2L Twin Cam build

18 posts

• Page 1 of 2 • 1, 2

Hi

I am gathering parts for a Twin Cam engine build to go in a Lotus 7

I have accrued an Alloy L block [it needs fettling but cost me less than a used iron L block !] it needs liners

I have a Farndon steel , narrow journal ,1600 x-flow crank [77.62mm stroke]

I have steel 'long' rods , 133mm/5.23" [originally I was going down the 711M block route to 1700cc]

I have been reading with great interest through the Elan.net Archive Threads on Twin Cam tuning , particularly with regards to head porting and valve diameters .

I have a couple of issues which I hope you enlightened fellows can help me answer :-

I am assuming my 5.23" rods are going to be too long to feasibly get short enough compression height pistons made

[ I have used 28.5mm height ones in the past - but these are still too tall -]

Is it possible to get shorter than 28.5mm comp. height pistons ? - my dodgy maths make it 25.32mm comp height required !?

The second issue is the head and valve diameters

I would like to use BDG liners [shortened for the L block] - 90.34mm bore

To make best use of the 2L capacity I think the largest available inlet valves should be used - 1.7" with 1.4" exhaust

From what I have read , using the 1.7 in. valves requires the valves to be recessed into the head to give valve clearance on overlap , resulting in an unreliable head structure .

Is there any way this can be overcome , eg by cam selection , running less overlap etc .

Cheers

Carl

I am gathering parts for a Twin Cam engine build to go in a Lotus 7

I have accrued an Alloy L block [it needs fettling but cost me less than a used iron L block !] it needs liners

I have a Farndon steel , narrow journal ,1600 x-flow crank [77.62mm stroke]

I have steel 'long' rods , 133mm/5.23" [originally I was going down the 711M block route to 1700cc]

I have been reading with great interest through the Elan.net Archive Threads on Twin Cam tuning , particularly with regards to head porting and valve diameters .

I have a couple of issues which I hope you enlightened fellows can help me answer :-

I am assuming my 5.23" rods are going to be too long to feasibly get short enough compression height pistons made

[ I have used 28.5mm height ones in the past - but these are still too tall -]

Is it possible to get shorter than 28.5mm comp. height pistons ? - my dodgy maths make it 25.32mm comp height required !?

The second issue is the head and valve diameters

I would like to use BDG liners [shortened for the L block] - 90.34mm bore

To make best use of the 2L capacity I think the largest available inlet valves should be used - 1.7" with 1.4" exhaust

From what I have read , using the 1.7 in. valves requires the valves to be recessed into the head to give valve clearance on overlap , resulting in an unreliable head structure .

Is there any way this can be overcome , eg by cam selection , running less overlap etc .

Cheers

Carl

Last edited by carlt on Sun Apr 29, 2012 4:18 pm, edited 1 time in total.

- carlt

- New-tral

- Posts: 12

- Joined: 21 Feb 2011

carlt wrote: ...OOPS double post - Please delete

Carl,

If you're reading this you can do it yourself. As shown:

Good luck with your eng. build.

Cheers - Richard

- ardee_selby

- Coveted Fifth Gear

- Posts: 1090

- Joined: 30 Sep 2003

Hi Carl

Sounds like a fun project

How much hassle a 1.7 / 1.4 inlet and exhaust valve combination is and whether you really need it at all or not depends like you say on the type of engine you are building and the cam you are going to use.

If you are building a max horsepower 9000 rpm two litre engine then you need them and you will need to recess the valves and do some big big head porting and combustion chamber modifications. You are best to start with one of the new race heads available or an Omnitech conversion if going down this route to have a sound base to work from.

If you are building a big high torque road engine with a shorter duration high lift cam and maybe a 7500 rpm to 8000 rpm max power band then valve clash on overlap will be less of a problem but will probably still need a little recessing of the valves depending on exactly which cam you use. Also a 1.625 inlet valve and the best porting you can get is may be all you need for this sort of engine.

What ever way you go there needs to be very careful assembly and measurement work to make sure no problems as there is no simple answer to use parts A,B and C and bolt them together and it works with what you are doing. Also not easy to set up and measure as the only reliable reference point to work from on these heads is the cam centreline.

