AKS water Pump Module Strip?

62 posts

• Page 3 of 5 • 1, 2, 3, 4, 5

john.p.clegg wrote:Phil

Method...just take the fixing screws out and screw then into the new tapped holes gently and together...they'll pull the flange away from the timing cover...

John

Aye. That's how the Burton etc. modular water pump is arranged. It contains its own built in puller in the form of 3 tapped holes (equidistant around the circle) from the clearance fixing holes.

Remember to tell the other guy that one of the threads will be bigger than the other two. Not strictly needed for it's puller function, but it is handy to simply use the 3 securing bolts/screws as the puller screws.

~~~~~~~~~~~

Meanwhile, since you have the front cover off now, gentle pressure on the centre of the pump shaft at the impeller end should push the module out of the front cover. With the bolts removed it is only held in by the stickiness of whatever gasket stuff was used and the friction of the o-rings on the toroidal thingy inside.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

Hi Bill,

I must admit I was looking at the cover this morning and without the extra holes to push out the module it must have still been a job and a half (if not impossible) to get the pump out whilst in situ.

I've doused the joint between the module and cover in penetrating fluid ready for the big push. There was certainly a load of crud around the joint so it might take some pressure to get it moving - perhaps with the help of a large saucepan and boiling water.

I must admit I was looking at the cover this morning and without the extra holes to push out the module it must have still been a job and a half (if not impossible) to get the pump out whilst in situ.

I've doused the joint between the module and cover in penetrating fluid ready for the big push. There was certainly a load of crud around the joint so it might take some pressure to get it moving - perhaps with the help of a large saucepan and boiling water.

Steve

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

-

AlfaLofa - Third Gear

- Posts: 459

- Joined: 19 Aug 2006

Well after hammering for 40 minutes with wooden drifts I finally got the water pump module out of the front cover.

Despite being a "module" it would have been completely impossible to extract without the removal of the front cover from the engine.

It was virtually welded in by huge quantities of sealant.

The removal of the shaft/bearing/impeller was then relatively straight forward using the press.

Despite being a "module" it would have been completely impossible to extract without the removal of the front cover from the engine.

It was virtually welded in by huge quantities of sealant.

The removal of the shaft/bearing/impeller was then relatively straight forward using the press.

Steve

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

-

AlfaLofa - Third Gear

- Posts: 459

- Joined: 19 Aug 2006

Yup, far too much goo.

If the O-rings are clean and the grooves and inside surface of the module are clean and scratch free, the O-rings should not have any goo on them at all, just possibly a smear of waterproof grease.

And then only the front flange should have any gasket cement, just a thin smear and it only needs to be around the circle inside the securing bolts.

Still next time you will have incorporated the extra threaded holes to make it a self pulling module.

If the O-rings are clean and the grooves and inside surface of the module are clean and scratch free, the O-rings should not have any goo on them at all, just possibly a smear of waterproof grease.

And then only the front flange should have any gasket cement, just a thin smear and it only needs to be around the circle inside the securing bolts.

Still next time you will have incorporated the extra threaded holes to make it a self pulling module.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

Well this morning I managed to extract a shaft for my AKS pump module from a ?10 water pump I bought on ebay.

There seem to be dozens of different Sierra pumps out there. (First one I bought had a shaft which was too long).

I went for one with a fixed fan.

It was listed as QCP2526 pump for Capri, Granada, Sierra & Cortina.

As mentioned elsewhere these are for the Pinto SOHC engines.

I don't know if the pumps for use with viscous fans are different internally (probably not).

Here's a picture of the pump before I destroyed it to extract the shaft.

Also a picture of the "new" shaft with the old shaft removed from the AKS timing cover.

All the dimensions are identical to the original shaft (sigh of relief).

There seem to be dozens of different Sierra pumps out there. (First one I bought had a shaft which was too long).

I went for one with a fixed fan.

