Cylinder Head

9 posts

• Page 1 of 1

Hi folks

I wonder if I could ask the opinions of people more learned than myself on the viability of the head in the pictures below.

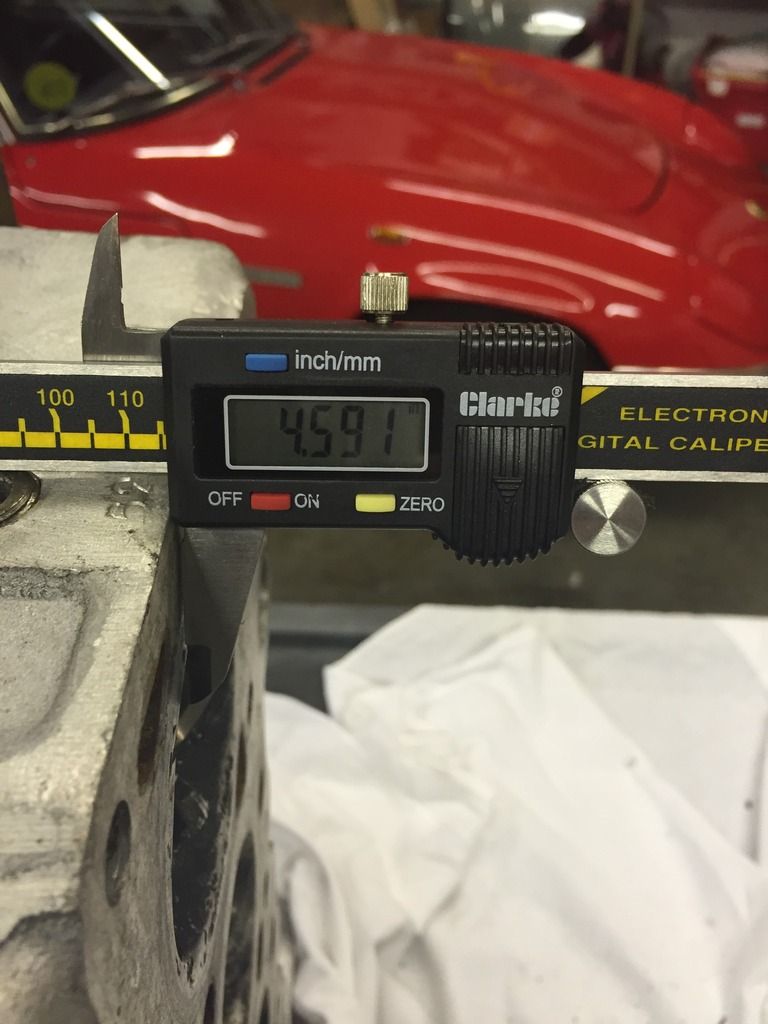

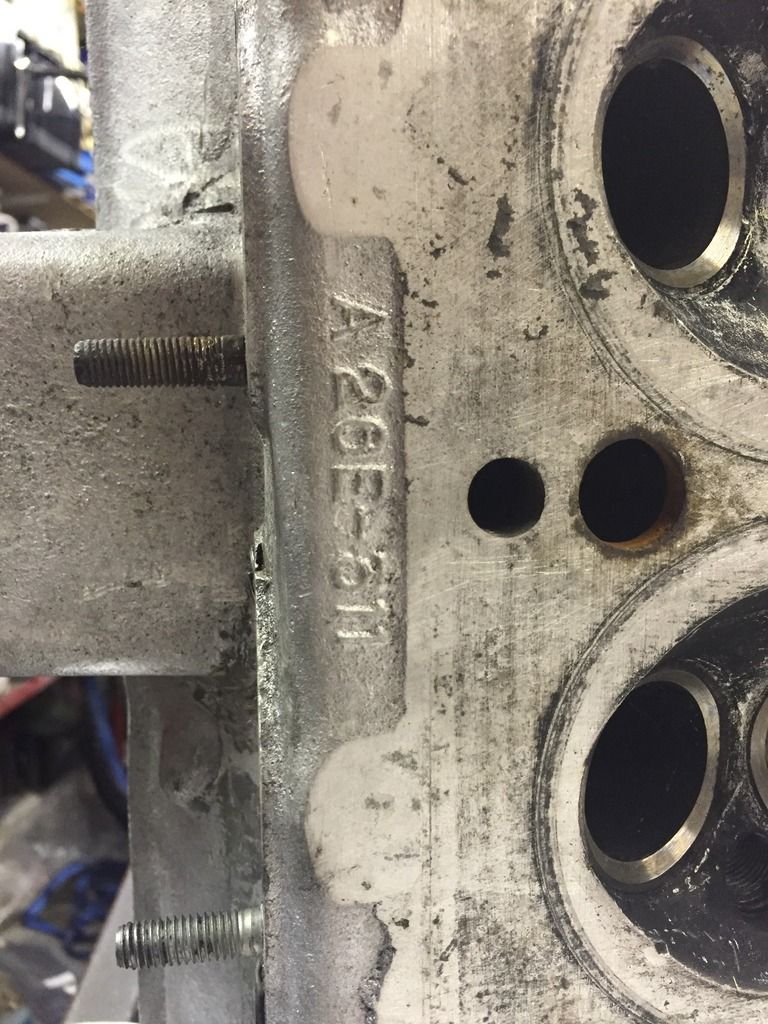

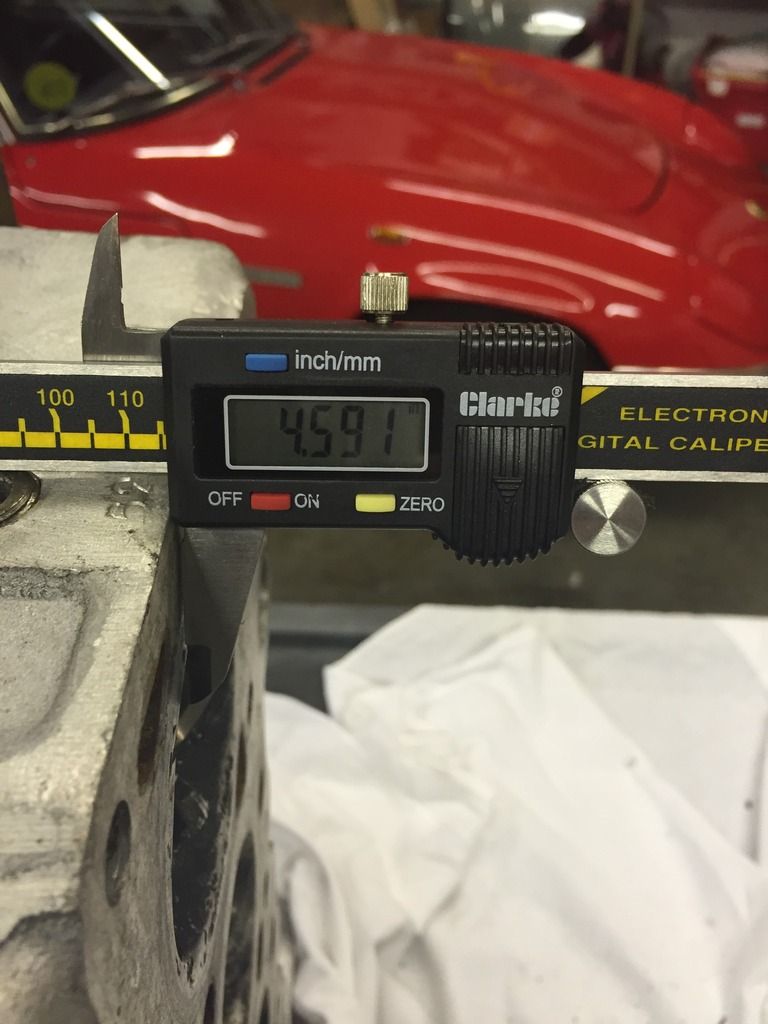

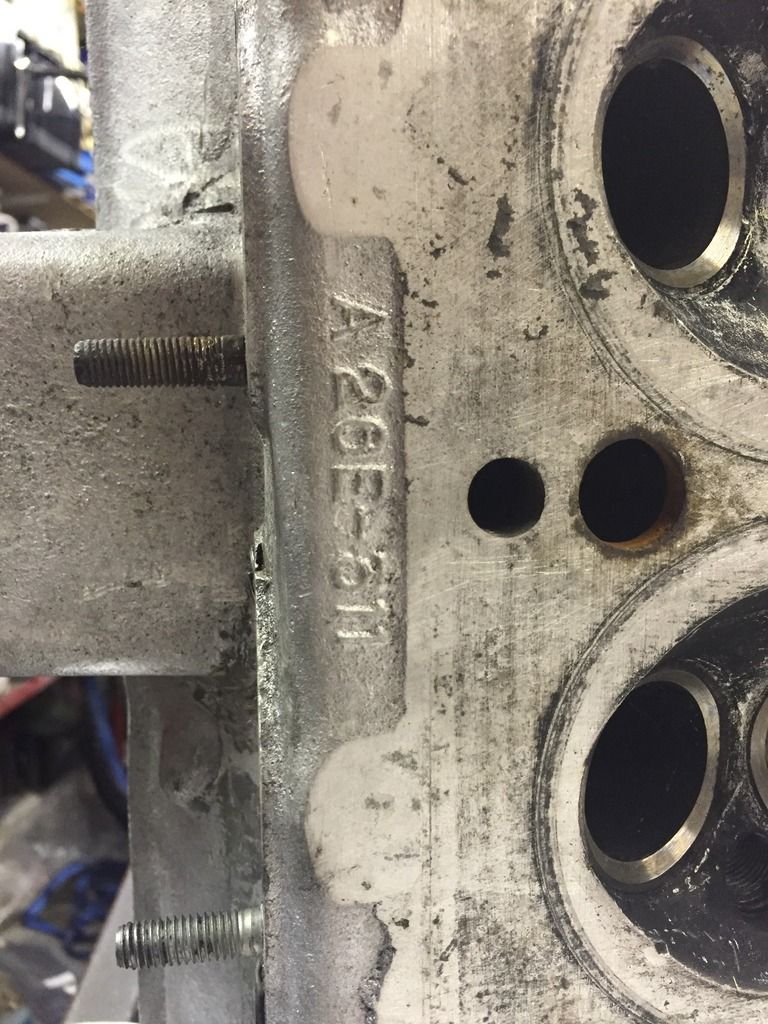

It would appear to have been skimmed below the recommended level that I have read from previous posts on the site, although I recall one post that said they had seen heads so far skimmed the lettering was missing on the underside.