The other alternative of having built the bottom end you have is get a BDx head of some description to put on the top

cheers

Rohan

Sounds like a fun project

How much hassle a 1.7 / 1.4 inlet and exhaust valve combination is and whether you really need it at all or not depends like you say on the type of engine you are building and the cam you are going to use.

If you are building a max horsepower 9000 rpm two litre engine then you need them and you will need to recess the valves and do some big big head porting and combustion chamber modifications. You are best to start with one of the new race heads available or an Omnitech conversion if going down this route to have a sound base to work from.

If you are building a big high torque road engine with a shorter duration high lift cam and maybe a 7500 rpm to 8000 rpm max power band then valve clash on overlap will be less of a problem but will probably still need a little recessing of the valves depending on exactly which cam you use. Also a 1.625 inlet valve and the best porting you can get is may be all you need for this sort of engine.

What ever way you go there needs to be very careful assembly and measurement work to make sure no problems as there is no simple answer to use parts A,B and C and bolt them together and it works with what you are doing. Also not easy to set up and measure as the only reliable reference point to work from on these heads is the cam centreline.

The other alternative of having built the bottom end you have is get a BDx head of some description to put on the top

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8415

- Joined: 22 Sep 2003

With 5.23" rods and 28.75mm comp height pistons it's looking like you may be left with the pistons sticking out of the head around 10/11mm if using a Lotus 1558 height block - that means pistons will need to be around 18mm comp height! Using Lotus 125e length rods (i know Genuine Lotus ones won't fit unless modified as you plan on using a narrow journal crank) will get you back to around 28mm comp height but you won't have the best stroke/rod ratio - the rods will have to go through more "angle" at the top of the stroke and therefore pistons don't efficiently put their energy into pushing the crank shaft down and around. It has been done before though - i believe there is a mk2 cortina in USA that uses Lotus block, 85mm pistons and xflow 77.62 crank (1762cc) and the engine SUPPOSEDLY makes 217bhp and 157 lb/ft of torque. I don't know any more of the internal spec but i'm intrigued as those figures are quite high!!

I don't know much about ideal valve sizes and combustion chamber shapes but the pure maths of what fits when the engine is static seems the first issue to me.

Stick with it - i'd love to see it. There's a guy who built a near 2 litre pre-crossflow engine and that's good for around 180bhp. He uses a Lotus block with all custom internal pieces so it's definitely do-able. Of course the pre-crossflow uses a head that is chambered so in theory his set-up could use a Lotus head without too much needing to be changed (valve cutouts in pistons etc etc).

I don't know much about ideal valve sizes and combustion chamber shapes but the pure maths of what fits when the engine is static seems the first issue to me.

Stick with it - i'd love to see it. There's a guy who built a near 2 litre pre-crossflow engine and that's good for around 180bhp. He uses a Lotus block with all custom internal pieces so it's definitely do-able. Of course the pre-crossflow uses a head that is chambered so in theory his set-up could use a Lotus head without too much needing to be changed (valve cutouts in pistons etc etc).

-

promotor - Fourth Gear

- Posts: 798

- Joined: 16 Mar 2012

Can I pass my calculations for required piston compression height by you , as my maths is pretty ropey

Lotus stroke = 72.74mm

BDA/X-flow stroke=77.62mm

difference in stroke = 4.88mm

increase in gudgeon pin height = 2.44mm

Lotus rod length = 4.825"/122.56mm

BDA long rod = 5.23"/132.84mm

difference in rod length = 10.28mm

Total increase in gudgeon pin height = 12.72mm

Lotus piston compression height = 39.00mm

Required Piston compression height : 39.0-12.72 = 26.28mm

Assuming this is correct , I think the Pistons are doable

Going to 1995cc BDG bore will require increasing the combustion chamber volume to get the compression back to usable figures

This being the case , recessing the larger valves could be part of the increase in combustion chamber work

Are the horror stories of unreliable heads with 1.7/1.4 valves based on the Brian Hart heads that were heavily skimmed to bring back the compression ratio for 1600cc race engines with recessed valves/chambers ?

The excessive head skimming should not be necessary as the combustion chamber needs increasing .

So is it the chamber/valve recessing AND/OR the excessive skimming that causes the unreliability in the heads ?

