Water Pump/Alternator Pulleys

12 posts

• Page 1 of 1

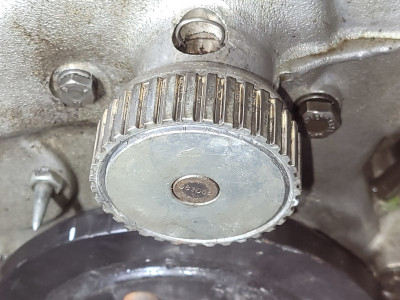

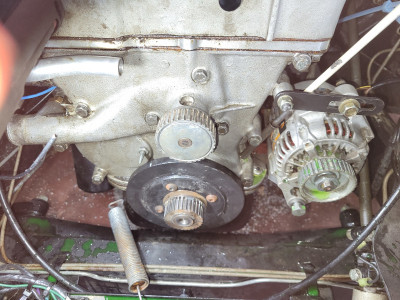

Does anyone recognize this pulley set? There is no manufacturer name on them. The water pump doesn't have a flange so the pulley is likely a press fit to the shaft. (?)

The car was restored/upgraded in Australia.

I'd greatly appreciate any information.

David

The car was restored/upgraded in Australia.

I'd greatly appreciate any information.

David

- 71elan

- New-tral

- Posts: 7

- Joined: 27 Jul 2018

Both Burton and QED used to produce a toothed belt conversion for the Twinc. The idea was to reduce the side loading on the waterpump to extend its life.

It could be a homebrew, the pulleys and belts are widely used in industrial automation. The reason I mention this is that the size ratio of the pulley on the crank and the alternator seems to be the wrong way round. The alternator needs to run faster than crank speed, so it is usual to have a big pulley on the crank, and small pulley on the alternator.

It could be a homebrew, the pulleys and belts are widely used in industrial automation. The reason I mention this is that the size ratio of the pulley on the crank and the alternator seems to be the wrong way round. The alternator needs to run faster than crank speed, so it is usual to have a big pulley on the crank, and small pulley on the alternator.

68 Elan S3 HSCC Roadsports spec

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

- Andy8421

- Coveted Fifth Gear

- Posts: 1220

- Joined: 27 Mar 2011

rgh0 wrote:I presume the engine was built as a race engine where its normal to use a small crank pulley to slow down the water pump and alternator due to the high RPM engine operation

cheers

Rohan

Rohan,

While that is certainly true for dynamos, the old Lucas 17ACR alternator (and I would agree that the alternator in the picture isn't a Lucas alternator) was rated for 15,000 rpm. It must be quite the racing engine if it was necessary to reduce its speed so the alternator could cope.

Red line at 20,000rpm perhaps?

68 Elan S3 HSCC Roadsports spec

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

- Andy8421

- Coveted Fifth Gear

- Posts: 1220

- Joined: 27 Mar 2011

Andy8421 wrote:rgh0 wrote:I presume the engine was built as a race engine where its normal to use a small crank pulley to slow down the water pump and alternator due to the high RPM engine operation

cheers

Rohan

Rohan,

While that is certainly true for dynamos, the old Lucas 17ACR alternator (and I would agree that the alternator in the picture isn't a Lucas alternator) was rated for 15,000 rpm. It must be quite the racing engine if it was necessary to reduce its speed so the alternator could cope.

Red line at 20,000rpm perhaps?

In a standard road engine the water pump runs at engine speed and the alternator at about twice engine speed. In a 8000rpm+ race engine you want to slow the water pump and alternator to maximise reliability and minimise parasitic engine HP loss driving these ancillaries. I have seen Lucas alternator cooling fans fail in race engines when the alternator operated around 15000 rpm

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8409

- Joined: 22 Sep 2003

Unfortunately, Rohan, the previous owner did not include your report in the package. I would love to see it.

The car is better traveled then I am. Delivered in California, US; revived in Victoria, AU; back to New York, US; now in Ontario, Canada.

Having a bit of overheating, so pulled the rad for a flush.

The car is better traveled then I am. Delivered in California, US; revived in Victoria, AU; back to New York, US; now in Ontario, Canada.

Having a bit of overheating, so pulled the rad for a flush.

- 71elan

- New-tral

- Posts: 7

- Joined: 27 Jul 2018

Andy8421 wrote:Both Burton and QED used to produce a toothed belt conversion for the Twinc.

Still do, but I think only in kit form with

Crank - 22t

W’pump - 24t

Alt - 16t

I have not seen any variances on these. Maybe these sizes are a good compromise for road and race engines.

Hal Adams

Evora SR

Elan +2

Evora SR

Elan +2

-

HCA - Coveted Fifth Gear

- Posts: 1087

- Joined: 03 Jan 2020

rgh0 wrote:Andy8421 wrote:rgh0 wrote:I presume the engine was built as a race engine where its normal to use a small crank pulley to slow down the water pump and alternator due to the high RPM engine operation

cheers

Rohan

Rohan,

While that is certainly true for dynamos, the old Lucas 17ACR alternator (and I would agree that the alternator in the picture isn't a Lucas alternator) was rated for 15,000 rpm. It must be quite the racing engine if it was necessary to reduce its speed so the alternator could cope.

Red line at 20,000rpm perhaps?

In a standard road engine the water pump runs at engine speed and the alternator at about twice engine speed. In a 8000rpm+ race engine you want to slow the water pump and alternator to maximise reliability and minimise parasitic engine HP loss driving these ancillaries. I have seen Lucas alternator cooling fans fail in race engines when the alternator operated around 15000 rpm

cheers

Rohan

Rohan,

I was (slightly) pulling your leg, the thing which stood out about the original picture was that the alternator appeared to be geared down from the crank, which would be unusual even for a racing engine - although I acknowledge your comment about parasitic losses is valid. The details of the commercial products listed above still have the alternator geared up relative to the crank.

Slightly off topic, I had a large aluminium Cosworth pulley on the dynamo of my competition Elan to protect the dynamo from over speeding. I was very proud of this, until one race the pully self destructed. It did however protect the dynamo.

Andy.

68 Elan S3 HSCC Roadsports spec

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

- Andy8421

- Coveted Fifth Gear

- Posts: 1220

- Joined: 27 Mar 2011

As far as I can remember these are referred to as Powergrip kits. They where very common on competition Ford and Mini engines in the 70's and 80's, at that time I used to manufacture the pulleys for a Fiat X19 kit. Burton still lists it and I believe Gates manufacture them.

John

John

1969 Elan S4 FHC, purchased in 1978, now with a big valve engine.

- JohnMorin

- Second Gear

- Posts: 113

- Joined: 29 Jul 2018

12 posts

• Page 1 of 1

Total Online:

Users browsing this forum: Lens4 and 34 guests