Heater valve clearance?

46 posts

• Page 3 of 4 • 1, 2, 3, 4

Well I did some checks over the weekend and here are the results:-

Exhaust is about 1/8" away from the lower bulge in the passenger footwell (really close).

Exhaust misses the un-butchered galv chassis by about the same amount !

Engine mount spacers are on the correct (exhaust side).

Engine mount seems to be ok, with about 8mm clearance between the top metal hoop and the top of the rubber.

Heater valve is opposite hand to the original one, but your previous comments seem to suggest this may be the correct one, as you say the other hand is not available? Do you think the one I'm using is the correct hand ? - the largest part of the riveted flange is on the top?

No washers spacing the body, as the body / chassis fit is a reasonable one - (as reasonable as any Galvanised one - I'm led to believe the painted only ones don't distort due to not being hot Galv dipped?).

Not checked the Rockerbox filler cap / bonnet clearance yet, as timing still to be done, and the r/box isn't fitted yet!

So everything clearance wise, seems to be on the upper limits ? (I.e. TIGHT FIT !)

I've ordered some 1mm heat reflectant to stick to the footwell, I'll distort the Phnumatic pipes run away from the exhaust, I'll buy another L/H engine mount - to pick the one with most clearance.

What's the story with the Bulge in the footwell wall -anybody know ?

Might have to notch the chassis to give better exhaust clearance - (but surely the Sprints were all fitted with tubular down pipes so I can't understand why there is a tight fit here ?) - although having said that, I remember at the time of purchase from Paul Matty, there was some talk of a batch of Stainless Steel exhaust systems being a bad fit, mine was tight but I was so relieved to get it fitted at all, that I may have not realised it was too tight a fit ? - May need to ' Persuade - it', a little.?

Still all very tight !

Problem not really resolved, but I'm sure I'll / you'll find the answer eventually, or is it just a "live with it" situation do you think ?

Thoughts please?

Regards,

Phil.

Exhaust is about 1/8" away from the lower bulge in the passenger footwell (really close).

Exhaust misses the un-butchered galv chassis by about the same amount !

Engine mount spacers are on the correct (exhaust side).

Engine mount seems to be ok, with about 8mm clearance between the top metal hoop and the top of the rubber.

Heater valve is opposite hand to the original one, but your previous comments seem to suggest this may be the correct one, as you say the other hand is not available? Do you think the one I'm using is the correct hand ? - the largest part of the riveted flange is on the top?

No washers spacing the body, as the body / chassis fit is a reasonable one - (as reasonable as any Galvanised one - I'm led to believe the painted only ones don't distort due to not being hot Galv dipped?).

Not checked the Rockerbox filler cap / bonnet clearance yet, as timing still to be done, and the r/box isn't fitted yet!

So everything clearance wise, seems to be on the upper limits ? (I.e. TIGHT FIT !)

I've ordered some 1mm heat reflectant to stick to the footwell, I'll distort the Phnumatic pipes run away from the exhaust, I'll buy another L/H engine mount - to pick the one with most clearance.

What's the story with the Bulge in the footwell wall -anybody know ?

Might have to notch the chassis to give better exhaust clearance - (but surely the Sprints were all fitted with tubular down pipes so I can't understand why there is a tight fit here ?) - although having said that, I remember at the time of purchase from Paul Matty, there was some talk of a batch of Stainless Steel exhaust systems being a bad fit, mine was tight but I was so relieved to get it fitted at all, that I may have not realised it was too tight a fit ? - May need to ' Persuade - it', a little.?

Still all very tight !

Problem not really resolved, but I'm sure I'll / you'll find the answer eventually, or is it just a "live with it" situation do you think ?

Thoughts please?

Regards,

Phil.

Philip.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

-

l10tus - Third Gear

- Posts: 476

- Joined: 10 Apr 2008

Looks like you need to do a set of "minor" adjustments

The exhaust mount looks like it is a few mm closer between the centre steel section and the inverted U than typical. A new mount may help that and slotting the holes in the mount to lift the engine a little will help also. The heater valve certainly orginally had the cable and lever on the bottom which I beleive provided more clearance. If you cant source this valve then raising the negine should help or fitting an elbow and a different style of valve in the hose may also be a solution.