It was listed as QCP2526 pump for Capri, Granada, Sierra & Cortina.

As mentioned elsewhere these are for the Pinto SOHC engines.

I don't know if the pumps for use with viscous fans are different internally (probably not).

Here's a picture of the pump before I destroyed it to extract the shaft.

Also a picture of the "new" shaft with the old shaft removed from the AKS timing cover.

All the dimensions are identical to the original shaft (sigh of relief).

Steve

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

-

AlfaLofa - Third Gear

- Posts: 459

- Joined: 19 Aug 2006

I should have chipped in with a bit of advise when you started this thread, but I have not been looking in much of late.

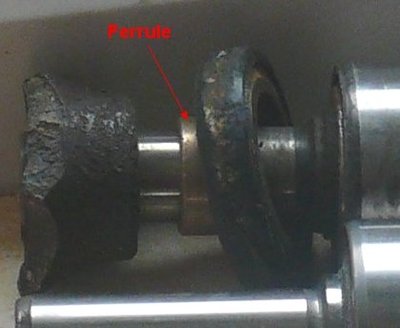

As picture shows, I know a little about water pump modules myself. What I found when I removed the module a couple of years ago, was that there was an almost interference fit between the o/d of the module and the casing, which is quite unnecessary. So on trying to remove it after 25 years in situ was a bar steward of a job, what with the O rings and some corrosion. Only reason for removal was the seal had gone and was leaking through the drain hole.

Once out, I wet and dryed the module outer and the casing inner, for a much more acceptable fit, and ran some copper slip round the module to prevent the aforementioned corrosion, and popped it back in. Job jobbed.

But as you said Steve, the idea that replacing a module is a half hour job is rubbish. The only thing it saved me, which I suppose is one of the things it was meant to, was removing the head. So that was a blessing. Well done George.

Leslie

As picture shows, I know a little about water pump modules myself. What I found when I removed the module a couple of years ago, was that there was an almost interference fit between the o/d of the module and the casing, which is quite unnecessary. So on trying to remove it after 25 years in situ was a bar steward of a job, what with the O rings and some corrosion. Only reason for removal was the seal had gone and was leaking through the drain hole.

Once out, I wet and dryed the module outer and the casing inner, for a much more acceptable fit, and ran some copper slip round the module to prevent the aforementioned corrosion, and popped it back in. Job jobbed.

But as you said Steve, the idea that replacing a module is a half hour job is rubbish. The only thing it saved me, which I suppose is one of the things it was meant to, was removing the head. So that was a blessing. Well done George.

Leslie

- 512BB

- Coveted Fifth Gear

- Posts: 1204

- Joined: 24 Jan 2008

It would be a half-hour job, if the module has the threaded extractor holes mentioned above and you also have a spare module already assembled with the pump kit.

As it is most of the time is spent getting the old pump kit out and fitting the replacement pump kit into the module case.

As it is most of the time is spent getting the old pump kit out and fitting the replacement pump kit into the module case.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

Thank you Leslie for your input.

When I get everything together I'll reassemble as you recommend!

Hi Bill - I've now had the 3 extra holes drilled and threaded, so removal should be more easy next time.

As said previously, because of the huge amount of sealant used to fit the module in the cover, I had to resort to brute force (albeit using a wooden drift) to force the module out of the cover.

Unfortunately I still managed to wreck the impeller.

When I get everything together I'll reassemble as you recommend!

Hi Bill - I've now had the 3 extra holes drilled and threaded, so removal should be more easy next time.

As said previously, because of the huge amount of sealant used to fit the module in the cover, I had to resort to brute force (albeit using a wooden drift) to force the module out of the cover.

Unfortunately I still managed to wreck the impeller.

Steve

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

-

AlfaLofa - Third Gear

- Posts: 459

- Joined: 19 Aug 2006

I've now got all the bits I need to reassemble the AKS water pump - but........

The original shaft (the impellor end) was fitted with a brass ferrule with id of 12.7mm and od of 16mm, plus an oil seal with a 16mm inside diameter.

The brass ferrule has a shallow groove on its circumference which I assume is "machined" rather than wear.

I also assume that the brass ferrule is simply pushed into the oil seal which is then fitted to the oil seal seating using a suitable compound.

The shaft (d 12.7mm) then rotates within the ferrule.

What I don't understand is what stops the ferrule from working loose from the oil seal and then migrating up and down the shaft.

