Distributor advance and dwell curves/settings

20 posts

• Page 1 of 2 • 1, 2

I have just installed a stealth black box controller for my electronic ignition.

You disable the weights advance in the distibutor and can set the advance via a laptop.

I can set advance adn dwell for 7 points along the rev range.

Anyone able to suggest initial settings before I take it off to a rolling road for proper tuning.

I can also set a rev limiter - 6500 or 6750?

You disable the weights advance in the distibutor and can set the advance via a laptop.

I can set advance adn dwell for 7 points along the rev range.

Anyone able to suggest initial settings before I take it off to a rolling road for proper tuning.

I can also set a rev limiter - 6500 or 6750?

1967 Plus 2 #0168

- Johnfm

- Third Gear

- Posts: 333

- Joined: 20 Jan 2013

Lots of info here

lotus-electrical-f38/distributor-question-t2109.html#p11140

I would use 6500 for road use; not a lot above this rev limit anyway.

HTH

lotus-electrical-f38/distributor-question-t2109.html#p11140

I would use 6500 for road use; not a lot above this rev limit anyway.

HTH

Stu

1969 Plus 2 Federal LHD

1969 Plus 2 Federal LHD

-

stugilmour - Coveted Fifth Gear

- Posts: 1962

- Joined: 03 Sep 2007

Thanks Stu.

Though that post doesn't contain the data I am after.

I can programme 7 data pour a for advance and 7 for dwell.

I would quite like data for the follow rev data points:

500

1000

2000

3000

4000

5000

6500

Though no doubt my tuner will tweak it, I was hoping to set a base map jus to get it running reasonably well.

Though that post doesn't contain the data I am after.

I can programme 7 data pour a for advance and 7 for dwell.

I would quite like data for the follow rev data points:

500

1000

2000

3000

4000

5000

6500

Though no doubt my tuner will tweak it, I was hoping to set a base map jus to get it running reasonably well.

1967 Plus 2 #0168

- Johnfm

- Third Gear

- Posts: 333

- Joined: 20 Jan 2013

I have one of these but it will be a while before it will be fitted.

I will follow with interest.

(the data of my engine is of no help as it is an odd ball size of 1841cc)

But when it was set up it would take 31 degree advance with ease on the rolling road.

Jon the Chief

I will follow with interest.

(the data of my engine is of no help as it is an odd ball size of 1841cc)

But when it was set up it would take 31 degree advance with ease on the rolling road.

Jon the Chief

- oldchieft

- Third Gear

- Posts: 374

- Joined: 17 Sep 2013

Miles Wilkins's book Lotus Twin Cam engine has a diagram on page 169 and a table on page 168 which for a big valve engine with a 41189 distributor & D-type cam has a basic 'curve' of:

RPM Degrees Crankshaft

2000 about 12

2500 14.5

3000 16.5

3500 19

4000 21.3

4500 23.5

5000 to 6500 26

For an S/E with C type camshaft, subtract 2 degrees from each of those figures.

I guess that should at least get the engine started.

RPM Degrees Crankshaft

2000 about 12

2500 14.5

3000 16.5

3500 19

4000 21.3

4500 23.5

5000 to 6500 26

For an S/E with C type camshaft, subtract 2 degrees from each of those figures.

I guess that should at least get the engine started.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4405

- Joined: 19 Apr 2008

Hadn't realised there was a thread on this.

Have been corresponding by PM with John on this. Will share some of my experience with the Stealth -

I set mine up in the usual way. Set engine at TDC and roughly put Dizzy at 10.

The only difference in the Dizzy is that there is now no mechanical advance in it.

It's locked, or should be, to allow the Black Box control advance.

Tony at accuspark recommends setting up static at 2 degrees below what you want it and then alter the Black Box static advance as necessary. (the box on the second from top left). NOTE the degree advance here is at the dizzy so 1 degree here is 2 at the crank.

I set my static up at 10 degrees at the crank (so 2 less than workshop manual for my engine) and have not used the static advance on the Black Box.

I used a timing light to check this.

As there is no additional advance needed below 2000 this is straight forward.

I had, previously, set it to 8 static but in the end 10 was 'perfect'.

Changed my advance curve a bit today and have got rid (fingers crossed) of a 2000 - 3000 partial throttle stumble.

Looked at the dwell - I have:

300 - 2000 RPM 45 degrees

3000 - 54

4000 - 56.8

5500 and up 60

Will tweak over the next while.

The great thing (I'm hoping) about the Black Box is that with the required advance to start the engine I can tweak the curve to avoid pinking higher up.

At present, after initially setting the Wilkins 'Big Valve' curve and then a lot of experimenting, I have set advance as:

Static - 10 degrees (at crank)

2000 - no additional advance

2250 - 3 additional degrees (= 13 total)

Linear to 4000 - 14 degrees additinal (= 24 total)

Flat at that to cut out at 6800 (starts to cut out around 6400 on my tach)

Goes like a rocket, pulling well from just over 1000rpm to cut out.

