Fitting window motor assemblies

14 posts

• Page 1 of 1

Would some be kind enough to provide an account of how to do this?

The doors are currently fitted with the glass and lock/latch mechanisms but not the internal lever latch and rods. I now have them hanging and latching very well after hours of fannying about

Do the rods need to be fitted before the window winders?

What is the technique for installing the motors and arms - it looks a little daunting!

Unfortunately the doors were stripped to their constituent parts when I bough the car so I would really appreciate a blow by blow account from someone who has recently tackled this.

I reckon the doors are the most work of any part of the car.

Cheers

jon

The doors are currently fitted with the glass and lock/latch mechanisms but not the internal lever latch and rods. I now have them hanging and latching very well after hours of fannying about

Do the rods need to be fitted before the window winders?

What is the technique for installing the motors and arms - it looks a little daunting!

Unfortunately the doors were stripped to their constituent parts when I bough the car so I would really appreciate a blow by blow account from someone who has recently tackled this.

I reckon the doors are the most work of any part of the car.

Cheers

jon

- jono

- Coveted Fifth Gear

- Posts: 1860

- Joined: 17 May 2007

Jon, I will be re & re' ing the left side motor next week, so maybe some better info then. A few points from memory of doing the right side a year or two ago.

The motors go in backward to the original GM design, so be careful if they are marked "Left" and Right". The square motor can goes to the front on about ~30 degree forward cant, with (I believe) the inserted large gear cup facing out.

I recall taping the window in the completely raised position to remove & install, although I see now the Workshop Manual mentions placing the glass ~2/3 up with the long operating arm essentially horizontal. I used tape to hold the glass as I think a block inside the door would just get in the way.

I recall putting the operating arm with the powerful spring into a cocked position to fit the motor; I am guessing this is to place it in a horizontal orientation. I recall putting a removable retaining bolt in a hole thru the arm and the plate to hold the arm in position while manipulating the motor assembly and arm into position. Sorry, can't remember more on this, but recall it helped a lot in positioning inside the door.

The parts book calls up screws and bolts for the install. Sorry, having trouble wading thru them, but I recall the set of four with spacers. When I do the job I can probably be clearer & take a few pics. Do you have all the required, bolts, screws, spacers, washers, etc. in your boxes?

The black grounding wire goes with a ring connector to one of the mounting bolts. The other two up and down wires go to the top of the motor assembly with spade connectors, maybe with a nylon connector; my rebuild motor has damage to this connector so will have to improvise a bit.

Can't recall details of attachment to the glass, but I think it just wedges in a slot with some rubber. More details when I get the assembly out.

The whole assembly (motor, mounting plate & arm) fits thru the hole in the door, so you can pre-assemble the whole thing.

I don't recall the rods being in the way during this operation, but if they are presently out of the car I think you are fine to fit them after the window motors are installed.

The motors go in backward to the original GM design, so be careful if they are marked "Left" and Right". The square motor can goes to the front on about ~30 degree forward cant, with (I believe) the inserted large gear cup facing out.

I recall taping the window in the completely raised position to remove & install, although I see now the Workshop Manual mentions placing the glass ~2/3 up with the long operating arm essentially horizontal. I used tape to hold the glass as I think a block inside the door would just get in the way.

I recall putting the operating arm with the powerful spring into a cocked position to fit the motor; I am guessing this is to place it in a horizontal orientation. I recall putting a removable retaining bolt in a hole thru the arm and the plate to hold the arm in position while manipulating the motor assembly and arm into position. Sorry, can't remember more on this, but recall it helped a lot in positioning inside the door.

The parts book calls up screws and bolts for the install. Sorry, having trouble wading thru them, but I recall the set of four with spacers. When I do the job I can probably be clearer & take a few pics. Do you have all the required, bolts, screws, spacers, washers, etc. in your boxes?

The black grounding wire goes with a ring connector to one of the mounting bolts. The other two up and down wires go to the top of the motor assembly with spade connectors, maybe with a nylon connector; my rebuild motor has damage to this connector so will have to improvise a bit.

Can't recall details of attachment to the glass, but I think it just wedges in a slot with some rubber. More details when I get the assembly out.

The whole assembly (motor, mounting plate & arm) fits thru the hole in the door, so you can pre-assemble the whole thing.

I don't recall the rods being in the way during this operation, but if they are presently out of the car I think you are fine to fit them after the window motors are installed.

Stu

1969 Plus 2 Federal LHD

1969 Plus 2 Federal LHD

-

stugilmour - Coveted Fifth Gear

- Posts: 1944

- Joined: 03 Sep 2007

Bit more info today Jon as it was a sunny day and I successfully replaced my left side motor.  I managed to remove and install the new motor without disturbing the raising arm and attachment to the window glass, so you may have to check with others on these details. The motor mounting plates can be moved fore and aft when freed from the door skin, so I assume there are some rollers way up in there. My notes below might help, but are more about motor replacement than taking all of the parts out of boxes and installing them.