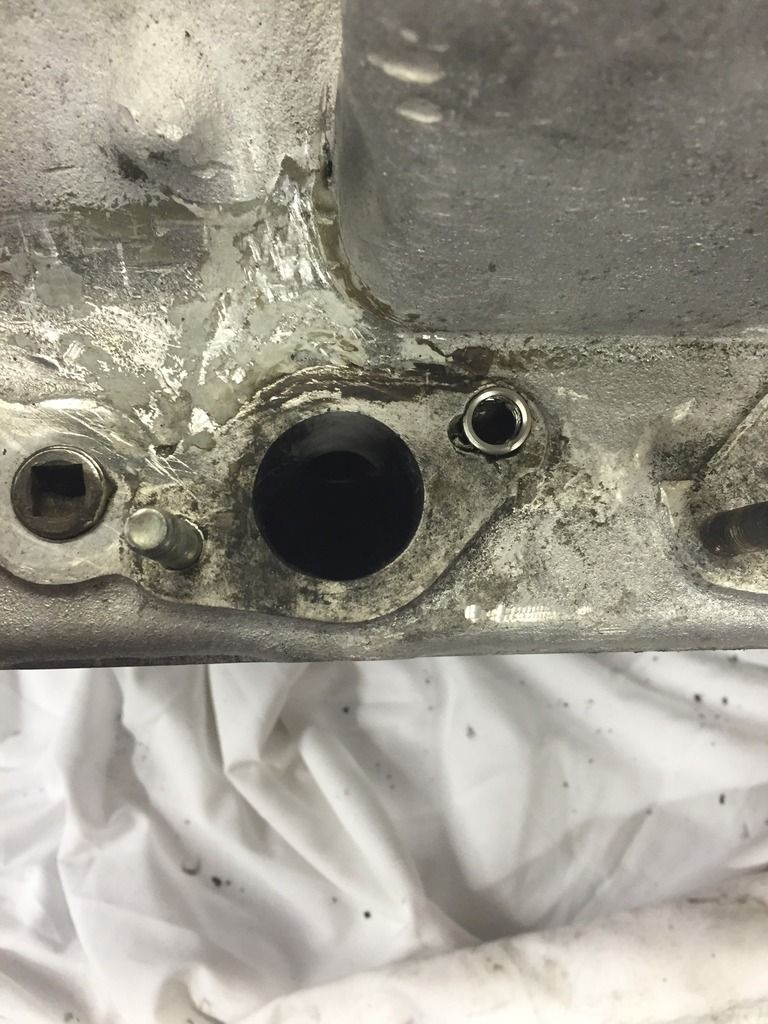

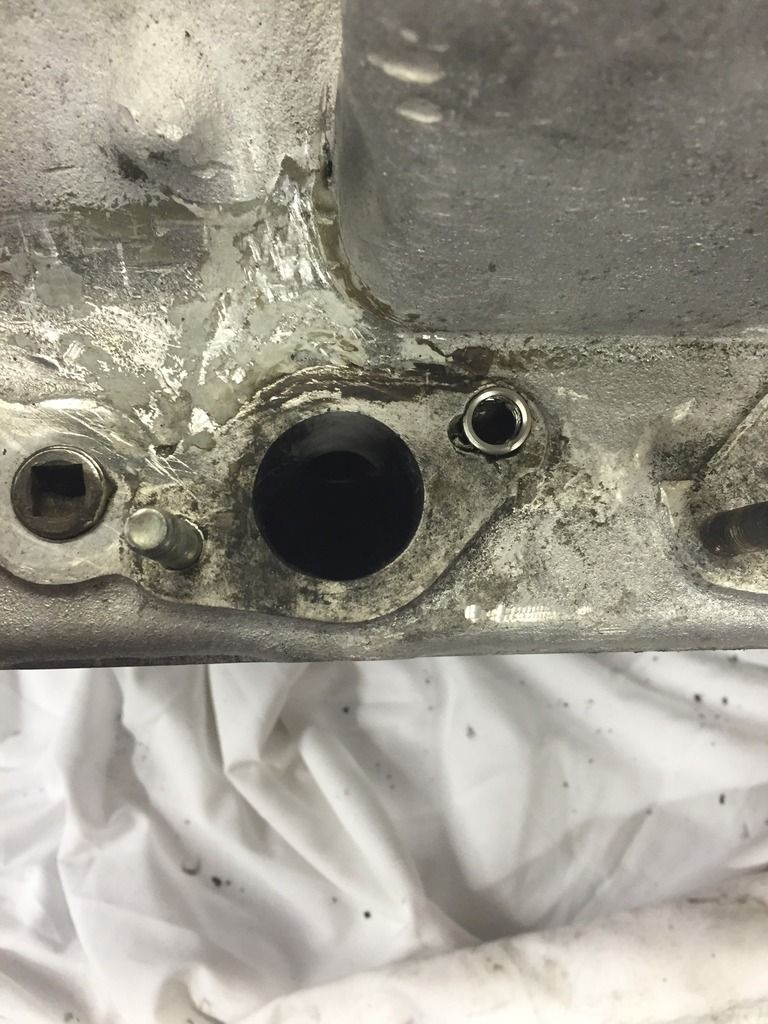

There is some damage around number one cylinder face and there is a helicoil in number two exhaust stud.

I wonder if I could ask the opinions of people more learned than myself on the viability of the head in the pictures below.

It would appear to have been skimmed below the recommended level that I have read from previous posts on the site, although I recall one post that said they had seen heads so far skimmed the lettering was missing on the underside.