This engine is going to be for Hillclimb/Sprint and occasional sunny day Blats in the country , so no great high mileage longevity required

My thinking on the Twink [other than it is a lovely engine and Very cool] , what is its advantage over a v.hot , all steel x-flow producing 180+bhp ?

The benefit of twin overhead cams over push rods is Revs.

So , build an engine that can rev

Cheers

Carl

Lotus stroke = 72.74mm

BDA/X-flow stroke=77.62mm

difference in stroke = 4.88mm

increase in gudgeon pin height = 2.44mm

Lotus rod length = 4.825"/122.56mm

BDA long rod = 5.23"/132.84mm

difference in rod length = 10.28mm

Total increase in gudgeon pin height = 12.72mm

Lotus piston compression height = 39.00mm

Required Piston compression height : 39.0-12.72 = 26.28mm

Assuming this is correct , I think the Pistons are doable

Going to 1995cc BDG bore will require increasing the combustion chamber volume to get the compression back to usable figures

This being the case , recessing the larger valves could be part of the increase in combustion chamber work

Are the horror stories of unreliable heads with 1.7/1.4 valves based on the Brian Hart heads that were heavily skimmed to bring back the compression ratio for 1600cc race engines with recessed valves/chambers ?

The excessive head skimming should not be necessary as the combustion chamber needs increasing .

So is it the chamber/valve recessing AND/OR the excessive skimming that causes the unreliability in the heads ?

This engine is going to be for Hillclimb/Sprint and occasional sunny day Blats in the country , so no great high mileage longevity required

My thinking on the Twink [other than it is a lovely engine and Very cool] , what is its advantage over a v.hot , all steel x-flow producing 180+bhp ?

The benefit of twin overhead cams over push rods is Revs.

So , build an engine that can rev

Cheers

Carl

- carlt

- New-tral

- Posts: 12

- Joined: 21 Feb 2011

Jay Leno is building a very customized Elan with a 2L all aluminum engine. (See jaylenosgarage.com) They are claiming 250HP. Perhaps he and/or Jim Hall, his fabricator, can help with the parts necessary to build this engine. It should be a screamer.

Herb

26/4618

Herb

26/4618

Herb

26/4618

26/4618

-

lotusS2guy - Second Gear

- Posts: 98

- Joined: 05 Oct 2010

Yes you're right - my maths was out so i apologize - Lotus block height is approx 197mm (top of deck to centre line of crank not sump face) which is the figure i got wrong! Short height pistons like you mention would do it - and if they were light it would help ease the stresses on the rods and bearings etc.

-

promotor - Fourth Gear

- Posts: 798

- Joined: 16 Mar 2012

carlt wrote:Can I pass my calculations for required piston compression height by you , as my maths is pretty ropey

Going to 1995cc BDG bore will require increasing the combustion chamber volume to get the compression back to usable figures

This being the case , recessing the larger valves could be part of the increase in combustion chamber work

Are the horror stories of unreliable heads with 1.7/1.4 valves based on the Brian Hart heads that were heavily skimmed to bring back the compression ratio for 1600cc race engines with recessed valves/chambers ?

The excessive head skimming should not be necessary as the combustion chamber needs increasing .

So is it the chamber/valve recessing AND/OR the excessive skimming that causes the unreliability in the heads ?

This engine is going to be for Hillclimb/Sprint and occasional sunny day Blats in the country , so no great high mileage longevity required

My thinking on the Twink [other than it is a lovely engine and Very cool] , what is its advantage over a v.hot , all steel x-flow producing 180+bhp ?

The benefit of twin overhead cams over push rods is Revs.

So , build an engine that can rev

Cheers

Carl

You can get 180 to190 hp in a road tractable 1600 twin cam in a Seven with a 8700 rpm rev limit. With 2 litres you can get the same hp at lower revs or somewhat more at similar revs. How much more really depends on how well you can make the engine breath but i think you would struggle to get the head to breath much above 210 to 220 hp no matter how big and engine you put underneath it.

The challenges with HART heads were as I understand them.

1. Recessing the valves required head skimming to get the right compression ratio was required in a 1600 as you say. The high comp ratio and ocmbustion pressures also stressed the heads and their bolts and head gaskets. Better bolts / head studs and head gaskets these days help

2. The big ports required left minimal metal between the port and vlave pocket and port and water jackets and in the inlet runners themselves. This plus the first point just took a lot of metal and strength out of the head but was OK as the heads were intended to just last a few races anyhow. The new castings or the McCoy conversion over come these issue to a great degree.