I managed to remove and install the new motor without disturbing the raising arm and attachment to the window glass, so you may have to check with others on these details. The motor mounting plates can be moved fore and aft when freed from the door skin, so I assume there are some rollers way up in there. My notes below might help, but are more about motor replacement than taking all of the parts out of boxes and installing them.  Anyway, hope it helps.

Anyway, hope it helps.

Also see this thread with some pic's from Bob.

elan-plus-f13/window-lift-mech-t24952.html

Fasteners required per door are as follows. These are not supplied with the replacement motor.

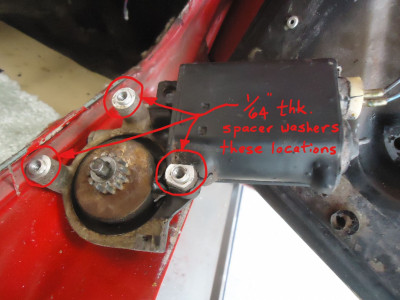

3 only 1/4" NF x 5/8" length with 'inside star' lock washers to mount the motors to the mounting plates. I think there are three of these. One bolt ends up behind the front 'mounting plate' or bar, so you can't see it in the photo's. There are also three only thin spacing washers over the motor mount boss (dimensions below) that act to space the motor gear housing off of the mounting plate.

2 only 1/4" NF x 5/8" length with 'inside star' lock washers to mount the front mounting plate bar to the square mounting plate. Sorry, I am a bit vague on this subtlety as I am celebrating the window going up and down at rapid speed.

2 only 1/4" NF x 1 1/2" length c/w 'inside star' lock washer and 1" outside diameter flat washer to attach the front mounting plate bar to the door skin. No spacers used in this fastening. Thread into captive nuts on front mounting plate bar.

2 only 1/4" NF x 1 1/2" length c/w 'inside star' lock washer and 1" outside diameter flat washer to attach the rear of the main square mounting plate to the door skin. These use 5/8" OD x 1/2" length metal spacers between the door skin and the mounting plate. Bob's photo in the other thread shows these spacers in place very well.

Replacement motors are available from Cardone in the US. Here are links to the parts call-up. Note the left hand side motor call-up for the 1969 Chevelle fits on the right hand side Lotus Plus 2 and visa versa. When you call up the Chev part number there is an additional link that cross references the part to numerous other NA GM models (Caddy, Buick, Pontiac etc.). The motors are provided without the drive gear and fasteners; re-use the ones you have. Electrical connection configuration on the motor may vary (parallel spades or right angle spades), but this is not an issue as the Lotus uses individual spades to connect to the motor. The three motor mounts include a thin 3/8" ID x 5/8" OD x 1/64" thick spacing washer for each mounting boss; these fell out of place when I installed my motor and I re-installed the new motor without them and it seems to work fine. YMMV.

Cardone Part Number: 42-13

Front Left, Rear Left for Chev; fits RHS on Lotus Plus 2

Supplied w/o Gear;Supplied w/o Regulator

http://www.cardone.com/Products/Product ... +Regulator

Cardone Part Number: 42-14

Front Right, Rear Right for Chev; fits LHS on Lotus Plus 2

Supplied w/o Gear;Supplied w/o Regulator

http://www.cardone.com/Products/Product ... +Regulator

The wires to the motor in my car looking to front of car, Blue / Yellow on right spade connector ans Black / Blue on left spade connector. The Black ground wire can be easily mounted on the top motor to vertical mounting plate bolt with a ring connector; evidence in stock form this was connected to the hidden motor mount bolt underneath the mounting bar, but truly beyond me how this may have been assembled. Connect the motor wires on the top of the motor before placing & fastening the motor and mounting plates in position; I couldn't reach them once the motor was fully fastened. The pic of the new motor shows a short pigtail. I dispensed with this and just plugged my wiring directly to the spade motor terminals. I think this pigtail was only included to connect to the stock Chevy wiring that the motors are used for. The gear is not supplied with the replacement motors and has to be cleaned and re-used.

Connect the motor wires on the top of the motor before placing & fastening the motor and mounting plates in position; I couldn't reach them once the motor was fully fastened. The pic of the new motor shows a short pigtail. I dispensed with this and just plugged my wiring directly to the spade motor terminals. I think this pigtail was only included to connect to the stock Chevy wiring that the motors are used for. The gear is not supplied with the replacement motors and has to be cleaned and re-used.

I was able to undo everything without the spring causing a minor explosion in there. The spring is reasonably powerful though, so care required. I unfastened the mounting plate to door skin bolts first. Appears weight of motor holds everything in place.

I unfastened the motor bolts, and still no explosion. Think the engagement of the gear in the worm gear prevents anything moving.