The exhaust looks like it has not been bent quite right as it comes to close to the body at the bulge where the steering column comes out in a left hand drive car. It looks like your exhaust pipes are bigger diameter? than the standard sprint ones (which were very small) most people seem to notch the chassis to fit in the bigger diameter pipes and still dont have problems with them being to close to the body. If you cant get a new set of exhaust headers or rebend the ones you have a little I would probably put additional spacers on the LH side of the engine to move the engine about 5mm further to the right to increase clearances.between body and chassis and pipes. The RH engine mount will need its holes slotted to accomodate this movement. Check clearances on the RH side with things like the oil pump and steering column to ensure you can move it across OK.

cheers

Rohan

The exhaust mount looks like it is a few mm closer between the centre steel section and the inverted U than typical. A new mount may help that and slotting the holes in the mount to lift the engine a little will help also. The heater valve certainly orginally had the cable and lever on the bottom which I beleive provided more clearance. If you cant source this valve then raising the negine should help or fitting an elbow and a different style of valve in the hose may also be a solution.

The exhaust looks like it has not been bent quite right as it comes to close to the body at the bulge where the steering column comes out in a left hand drive car. It looks like your exhaust pipes are bigger diameter? than the standard sprint ones (which were very small) most people seem to notch the chassis to fit in the bigger diameter pipes and still dont have problems with them being to close to the body. If you cant get a new set of exhaust headers or rebend the ones you have a little I would probably put additional spacers on the LH side of the engine to move the engine about 5mm further to the right to increase clearances.between body and chassis and pipes. The RH engine mount will need its holes slotted to accomodate this movement. Check clearances on the RH side with things like the oil pump and steering column to ensure you can move it across OK.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8415

- Joined: 22 Sep 2003

Phil,

Further to Rohan's reply, some pictures of my 68 S4. Your engine mount definitely looks to have sagged badly. I have an old one that is similar, they take up a "set" and can't be saved. Replacement, probably of both, is the cure to your clearance problems.

Cheers,

Colin.

Further to Rohan's reply, some pictures of my 68 S4. Your engine mount definitely looks to have sagged badly. I have an old one that is similar, they take up a "set" and can't be saved. Replacement, probably of both, is the cure to your clearance problems.

Cheers,

Colin.

'68 S4 DHC

- fatboyoz

- Fourth Gear

- Posts: 631

- Joined: 04 Oct 2003

Rohan, Colin,

Really appreciate your replies, thanks for the in depth info and great pictures.

Colin,

Wow ! the picture of your L/H engine mount is miles different to mine, massive amount of clearance compared to mine! ( although, I suppose it does compress a little when weighted down with the engine ? )

Just can't understand why my mount has collapsed - never had the engine running since being installed !? - unless it was one from the 'bad batch' perhaps ?

I'll definitely buy a new one now!

Must admit, it was difficult to install the pipes - (but still didn't need to notch the chassis) but I guess if the engine position has sagged a little, it has maybe caused 'twist ' and hence that's why the pipes are nearer the fibreglass footwell ?

Rohan,

When you say 'slot the holes' - won't this cause the engine to eventually drop again, due to friction giving way to the weight of the engine ? (Or do you weld up the top of the hole when slotted? )

Do you slot the engine holes, or the ones into the chassis - not sure what you mean?

I wonder which application my 'opposite hand' heater valve is from ? - as it does give a straight pull / push on the cable operation - which I quite like !

I'll obtain and fit the new L/H mount and see where that puts me, before replacing the other items.

Great support, thanks once again!

Regards,

Phil.

Really appreciate your replies, thanks for the in depth info and great pictures.

