Die cast vs sand cast Twin Cam heads

14 posts

• Page 1 of 1

Thank You James for putting together a nice slide show on the differences between a Die-cast Twin Cam head and a Sand cast Twin Cam head.

http://www.kodakgallery.com/Slideshow.j ... 4q0yt&Ux=1

http://www.kodakgallery.com/Slideshow.j ... 4q0yt&Ux=1

-

garyeanderson - Coveted Fifth Gear

- Posts: 2626

- Joined: 12 Sep 2003

So this would be a die-cast head just popped up on Ebay (UK) ?

http://cgi.ebay.co.uk/ws/eBayISAPI.dll? ... 0399508949

Paddy

http://cgi.ebay.co.uk/ws/eBayISAPI.dll? ... 0399508949

Paddy

1963 Elan S1

-

paddy - Coveted Fifth Gear

- Posts: 1036

- Joined: 27 Oct 2008

Link to SAS Engineering web site. for TC heads. Coming out w. TC cam covers.

http://sasengineering.co.uk/lotus-tc-cylinder-head.html

http://sasengineering.co.uk/lotus-tc-cylinder-head.html

Phil

1968 S4/SE FHC 36-7936

1968 S4/SE FHC 36-7936

- pamitchell

- Third Gear

- Posts: 269

- Joined: 11 Sep 2003

garyeanderson wrote:Thank You James for putting together a nice slide show on the differences between a Die-cast Twin Cam head and a Sand cast Twin Cam head.

http://www.kodakgallery.com/Slideshow.j ... 4q0yt&Ux=1

Hi,

I'm having a bit of difficulty with this one.

Having looked at all of the Photo's, I've not been able to see any signs of "die casting" to my eyes they all appear to be sand castings.

Did someone really go to the tremendous expense of producing metal dies to produce die castings of a cylinder head which would be produced in such low numbers.

Perhaps a mix up in terminoligy ("Die-Cast") here?

A die cast cylinder head would probably be a "Worlds first"

Cheers

John

Beware of the Illuminati

Editor: On Sunday morning, February 8th 2015, Derek "John" Pelly AKA GrumpyBodger passed away genuinely peacefully at Weston Hospicecare, Weston Super Mare. He will be missed.

Editor: On Sunday morning, February 8th 2015, Derek "John" Pelly AKA GrumpyBodger passed away genuinely peacefully at Weston Hospicecare, Weston Super Mare. He will be missed.

-

GrUmPyBoDgEr - Coveted Fifth Gear

- Posts: 2340

- Joined: 29 Oct 2004

See the Miles Wilkins book here:

http://books.google.co.uk/books?id=b66Qyh9bdpUC&pg=PA25

It implies that very few were made - anyone know how many?

Paddy

http://books.google.co.uk/books?id=b66Qyh9bdpUC&pg=PA25

It implies that very few were made - anyone know how many?

Paddy

1963 Elan S1

-

paddy - Coveted Fifth Gear

- Posts: 1036

- Joined: 27 Oct 2008

As Miles says in his book, no records were kept. I'm wondering if the confusion is around the early 'Mk 1' heads having the same characteristics as the die-cast heads...i.e., the half moon projections in the chamber between the cams. These heads were on all Mk 1 (4 bolt crank) engines up until 1965 ish, so there were / are plenty of them about. My S4 has one fitted...though that was undoubtedly taken from an earlier car to convert Stromberg to Weber.

Mark

Mark

-

Elanintheforest - Coveted Fifth Gear

- Posts: 2489

- Joined: 04 Oct 2005

Hmmm,

I'm still not convinced. The talk of "Patterns" means sand casting to me.

The cost of making "steel dies" with all of the associated cooling for what was even then a low volume engine, doesn't bear thinking about.

The surface finish of the casting between the cams in Marks photo looks pretty good.

Any chance of a close up?

Some of the external profiles, especially in the area of the intake manifold don't seem to lend themselves to Die Casting.

I know that I'm rivet counting now, but Die Casting means the elimination of any sand forms, including cores because they would not stand up to the pressures & velocities of molten aluminium used in Die Casting.

The most used method for casting todays cylinder heads is to use steel dies for external surfaces & sand for the cores.

This is a type of low pressure Die Casting & does provide a very good surface finish provided the dies are in good shape.

I'm scraping around for the name of the process in English. "Kokillengu?"

It'll probably occur to me the next time I'm sat on the toilet

More recently "Lost Foam" casting has been introduced (Investment Casting) by some car makers.

Never mind; I'm still at a loss to understand the financial feasability of "Die Casting" twin cam heads

Cheers

John

I'm still not convinced. The talk of "Patterns" means sand casting to me.

The cost of making "steel dies" with all of the associated cooling for what was even then a low volume engine, doesn't bear thinking about.

The surface finish of the casting between the cams in Marks photo looks pretty good.