Removed motor from back of the square mounting plate. This is where the spring starts to try and collapse things, so be careful. I think the 'trick' is to insert a temporary bolt into the hole shown below to keep everything cocked. Not sure, but perhaps when the motor is properly attached to the mounting plate the worm gear keeps everything cocked and indexed.

Had to muscle the spring and regulator gear into position to re-fit motor. This is what I meant above by cocking. I used one of the 1 1/2" mounting bolts to retain the arm in a cocked position by threading it into one of the mounting holes and thru a big hole in the regulator gear. Bit awkward, and think there is a better way...

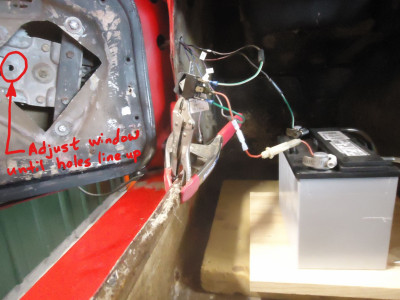

Noticed after all together if you position the window glass approx 1/3 closed 2/3 open (as the Workshop Manual mentions ), there is a 1/4" hole that will retain the regulator gear & mounting plate correctly. Hopefully you can see this in my blurry photo.

), there is a 1/4" hole that will retain the regulator gear & mounting plate correctly. Hopefully you can see this in my blurry photo.

I would revise my previous statement that the whole show can be assembled outside the car and inserted. I think the mounting plate bar will not fit thru the opening in 'stock' form. Expect it is OK to assemble the cocked arm and regulator gear assembly, motor, and square mounting plate and insert this assembly thru the access hole. Then attach the front mounting bar plate to the square mounting plate inside the door. Attach the drive wires. Muscle the mounting plates into position and attach to the door skin. Remove the temporary bolt inserted to keep the arm cocked.

All in all a success today with only three washers left over and minor bleeding.

HTH

Also see this thread with some pic's from Bob.

elan-plus-f13/window-lift-mech-t24952.html

Fasteners required per door are as follows. These are not supplied with the replacement motor.

3 only 1/4" NF x 5/8" length with 'inside star' lock washers to mount the motors to the mounting plates. I think there are three of these. One bolt ends up behind the front 'mounting plate' or bar, so you can't see it in the photo's. There are also three only thin spacing washers over the motor mount boss (dimensions below) that act to space the motor gear housing off of the mounting plate.

2 only 1/4" NF x 5/8" length with 'inside star' lock washers to mount the front mounting plate bar to the square mounting plate. Sorry, I am a bit vague on this subtlety as I am celebrating the window going up and down at rapid speed.

2 only 1/4" NF x 1 1/2" length c/w 'inside star' lock washer and 1" outside diameter flat washer to attach the front mounting plate bar to the door skin. No spacers used in this fastening. Thread into captive nuts on front mounting plate bar.

2 only 1/4" NF x 1 1/2" length c/w 'inside star' lock washer and 1" outside diameter flat washer to attach the rear of the main square mounting plate to the door skin. These use 5/8" OD x 1/2" length metal spacers between the door skin and the mounting plate. Bob's photo in the other thread shows these spacers in place very well.

Replacement motors are available from Cardone in the US. Here are links to the parts call-up. Note the left hand side motor call-up for the 1969 Chevelle fits on the right hand side Lotus Plus 2 and visa versa. When you call up the Chev part number there is an additional link that cross references the part to numerous other NA GM models (Caddy, Buick, Pontiac etc.). The motors are provided without the drive gear and fasteners; re-use the ones you have. Electrical connection configuration on the motor may vary (parallel spades or right angle spades), but this is not an issue as the Lotus uses individual spades to connect to the motor. The three motor mounts include a thin 3/8" ID x 5/8" OD x 1/64" thick spacing washer for each mounting boss; these fell out of place when I installed my motor and I re-installed the new motor without them and it seems to work fine. YMMV.

Cardone Part Number: 42-13

Front Left, Rear Left for Chev; fits RHS on Lotus Plus 2

Supplied w/o Gear;Supplied w/o Regulator

http://www.cardone.com/Products/Product ... +Regulator

Cardone Part Number: 42-14

Front Right, Rear Right for Chev; fits LHS on Lotus Plus 2

Supplied w/o Gear;Supplied w/o Regulator

http://www.cardone.com/Products/Product ... +Regulator

The wires to the motor in my car looking to front of car, Blue / Yellow on right spade connector ans Black / Blue on left spade connector. The Black ground wire can be easily mounted on the top motor to vertical mounting plate bolt with a ring connector; evidence in stock form this was connected to the hidden motor mount bolt underneath the mounting bar, but truly beyond me how this may have been assembled.

I was able to undo everything without the spring causing a minor explosion in there. The spring is reasonably powerful though, so care required. I unfastened the mounting plate to door skin bolts first. Appears weight of motor holds everything in place.

I unfastened the motor bolts, and still no explosion. Think the engagement of the gear in the worm gear prevents anything moving.

