Wobbling wiper motor bracket

5 posts

• Page 1 of 1

Hi all,

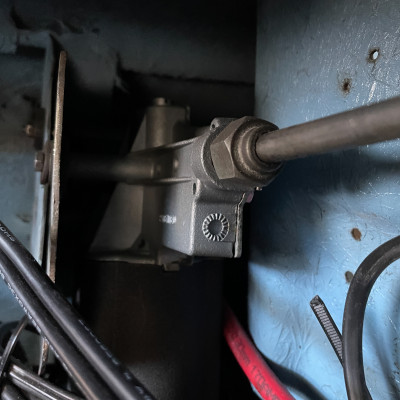

I'd be grateful for recommendations on how best to tackle an issue with the wiper motor bracket on my S3.

The mounting bracket flexes so badly when the wiper operates that I am surprised it hasn't fatigued off already. Check out the horror movie here https://streamable.com/lcx972

Comparing my bracket to the illustration on page M79 of the Workshop Manual it is clear mine is missing a stiffening flange and is the wrong shape + someone has added another misshapen plate and attached the motor to it with just 2 out of the 3 fixing bolts.

Options seem to be:

A - Cut out the current bracket. Fabricate a properly formed replacement and weld it to the lattice and add glass to strengthen (or does somebody sell this bracket?)

B - Fabricate a properly formed replacement and [rivet] it to the current malformed bracket, and glass in a bracing bar to firm it all up

Neither is particularly tempting given the very poor and inverted access.

Better suggestions most welcome

I'd be grateful for recommendations on how best to tackle an issue with the wiper motor bracket on my S3.

The mounting bracket flexes so badly when the wiper operates that I am surprised it hasn't fatigued off already. Check out the horror movie here https://streamable.com/lcx972

Comparing my bracket to the illustration on page M79 of the Workshop Manual it is clear mine is missing a stiffening flange and is the wrong shape + someone has added another misshapen plate and attached the motor to it with just 2 out of the 3 fixing bolts.

Options seem to be:

A - Cut out the current bracket. Fabricate a properly formed replacement and weld it to the lattice and add glass to strengthen (or does somebody sell this bracket?)

B - Fabricate a properly formed replacement and [rivet] it to the current malformed bracket, and glass in a bracing bar to firm it all up

Neither is particularly tempting given the very poor and inverted access.

Better suggestions most welcome

Last edited by DamianB on Wed Feb 14, 2024 4:50 am, edited 1 time in total.

Damian

67 French-Blue Elan S3 DHC 45/7001

67 French-Blue Elan S3 DHC 45/7001

- DamianB

- First Gear

- Posts: 43

- Joined: 04 Sep 2022

On reflection, it occurred to me that the reaction forces in a properly working wiper system should be mostly internal to that system and that tightening the bolt between the gearbox unit and the cable sheath should help to reduce the bending.

Doesn’t change my resolve to fix the bracket properly, but should at least extend the current one’s cycles-to -failure while I engineer a permanent fix.

Doesn’t change my resolve to fix the bracket properly, but should at least extend the current one’s cycles-to -failure while I engineer a permanent fix.

Damian

67 French-Blue Elan S3 DHC 45/7001

67 French-Blue Elan S3 DHC 45/7001

- DamianB

- First Gear

- Posts: 43

- Joined: 04 Sep 2022

DamianB wrote:On reflection, it occurred to me that the reaction forces in a properly working wiper system should be mostly internal to that system and that tightening the bolt between the gearbox unit and the cable sheath should help to reduce the bending.

Doesn’t change my resolve to fix the bracket properly, but should at least extend the current one’s cycles-to -failure while I engineer a permanent fix.

Your reflection on the wiper system is nearly but not quite correct, The reaction forces are (or should be) 'totally' contained rather than 'mostly'. I think that for some reason the outer Bundy type tubing is not being retained correctly at the gearbox or the wheel housing end.

All the bracket should do is support the weight of the motor.

Ian

68 Elan S4 DHC. Built in a weekend from a kit (just like the advert said)

-

Elanman99 - Third Gear

- Posts: 449

- Joined: 11 Sep 2003

5 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 49 guests