There is some damage around number one cylinder face and there is a helicoil in number two exhaust stud.

- Type28

- Second Gear

- Posts: 112

- Joined: 26 Dec 2013

Yes the head thickness is fine and can go a lot less if needed. If it needs a big skim to get a clean face and remove the small areas of corrosion I would look at welding up the corroded areas and skimming it less to increase its future life. However I would first check the heads hardness before I did anything to ensure its not to soft as this is the real reason why heads mainly need to be scrapped these days. I would also pressure test it to identify any cracks that may require welding as some cracks in some areas can be very hard and expensive to repair. With new replacement heads available these days it becomes an economic question of how much do you spend retrieving an old head versus just buying a new head.

As heads get thinner the challenge is all the other subtle changes you need to make to the valve gear and head hemispherical chamber setup to compensate for the reduced thickness. So you need to know what your doing when building up thinner heads.

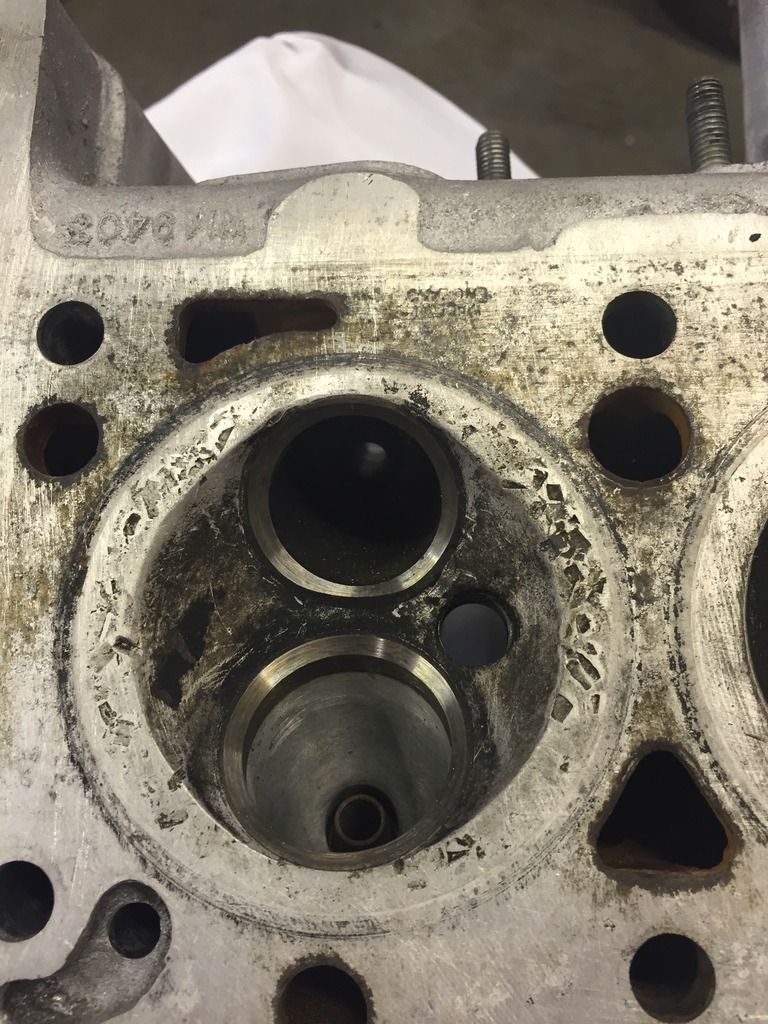

None of the damage looks unacceptable from the photos. The dings in the cylinder head squish area are a relatively common issue and just need cleaning up to remove any sharp edges that can create hot spots. Helicoils are not an issue assuming they have been installed correctly

cheers

Rohan

As heads get thinner the challenge is all the other subtle changes you need to make to the valve gear and head hemispherical chamber setup to compensate for the reduced thickness. So you need to know what your doing when building up thinner heads.