Removed motor from back of the square mounting plate. This is where the spring starts to try and collapse things, so be careful. I think the 'trick' is to insert a temporary bolt into the hole shown below to keep everything cocked. Not sure, but perhaps when the motor is properly attached to the mounting plate the worm gear keeps everything cocked and indexed.

Had to muscle the spring and regulator gear into position to re-fit motor. This is what I meant above by cocking. I used one of the 1 1/2" mounting bolts to retain the arm in a cocked position by threading it into one of the mounting holes and thru a big hole in the regulator gear. Bit awkward, and think there is a better way...

Noticed after all together if you position the window glass approx 1/3 closed 2/3 open (as the Workshop Manual mentions

I would revise my previous statement that the whole show can be assembled outside the car and inserted. I think the mounting plate bar will not fit thru the opening in 'stock' form. Expect it is OK to assemble the cocked arm and regulator gear assembly, motor, and square mounting plate and insert this assembly thru the access hole. Then attach the front mounting bar plate to the square mounting plate inside the door. Attach the drive wires. Muscle the mounting plates into position and attach to the door skin. Remove the temporary bolt inserted to keep the arm cocked.

All in all a success today with only three washers left over and minor bleeding.

HTH

- Attachments

-

- This one is after I buttoned everything up and discovered the 'correct' position for the window glass for installing the whole assembly. There is a hole that I think a temporary bolt can be wedged in to that would keep the arm and regulator in a cocked position. I didn't do it this way, so please be careful; this spring is reasonably powerful.

-

- Shows the old and new motors side by side. The replacement is called up for a 1969 Chevy Chevelle at the parts counter, but was used in a wide variety of GM's of the era. Note you need the Chevy right door motor for the Lotus left door install and visa versa. This quirk makes installing the motor considerably more difficult without a Proctology degree because the motor is located behind the mounting plates in the Lotus. Can also see the pigtail on the new motor that was not required in the Lotus application. The drive gear that engages to the worm from the motor shaft has already been cleaned and swapped over to the new motor; the gear is not supplied with the rebuilt motor. My rebuilt motors are from Cardone in the US, a apparently large supplier of rebuilt motors. They were a simple call-up at my local parts store; no vintage parts supplier required. I think it is a $40 core on the old motor without the gear, so save the receipt.

You can also see the three threaded holes for the 1/4" NF x 5/8" mounting bolts. Looking at the plate pic you can see how one of the bolts ends up located under the bar plate.

The three thin washers I have left over go on the mounting boss' you can see on the motor housing around the gear. I expect they keep the gear from rubbing on the mounting plate.

-

- Shows the motor and mounting plates positioned and in place with the window glass approx 1/3 closed 2/3 open as in the other pic without tape. The 'dome' in the centre of the mounting plate is where the motor gear spindle is received into the mounting plate. Note the hole on the left side of the plate; this is where I believe you can insert a temporary retaining bolt or screwdriver to keep the arm in the cocked position. It is lined up with a corresponding hole in the regulator gear plate so you can see right thru to the outer door skin. You can see two of the motor mounting bolts (1/4" NF x 5/8" long) with their star washers and no flat washer. A third motor mounting bolt is hidden by the mounting plate bar at the front of the assembly. The mounting bar goes with the bent end to the top. There are also two 1/4" NF x 5/8" bolts that I think mount the bar to the plate, but not sure at this point. You can see the black grounding wire attached to the bar plate mounting bolt with a ring connector.

Stu

1969 Plus 2 Federal LHD

1969 Plus 2 Federal LHD

-

stugilmour - Coveted Fifth Gear

- Posts: 1944

- Joined: 03 Sep 2007

Stu,

Many, many thanks for the time you have taken to explain this. Following your instructions I now have a +2 with electric windows working for the first time in 25 years - you really are a true gent of this forum.

- you really are a true gent of this forum.

I am feeling a huge sense of satisfaction gradually turning this basket case into a lovely looking car. The windows actually work faster than my modern Subaru - quite a result

Many thanks again.

Jon

Many, many thanks for the time you have taken to explain this. Following your instructions I now have a +2 with electric windows working for the first time in 25 years

I am feeling a huge sense of satisfaction gradually turning this basket case into a lovely looking car. The windows actually work faster than my modern Subaru - quite a result

Many thanks again.

Jon

- jono

- Coveted Fifth Gear

- Posts: 1860

- Joined: 17 May 2007

jono wrote:Stu,

I am feeling a huge sense of satisfaction gradually turning this basket case into a lovely looking car. The windows actually work faster than my modern Subaru - quite a result

Many thanks again.

Jon

Thanks for the kind words Jon. Very satisfying at this end as well. Really fun to think you can help someone out 6 or 7 time zones away.

Please if you have time could you add any remarks or clarification on the attachment of the arms to the window glass? Thinking it would be nice to have all the info in one thread for future reference.

