Deck height

23 posts

• Page 1 of 2 • 1, 2

I have always suspected that my cylinder block had been skimmed. Last time I had the head off I took a few measurements and found the top of the pistons 5 thou above the surface of the block. How does this compare to a standard engine? Searching back through the forum suggests they should be 25 thou below the surface at TDC. Has anyone with an unmodified engine measured this?

Alan.

Alan.

- alan71

- Second Gear

- Posts: 219

- Joined: 15 Jul 2007

The nominal standard dimensions as I understand them are as follows:

Crank centreline to block top 198.0 mm. Note the crank centreline is slightly above the bottom of the block bottom face thus less than the 200mm total block height. Blocks may not have had the top deck skimmed but may have been line bored moving the crank location and this needs to be checked.

The moving parts assembly dimensions are as follows

Half crank stroke = 72.75/2 = 36.38mm

Rod bearing centre length = 121.91mm

Piston deck height above centre of rod small end= 39.04mm

Total height of assembly at TDC above crank centreline = 197.33mm

Thus clearance of piston deck to top of block = 0.67mm

Tolerance on this clearance would have been around +/- 0.2 mm

hope this helps

cheers

Rohan

Crank centreline to block top 198.0 mm. Note the crank centreline is slightly above the bottom of the block bottom face thus less than the 200mm total block height. Blocks may not have had the top deck skimmed but may have been line bored moving the crank location and this needs to be checked.

The moving parts assembly dimensions are as follows

Half crank stroke = 72.75/2 = 36.38mm

Rod bearing centre length = 121.91mm

Piston deck height above centre of rod small end= 39.04mm

Total height of assembly at TDC above crank centreline = 197.33mm

Thus clearance of piston deck to top of block = 0.67mm

Tolerance on this clearance would have been around +/- 0.2 mm

hope this helps

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

ncm wrote:Hi Alan, according to Haynes standard block height for the 1500cc pre-xflow engine was 7.891-7.896 inches ( 200.4-200.6 mm if you prefer..). As far as I am aware Lotus did not machine the deck of the block when building the twincam.

Brian.

There seems like there is some discrepency in the Haynes figure

http://www.lotuselan.net/forums/viewtopic.php?t=7935

Rohan mentions it again hear

http://www.lotuselan.net/forums/viewtopic.php?t=1372

Stan mentions 7.91 inch in this note

http://www.lotuselan.net/forums/viewtopic.php?t=7045

Possibly the 7.91 is the height of the block from the panrail to the cylinder head deck and 7.78 is the height of the crankshaft centerline to the top of the cylinder head deck.

Gary

-

garyeanderson - Coveted Fifth Gear

- Posts: 2634

- Joined: 12 Sep 2003

Hi gary

Yes the difference I beleive is the small step in the bottom block flange where the bearing caps mount of about 2mm.

You also note from my posts that I have changed my nominal standard for crank centreline to block top from 197.6 - 197.8mm to 198.0mm over the years as I have measured more blocks and considered more closely what I think Ford was trying to achieve without access to the original dimensioned drawings.

I see a 0.2mm variation in crank centreline to block height across the length of the block commonly as Ford were not good at getting them parallel either

cheers

Rohan

Yes the difference I beleive is the small step in the bottom block flange where the bearing caps mount of about 2mm.

You also note from my posts that I have changed my nominal standard for crank centreline to block top from 197.6 - 197.8mm to 198.0mm over the years as I have measured more blocks and considered more closely what I think Ford was trying to achieve without access to the original dimensioned drawings.

I see a 0.2mm variation in crank centreline to block height across the length of the block commonly as Ford were not good at getting them parallel either

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

Thanks for the replies they are really helpful

So it looks like I have lost 30 thou off the block. I hadn?t thought of it being the result of line boring but I suppose the result is the same, I need a thicker head gasket. That raises a few questions

How thick is the original gasket when compressed.

Which type to choose, some manufactures recommend the surface finish required. The top surface of my block has quite course looking machining marks.

Does it matter that most replacement gaskets don?t have the restricted coolant holes the original had.

Thanks for your help, Alan.

So it looks like I have lost 30 thou off the block. I hadn?t thought of it being the result of line boring but I suppose the result is the same, I need a thicker head gasket. That raises a few questions

How thick is the original gasket when compressed.

Which type to choose, some manufactures recommend the surface finish required. The top surface of my block has quite course looking machining marks.

Does it matter that most replacement gaskets don?t have the restricted coolant holes the original had.

Thanks for your help, Alan.