Colin,

Wow ! the picture of your L/H engine mount is miles different to mine, massive amount of clearance compared to mine! ( although, I suppose it does compress a little when weighted down with the engine ? )

Just can't understand why my mount has collapsed - never had the engine running since being installed !? - unless it was one from the 'bad batch' perhaps ?

I'll definitely buy a new one now!

Must admit, it was difficult to install the pipes - (but still didn't need to notch the chassis) but I guess if the engine position has sagged a little, it has maybe caused 'twist ' and hence that's why the pipes are nearer the fibreglass footwell ?

Rohan,

When you say 'slot the holes' - won't this cause the engine to eventually drop again, due to friction giving way to the weight of the engine ? (Or do you weld up the top of the hole when slotted? )

Do you slot the engine holes, or the ones into the chassis - not sure what you mean?

I wonder which application my 'opposite hand' heater valve is from ? - as it does give a straight pull / push on the cable operation - which I quite like !

I'll obtain and fit the new L/H mount and see where that puts me, before replacing the other items.

Great support, thanks once again!

Regards,

Phil.

Philip.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

-

l10tus - Third Gear

- Posts: 476

- Joined: 10 Apr 2008

I slot the engine mount holes if I need for engine vertical alignment fine tuning. I don't touch the chassis holes. If you clamp up the bolts tight it will not move in the slots. However if you want to be certain of a positive alignment you can then tack weld a washer in the position you end up with just be careful not to put to much heat into the mount or you will damage the rubber when doing the tack welds

cheers

Rohan

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8415

- Joined: 22 Sep 2003

Rohan, Colin,

Thanks for the reply, I understand what you mean now. I'll obtain a new engine mount first.

I just can 't believe how much more rubber there is on the green engine mount, should / are they all this sort of set up, (I don't think mine was ever quite like!)

If I can obtain one similar, it should sort out my original issue ok.

Can't remember who I brought mine off originally, is there a preferred supplier of the larger mount - do you know ?

Regards,

Phil.

Thanks for the reply, I understand what you mean now. I'll obtain a new engine mount first.

I just can 't believe how much more rubber there is on the green engine mount, should / are they all this sort of set up, (I don't think mine was ever quite like!)

If I can obtain one similar, it should sort out my original issue ok.

Can't remember who I brought mine off originally, is there a preferred supplier of the larger mount - do you know ?

Regards,

Phil.

Philip.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

-

l10tus - Third Gear

- Posts: 476

- Joined: 10 Apr 2008

Phil,

The engine mounts are not larger than standard. The gap at the top is just filled in with rubber.

You can buy them from various places, here are a couple of examples:

http://www.rdent.com/ (select Elan parts and spool down about 2/3)

ON this page, you will find the engine mounts and the correct heater valve:

http://qedmotorsport.co.uk/qed-shop/lot ... ncillaries

Here is a internet search for images of the engine mounts:

http://www.google.com.au/search?q=heavy ... 24&bih=690

Cheers,

Colin.

The engine mounts are not larger than standard. The gap at the top is just filled in with rubber.

You can buy them from various places, here are a couple of examples:

http://www.rdent.com/ (select Elan parts and spool down about 2/3)

ON this page, you will find the engine mounts and the correct heater valve:

http://qedmotorsport.co.uk/qed-shop/lot ... ncillaries

Here is a internet search for images of the engine mounts:

http://www.google.com.au/search?q=heavy ... 24&bih=690

Cheers,

Colin.

l10tus wrote:Rohan, Colin,

Thanks for the reply, I understand what you mean now. I'll obtain a new engine mount first.

I just can 't believe how much more rubber there is on the green engine mount, should / are they all this sort of set up, (I don't think mine was ever quite like!)

If I can obtain one similar, it should sort out my original issue ok.

Can't remember who I brought mine off originally, is there a preferred supplier of the larger mount - do you know ?

Regards,

Phil.

'68 S4 DHC

- fatboyoz

- Fourth Gear

- Posts: 631

- Joined: 04 Oct 2003

Colin,

I received my new mount from QED, also new heater valve from Sue Miller (nice fast delivery on both, by the way!) the mount is one of the heavy duty ones you recommended and appears to be less likely to sag.