As an adder, I found with the windows working so quickly that 15 amp fuses were required on the power circuit to the motors. 10 amp fuses tended to blow at the limit stall points and I wouldn't switch them off quickly enough. I used 25 amp thin wall cable, so the circuit is properly protected. Also used relays to protect the weak original dash switches.

Stu

1969 Plus 2 Federal LHD

1969 Plus 2 Federal LHD

-

stugilmour - Coveted Fifth Gear

- Posts: 1944

- Joined: 03 Sep 2007

Stu,

I have added below some comments on my own experiences.

I greased up the springs on the arms and then turned the plat through around 90 degrees to 'cock' the arms then pushed the bolt through the obvious hole to hold the arms in the tensioned position (you are right - you do not want to get your fingers guillotined if it all lets go )

)

The driver?s side had had the motor aperture opened out so that side was easier - I could get the whole assembly in inc. the motor attached to the arm and plate. The passenger side is unaltered so I will give an account of that side being as it was the most difficult. I found that it was best to leave the glass free to slide up and down and I hooked a bungee tie onto the bottom of the glass which I was then able to raise or lower to various positions which eased the process of engaging the nylon capstan on the end of the arms into the lower glass channel. I had new capstans made up in nylon and riveted onto the arms as the old ones were collapsed. I should add that I did a complete strip down of the glass and cleaned and re fitted the guide channels complete with new stainless set screws and foam washers (as the door frames have been away for chroming).

The arm with cocked spring and plate was entered through the aperture on the front of the door and the glass tracks were greased by reaching in from the front an drear apertures and ?dobbing? (an English colloquilism) grease in with the fingers. The end of the arm is engaged into the channel at the rear by passing a hand into the rear door shell aperture and then it can be slid along to the front and left to hang down. I found that a timber block was useful in holding the glass in place at various heights by sticking this through the rear door aperture.

The motor is then pass into the front aperture and connected to the (new) wiring loom before it is fixed into place ? the earth tab is left hanging.

Next up is to fix the motor to the arm plate with the 3 short UNF set screws with shake proof washers (have added copious grease to the motor drive pinion (this is where a third hand would come in useful but there was neither the space for nor indeed a ?handy? third hand on hand so to speak!).

After some Anglo Saxon words I managed to get the motor bolted up to the plate and the pinion engaged with the arc shaped rack on the arm ? you can remove the spare bolt now as the motor now holds the spring tension.

Next up ? loosely fit the plate to the rear most door bobbins including the 2 spacers with penny washers and anti shake washers using the unf bolts. Next fit the forward mounting strap to the plate making sure you use the shorter unf set screws which need to clear the arm rack. The earth tab goes under the top set screw.

Next up fix the strap to the upper and lower bobbins with the unf bolts (no spacers) using a penny washer and anti shake washer.

Tighten everything up and power up. Watch glass whizz up and down!

In all the excitement I forgot to take any photos

Jon

I have added below some comments on my own experiences.

I greased up the springs on the arms and then turned the plat through around 90 degrees to 'cock' the arms then pushed the bolt through the obvious hole to hold the arms in the tensioned position (you are right - you do not want to get your fingers guillotined if it all lets go

The driver?s side had had the motor aperture opened out so that side was easier - I could get the whole assembly in inc. the motor attached to the arm and plate. The passenger side is unaltered so I will give an account of that side being as it was the most difficult. I found that it was best to leave the glass free to slide up and down and I hooked a bungee tie onto the bottom of the glass which I was then able to raise or lower to various positions which eased the process of engaging the nylon capstan on the end of the arms into the lower glass channel. I had new capstans made up in nylon and riveted onto the arms as the old ones were collapsed. I should add that I did a complete strip down of the glass and cleaned and re fitted the guide channels complete with new stainless set screws and foam washers (as the door frames have been away for chroming).

The arm with cocked spring and plate was entered through the aperture on the front of the door and the glass tracks were greased by reaching in from the front an drear apertures and ?dobbing? (an English colloquilism) grease in with the fingers. The end of the arm is engaged into the channel at the rear by passing a hand into the rear door shell aperture and then it can be slid along to the front and left to hang down. I found that a timber block was useful in holding the glass in place at various heights by sticking this through the rear door aperture.

The motor is then pass into the front aperture and connected to the (new) wiring loom before it is fixed into place ? the earth tab is left hanging.

Next up is to fix the motor to the arm plate with the 3 short UNF set screws with shake proof washers (have added copious grease to the motor drive pinion (this is where a third hand would come in useful but there was neither the space for nor indeed a ?handy? third hand on hand so to speak!).

After some Anglo Saxon words I managed to get the motor bolted up to the plate and the pinion engaged with the arc shaped rack on the arm ? you can remove the spare bolt now as the motor now holds the spring tension.

Next up ? loosely fit the plate to the rear most door bobbins including the 2 spacers with penny washers and anti shake washers using the unf bolts. Next fit the forward mounting strap to the plate making sure you use the shorter unf set screws which need to clear the arm rack. The earth tab goes under the top set screw.

