PJH 97H - Engine Re-Build

5 posts

• Page 1 of 1

Finally started the engine rebuild on the Elan, it?s the original engine fitted to a SE Elan from 1970 and has a genuine 74114 miles recorded (I bought the car in 1984 and have stored it for many years).

It went into my garage with fresh engine oil and a strong water/anti-freeze mix to avoid the worst of corrosion and if started, was allowed to run until the water temp was high enough to bring the rad fan on. So I?m hoping the engine will be in reasonable condition, it certainly pulled strongly before storage. Unfortunately the water pump seal has failed in the intervening time so the engine requires stripping to replace and given the engines mileage, an inspection of the internals would be best practise.

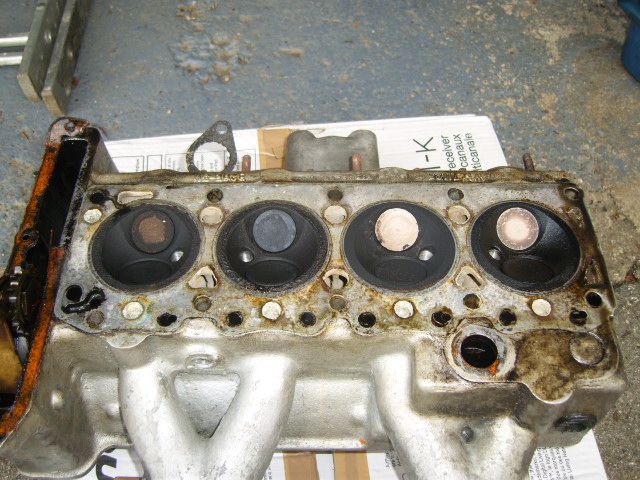

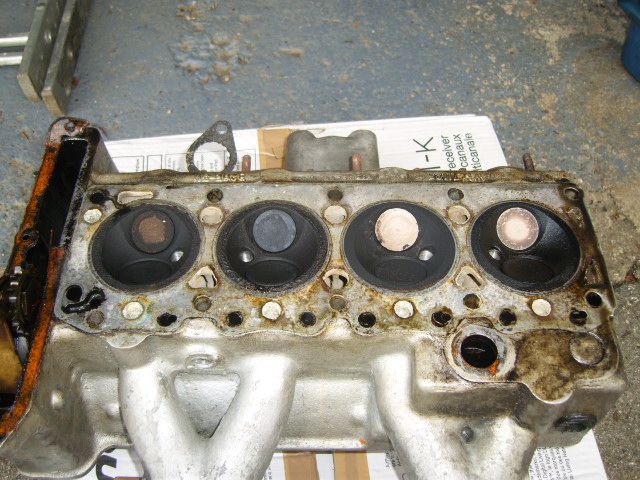

Starting with the head, this came off without any problems; I was certainly expecting something more challenging, the use of bolts rather than studs to secure the head no doubt the reason.

Initial inspection of the head indicates that there has been no leaks between the various passages and the cylinders, I did not expect any but???????..

There is some lime scaling on the head to block surface and the head gasket bears witness to such with it being indented, may be the head had previously been re-fitted with this corrosion present? (Orange sealant bears witness to a previous head removal). Hopefully a light skim should restore the head.