3. With the long duration cams and relatively gentle profile in the race cams of that era you had a lot of lift on overlap and any error in valve timing or valves not following the cams meant a disastrous valve clash. The modern race cams are better in this respect but you still dont have much room to play with.

4. Valve springs were not as good in those days and you struggled to fit the high lift springs needed into the space aviailable. This is not such a challenge these days and you dont need to deepen the vlave pockets like you did then.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8415

- Joined: 22 Sep 2003

elan-for-sale-f2/alloy-711m-block-t17907-15.html

Cylinder-head LP3470

Hi Carl

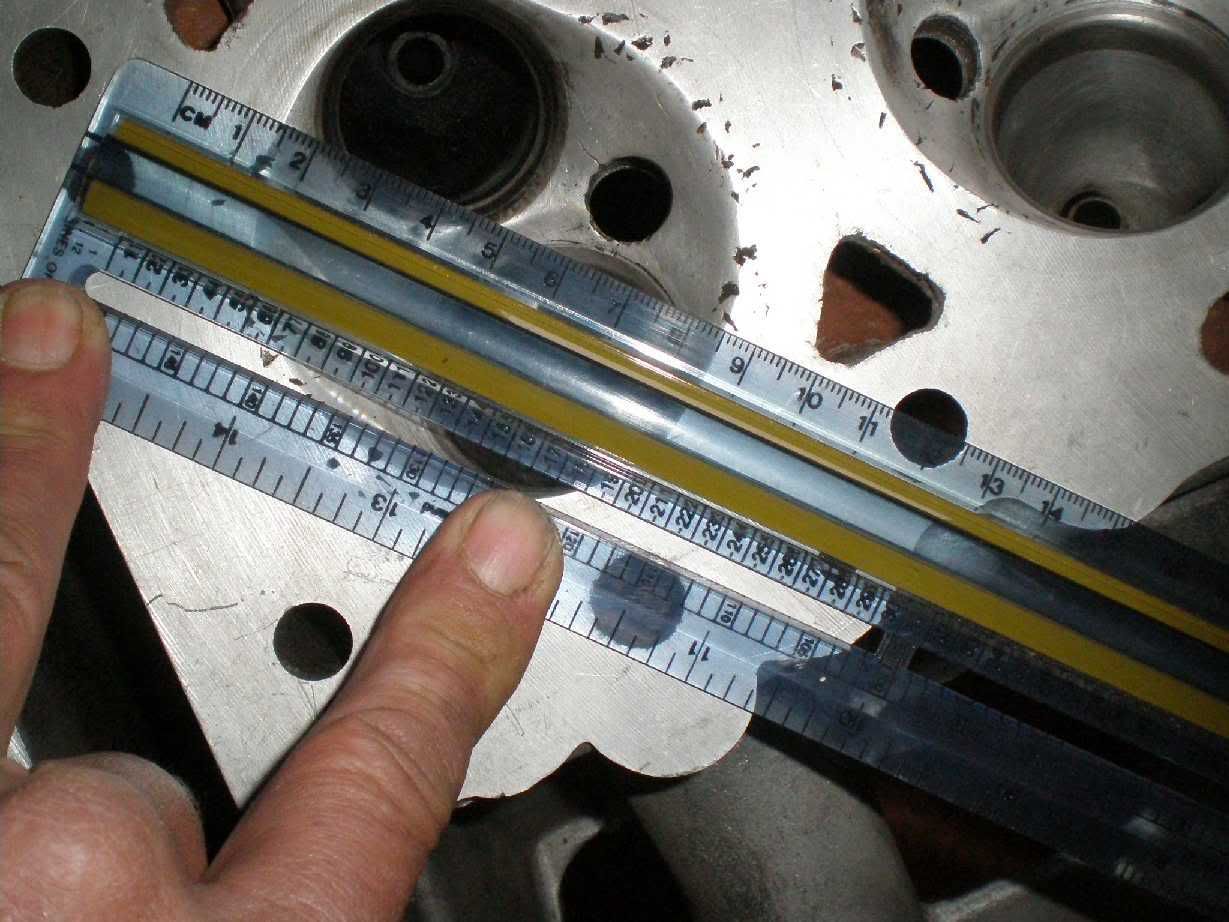