Next up fix the strap to the upper and lower bobbins with the unf bolts (no spacers) using a penny washer and anti shake washer.

Tighten everything up and power up. Watch glass whizz up and down!

In all the excitement I forgot to take any photos

Jon

- jono

- Coveted Fifth Gear

- Posts: 1860

- Joined: 17 May 2007

Excellent Jon. I vaguely remember the nylon capstan's now from when I did the RHS a few years ago. I chickened out on removal of the glass and window frames, although I still have the gasket material Sue Miller sent when I had more courage and money.  Did the job without a third hand as well, which probably preserved the marriage. I may have swore at the dog once, but she seems to be OK now.

Did the job without a third hand as well, which probably preserved the marriage. I may have swore at the dog once, but she seems to be OK now.

Thanks for clarifying the key safety issue on the motor worm gear / drive gear engagement retaining the spring tension until removal of the spare 'cocking bolt'. I had a lot of trepidation approaching this job both times, half expecting the spring to smash the glass or grab my hand at some unexpected moment. Should have made better notes the first time, but I of course assumed I would remember everything clear as a bell.

Note this post edited to indicate my door seal supplier was Spyder not RD ...

...

One last question at the risk of a bit of thread drift. I am happy with the LHS door alignment, although the interior latch is under enough strain when actuated that the rod is deflecting and causing the door to jam shut some times. My RHS door sticks out at the rear further than ideal. I have endlessly fiddled with the door latches to try and correct the issue, and they are presently at the max of the adjustment range and still don't look right. When I remove the gasket seal the door can be closed flush, so suspect my door seal is too thick.

During my rebuild a few years ago I sourced the new door gaskets from Spyder in the UK. Have attached three profile pic's below. One pic is what I received from Spyder, and the other two pic's are the current reference photo's from Ray's web site at RDent.com . On the piece I received from Spyder a few year's ago the oval seal is 5/8" OD on the major axis. Comparing with the reference photo the seal bulb sizes look similar to one another, although the one I have received has a small additional seal bulb.

Here is Ray's part description (Emphasis added):

Door Seal

Replacement bulb style door seal for Elan Plus 2.

Supplied as a length; you must cut and miter upper rear corner for all the above applications. Grained pattern on vinyl channel; channel is metal reinforced to securely attach to body. Round rubber sealing bulb.

Ref. 50B6029 Elan +2 $29.00

one piece required per door

Were you (or anyone else) able to get new door seals your side of the pond (perhaps a different profile or the Elan profile shown below?) that resulted in good door fit and smooth latch operation on a Plus 2? Did you have to trim the gasket at any of the sharp radius corners in the door opening as Ray suggests? Can I perhaps trim mine a bit to get a more compact seal? Are either of the photo's close to the stock profile for the Plus 2? I note Ray shows a different seal for the Elan S3 / S4, which might be a possibility?

Edit... Just got off the phone with Ray. He is going to ship two of his bulb type seals in a couple of weeks, and I will give them a try. He mentioned he has not had problems he can recall with Plus 2 seals, but has had some customer reports with Elan and Europa seal fitment requiring trimming. Based on this we decided to try the bulb seals first. I am hoping the new seals will be more compressible than the one's I have now. Anyway, still interested in other's experience with seals from other suppliers and what the stock seal may have looked like.

Thanks in advance.

Thanks for clarifying the key safety issue on the motor worm gear / drive gear engagement retaining the spring tension until removal of the spare 'cocking bolt'. I had a lot of trepidation approaching this job both times, half expecting the spring to smash the glass or grab my hand at some unexpected moment. Should have made better notes the first time, but I of course assumed I would remember everything clear as a bell.

Note this post edited to indicate my door seal supplier was Spyder not RD

One last question at the risk of a bit of thread drift. I am happy with the LHS door alignment, although the interior latch is under enough strain when actuated that the rod is deflecting and causing the door to jam shut some times. My RHS door sticks out at the rear further than ideal. I have endlessly fiddled with the door latches to try and correct the issue, and they are presently at the max of the adjustment range and still don't look right. When I remove the gasket seal the door can be closed flush, so suspect my door seal is too thick.

During my rebuild a few years ago I sourced the new door gaskets from Spyder in the UK. Have attached three profile pic's below. One pic is what I received from Spyder, and the other two pic's are the current reference photo's from Ray's web site at RDent.com . On the piece I received from Spyder a few year's ago the oval seal is 5/8" OD on the major axis. Comparing with the reference photo the seal bulb sizes look similar to one another, although the one I have received has a small additional seal bulb.

Here is Ray's part description (Emphasis added):

Door Seal

Replacement bulb style door seal for Elan Plus 2.

Supplied as a length; you must cut and miter upper rear corner for all the above applications. Grained pattern on vinyl channel; channel is metal reinforced to securely attach to body. Round rubber sealing bulb.