- alan71

- Second Gear

- Posts: 219

- Joined: 15 Jul 2007

Alan

Your pistons appear to have a small intruder above the deck height did you measure the top of the intruder or the top of the ring around it to get the piston 5 thou above the top of block. My clearance specification is to the top of that ring around any intruder. If its the intruder above the top of the block and not the surrounding ring then you may not need a thicker gasket.

If its the surrounding ring above above the block top then apart from a thicker gasket you need to ensure the gasket fire ring does not overlap the bore anywhere which given tolerances and bore size may mean using a special larger bore gasket. You need a minimum of around 1.0 mm from piston deck top to bottom of cylinder head to ensure no clash when bearings wear and components stretch at full revs.

Original gasket uncompressed approx 0.8mm and compressed is around 0.6mm. Modern composite gaskets up to around 2.2 mm thickness uncompressed available in Australia at least. These compress down to around 1.7mm

Normal required surface finish is very fine tooling marks you can just see and just feel. The surface should not be polished. However you do need to check finish required versus the gasket being used to make sure and measure it properly if uncertain.

I always use modern composite style gaskets these days as they are more tolerant of distortion and head to block movement than the orginal copper steel laminate.

The smaller holes in the gaskets are important to get the coolant flow correct for the Lotus cross flow head. Otherwise you dont get enough flow around the exhaust valve area.

cheers

Rohan

Your pistons appear to have a small intruder above the deck height did you measure the top of the intruder or the top of the ring around it to get the piston 5 thou above the top of block. My clearance specification is to the top of that ring around any intruder. If its the intruder above the top of the block and not the surrounding ring then you may not need a thicker gasket.

If its the surrounding ring above above the block top then apart from a thicker gasket you need to ensure the gasket fire ring does not overlap the bore anywhere which given tolerances and bore size may mean using a special larger bore gasket. You need a minimum of around 1.0 mm from piston deck top to bottom of cylinder head to ensure no clash when bearings wear and components stretch at full revs.

Original gasket uncompressed approx 0.8mm and compressed is around 0.6mm. Modern composite gaskets up to around 2.2 mm thickness uncompressed available in Australia at least. These compress down to around 1.7mm

Normal required surface finish is very fine tooling marks you can just see and just feel. The surface should not be polished. However you do need to check finish required versus the gasket being used to make sure and measure it properly if uncertain.

I always use modern composite style gaskets these days as they are more tolerant of distortion and head to block movement than the orginal copper steel laminate.

The smaller holes in the gaskets are important to get the coolant flow correct for the Lotus cross flow head. Otherwise you dont get enough flow around the exhaust valve area.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

Rohan

I was measuring from the centre of the piston, the ring around the edge is 7 thou below the block. With the standard gasket this still gives less clearance than you recommend.

Burton Power sell a gasket with a 1mm crushed thickness and larger bore size but it has the big coolant holes. I can?t find any other gaskets with the small holes.

Alan

I was measuring from the centre of the piston, the ring around the edge is 7 thou below the block. With the standard gasket this still gives less clearance than you recommend.

Burton Power sell a gasket with a 1mm crushed thickness and larger bore size but it has the big coolant holes. I can?t find any other gaskets with the small holes.

Alan

- alan71

- Second Gear

- Posts: 219

- Joined: 15 Jul 2007

Hi Alan

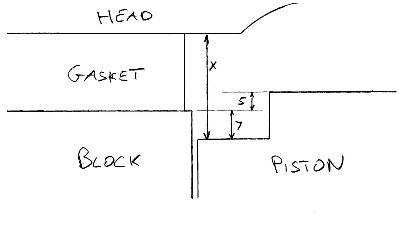

You want your dimension X to be around 1 mm minimum and ensure you have no overlap of the head gasket with the bore at any point and you need to check you compression ration to see what you have..

In standard engines X is around 1.3 mm but you can reduce to around 1.0 mm if you have to but you will have a higher compression ration with this reduced dimension and the intruder as well and you need to determine the copression ratio and selct a suitable gasket which may be thicker. than what needed for just piston to head clearance. You also need to check the intruder to cylinder head bowl clearance at its closet point as this may be less than the piston deck to cylinder head base clearance at its closest point.

The Elan Factory in Australia should be able to supply a suitable gasket with the needed bore and thickness and the correct coolant holes to satisfy your needs if no one else can locally.

cheers

Rohan

You want your dimension X to be around 1 mm minimum and ensure you have no overlap of the head gasket with the bore at any point and you need to check you compression ration to see what you have..

