Installing and torquing crankshaft pulley

22 posts

• Page 2 of 2 • 1, 2

I'm puzzled as to why you didn't simply engage the handbrake and put the car in top-gear?

I don't think I've ever had problems putting the crankshaft pulley on and I usually remove it when fitting a new sump gasket in that area.

I don't think I've ever had problems putting the crankshaft pulley on and I usually remove it when fitting a new sump gasket in that area.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

berni29 wrote:Hi

What was the crank position sensor/wheel combo that you bought? Also I am curious about what ECU you will use. I am planning to do something similar once my Zetec car is running......

All the best

Berni

Hi Bernie

I got the sensor mount and pulley from QED. They are in the links below:

https://qedmotorsport.co.uk/product/cra ... -36-teeth/

https://qedmotorsport.co.uk/product/cra ... g-bracket/

They also list the compatible Ford sensor, although I got mine from the ECU supplier instead.

https://qedmotorsport.co.uk/product/cra ... ford-type/

I am going with the ignition only version of Motorsports-Electronics ECU called the Nodiz Gen-X.

https://motorsport-electronics.co.uk/pr ... c-harness/

The Nodiz Gen-X seems to be a relatively new model. I believe the programming software is now similar to their fuel injection products, rather than earlier versions with mode buttons and some flashing LED’s. The box is water resistant and rugged looking, although still debating whether to mount it under the bonnet or in the interior.

The system will also use a throttle position sensor. I am using this one, which was a very complete & simple screw on kit. You do need to add the matching connector & boot to make up a short loom run to the main Nodiz connector, or specify this loom leg when you purchase the complete deal from ME.

https://www.webcon.co.uk/products/9948- ... 4045-dcoe/

For simplicity of installation I have opted to not use the other features included in the ignition only ECU, including coolant temperature and cooling fan control. I am happy with my already installed Clivey Boy fan controller.

Next on the list is to finish off the loom and unit mounting. I plan to test fire the engine before removing the dizzy. Once I am confident it functions OK I plan to permanently mount the Ford coil pack over top of the dizzy blanking plug; I got one one on eBay that looks a bit better than the QED offering. I am also using a coil pack mounting bracket from TriggerWheels.com, but that still needs some MacGyvering. The idea is the engine can easily be pulled by simply disconnecting the coil pack, TPS, and CPS at their respective sealed connectors and leaving the coil pack and wires in place.

Basically the plan is to retain my new style Weber 45’s but get better ignition performance. I am particularly wanting more advance at highway cruising speed with very small throttle openings. Struggling to get smooth engine performance and reasonable fuel economy without vacuum advance.

Once I get the Nodiz working I am hoping to do up a more complete thread on how it works and so forth. Although the ECU is preloaded with a suitable ignition curve the system will require one time only programming to set the position of the missing tooth relative to TDC. Other than the three connections to the engine, the only other wiring required is a four way connector with ground, pure clean 12v power supply, ignition trigger wire, and tach signal output, so the whole thing is really quite simple and slimmed down.

Anyway, I got the trigger wheel mounted and a very nice consistent gap to the sensor, although I had to bend the mount slightly. The QED mount included three 1 1/4” hex head cap screws, but I separately purchased longer socket head screws to stay consistent with the other oil pan fasteners. Hopefully I haven’t created a pan leak.

I am presently waiting on a correct fan belt, which has to be installed before the sensor is buttoned up for the final time.

Bill, I didn’t know my Plus 2 has a handbrake. Always wondered what that deal is for.

Cheers guys. Thanks again for the help. Keep buggering on!

Stu

1969 Plus 2 Federal LHD

1969 Plus 2 Federal LHD

-

stugilmour - Coveted Fifth Gear

- Posts: 1942

- Joined: 03 Sep 2007

stugilmour wrote:Next on the list is to finish off the loom and unit mounting. I plan to test fire the engine before removing the dizzy. Once I am confident it functions OK I plan to permanently mount the Ford coil pack over top of the dizzy blanking plug; I got one one on eBay that looks a bit better than the QED offering.

Electrical / electronics generally don't like heat and vibration. Depending on the Ford coil pack you use, it was likely mounted on an inner wing or firewall in its original fitment. Not sure how happy it will be bolted to the engine. There have been others on here who have gone for the 'coil pack over the dizzy hole' route, so perhaps they can comment whether they suffered with reliability issues.

Modern coil over plug arrangements obviously suffer from both heat and vibration - but they are supposedly designed for it - although I have just had to replace 2 on my son's Mini.

68 Elan S3 HSCC Roadsports spec

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

- Andy8421

- Coveted Fifth Gear

- Posts: 1221

- Joined: 27 Mar 2011

Hi Stu,

You made a great choice with the Nodiz Pro Gen-X. I installed exactly the same combination of TPS, Pulley, Sensor, Coil Pack on my Twincam as described in this https://lotuselan.net/forums/viewtopic.php?f=31&t=47916 forum thread. Only difference I can see is that I am using 40 DCOEs.

Couple of things to consider:

-Motorsport Electronics https://motorsport-electronics.co.uk/ provide excellent customer support. Whenever I needed help, they responded immediately and with useful advice.

-I sympathise with the comments about coil pack location / vibration etc, but to date have had no problems.