Ref. 50B6029 Elan +2 $29.00

one piece required per door

Were you (or anyone else) able to get new door seals your side of the pond (perhaps a different profile or the Elan profile shown below?) that resulted in good door fit and smooth latch operation on a Plus 2? Did you have to trim the gasket at any of the sharp radius corners in the door opening as Ray suggests? Can I perhaps trim mine a bit to get a more compact seal? Are either of the photo's close to the stock profile for the Plus 2? I note Ray shows a different seal for the Elan S3 / S4, which might be a possibility?

Edit... Just got off the phone with Ray. He is going to ship two of his bulb type seals in a couple of weeks, and I will give them a try. He mentioned he has not had problems he can recall with Plus 2 seals, but has had some customer reports with Elan and Europa seal fitment requiring trimming. Based on this we decided to try the bulb seals first. I am hoping the new seals will be more compressible than the one's I have now. Anyway, still interested in other's experience with seals from other suppliers and what the stock seal may have looked like.

Thanks in advance.

- Attachments

-

- Reference photo from Ray's site for the Elan S3/S4 main door seal. He lists the same seal for coupe and convertible, but presumably different lengths.

- RD Enterprises Elan S3 S4 door seal profile from Ray's web site.JPG (20.46 KiB) Viewed 5269 times

-

- Reference photo from Ray's site for the Plus 2 main door seal.

- RD Enterprises Plus 2 door seal profile from Ray's web site.JPG (20.97 KiB) Viewed 5270 times

Stu

1969 Plus 2 Federal LHD

1969 Plus 2 Federal LHD

-

stugilmour - Coveted Fifth Gear

- Posts: 1944

- Joined: 03 Sep 2007

Guys - great to hear that the windows can be made to move at a reasonable speed, what would you say would be the most effective part of your installs that achieved this? Relays? Serviced motors?

P.S. Stu - I've still not had chance to check out the window stops

Cheers

Robbie

P.S. Stu - I've still not had chance to check out the window stops

Cheers

Robbie

-

Robbie693 - Coveted Fifth Gear

- Posts: 1515

- Joined: 08 Oct 2003

Robbie693 wrote:Guys - great to hear that the windows can be made to move at a reasonable speed, what would you say would be the most effective part of your installs that achieved this? Relays? Serviced motors?

P.S. Stu - I've still not had chance to check out the window stops

Cheers

Robbie

Motors for sure in terms of speed. I did the re-wire and relay thing on both sides, but only replaced one motor due to it's complete failure. The driver's side remained very slow, not much better than original. Recent replacement with rebuilt motor has the window moving very well. I noticed on the Cardone site they include re-magnetizing as part of the rebuild process; perhaps this is the biggest improvement factor? The grease in the original drive gear was pretty sticky as well.

That said, the relays are a good feature to protect the antique switches. One of my switches is clearly dirty as I can hear the relay clicking sometimes; might not have worked at all with the full motor current.

Bottom line if you are digging around to address the stop issue might be good idea to get a new motor; I bet Jon would agree that you don't particularly want to go in there twice!

Stu

1969 Plus 2 Federal LHD

1969 Plus 2 Federal LHD

-

stugilmour - Coveted Fifth Gear

- Posts: 1944

- Joined: 03 Sep 2007

Stu,

I got my door seals from Sue Miller. They are quite tight but I have managed to acheive acceptable shut lines.

I am working on the basis that as the seals compress with age I can pull the doors in a little to achieve perfect lines. In the meantime however I am happy with what I have achieved - the doors shut nicely without undue force and achieve acceptable lines.

I have attached a photo of the Sue seal set agianst the original door seal on my JPS + 2 (the JPS seals are factory originals). They are very similar but the Sue seal has a thicker material to the bulb which probabaly accounts for them being a tad tight.

Not sure what the query was on the window stops but the bottom guide channel had a small platform to the front onto which a piece of rubber is glued - this impacts on the indent in the bottom of the fibreglass door shell. I replaced mine with polyurethane foam and it seems to work well. If teh rubber buffers are missing (likely) you can just reach into the door shell to replace them from the forward latch aperture without having to tear everything down.

Cheers

Jon

I got my door seals from Sue Miller. They are quite tight but I have managed to acheive acceptable shut lines.

I am working on the basis that as the seals compress with age I can pull the doors in a little to achieve perfect lines. In the meantime however I am happy with what I have achieved - the doors shut nicely without undue force and achieve acceptable lines.

I have attached a photo of the Sue seal set agianst the original door seal on my JPS + 2 (the JPS seals are factory originals). They are very similar but the Sue seal has a thicker material to the bulb which probabaly accounts for them being a tad tight.

Not sure what the query was on the window stops but the bottom guide channel had a small platform to the front onto which a piece of rubber is glued - this impacts on the indent in the bottom of the fibreglass door shell. I replaced mine with polyurethane foam and it seems to work well. If teh rubber buffers are missing (likely) you can just reach into the door shell to replace them from the forward latch aperture without having to tear everything down.

