mayonnaise in the cam cover

24 posts

• Page 2 of 2 • 1, 2

Thanks Andy,

That is a good analysis of the situation.

I did try a pressure test of the cooling system with not much success. I had too many difficulties sealing the equipment and lashed up hoses and fittings from the compressor to the engine and pressure gauge to be confident of it.

Obviously the pressure I could use was limited by the radiator and heater. Above 10 PSI the radiator starts to creak.

At 10PSI it had dropped to 2 PSI in less than half an hour.

It was what I call a negative test.

If it holds then it could be called good. If it doesn`t then either there is a fault or the test procedure is weak.

Such tests are useful and worthwhile, but must be considered as one way only.

One point was, could a faulty water pump cause water to be lost via the cylinders and blown out as steam.

I do not know the construction of the pump, or if there is any pathway into the engine.

if it is at all likely then I can remove the block and replace what at the moment seems a perfectly sound pump.

It is before my time, but was probably changed about 11 or 12 years ago, when the previous owner was restoring this car. I have had the car nearly 10 years and done about 12,000 miles. it has not been stood idle for more than a few weeks in that time.

At the moment I appear to have two options.

If the consensus appears to be that the head gasket was the culprit then I can replace it quite easily. If I am wrong then the engine will have to come out to change the pump. The cost of this will just be another head gasket.

Or if the pump is quite likely to cause this problem, then I will take the rest of the engine out now and change it.

All further thoughts and comments are welcome

Cheers

Eric in Burnley

That is a good analysis of the situation.

I did try a pressure test of the cooling system with not much success. I had too many difficulties sealing the equipment and lashed up hoses and fittings from the compressor to the engine and pressure gauge to be confident of it.

Obviously the pressure I could use was limited by the radiator and heater. Above 10 PSI the radiator starts to creak.

At 10PSI it had dropped to 2 PSI in less than half an hour.

It was what I call a negative test.

If it holds then it could be called good. If it doesn`t then either there is a fault or the test procedure is weak.

Such tests are useful and worthwhile, but must be considered as one way only.

One point was, could a faulty water pump cause water to be lost via the cylinders and blown out as steam.

I do not know the construction of the pump, or if there is any pathway into the engine.

if it is at all likely then I can remove the block and replace what at the moment seems a perfectly sound pump.

It is before my time, but was probably changed about 11 or 12 years ago, when the previous owner was restoring this car. I have had the car nearly 10 years and done about 12,000 miles. it has not been stood idle for more than a few weeks in that time.

At the moment I appear to have two options.

If the consensus appears to be that the head gasket was the culprit then I can replace it quite easily. If I am wrong then the engine will have to come out to change the pump. The cost of this will just be another head gasket.

Or if the pump is quite likely to cause this problem, then I will take the rest of the engine out now and change it.

All further thoughts and comments are welcome

Cheers

Eric in Burnley

- ericbushby

- Coveted Fifth Gear

- Posts: 1353

- Joined: 13 Jun 2011

If the impeller seal on the water pump has failed you should see evidence of water from the small ‘dribble hole‘ in the front cover, hole is below the pump pulley check its clear with a small stiff wire. For coolant to get into the oil the ‘O’ ring internal housing seals would have to have failed, quite unlikely with an established working pump.

I would drain the engine oil and check for water content, modern oils can take-up quite a bit of water without going milky. If water vapour was drawn into the air box and then into the engine would produce steam, it may have condensed out in the air box causing water drops under the carbs.

FWIW

I would drain the engine oil and check for water content, modern oils can take-up quite a bit of water without going milky. If water vapour was drawn into the air box and then into the engine would produce steam, it may have condensed out in the air box causing water drops under the carbs.