Would love to get it to a rolling road, but that is not practical at the moment.

Peter

Have been corresponding by PM with John on this. Will share some of my experience with the Stealth -

I set mine up in the usual way. Set engine at TDC and roughly put Dizzy at 10.

The only difference in the Dizzy is that there is now no mechanical advance in it.

It's locked, or should be, to allow the Black Box control advance.

Tony at accuspark recommends setting up static at 2 degrees below what you want it and then alter the Black Box static advance as necessary. (the box on the second from top left). NOTE the degree advance here is at the dizzy so 1 degree here is 2 at the crank.

I set my static up at 10 degrees at the crank (so 2 less than workshop manual for my engine) and have not used the static advance on the Black Box.

I used a timing light to check this.

As there is no additional advance needed below 2000 this is straight forward.

I had, previously, set it to 8 static but in the end 10 was 'perfect'.

Changed my advance curve a bit today and have got rid (fingers crossed) of a 2000 - 3000 partial throttle stumble.

Looked at the dwell - I have:

300 - 2000 RPM 45 degrees

3000 - 54

4000 - 56.8

5500 and up 60

Will tweak over the next while.

The great thing (I'm hoping) about the Black Box is that with the required advance to start the engine I can tweak the curve to avoid pinking higher up.

At present, after initially setting the Wilkins 'Big Valve' curve and then a lot of experimenting, I have set advance as:

Static - 10 degrees (at crank)

2000 - no additional advance

2250 - 3 additional degrees (= 13 total)

Linear to 4000 - 14 degrees additinal (= 24 total)

Flat at that to cut out at 6800 (starts to cut out around 6400 on my tach)

Goes like a rocket, pulling well from just over 1000rpm to cut out.

Would love to get it to a rolling road, but that is not practical at the moment.

Peter

I is an Inginear....please excuse my speeling!

'73 +2S 130/5

Scimitar GTE for the lazy days, 3008, Some bicycles, Wife, Kids, Cats, Dogs....chickens....cluck cluck...one duck...the others flew away!

'73 +2S 130/5

Scimitar GTE for the lazy days, 3008, Some bicycles, Wife, Kids, Cats, Dogs....chickens....cluck cluck...one duck...the others flew away!

-

peterako - Fourth Gear

- Posts: 681

- Joined: 02 Mar 2006

Interesting.

Having read the archives, it seems the aim is to reach max advance of 26-28 degrees at around 3500 rpm.

The black box allows a lot of flexibility - in that we can set a lower idle advance and still get as much advance as we want at revs - the distributors were limited by their 'total advance availability', which meant compromising static advance to get enough advance at high revs.

I am going to take it to a rolling road in a few weeks to get properly set up - but using peter's figures as a guide, will set idle a 10 and then get advance to 26 by 3500 and see how it runs.

However I cannot understand why peak advance should be at an engine speed that is only just over half redline speed.

You'd think you'd want to continue advancing the timing incrementally as engine speed continues up to 6500.

Having read the archives, it seems the aim is to reach max advance of 26-28 degrees at around 3500 rpm.

The black box allows a lot of flexibility - in that we can set a lower idle advance and still get as much advance as we want at revs - the distributors were limited by their 'total advance availability', which meant compromising static advance to get enough advance at high revs.

I am going to take it to a rolling road in a few weeks to get properly set up - but using peter's figures as a guide, will set idle a 10 and then get advance to 26 by 3500 and see how it runs.

However I cannot understand why peak advance should be at an engine speed that is only just over half redline speed.

You'd think you'd want to continue advancing the timing incrementally as engine speed continues up to 6500.

1967 Plus 2 #0168

- Johnfm

- Third Gear

- Posts: 333

- Joined: 20 Jan 2013

The aim of increasing the advance is to maximumize the average cylinder pressure on the power stroke. As the engine speed increases the available time for the combustion burn to take place decreases so you need more advance to get more burn ahead of the power stroke to get maximum pressure during the power stroke. To much advance produces to much cylinder pressure at the end of the compression stroke that leads to detonation and "pinging".

The required burn time also does not stay constant however but it shortens as the engine revs faster due to increasing turbulence in the combustion chamber but also lengthens as volumetric efficency drops off (either due to revs or due to a part open throttle at cruise), all these factors interact to produce the curve needed.

