 2017

I was thinking of doing it like yours.....but.....it gets a bit thin in certain areas to "plough"..

John

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

19 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 6 guests