-The new CPS sensor mounting bracket makes it a challenge to mount a degree wheel between the new QED pulley and the chassis cross-member if you need to check your cam timing. I ended up building a custom degree wheel assembly on top of the old cast iron crank pulley, and fitting it whenever I wanted to adjust the cams (I have 'vernier' pulleys fitted and like to tinker)

-I did fit water and air temperature sensors. The water temperature sensor was very useful in revealing that my standard gauge was reading way too low. It is being serviced now by Caerbont https://www.smiths-instruments.co.uk/ and hopefully will be closer match when it comes back.

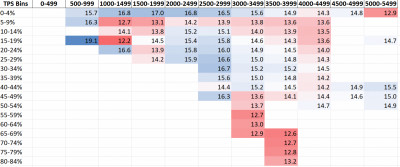

-The air temperature sensor was unnecessary and, with the excellent help of Motorsport Electronics I have repurposed the 0-5V analogue input on the Nodiz unit to read instead the 0-5V output from my AEM AFR sensor. Together with the Rev and TPS it means I can generate a mixture plot (obsolete example below) to guide my tinkering with carb jets.

The result of all this? I have a twincam which even with 420 cams will idle smoothly down to 650 rpm if asked to, starts on first turn, is tractable in city traffic, and pulls strongly all the way up.

If you feel I can help with anything, feel free to get in touch

You made a great choice with the Nodiz Pro Gen-X. I installed exactly the same combination of TPS, Pulley, Sensor, Coil Pack on my Twincam as described in this https://lotuselan.net/forums/viewtopic.php?f=31&t=47916 forum thread. Only difference I can see is that I am using 40 DCOEs.

Couple of things to consider:

-Motorsport Electronics https://motorsport-electronics.co.uk/ provide excellent customer support. Whenever I needed help, they responded immediately and with useful advice.

-I sympathise with the comments about coil pack location / vibration etc, but to date have had no problems.

-The new CPS sensor mounting bracket makes it a challenge to mount a degree wheel between the new QED pulley and the chassis cross-member if you need to check your cam timing. I ended up building a custom degree wheel assembly on top of the old cast iron crank pulley, and fitting it whenever I wanted to adjust the cams (I have 'vernier' pulleys fitted and like to tinker)

-I did fit water and air temperature sensors. The water temperature sensor was very useful in revealing that my standard gauge was reading way too low. It is being serviced now by Caerbont https://www.smiths-instruments.co.uk/ and hopefully will be closer match when it comes back.

-The air temperature sensor was unnecessary and, with the excellent help of Motorsport Electronics I have repurposed the 0-5V analogue input on the Nodiz unit to read instead the 0-5V output from my AEM AFR sensor. Together with the Rev and TPS it means I can generate a mixture plot (obsolete example below) to guide my tinkering with carb jets.

The result of all this? I have a twincam which even with 420 cams will idle smoothly down to 650 rpm if asked to, starts on first turn, is tractable in city traffic, and pulls strongly all the way up.

If you feel I can help with anything, feel free to get in touch

Damian

67 French-Blue Elan S3 DHC 45/7001

67 French-Blue Elan S3 DHC 45/7001

- DamianB

- First Gear

- Posts: 43

- Joined: 04 Sep 2022

Andy8421 wrote:Modern coil over plug arrangements obviously suffer from both heat and vibration - but they are supposedly designed for it - although I have just had to replace 2 on my son's Mini.

I lost count of the number of them I had to replace on a 2002 VW GTI 1.8T I had from new until 156K miles. And it was always the #1 coil that blew, which of course is the one that has something mounted in the way of removing it. It got to the point where I started carrying a spare in the car!

1970 Elan Plus 2 (not S) 50/2036

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

-

The Veg - Coveted Fifth Gear

- Posts: 2185

- Joined: 16 Nov 2015

Damian, thanks so much for posting. Rereading the highlighted thread was very illuminating for my next steps.

Here is a picture of my progress so far. This is absolutely a radiator out job. I didn’t have to raise the engine on my mounts to fit the pulley and sensor, but my Spyder engine mounts have been gently modified already so might not work for others. The clearance between the larger diameter teeth and the brake lines is tighter now.

For the remainder of my installation I have started a new properly titled thread under the mods section. I have also include links to the previous discussions.

viewtopic.php?f=31&t=53911&p=393358#p393358

I am particularly interested in getting advice from Damian on connecting the AFR log to the Gen-X, which is a pretty major thread shift from details on pulley installation and Valentine’s Day dating. The Gen-X with the Meite software includes the ability to connect a laptop, which is a whole different deal again; I am still lining up an appropriate laptop.

The Gen-X with the Meite software includes the ability to connect a laptop, which is a whole different deal again; I am still lining up an appropriate laptop.

Thanks again for all the help. Going to pull the information together better before I proceed further.

Here is a picture of my progress so far. This is absolutely a radiator out job. I didn’t have to raise the engine on my mounts to fit the pulley and sensor, but my Spyder engine mounts have been gently modified already so might not work for others. The clearance between the larger diameter teeth and the brake lines is tighter now.

For the remainder of my installation I have started a new properly titled thread under the mods section. I have also include links to the previous discussions.

viewtopic.php?f=31&t=53911&p=393358#p393358

I am particularly interested in getting advice from Damian on connecting the AFR log to the Gen-X, which is a pretty major thread shift from details on pulley installation and Valentine’s Day dating.

Thanks again for all the help. Going to pull the information together better before I proceed further.

Stu

1969 Plus 2 Federal LHD

1969 Plus 2 Federal LHD

-

stugilmour - Coveted Fifth Gear

- Posts: 1942

- Joined: 03 Sep 2007

22 posts

• Page 2 of 2 • 1, 2

Total Online:

Users browsing this forum: Ianashdown and 42 guests