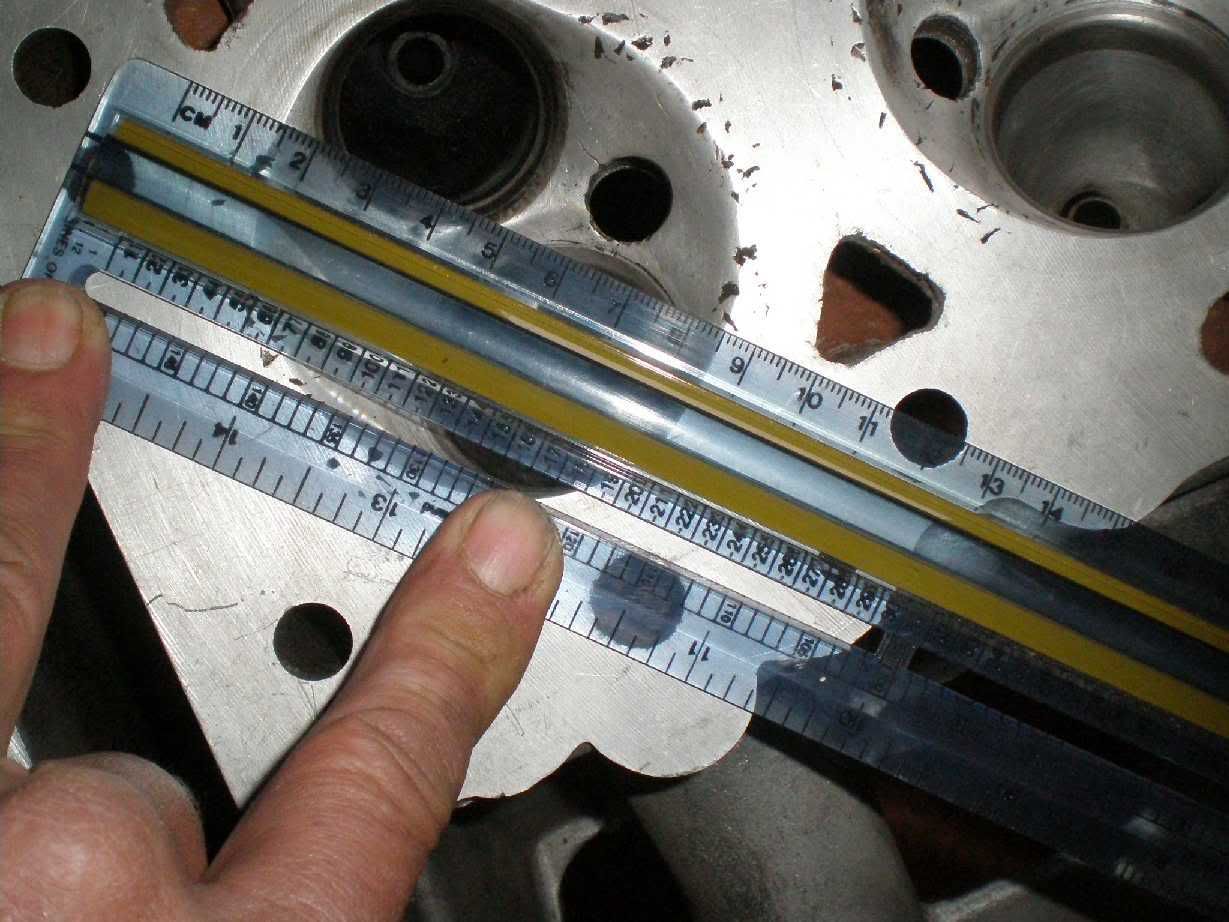

I would get a used head gasket for a 90.x mm bore BDG engine and lay it on the proposed twin cam cylinder-head before you get to far. A couple more pictures of a different head (LP7160)

The next thing would be to sell the current rods you have and get something a bit shorter. I have heard in the past that JE will do a pin height of (from my bad memory) of .98 inch but that is squishing the ring pack real tight and may not be a good street engine. My 2 liter has been on hold for a number of years now, my combo is an alloy tall deck KAM block that will (if it ever happens) be an 87mm bore (current size) with an 82mm stroke, 5.23 inch rods and 1.35 pin height or there abouts.