FWIW

- Craven

- Coveted Fifth Gear

- Posts: 1624

- Joined: 14 Sep 2013

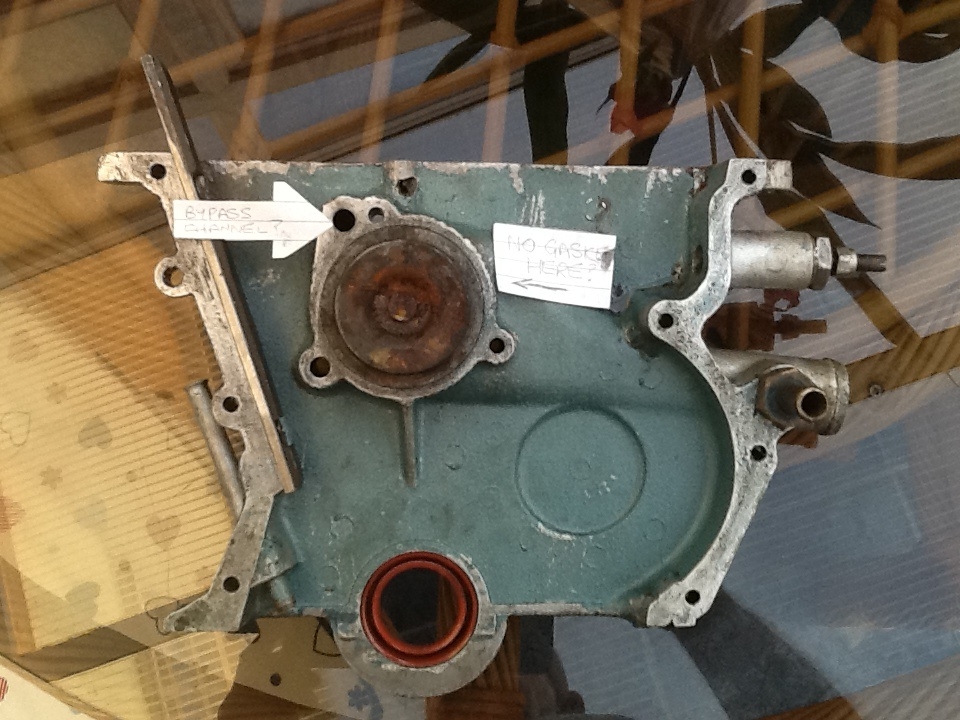

ericbushby wrote:I do not know the construction of the pump, or if there is any pathway into the engine.

you may want to check previous posts on the subject, in case that help diagnosing the problem, e.g.

viewtopic.php?f=39&t=29484&start=

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 2000

- Joined: 02 Sep 2013

Hi Craven,

Thanks for that. I have not seen any drips from the bleed hole, nor have there been any water drops on the cardboard drip catcher on the floor.

No visible water came out when I drained the sump and no water seems to have settled in the bottle.

However as always that is not proof of anything. As I said I am only asking for suggestions in order to learn more. Now I know that there is an O ring which if failing would cause a leak into the oil. Thanks.

nmauduit.

That is what I have failed to find in my searches. There is a lot of information there which I will read.

It is beginning to look like a full pump rebuild so far.

Thanks

Eric in Burnley

Thanks for that. I have not seen any drips from the bleed hole, nor have there been any water drops on the cardboard drip catcher on the floor.

No visible water came out when I drained the sump and no water seems to have settled in the bottle.

However as always that is not proof of anything. As I said I am only asking for suggestions in order to learn more. Now I know that there is an O ring which if failing would cause a leak into the oil. Thanks.

nmauduit.

That is what I have failed to find in my searches. There is a lot of information there which I will read.

It is beginning to look like a full pump rebuild so far.

Thanks

Eric in Burnley

- ericbushby

- Coveted Fifth Gear

- Posts: 1353

- Joined: 13 Jun 2011

It is possible for the O rings and / or metal to metal seal between the front and back covers to fail allowing water to leak directly into the chain cover area from inside the water pump passages. The actual pump shaft seal if it fails leaks to drain hole as observed or through the bearing rusting it out until it fails and has no path to the oil.

I agree the leak was small where ever it was, if it was actually present beyond normal water entering the sump from blow by, as the oil was succeeding in vaporising the water entering into it

cheers

Rohan

I agree the leak was small where ever it was, if it was actually present beyond normal water entering the sump from blow by, as the oil was succeeding in vaporising the water entering into it

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8415

- Joined: 22 Sep 2003

Hi Rohan,

Thanks for that. So it is a new pump assembly then. I am not surprised but I wanted to understand it before I committed to it. I have not been there before.

Cheers.

Eric in Burnley

Thanks for that. So it is a new pump assembly then. I am not surprised but I wanted to understand it before I committed to it. I have not been there before.

Cheers.

Eric in Burnley

- ericbushby

- Coveted Fifth Gear

- Posts: 1353

- Joined: 13 Jun 2011

Hi all, this is an update.

I have re-read this topic and this is the result.

The head was welded, pressure tested and skimmed 10 thou`.

I fitted a new original type water pump after reading everything I could find and with the help of a friendly engine builder for the parts where I needed a press.

The car is now back on the road, with clean oil and water, no mayonaisse in the cam cover, no cloud of steam and a consistent water level.

I now have a slight misfire that I am working on but that is a seperate snag. I do not think it is related to the main job.

The defects in the cylinder head gasket surface appeared minimal to me, but the head specialist wanted them welding.

The drain hole from the water pump bearing was blocked to the point that I could not see it and it may even have been painted over.

Thanks to all those who contributed with suggestions and advice. It is much appreciated.

Eric in Burnley

1967 S3SE DHC

I have re-read this topic and this is the result.

The head was welded, pressure tested and skimmed 10 thou`.

I fitted a new original type water pump after reading everything I could find and with the help of a friendly engine builder for the parts where I needed a press.

The car is now back on the road, with clean oil and water, no mayonaisse in the cam cover, no cloud of steam and a consistent water level.

I now have a slight misfire that I am working on but that is a seperate snag. I do not think it is related to the main job.

The defects in the cylinder head gasket surface appeared minimal to me, but the head specialist wanted them welding.

The drain hole from the water pump bearing was blocked to the point that I could not see it and it may even have been painted over.

Thanks to all those who contributed with suggestions and advice. It is much appreciated.

Eric in Burnley

1967 S3SE DHC

- ericbushby

- Coveted Fifth Gear

- Posts: 1353

- Joined: 13 Jun 2011

ericbushby wrote:Hi all, this is an update.....

The car is now back on the road, with clean oil and water, no mayonaisse in the cam cover, no cloud of steam and a consistent water level.

Eric in Burnley

1967 S3SE DHC

Congrats

Phil Harrison

1972 Elan Sprint 0260K

1972 Elan Sprint 0260K

-

pharriso - Coveted Fifth Gear

- Posts: 3186

- Joined: 15 Sep 2010

24 posts

• Page 2 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 39 guests