Any chance of a close up?

Some of the external profiles, especially in the area of the intake manifold don't seem to lend themselves to Die Casting.

I know that I'm rivet counting now, but Die Casting means the elimination of any sand forms, including cores because they would not stand up to the pressures & velocities of molten aluminium used in Die Casting.

The most used method for casting todays cylinder heads is to use steel dies for external surfaces & sand for the cores.

This is a type of low pressure Die Casting & does provide a very good surface finish provided the dies are in good shape.

I'm scraping around for the name of the process in English. "Kokillengu?"

It'll probably occur to me the next time I'm sat on the toilet

More recently "Lost Foam" casting has been introduced (Investment Casting) by some car makers.

Never mind; I'm still at a loss to understand the financial feasability of "Die Casting" twin cam heads

Cheers

John

Beware of the Illuminati

Editor: On Sunday morning, February 8th 2015, Derek "John" Pelly AKA GrumpyBodger passed away genuinely peacefully at Weston Hospicecare, Weston Super Mare. He will be missed.

Editor: On Sunday morning, February 8th 2015, Derek "John" Pelly AKA GrumpyBodger passed away genuinely peacefully at Weston Hospicecare, Weston Super Mare. He will be missed.

-

GrUmPyBoDgEr - Coveted Fifth Gear

- Posts: 2340

- Joined: 29 Oct 2004

I get only gray pages here:

http://books.google.co.uk/books?id=b66Qyh9bdpUC&pg=PA25

http://books.google.co.uk/books?id=b66Qyh9bdpUC&pg=PA25

Art Frederick

S2 Roadster, built in 1965, registered in 1966, No. 26/4934

Nothing else of interest at present

S2 Roadster, built in 1965, registered in 1966, No. 26/4934

Nothing else of interest at present

-

frearther - Third Gear

- Posts: 373

- Joined: 23 Sep 2003

I'm not sure why. This is the google books viewer which should work in every browser as far as I can tell. It is just page 25 from the Miles Wilkins Twincam book.

However, here is the image of that page directly:

http://books.google.co.uk/books?id=b66Q ... Q3Fw&w=575

Paddy

However, here is the image of that page directly:

http://books.google.co.uk/books?id=b66Q ... Q3Fw&w=575

Paddy

1963 Elan S1

-

paddy - Coveted Fifth Gear

- Posts: 1036

- Joined: 27 Oct 2008

I thought I would share some interesting information I found out when researching the differences in the 2 heads. I had one of each and was able to compare side by side. I wanted to keep one and sell the other

The Mk1 head is a [url]much[/url]cleaner casting with more apparent strength.

It looks like a more percise method of manufacture was used on the earilier head

The Mk1 head did not orginally have steel liners in the bucket area.

I spoke to Tony Thompson about about the differences. According to Tony the MK1 will produce 3~5 hp more with exactly the same modifications. Tony said he thought it was because of the ridgity of the casting

Tony said if you can find a good Mk1 head, grab it and the 26R boys really liked getting ther hands on them.

The material (alloy) appears to be different in the MK1 and MK2 heads (I found this during porting) The Mk1 is much harder to work

I kept th MK1 head, based on TT comments

James

The Mk1 head is a [url]much[/url]cleaner casting with more apparent strength.

It looks like a more percise method of manufacture was used on the earilier head

The Mk1 head did not orginally have steel liners in the bucket area.

I spoke to Tony Thompson about about the differences. According to Tony the MK1 will produce 3~5 hp more with exactly the same modifications. Tony said he thought it was because of the ridgity of the casting

Tony said if you can find a good Mk1 head, grab it and the 26R boys really liked getting ther hands on them.

The material (alloy) appears to be different in the MK1 and MK2 heads (I found this during porting) The Mk1 is much harder to work

I kept th MK1 head, based on TT comments

James

-

holywood3645 - Fourth Gear

- Posts: 889

- Joined: 07 Oct 2003

I agree and I struggle to see how a head could be completely "die cast" some sort of core is required for the water jackets and I dont see how this could be a permanent removable metal die. Potentially the method had some combination of external steel moulds with some sort of sand internal cores

As for the "die cast" heads producing more power due to greater rigidity I also struggle with that. I fail to see how rigidity translates to hp with everything else the same. I suspect it means they had more metal and could be ported more before you break into the water jackets or spring seats.

It does not surpise me that the metal in the "die cast" heads may be harder. The older sand cast heads in particular are showing substantial problems due to low hardness, a different casting method and foundry would have used different alloys and heat treatment this could easily result in a better, harder head material.

In assessing a heads condition whats critical is

1. hardness

2. corrosion

3. metal thickness left from previous machining done.