With simple mechanical distributors the best compromise for a twin cam was a linear increase from an idle of around 10 to 12 degrees to 25 to 28 degrees at the 3000 to 4000 rpm range and then flat above that for a Weber head. For a Stromberg head a slower second stage increase to 32 degrees at 6500 rpm was used due to the lower volumetric efficiency of this head at high revs. With the capabilities of modern ignition management systems you should be able to tweek these curves on a dyno to optimise the engine better over the full rev range and throttle opening range for a much more complex ignition timing map.

cheers

Rohan

The required burn time also does not stay constant however but it shortens as the engine revs faster due to increasing turbulence in the combustion chamber but also lengthens as volumetric efficency drops off (either due to revs or due to a part open throttle at cruise), all these factors interact to produce the curve needed.

With simple mechanical distributors the best compromise for a twin cam was a linear increase from an idle of around 10 to 12 degrees to 25 to 28 degrees at the 3000 to 4000 rpm range and then flat above that for a Weber head. For a Stromberg head a slower second stage increase to 32 degrees at 6500 rpm was used due to the lower volumetric efficiency of this head at high revs. With the capabilities of modern ignition management systems you should be able to tweek these curves on a dyno to optimise the engine better over the full rev range and throttle opening range for a much more complex ignition timing map.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8419

- Joined: 22 Sep 2003

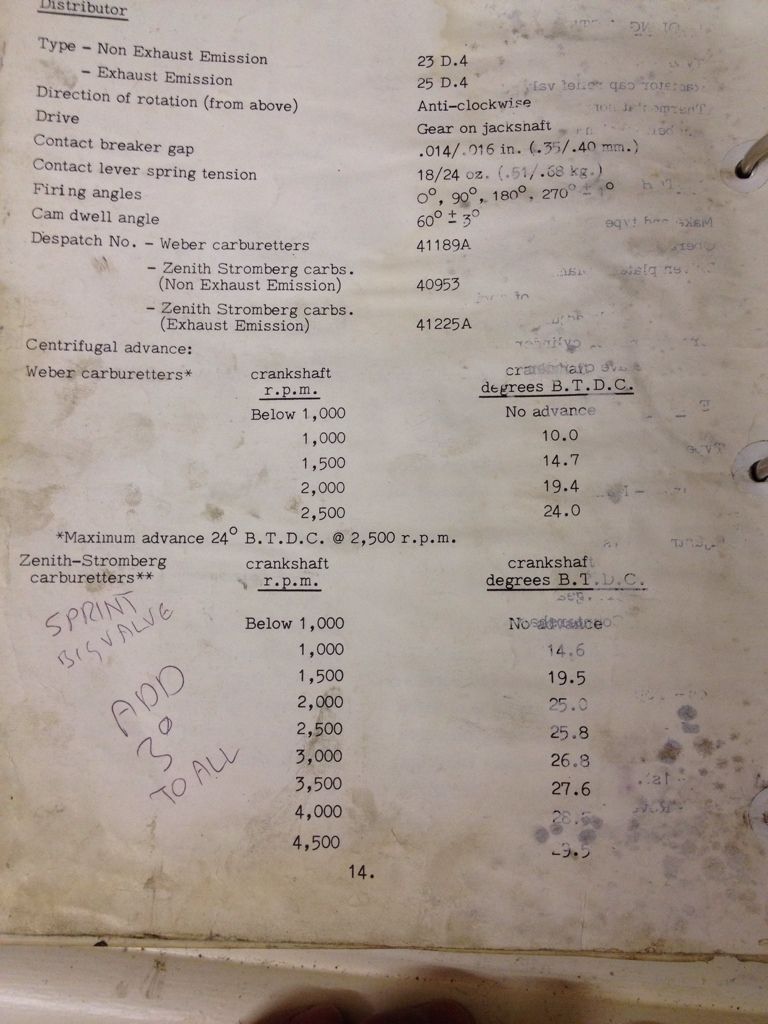

there is a lot of confusion in the various printings of the work shop manual as a combination of errors and lack off specific data and just unexplained changes makes it all unclear.

i.e.

Is static setting included or not

was it crankshaft or distributor rpm or not

which version of curves were used for emission purposes or not

was it just wrong or not

The Wilkins book gives a graph of most of the curve versions as best he could correct for the errors..

The data I gave is what I believe are the best curves to use these days based on my interpretation of the Wilkins and workshop manual data and my own dyno tests. In the end you need to run it on a dyno and determine what suits your engine and fuel combination.

Here are the advance data from my manual - slightly different as you will see

cheers

Rohan

i.e.

Is static setting included or not

was it crankshaft or distributor rpm or not

which version of curves were used for emission purposes or not

was it just wrong or not

The Wilkins book gives a graph of most of the curve versions as best he could correct for the errors..

The data I gave is what I believe are the best curves to use these days based on my interpretation of the Wilkins and workshop manual data and my own dyno tests. In the end you need to run it on a dyno and determine what suits your engine and fuel combination.

Here are the advance data from my manual - slightly different as you will see

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8419

- Joined: 22 Sep 2003

20 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: jdouglas300 and 32 guests