In standard engines X is around 1.3 mm but you can reduce to around 1.0 mm if you have to but you will have a higher compression ration with this reduced dimension and the intruder as well and you need to determine the copression ratio and selct a suitable gasket which may be thicker. than what needed for just piston to head clearance. You also need to check the intruder to cylinder head bowl clearance at its closet point as this may be less than the piston deck to cylinder head base clearance at its closest point.

The Elan Factory in Australia should be able to supply a suitable gasket with the needed bore and thickness and the correct coolant holes to satisfy your needs if no one else can locally.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

The 120E block that I'm currently building up as a Twin Cam from a pushrod has cleaned up after line boring for steel caps to 7.786".

So, I make that as 9 thou off standard if standard is nominated as 198mm.

So, I make that as 9 thou off standard if standard is nominated as 198mm.

Ford Escort Mk1 Lotus Twin Cam

Elfin Monocoque (Twin Cam)

Elfin Type 300 (Holbay S65 - 120E) mechanic

[email protected]

Elfin Monocoque (Twin Cam)

Elfin Type 300 (Holbay S65 - 120E) mechanic

[email protected]

-

SJ Lambert - Fourth Gear

- Posts: 681

- Joined: 19 Nov 2010

Is it appropriate to use a gasket that's fire rings are one millimetre larger than your build diameter?

If you're working with bores that are 81.5 mm & 83.5mm & are struggling to get gaskets at 82.5 & 84.5 should I go next half mm up or 1.5 mm larger than bore size?

Are Cometic gaskets better suited to alloy heads on alloy blocks & iron heads on iron blocks or are they equally suited to alloy heads on iron blocks.

What's the preferred gasket construction for racing engines on Avgas?

If you're working with bores that are 81.5 mm & 83.5mm & are struggling to get gaskets at 82.5 & 84.5 should I go next half mm up or 1.5 mm larger than bore size?

Are Cometic gaskets better suited to alloy heads on alloy blocks & iron heads on iron blocks or are they equally suited to alloy heads on iron blocks.

What's the preferred gasket construction for racing engines on Avgas?

Last edited by SJ Lambert on Sat Aug 03, 2013 10:44 pm, edited 1 time in total.

Ford Escort Mk1 Lotus Twin Cam

Elfin Monocoque (Twin Cam)

Elfin Type 300 (Holbay S65 - 120E) mechanic

[email protected]

Elfin Monocoque (Twin Cam)

Elfin Type 300 (Holbay S65 - 120E) mechanic

[email protected]

-

SJ Lambert - Fourth Gear

- Posts: 681

- Joined: 19 Nov 2010

Hi James

I use composite fibre gaskets made locally by the guy who supplies the Elan Factory. He will make them in what ever bore size you want I think and also in a range of thicknesses. I normally use a 85mm gasket in my 83.5mm bore race engines.

The guy is Dale Collet at HJ Gaskets 9844 1822 he is in North Warrandyte

Cometic gaskets are a problem getting to seal in twin cams for some reason. I know of 2 guys who are good engine builders who have tried them and have followed all the surface finish recommendation and who use ARP head studs at higher torque loads than standard and they have still had major water leaks into the bores and gone back to the composite fibre ones. I personally have not tried them due to these problems

cheers

Rohan

I use composite fibre gaskets made locally by the guy who supplies the Elan Factory. He will make them in what ever bore size you want I think and also in a range of thicknesses. I normally use a 85mm gasket in my 83.5mm bore race engines.

The guy is Dale Collet at HJ Gaskets 9844 1822 he is in North Warrandyte

Cometic gaskets are a problem getting to seal in twin cams for some reason. I know of 2 guys who are good engine builders who have tried them and have followed all the surface finish recommendation and who use ARP head studs at higher torque loads than standard and they have still had major water leaks into the bores and gone back to the composite fibre ones. I personally have not tried them due to these problems

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

Thanks Rohan,

I've been buying composite gaskets from Larners. They may well be using your guy to put theirs together!

I've been buying composite gaskets from Larners. They may well be using your guy to put theirs together!

Ford Escort Mk1 Lotus Twin Cam

Elfin Monocoque (Twin Cam)

Elfin Type 300 (Holbay S65 - 120E) mechanic

[email protected]

Elfin Monocoque (Twin Cam)

Elfin Type 300 (Holbay S65 - 120E) mechanic

[email protected]

-

SJ Lambert - Fourth Gear

- Posts: 681

- Joined: 19 Nov 2010

23 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 19 guests