The heater valve is now the correct orientation also.

I won't be fitting them for a few days, but I'll post a reply when complete, to hopefully wrap up the issues I've experienced.

Thanks for your help, also to everyone who assisted,

Regards,

Phil.

I received my new mount from QED, also new heater valve from Sue Miller (nice fast delivery on both, by the way!) the mount is one of the heavy duty ones you recommended and appears to be less likely to sag.

The heater valve is now the correct orientation also.

I won't be fitting them for a few days, but I'll post a reply when complete, to hopefully wrap up the issues I've experienced.

Thanks for your help, also to everyone who assisted,

Regards,

Phil.

Philip.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

-

l10tus - Third Gear

- Posts: 476

- Joined: 10 Apr 2008

Phil, your 1/8" clearance issue between the pipes and the footwell bulge is likely to cause problems when the whole area heats up. Unless you can do something to reduce the heat transfer you're likely to start damaging the glassfibre.

My previous set of pipes had a little more clearance than that (about double - 1/4") and over a month or two the area round the bulge started delaminating. I ended up both wrapping the pipes (not a good idea long term) and sticking some heat insulation on the footwell (the original version was a plumbers soldering mat from B&Q!). The pipe wrapping's gone now but the the insulated pad remains.

My previous set of pipes had a little more clearance than that (about double - 1/4") and over a month or two the area round the bulge started delaminating. I ended up both wrapping the pipes (not a good idea long term) and sticking some heat insulation on the footwell (the original version was a plumbers soldering mat from B&Q!). The pipe wrapping's gone now but the the insulated pad remains.

Stuart Holding

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

- 69S4

- Coveted Fifth Gear

- Posts: 1124

- Joined: 23 Sep 2004

Stuart,

Thanks for the reply.

I am trying to fit the new heavy duty engine mounts, but oh boy is it a job when the exhausts are still in place !

Any ideas if the bolts heads should be exhaust side or radiator side of the engine mounts?

Just wondering how I'm going to get the washer and nut back on after replacing the mount, unless the 2 bolts are 'reversed' in the mounts ?

Aaaaaaaaagh !! - didn't want to remove the down pipes but just can't get at the rather blind nuts!

Regards,

Phil.

Thanks for the reply.

I am trying to fit the new heavy duty engine mounts, but oh boy is it a job when the exhausts are still in place !

Any ideas if the bolts heads should be exhaust side or radiator side of the engine mounts?

Just wondering how I'm going to get the washer and nut back on after replacing the mount, unless the 2 bolts are 'reversed' in the mounts ?

Aaaaaaaaagh !! - didn't want to remove the down pipes but just can't get at the rather blind nuts!

Regards,

Phil.

Philip.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

-

l10tus - Third Gear

- Posts: 476

- Joined: 10 Apr 2008

HI Phil

I hope you have changed the heater valve when you had the mount off as you need to jack up the engine a little to be able to screw the valve out and the new one in.

I use socket head bolts for the engine mount inserted from the rear as it is easiest to then hold them with an allen key when doing up the nut at the front. Do the top bolt first and then adjust the engine height until the bottom one lines up and insert it.

A heat shield around the exhaust side mount also prolongs its life. i stick the same aluminium faced kevlar heat shield sheet onto it that i use on the footwell fibregalss.

cheers

Rohan

I hope you have changed the heater valve when you had the mount off as you need to jack up the engine a little to be able to screw the valve out and the new one in.

I use socket head bolts for the engine mount inserted from the rear as it is easiest to then hold them with an allen key when doing up the nut at the front. Do the top bolt first and then adjust the engine height until the bottom one lines up and insert it.

A heat shield around the exhaust side mount also prolongs its life. i stick the same aluminium faced kevlar heat shield sheet onto it that i use on the footwell fibregalss.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8415

- Joined: 22 Sep 2003

Update as promised.

Well, I fitted the new, heavy duty engine mount as advised, and guess what ?- immediate SUCCESS!