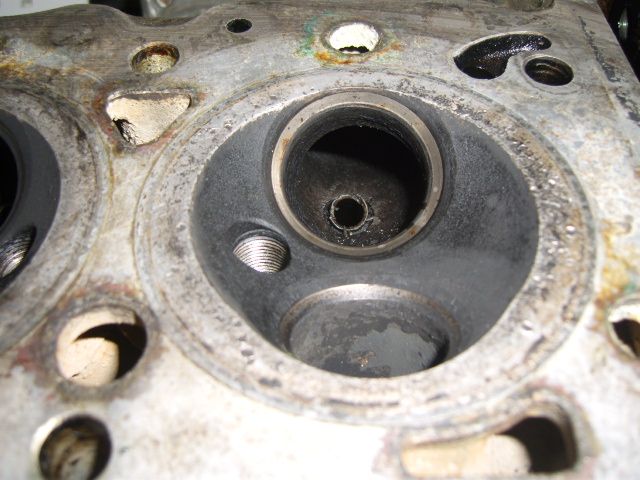

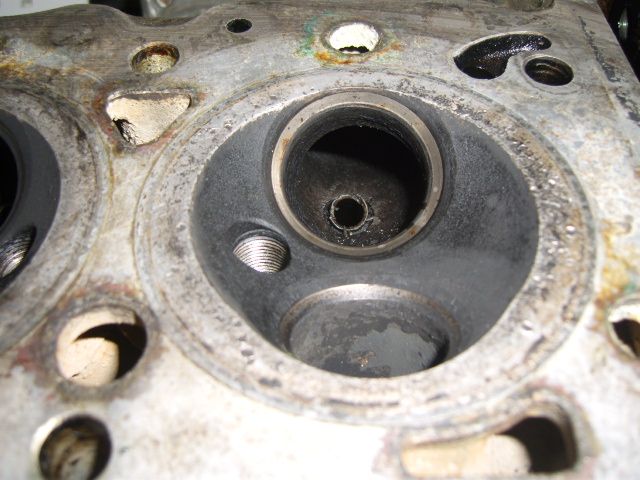

Something has been ingested by No. 1 cylinder resulting in the head being pitted forward of the hemi recess. This has also damaged the piston and it will need replacing (all 4 ? ouch!). The inlet valve guide also has some damage to its lower edge.

Stripping the head presented no issues, the use of a pair of these made the valve/spring removal very easy ?

Not the cheapest available but well worth the money IMO.

Inspection of the parts

Cams ? These appear OK with only light scoring on some of the bearing surfaces (I need to measure for wear). The lobes are clean. I expect to run a hotter cams so not too concerned about their condition.

Valve Followers ? These measure .002? under size (1.3735?) and are round. Is this a problem? Note - I do need to measure the i/d of the sleeve liners to determine the total clearance.

Valve Guides ? Valves are a bit loose in the guides so all will be replaced with Colsibro type. What internal diameter should they be wrt to the valve dia? I believe you can run a tighter fit with Colsibro guides than the cast iron type.

Valves ? All to be replaced, Big Valve Inlets and standard Exhaust.

Valve Seats ? Inlets to be re-cut or replaced depending on the machinist recommendation. Exhaust Seats to be replaced. I will be asking for a triple angle cut (30/45/60 degrees) but what is the recommended width for the 45 degree seat ie the valve mating surface? A. Graham Bell from his excellent book 'Four Stroke Performance Tuning' recommends .050? to .060? and 070?-.080? for the inlet and exhaust respectively. (For book see - http://www.amazon.co.uk/Four-stroke-Performance-Tuning-Graham-Bell/dp/0857331256/ref=sr_1_1?ie=UTF8&qid=1442901054&sr=8-1&keywords=four+stroke+performance+tuning

More to follow but it would be good to get some feedback on the questions asked. I hope to get the head off for re-work later this week.

Thank you,

It went into my garage with fresh engine oil and a strong water/anti-freeze mix to avoid the worst of corrosion and if started, was allowed to run until the water temp was high enough to bring the rad fan on. So I?m hoping the engine will be in reasonable condition, it certainly pulled strongly before storage. Unfortunately the water pump seal has failed in the intervening time so the engine requires stripping to replace and given the engines mileage, an inspection of the internals would be best practise.

Starting with the head, this came off without any problems; I was certainly expecting something more challenging, the use of bolts rather than studs to secure the head no doubt the reason.

Initial inspection of the head indicates that there has been no leaks between the various passages and the cylinders, I did not expect any but???????..