Should I super glue the ferrule into the oil seal or should there be another spacer between the ferrule and the impeller which would keep the ferrule in place?

The original shaft (the impellor end) was fitted with a brass ferrule with id of 12.7mm and od of 16mm, plus an oil seal with a 16mm inside diameter.

The brass ferrule has a shallow groove on its circumference which I assume is "machined" rather than wear.

I also assume that the brass ferrule is simply pushed into the oil seal which is then fitted to the oil seal seating using a suitable compound.

The shaft (d 12.7mm) then rotates within the ferrule.

What I don't understand is what stops the ferrule from working loose from the oil seal and then migrating up and down the shaft.

Should I super glue the ferrule into the oil seal or should there be another spacer between the ferrule and the impeller which would keep the ferrule in place?

Steve

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

-

AlfaLofa - Third Gear

- Posts: 459

- Joined: 19 Aug 2006

I don't understand what the lip seal and brass sleeve is there for at all. Was this the only seal ? Normally water pumps have a carbon face spring loaded mechanical seal. A lip seal like what is shown is not designed for sealing water under pressure and would leak huge amounts continually?

cheers

Rohan

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8415

- Joined: 22 Sep 2003

Hi Rohan - yes the lip seal and the ferrule were both originally on the shaft (as per top photo).

The photo shows what was remaining of the original seal immediately after it was removed from the module.

The other photos show a new (similar) seal.

From what you say it appears that the original fit was accomplished via a bodge.

Oh well I now need to find something more appropriate (or give up).

The photo shows what was remaining of the original seal immediately after it was removed from the module.

The other photos show a new (similar) seal.

From what you say it appears that the original fit was accomplished via a bodge.

Oh well I now need to find something more appropriate (or give up).

Steve

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

-

AlfaLofa - Third Gear

- Posts: 459

- Joined: 19 Aug 2006

The AKS module should have been designed to take the same mechanical seal that the bearing for it was designed to use. One of these seals (or something similar) should have been in the water pump you purchased to get the bearing from.

I don't know what the person who originally assembled this module was doing as it could never have worked :roll

cheers

Rohan:

I don't know what the person who originally assembled this module was doing as it could never have worked :roll

cheers

Rohan:

-

rgh0 - Coveted Fifth Gear

- Posts: 8415

- Joined: 22 Sep 2003

Hi Rohan

I must admit that the seal which came from the "sacrificed" Sierra pump just looks like a cheap version of ferrule/oil seal that was originally fitted to the AKS module.

The Sierra seal is soft rubber and the ferrule is hard plastic.

I must admit that the seal which came from the "sacrificed" Sierra pump just looks like a cheap version of ferrule/oil seal that was originally fitted to the AKS module.

The Sierra seal is soft rubber and the ferrule is hard plastic.

Steve

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

'64 S1 Elan (Owned since '73)

'69 Alfa Romeo 1750 Spider Veloce (Owned since '77)

'70 Morris Minor 1000 (Owned since '85)

-

AlfaLofa - Third Gear

- Posts: 459

- Joined: 19 Aug 2006

Value engineering taken to the extreme compared to what water seals of 20 years ago looked like. I presume the plastic centre section now forms the seal against the rotating face of the impellor and it was sealed to the rubber section in someway.. The "plastic" I am sure is probably loaded with carbon to form a wearing surface

Was there a spring of some sort to hold the plastic centre piece against the face of the impellor and form the rotating seal or did it just rely on the rubber diaphragm. I struggle to see from the photo the rubber section exerting enough seal face pressure to counteract the water pressure but maybe it does based on how it assembles into the alloy pump body.

cheers

Was there a spring of some sort to hold the plastic centre piece against the face of the impellor and form the rotating seal or did it just rely on the rubber diaphragm. I struggle to see from the photo the rubber section exerting enough seal face pressure to counteract the water pressure but maybe it does based on how it assembles into the alloy pump body.

cheers

-

rgh0 - Coveted Fifth Gear

- Posts: 8415

- Joined: 22 Sep 2003

62 posts

• Page 3 of 5 • 1, 2, 3, 4, 5

Total Online:

Users browsing this forum: No registered users and 5 guests