When I removed the existing LHS mount it all but fell apart in my hands ! (see picture attached)

I just can't believe that this mount has failed!

The engine has not been run since the mount was installed, the engine has just been suspended on the mount and it's been sitting in my garage with no stress on it, for 5 years - and failed !!!

Conclusion: This must have been one from the batch (at that time) that there were problems with ?

Just as a matter of interest, it appears that the rubber was vulcanised (if that's the correct terminology?) to painted steel parts of the bracket - as I can detect black paint on the metal where the rubber has become un-attached ?

I wouldn't have thought it was a good idea to bond the rubber to a painted surface ?

Least ways the new mount installation has pretty well cured all the issues in one hit -

Namely:-

More clearance under the heater valve (25mm now)

More clearance between the fibreglass footwell and the exhaust down pipes 1/4" ?

Obviously more rigid support of the engine( Rohan I really appreciate your advice but I read it too late! - so must admit I did forget to change the Heater valve whilst in progress - dummy me !!!)

Totally pleased with the outcome,

So, I'd just like to say a big thanks to all you guys on this Forum, who suggested I check the engine mounts, etc., and offered suggestions.

Great advice, great help, much appreciated.

Job jobbed !

Regards,

Phil.

Well, I fitted the new, heavy duty engine mount as advised, and guess what ?- immediate SUCCESS!

When I removed the existing LHS mount it all but fell apart in my hands ! (see picture attached)

I just can't believe that this mount has failed!

The engine has not been run since the mount was installed, the engine has just been suspended on the mount and it's been sitting in my garage with no stress on it, for 5 years - and failed !!!

Conclusion: This must have been one from the batch (at that time) that there were problems with ?

Just as a matter of interest, it appears that the rubber was vulcanised (if that's the correct terminology?) to painted steel parts of the bracket - as I can detect black paint on the metal where the rubber has become un-attached ?

I wouldn't have thought it was a good idea to bond the rubber to a painted surface ?

Least ways the new mount installation has pretty well cured all the issues in one hit -

Namely:-

More clearance under the heater valve (25mm now)

More clearance between the fibreglass footwell and the exhaust down pipes 1/4" ?

Obviously more rigid support of the engine( Rohan I really appreciate your advice but I read it too late! - so must admit I did forget to change the Heater valve whilst in progress - dummy me !!!)

Totally pleased with the outcome,

So, I'd just like to say a big thanks to all you guys on this Forum, who suggested I check the engine mounts, etc., and offered suggestions.

Great advice, great help, much appreciated.

Job jobbed !

Regards,

Phil.

Philip.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

-

l10tus - Third Gear

- Posts: 476

- Joined: 10 Apr 2008

"( Rohan I really appreciate your advice but I read it too late! - so must admit I did forget to change the Heater valve whilst in progress - dummy me !!!)"

Phil,

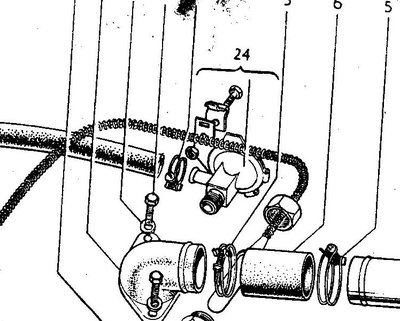

If you don't want to undo the L/H engine mount to raise the engine to change the heater valve, there is another method you can use to achieve the correct orientation of the valve. To do this, the section of the valve that carries the diaphragm and the operating mechanism are removed from both valves and the parts swapped over.

If you refer to my photos above, you can see a pop rivet at the top of the valve. This rivet needs to be drilled out of both valves to allow disassembly. Twist the operating half of the valve (cw or ccw shouldn't matter) whilst holding the back of the valve, about 5 or 10 degrees, and carefully withdraw the innards. Swap over, replace rivet and all should be okay.

Cheers.

Colin.

