New Alternator - not charging - Batt light stays on

20 posts

• Page 2 of 2 • 1, 2

Hi all again

This post has raised quite a few comments. I thought I should clarify the position with a dynamo. The earlier test will work fine with an alternator. the rectifiers diode in an alternator ( see circuit attached by Bill) will prevent the battery sourcing current into the machine. A dynamo when not running will draw current and may actually revolve --this would confirm that it does work by the way! this is why the controllers have a cut out to disconnect the dynamo at low speed or when the engine is not running.

with a dynamo add a further bulb in the armature circuit should provide protection and prevent excess current flow until the machine speed builds up. initially bulb will light then as machine revs up both bulbs should go out then further speed the 12V/21W bulb will glow slightly as the dynamo provides some charging current to the battery. Have atached a updated sketch

Hope this helps and that the test go well

best of luck

Bob

This post has raised quite a few comments. I thought I should clarify the position with a dynamo. The earlier test will work fine with an alternator. the rectifiers diode in an alternator ( see circuit attached by Bill) will prevent the battery sourcing current into the machine. A dynamo when not running will draw current and may actually revolve --this would confirm that it does work by the way! this is why the controllers have a cut out to disconnect the dynamo at low speed or when the engine is not running.

with a dynamo add a further bulb in the armature circuit should provide protection and prevent excess current flow until the machine speed builds up. initially bulb will light then as machine revs up both bulbs should go out then further speed the 12V/21W bulb will glow slightly as the dynamo provides some charging current to the battery. Have atached a updated sketch

Hope this helps and that the test go well

best of luck

Bob

- bob_rich

- Fourth Gear

- Posts: 555

- Joined: 06 Aug 2009

Alternator now working after fitting a new fan belt (another toothed one). The impossible turned out to be true - even though the pulley was turning smartly it was not turning at the crank pulley speed. This was obviously also true of the generator before.

When working, I get a beautifully steady 13-14v. Anxiety has now switched to whether my water pump will suffer from the tighter belt. But at least I know the alternators not a dud.

When working, I get a beautifully steady 13-14v. Anxiety has now switched to whether my water pump will suffer from the tighter belt. But at least I know the alternators not a dud.

68 +2 Carnival Red

- dgently

- Second Gear

- Posts: 73

- Joined: 21 Apr 2008

If you are worried about your waterpump, and not too concerned with originality, try one of these toothed belt drive kits. I have one fitted, and run the belt quite slack. Very little side load is applied to the waterpump with this installation.

http://www.burtonpower.com/parts-by-fit ... _group=398

Cheers,

Colin.

http://www.burtonpower.com/parts-by-fit ... _group=398

Cheers,

Colin.

dgently wrote:Alternator now working after fitting a new fan belt (another toothed one). The impossible turned out to be true - even though the pulley was turning smartly it was not turning at the crank pulley speed. This was obviously also true of the generator before.

When working, I get a beautifully steady 13-14v. Anxiety has now switched to whether my water pump will suffer from the tighter belt. But at least I know the alternators not a dud.

'68 S4 DHC

- fatboyoz

- Fourth Gear

- Posts: 631

- Joined: 04 Oct 2003

billwill wrote:billwill wrote:I wonder if there is any way of testing the alternator alone. Clamp it in a vice, connect a multimeter between the case and the output and spin the alternator with say an electric drill with a buffing pad on it.

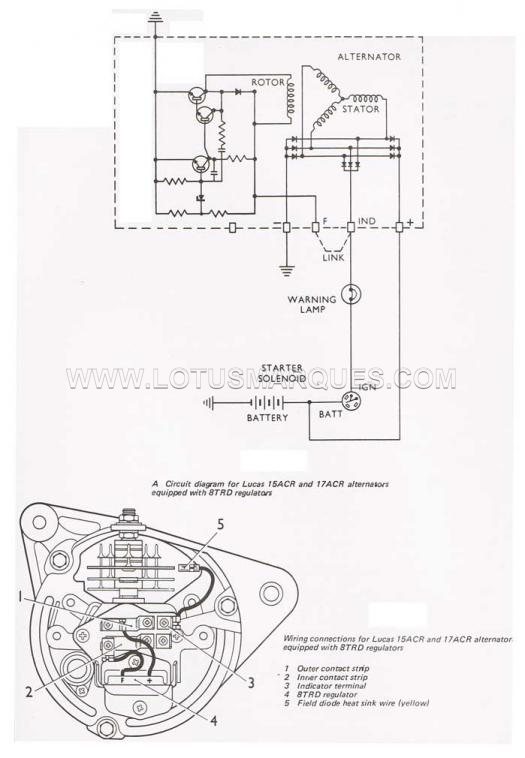

While checking whether or not this was practical (i.e without a battery) I found on the net this diagram which shows the internal circuitry of a standard alternator.

From this, to me, it is clear, that you definitely need a battery there to get the alternator started. The voltage from the car battery causes current through the indicator light which feeds the transistors (which are the generated voltage regulator) at top left, which in turn control the field current (in the rotor) via slip-ring brushes.

The strength of the magnetic field in the rotor determines how many volts the stator coils generate, the alternating voltage/current from the stator coils is rectified be the 3 left diodes and the 3 right diodes to produce the main output at the terminal marked +

Meanwhile an extra set of diodes (centre set) also rectify the generated output and feed it back to the input that came through the bulb, this (via link IND->F) takes over supplying the current to the regulator (and hence the rotor field), which is no longer drawn through the bulb and the indicator light goes out.

~~~~~

There are lots of bits to go wrong in there.

An incidental consequence is that if your ignition indicator bulb fails or is not connected properly the alternator will not get started and you won't charge your battery.

"For want of a nail a shoe was lost ..... " etc.

Bill,

In most cases there is sufficient residual magnetism in the rotor for the alternator to pick itself up by its own bootstraps. The alternator will 'come alive' at lower revs with the bulb in circuit, but usually a good blip of the throttle will get the alternator to self sustain even without a bulb in circuit.

Andy.

68 Elan S3 HSCC Roadsports spec

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

- Andy8421

- Coveted Fifth Gear

- Posts: 1227

- Joined: 27 Mar 2011

20 posts

• Page 2 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 14 guests