There is some lime scaling on the head to block surface and the head gasket bears witness to such with it being indented, may be the head had previously been re-fitted with this corrosion present? (Orange sealant bears witness to a previous head removal). Hopefully a light skim should restore the head.

Something has been ingested by No. 1 cylinder resulting in the head being pitted forward of the hemi recess. This has also damaged the piston and it will need replacing (all 4 ? ouch!). The inlet valve guide also has some damage to its lower edge.

Stripping the head presented no issues, the use of a pair of these made the valve/spring removal very easy ?

Not the cheapest available but well worth the money IMO.

Inspection of the parts

Cams ? These appear OK with only light scoring on some of the bearing surfaces (I need to measure for wear). The lobes are clean. I expect to run a hotter cams so not too concerned about their condition.

Valve Followers ? These measure .002? under size (1.3735?) and are round. Is this a problem? Note - I do need to measure the i/d of the sleeve liners to determine the total clearance.

Valve Guides ? Valves are a bit loose in the guides so all will be replaced with Colsibro type. What internal diameter should they be wrt to the valve dia? I believe you can run a tighter fit with Colsibro guides than the cast iron type.

Valves ? All to be replaced, Big Valve Inlets and standard Exhaust.

Valve Seats ? Inlets to be re-cut or replaced depending on the machinist recommendation. Exhaust Seats to be replaced. I will be asking for a triple angle cut (30/45/60 degrees) but what is the recommended width for the 45 degree seat ie the valve mating surface? A. Graham Bell from his excellent book 'Four Stroke Performance Tuning' recommends .050? to .060? and 070?-.080? for the inlet and exhaust respectively. (For book see - http://www.amazon.co.uk/Four-stroke-Performance-Tuning-Graham-Bell/dp/0857331256/ref=sr_1_1?ie=UTF8&qid=1442901054&sr=8-1&keywords=four+stroke+performance+tuning

More to follow but it would be good to get some feedback on the questions asked. I hope to get the head off for re-work later this week.

Thank you,

Last edited by fasterbyelan on Tue Sep 22, 2015 10:37 am, edited 1 time in total.

Karl

1970 S4 FHC SE

1970 S4 FHC SE

-

fasterbyelan - Second Gear

- Posts: 189

- Joined: 14 Nov 2003

FACOM is for some (french and many a swiss) the world's finest. for some others, like myself, you some how get forced to use snap on - ......................... the phrase: aren't you ashamed of yourself using safeway (or equal) tools? btw: one of my 1/4 inch ratchets is a fine toothed facom!! sandy, alps 4982

- el-saturn

- Coveted Fifth Gear

- Posts: 1031

- Joined: 27 Jun 2012

Hi Karl

It looks like a fairly typical well used twin cam. The starting point for any rebuild is how much money do you have and how much performance upgrade do you want

Once you have rough match between your aspirations and hip pocket then the next issue is the cam needed and compression ratio to produce what performance you want / can afford. Based on this you can then determine valve train components and porting and bottom end components needed. Twinks love lots of valve lift so focus on that rather than valve duration when selecting a performance cam. Finally you can then determine carb and exhaust required and plan a dyno session to dial in the tuning after the rebuild.

With regards some of you specific questions.

Valve cam followers normally wear into a barrel shape and thus will be under size top and bottom and bigger in the middle. The sleeves wear into an hour glass shape. so you need to check both top middle and bottom of both components to determine wear versus specifications and if replacement needed.

With bronze guide I run the bottom end of the tolerance clearance range for inlets and the middle of the range for the exhaust. Get your valves first and then hone the guides based on the actual measure of valve stem diameter for the correct clearance. This is also good practice for the cam followers and piston bores. Any thing you need to hone to clearance should be based on the actual measured component you will be fitting.