Phil,

If you don't want to undo the L/H engine mount to raise the engine to change the heater valve, there is another method you can use to achieve the correct orientation of the valve. To do this, the section of the valve that carries the diaphragm and the operating mechanism are removed from both valves and the parts swapped over.

If you refer to my photos above, you can see a pop rivet at the top of the valve. This rivet needs to be drilled out of both valves to allow disassembly. Twist the operating half of the valve (cw or ccw shouldn't matter) whilst holding the back of the valve, about 5 or 10 degrees, and carefully withdraw the innards. Swap over, replace rivet and all should be okay.

Cheers.

Colin.

fatboyoz wrote:Phil,

Further to Rohan's reply, some pictures of my 68 S4. Your engine mount definitely looks to have sagged badly. I have an old one that is similar, they take up a "set" and can't be saved. Replacement, probably of both, is the cure to your clearance problems.

Cheers,

Colin.

'68 S4 DHC

- fatboyoz

- Fourth Gear

- Posts: 631

- Joined: 04 Oct 2003

This may be of interest.

The configuration of the heater control valve within the S1 workshop manual is different to that posted by Colin above.

The control cable is connected to the top of the valve - giving more clearance beneath the valve.

I have this type of valve (purchased from a Land Rover parts supplier) fitted to my car:

It now seems that the vast majority of valves which are for sale are of the type shown in Colin's post rather than that shown in the S1 manual.

However I did find this one:

http://www.famousfour.co.uk/new_parts/p ... rtID=15121

The configuration of the heater control valve within the S1 workshop manual is different to that posted by Colin above.

The control cable is connected to the top of the valve - giving more clearance beneath the valve.

I have this type of valve (purchased from a Land Rover parts supplier) fitted to my car:

It now seems that the vast majority of valves which are for sale are of the type shown in Colin's post rather than that shown in the S1 manual.

However I did find this one:

http://www.famousfour.co.uk/new_parts/p ... rtID=15121

Steve

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

-

AlfaLofa - Third Gear

- Posts: 459

- Joined: 19 Aug 2006

Steve, Colin, Rohan,

Interesting info on both accounts thanks!

I purchased the valve with the 'Top Mounted' control from ebay some years ago, thinking it was the correct one, it was advertised as suitable for Lotus, so no complaints there, but didn't realise it was for S1 models only !

The only real issue here is that this valve works in the opposite direction to the other one, i.e. Pull the control knob to shut and vice versa to open, but does give more clearance below.

I think now that the new engine mount has cured the clearance issue with the footwell, I'll use the S4 type recommended valve, to ensure the dash board control knob is pushed in during normal UK summer weather conditions, as the use in winter is not so often in my case with the control pulled out of the Dash - not that it's really an issue is it?

Just trying to retain originality to some degree.

Obviously, there are several options here which is a good thing no doubt?

Thanks for the infinite detail answers, it's very much appreciated, and hopefully will be of reference for others.

Best regards,

Phil.

Interesting info on both accounts thanks!

I purchased the valve with the 'Top Mounted' control from ebay some years ago, thinking it was the correct one, it was advertised as suitable for Lotus, so no complaints there, but didn't realise it was for S1 models only !

The only real issue here is that this valve works in the opposite direction to the other one, i.e. Pull the control knob to shut and vice versa to open, but does give more clearance below.

I think now that the new engine mount has cured the clearance issue with the footwell, I'll use the S4 type recommended valve, to ensure the dash board control knob is pushed in during normal UK summer weather conditions, as the use in winter is not so often in my case with the control pulled out of the Dash - not that it's really an issue is it?

Just trying to retain originality to some degree.

Obviously, there are several options here which is a good thing no doubt?

Thanks for the infinite detail answers, it's very much appreciated, and hopefully will be of reference for others.

Best regards,

Phil.

Philip.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

UK '72 Sprint DHC

Sometimes my Lotus makes me cry.

-

l10tus - Third Gear

- Posts: 476

- Joined: 10 Apr 2008

46 posts

• Page 3 of 4 • 1, 2, 3, 4

Total Online:

Users browsing this forum: No registered users and 32 guests