Cheers

Jon

- jono

- Coveted Fifth Gear

- Posts: 1860

- Joined: 17 May 2007

Thanks Both, I was hoping I could use some poly foam as a pad, sounds like an easy fix. The motors will have to wait until I have nothing else to sort out for now though!

Cheers

Robbie

Cheers

Robbie

-

Robbie693 - Coveted Fifth Gear

- Posts: 1515

- Joined: 08 Oct 2003

Just started this job on my Zetec restoration but (like the first correspondent) I didn't take the doors apart so I am feeling my way in reassembling things, this thread is very useful, thanks Stu.

One initial comment, the screws for mounting the motor to the mechanism are 1/4 UNC not UNF (because it's into alloy). Strangely the manual shows the Motor and mechanism as a single part and doesn't show the screws separately. Does anyone know the length? If not, I'll use the longest that fits.

Finally, a stupid question..... how do I identify the LH and RH mechanisms, they are not the same and they have both part numbers stamped on them!

One initial comment, the screws for mounting the motor to the mechanism are 1/4 UNC not UNF (because it's into alloy). Strangely the manual shows the Motor and mechanism as a single part and doesn't show the screws separately. Does anyone know the length? If not, I'll use the longest that fits.

Finally, a stupid question..... how do I identify the LH and RH mechanisms, they are not the same and they have both part numbers stamped on them!

- mikealdren

- Coveted Fifth Gear

- Posts: 1194

- Joined: 26 Aug 2006

Reply to myself, trial fitting the mechanisms shows which one fits which door, the wrong way round they don't have enough travel to reach the bottom of the door.

- mikealdren

- Coveted Fifth Gear

- Posts: 1194

- Joined: 26 Aug 2006

Easy reply first. The window motor bolts are 1/2" long (1/4" UNC). When installing the motors, be sure to install spacer washers on the motor side behind the window arm plate per the photo attachment.

I struggled taking my windows apart. I did the RH side first and almost took my hand off due to the spring load on the window arm bracket which I had not secured at all before removing the bolts. I got much smarter on the LH window. Unfortunately I had the door glass down only about a few inches. This position worked well to allow removal of the door lock, handle, and mirror. Since I had also already removed my dash and wiring, I did a temporary window motor hookup to reposition the door glass. You need to line up a hole in the window arm backing plate as shown.

With the bolt in place, you can remove all of the window arm bolts along with the window motor bolts and drop the motor into the door recess. You can slide the window arm assembly towards the rear of the door which will allow for removal of the motor out of the door aperture. No need to enlarge any openings but be careful sliding the arm backward too far or it may slide off the end of the window glass bracket.

Attached are additional photos of the LH arm, front and rear views, with the temporary bolt in place.

You where also correct stating that both the RH and LH part numbers are stamped in each arm. Following is a photo of both arms side by side with the arms in the basically full-up position. The "ear" on the spring tensioner goes on the underside of the tab that is part of the window arm plate. In this position, there will be a slight spring tension for the window in the full-up position with greater tension in the full-down position.

Last photo is of the complete LH door glass assembly. I have removed everything since I will be having the window frame replated. Hope this helps. If anyone needs more photo details, just ask.

I struggled taking my windows apart. I did the RH side first and almost took my hand off due to the spring load on the window arm bracket which I had not secured at all before removing the bolts. I got much smarter on the LH window. Unfortunately I had the door glass down only about a few inches. This position worked well to allow removal of the door lock, handle, and mirror. Since I had also already removed my dash and wiring, I did a temporary window motor hookup to reposition the door glass. You need to line up a hole in the window arm backing plate as shown.

With the bolt in place, you can remove all of the window arm bolts along with the window motor bolts and drop the motor into the door recess. You can slide the window arm assembly towards the rear of the door which will allow for removal of the motor out of the door aperture. No need to enlarge any openings but be careful sliding the arm backward too far or it may slide off the end of the window glass bracket.

Attached are additional photos of the LH arm, front and rear views, with the temporary bolt in place.

You where also correct stating that both the RH and LH part numbers are stamped in each arm. Following is a photo of both arms side by side with the arms in the basically full-up position. The "ear" on the spring tensioner goes on the underside of the tab that is part of the window arm plate. In this position, there will be a slight spring tension for the window in the full-up position with greater tension in the full-down position.

Last photo is of the complete LH door glass assembly. I have removed everything since I will be having the window frame replated. Hope this helps. If anyone needs more photo details, just ask.

Steve

'73 Elan +2S 130/5 Cabriolet

'73 Elan +2S 130/5 Cabriolet

-

Hethel_Haus - First Gear

- Posts: 41

- Joined: 18 Jul 2009

14 posts

• Page 1 of 1

Total Online:

Users browsing this forum: pharriso and 36 guests