While the early die cast head may be better in some of these parameters I would not trust it as a general rule and test each head before deciding which to keep and which to sell.

cheers

Rohan

As for the "die cast" heads producing more power due to greater rigidity I also struggle with that. I fail to see how rigidity translates to hp with everything else the same. I suspect it means they had more metal and could be ported more before you break into the water jackets or spring seats.

It does not surpise me that the metal in the "die cast" heads may be harder. The older sand cast heads in particular are showing substantial problems due to low hardness, a different casting method and foundry would have used different alloys and heat treatment this could easily result in a better, harder head material.

In assessing a heads condition whats critical is

1. hardness

2. corrosion

3. metal thickness left from previous machining done.

While the early die cast head may be better in some of these parameters I would not trust it as a general rule and test each head before deciding which to keep and which to sell.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8429

- Joined: 22 Sep 2003

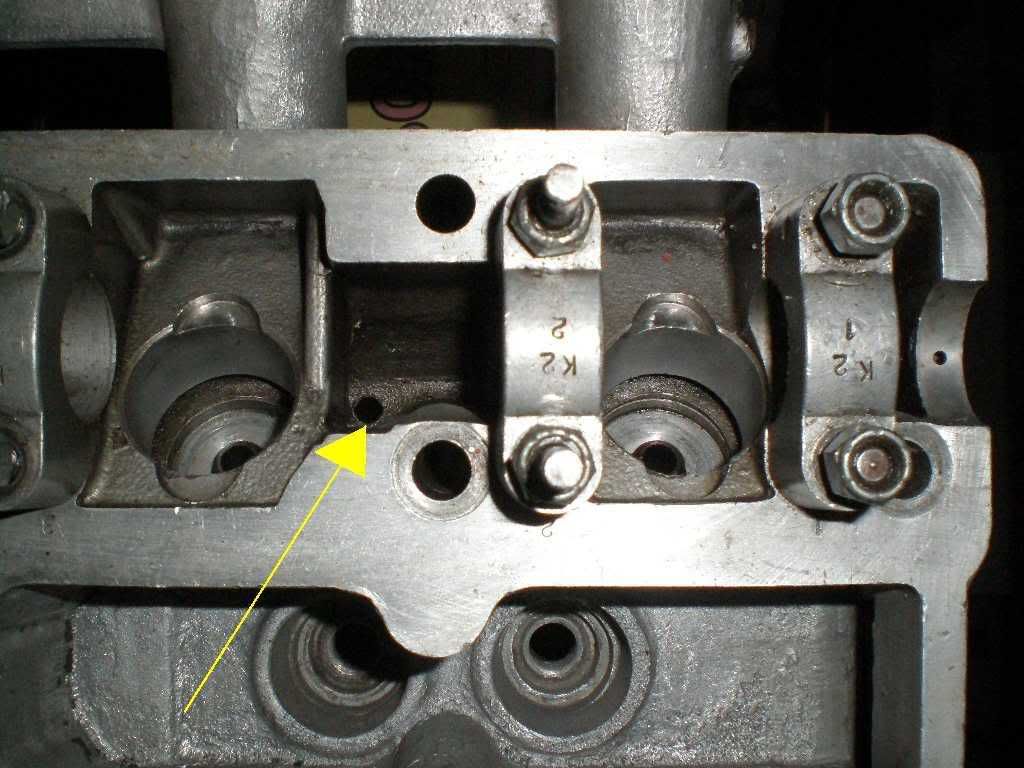

James the above photo show the drain hole (yellow arrow), this is has already been done on every head that I have looked at. There may be a couple that were cast and machined with out it but my guess is there are few.

As far as the die-cast name goes, thats what it has been called in what I have read before so that's how I refered to it. If there needs to be a debate on whether it was "die-cast" or not, I don't know. It doesn't make any difference to me. If some one were to come along and call it mk-1b.3 head then thats great. Until then it needs a name, just like the S1 1/2, there is a need to call them something, because they are enough different from the early and later models that they are supposed to be. A late S1 with a full width full with dash is the same as an early S2 with all of the S1 cary over parts. The bottom line is when someone mentions a name, you don't have to agree that that is what it is, you only have to understand name to know what people are talking about.

Maybe this is all just Lotus slang.

-

garyeanderson - Coveted Fifth Gear

- Posts: 2626

- Joined: 12 Sep 2003

Here in the US, the National Geographic TV channel ran a show "Ultimate Factories".

The Ferrarri factory episode showed the amazing engine sand casting process at Maranello. Very informative.

http://channel.nationalgeographic.com/s ... b-Overview

The Ferrarri factory episode showed the amazing engine sand casting process at Maranello. Very informative.

http://channel.nationalgeographic.com/s ... b-Overview

Phil

1968 S4/SE FHC 36-7936

1968 S4/SE FHC 36-7936

- pamitchell

- Third Gear

- Posts: 269

- Joined: 11 Sep 2003

14 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 25 guests