Three angle or multi-angle seats are good for flow, in combination with suitable porting to match the cam used. The sealing face at 1.5 mm for inlets and 2 mm for exhaust is good for a road engine. In Race engines you can squeeze that down to 1 mm and 1.5 mm.

cheers

Rohan

It looks like a fairly typical well used twin cam. The starting point for any rebuild is how much money do you have and how much performance upgrade do you want

Once you have rough match between your aspirations and hip pocket then the next issue is the cam needed and compression ratio to produce what performance you want / can afford. Based on this you can then determine valve train components and porting and bottom end components needed. Twinks love lots of valve lift so focus on that rather than valve duration when selecting a performance cam. Finally you can then determine carb and exhaust required and plan a dyno session to dial in the tuning after the rebuild.

With regards some of you specific questions.

Valve cam followers normally wear into a barrel shape and thus will be under size top and bottom and bigger in the middle. The sleeves wear into an hour glass shape. so you need to check both top middle and bottom of both components to determine wear versus specifications and if replacement needed.

With bronze guide I run the bottom end of the tolerance clearance range for inlets and the middle of the range for the exhaust. Get your valves first and then hone the guides based on the actual measure of valve stem diameter for the correct clearance. This is also good practice for the cam followers and piston bores. Any thing you need to hone to clearance should be based on the actual measured component you will be fitting.

Three angle or multi-angle seats are good for flow, in combination with suitable porting to match the cam used. The sealing face at 1.5 mm for inlets and 2 mm for exhaust is good for a road engine. In Race engines you can squeeze that down to 1 mm and 1.5 mm.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8427

- Joined: 22 Sep 2003

Thanks for the reply Rohan and your comments.

I have taken the head to work and measured the cam followers and sleeves more accurately. I have attached the results for those interested.

To summarise, the parts are worn in the manner you mention. What I would like to know is the maximum amount of wear over and above the tolerance of the manufactured parts that is acceptable? Taking the worst case gives a distance between them of .0014? (maximum sleeve diameter - minimum cam follower diameter). The maximum wear I have is .0003? above this value. Is this too much and if so, would a cost effective solution be to replace the cam followers only and hone the sleeves to suit?

Regarding the cams, I?m looking at either the 360 or 420 cam from QED. There is not a lot in them really particularly when I consider the amount of time I will be spending at 6500 rpm ie very little! I will not be putting the head together yet so I can decide later which to use. I will however be getting the head ported/gas flowed so am looking at improving the shape behind the valve seats and opening out/cleaning the inlet/exhaust tracts. Am I correct in thinking that there is no need to polish everything to the n?th degree, in fact to do so may be detrimental?

Regards,

Karl

I have taken the head to work and measured the cam followers and sleeves more accurately. I have attached the results for those interested.

To summarise, the parts are worn in the manner you mention. What I would like to know is the maximum amount of wear over and above the tolerance of the manufactured parts that is acceptable? Taking the worst case gives a distance between them of .0014? (maximum sleeve diameter - minimum cam follower diameter). The maximum wear I have is .0003? above this value. Is this too much and if so, would a cost effective solution be to replace the cam followers only and hone the sleeves to suit?

Regarding the cams, I?m looking at either the 360 or 420 cam from QED. There is not a lot in them really particularly when I consider the amount of time I will be spending at 6500 rpm ie very little! I will not be putting the head together yet so I can decide later which to use. I will however be getting the head ported/gas flowed so am looking at improving the shape behind the valve seats and opening out/cleaning the inlet/exhaust tracts. Am I correct in thinking that there is no need to polish everything to the n?th degree, in fact to do so may be detrimental?

Regards,

Karl

-

fasterbyelan - Second Gear

- Posts: 189

- Joined: 14 Nov 2003

Just for info, I noted that David bean can supply oversize Cam Followers. Living in the UK, a quick search revealed that Burton Power can supply the same so have ordered a set after discussion with the machinist I will be using.

Karl

1970 S4 FHC SE

1970 S4 FHC SE

-

fasterbyelan - Second Gear

- Posts: 189

- Joined: 14 Nov 2003

5 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 39 guests