Gary

Cylinder-head LP3470

Hi Carl

I would get a used head gasket for a 90.x mm bore BDG engine and lay it on the proposed twin cam cylinder-head before you get to far. A couple more pictures of a different head (LP7160)

The next thing would be to sell the current rods you have and get something a bit shorter. I have heard in the past that JE will do a pin height of (from my bad memory) of .98 inch but that is squishing the ring pack real tight and may not be a good street engine. My 2 liter has been on hold for a number of years now, my combo is an alloy tall deck KAM block that will (if it ever happens) be an 87mm bore (current size) with an 82mm stroke, 5.23 inch rods and 1.35 pin height or there abouts.

Gary

-

garyeanderson - Coveted Fifth Gear

- Posts: 2626

- Joined: 12 Sep 2003

Yeah to go to really big bores such as a 90 mm bore you need to weld up and redrill the water holes in the face - just one of the many little challenges. I have a spare head here someone I think where that was done prior to me acquiring it.

The biggest issue with the low compression height and big valves is keep the cut outs in the piston clear of the ring grooves

cheers

Rohan

The biggest issue with the low compression height and big valves is keep the cut outs in the piston clear of the ring grooves

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8415

- Joined: 22 Sep 2003

piss-ant wrote:http://www.lotuselan.net/forums/elan-for-sale-f2/alloy-711m-block-t17907-15.html

Hi Carl

I would get a used head gasket for a 90.x mm bore BDG engine and lay it on the proposed twin cam cylinder-head before you get to far. A couple more pictures of a different head (LP7160)

The next thing would be to sell the current rods you have and get something a bit shorter. I have heard in the past that JE will do a pin height of (from my bad memory) of .98 inch but that is squishing the ring pack real tight and may not be a good street engine. My 2 liter has been on hold for a number of years now, my combo is an alloy tall deck KAM block that will (if it ever happens) be an 87mm bore (current size) with an 82mm stroke, 5.23 inch rods and 1.35 pin height or there abouts.

Gary

Good shout re the BDG gasket , I had measured with a disc of card , but that doesn't give a true measurement

Does the second head in the pictures have recessed valves , it has unusual [in my experience] relieving around the edges of the combustion chamber at the valves.

I had thought of selling the 5.23" rods and using Lotus long rods 5.1" , but ultimately the 5.23" rods are the length of choice for all the experienced/good/famous engine builders , when using the 77.62mm stroke crank .

26.28mm comp height = 1.035" , I have used 28.5mm/1.131" JE pistons where the oil ring cuts across the top of the piston pin bore to give more space to the ring pack

It gives a very light piston as well !

Rohan , I see your thread on valve springs - will be interested in your results

A bit of a misnomer I know - but believe me , so far this is still a budget build

- carlt

- New-tral

- Posts: 12

- Joined: 21 Feb 2011

elan-f14/sows-ear-chassis-t24752-45.html

For info on the head read this topic starting at the 14th post on that page. I have owned it for 36 years and its not been apart since 1978 till 10 days ago. I can't tell you much about it other that its as tired as I am and it had some reground cams that had .390 lift and probably quite a few valve jobs before I bought it. I would guess that the BDG head gaskets have about 91.5mm i.d. maybe 92, Mark might know as he has one.

Gary

this photo of the head gasket is what I got with the 87 mm bore KAM block. it looks like 88mm on the i.d.

For info on the head read this topic starting at the 14th post on that page. I have owned it for 36 years and its not been apart since 1978 till 10 days ago. I can't tell you much about it other that its as tired as I am and it had some reground cams that had .390 lift and probably quite a few valve jobs before I bought it. I would guess that the BDG head gaskets have about 91.5mm i.d. maybe 92, Mark might know as he has one.

Gary

this photo of the head gasket is what I got with the 87 mm bore KAM block. it looks like 88mm on the i.d.

-

garyeanderson - Coveted Fifth Gear

- Posts: 2626

- Joined: 12 Sep 2003

18 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 31 guests