None of the damage looks unacceptable from the photos. The dings in the cylinder head squish area are a relatively common issue and just need cleaning up to remove any sharp edges that can create hot spots. Helicoils are not an issue assuming they have been installed correctly

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8427

- Joined: 22 Sep 2003

These days you use a hardness testing device to bounce a small hard steel ball point off the surface. The amount of rebound measured electronically is proportional to the hardness. For aluminum heads it is measured in Brinell hardness scale and ideally you want something over 50 down to 40 you can live with under forty and you have trouble keeping the head gaskets to seal and the head bolts will start sinking into the head. Modern new castings are typically in the 80 plus range.

Originally it was measure by driving a ball point of hardened steel into the head with a known force and measuring the size of the hole created

cheers

Rohan

Originally it was measure by driving a ball point of hardened steel into the head with a known force and measuring the size of the hole created

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8427

- Joined: 22 Sep 2003

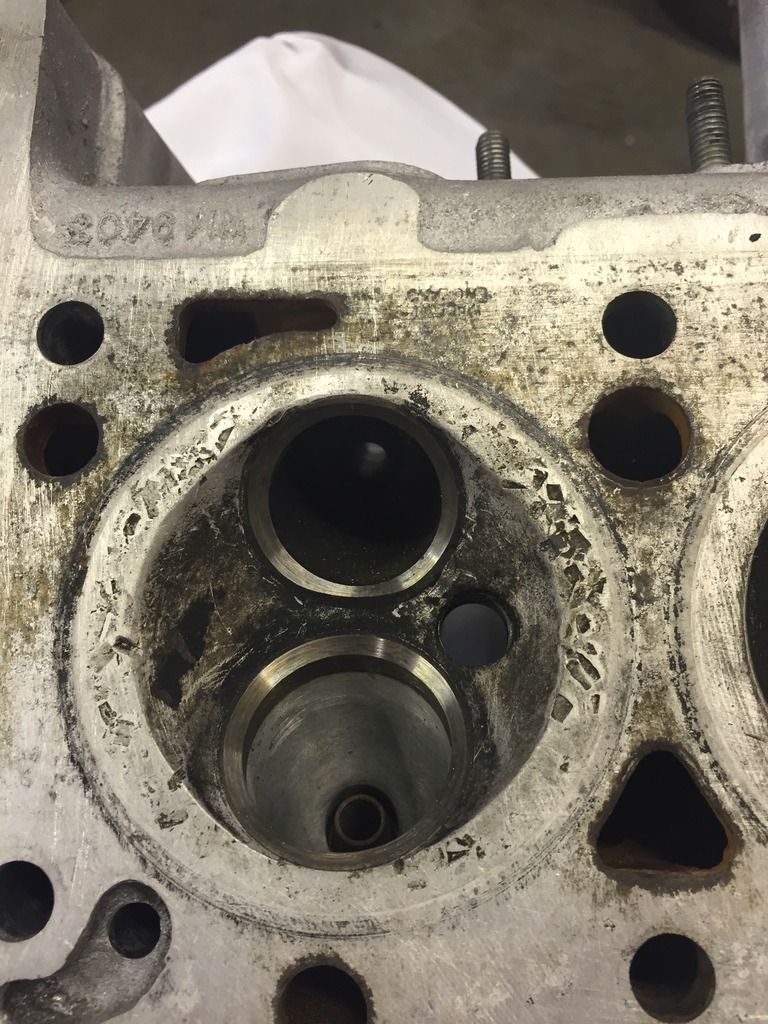

The third photo showing one combustion chamber looks like a piece of piston or piston ring was pushed into the head. One of the reasons that can happen is the distributor advance springs become weak and the distributor goes full advance at a low rpm causing detonation. The detonation breaks the top compression ring which eventually cuts its way out and into the cylinder. So, it would be a good idea to have the distributor checked on a distributor test machine to make sure it has the book correct advance curve.

1969 Elan S4

1700 cc, Dave Bean #112 cams.

Union Jack Exotics

1700 cc, Dave Bean #112 cams.

Union Jack Exotics

-

dlbutler - Second Gear

- Posts: 65

- Joined: 18 Sep 2003

9 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 27 guests