LHD Alternator Bracket

42 posts

• Page 2 of 3 • 1, 2, 3

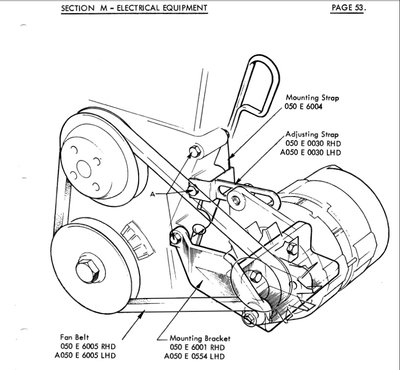

When I bought my bracket I didn't know there were two types and ended up with a LHD one. It's OK on a RHD car, I assume the difference is to do with clearance for the steering column.

Looking at the workshop manual again I see there are different part numbers for the adjusting strap and fan belt as well, I'm using the RHD parts without any problems.

Alan.

Looking at the workshop manual again I see there are different part numbers for the adjusting strap and fan belt as well, I'm using the RHD parts without any problems.

Alan.

- alan71

- Second Gear

- Posts: 220

- Joined: 15 Jul 2007

rgh0 wrote:Those brackets were fitted to both LHD and RHD late plus 2's with alternators - I have always thought they were identical in mounting height - but if they have different part numbers then I must have been wrongor maybe some other difference for the different part numbers. its strange to make 2 versions when the LHD version would suit both LHD and RHD cars

I would love to see the differences in dimensions - I have a RHD one and will measure it up

Just as a side note these are especially valuable for a high reving race twin cams if you use an alternator as they dont break with all the engine vibration you get above 8000 rpm around the front of the engine. I am just replacing the alternator top adjusting arm today on the elan as they fatigue and fail after about 2 years of racing. I am on version 5 now and each one has been stronger than the last - maybe this one will not fail.

Not easy to find them and a good candidate for someone to CNC machine a batch for sale in both LHD and RHD versions maybe

The one that came with my Plus 2 now resides on my Elan and an new one for the plus 2 plus a spare would be nice

cheers

Rohan

Rohan

Forgive me for being silly but why is it that the brackets break and why is the mounting for the alternator so much beefier than the dynamo, as I think I could make the dynamo bracket work with a length of threaded rod?

The engine vibrates the same but I suppose the alternator has a smaller pulley and spins faster??

Do you think my dynamo bracket would be Ok for an alternator for normal road use?

Thanks

Terry

- terryp

- Coveted Fifth Gear

- Posts: 1264

- Joined: 29 Nov 2007

terryp wrote:Rohan

Forgive me for being silly but why is it that the brackets break and why is the mounting for the alternator so much beefier than the dynamo, as I think I could make the dynamo bracket work with a length of threaded rod?

The engine vibrates the same but I suppose the alternator has a smaller pulley and spins faster??

Do you think my dynamo bracket would be Ok for an alternator for normal road use?

Thanks

Terry

I suspect the alternator is more vulnerable to a resonance due the inherent vibration due to its moountnig geometry and because more of its weight is concentrated up near the nose where the twink vibrates the most, its not due to the alternator spin speed itself. The heavy standard lotus bracket is not really needed for road use as it only becomes any issue with 8000 rpm plus engines in my experience. My plus 2 has a simple welded up bracket in a similar style to the standard dynamo mount for the bottom alternator mount and the standard top connection and has never had problems.

In my race engines I cracked the same simple welded lower bracket on several occassion and also cracked a block bolt hole where it mounts before swapping the mount from the plus 2. I have also cracked the front cover where the adjusting top link goes and now use a reinforcing plate that picks up the 3 bolts on that side of the cover. The top link still breaks ( hopefully not now) and the alternators have a limited life as their internals shake to bits but now it mainly stays in place

cheers

Rohan

A long rod through the standard dynamo bracket may work ok but could be subject to fatigue failure as it will see bending due to vibration

-

rgh0 - Coveted Fifth Gear

- Posts: 8425

- Joined: 22 Sep 2003

john.p.clegg wrote:Now would these be LHD or RHD..

http://www.ebay.co.uk/itm/Lotus-twincam ... _500wt_949

John

RHD , the position for the alternator is about 1.5 inches lower than on LHD.

The problem I have is I need to find a LHD one ...... or get someone to make one

Terry

- terryp

- Coveted Fifth Gear

- Posts: 1264

- Joined: 29 Nov 2007

bonjour Terry,

what i used in the past when i converted a +2 to alternater was a bracket from a ford escort.

You could do the same with a secondhand escort/cortina/capri bracket and just get the holes to mount the alternater modified. Extend the mounting lugs and drill new holes in higher position. If you do this, try to get the special fixing screws with the bracket. They have a special head with a serrated head to stop them coming undone

bon courage A+ Alan B

what i used in the past when i converted a +2 to alternater was a bracket from a ford escort.

You could do the same with a secondhand escort/cortina/capri bracket and just get the holes to mount the alternater modified. Extend the mounting lugs and drill new holes in higher position. If you do this, try to get the special fixing screws with the bracket. They have a special head with a serrated head to stop them coming undone

bon courage A+ Alan B

Alan.b Brittany 1972 elan sprint fhc Lagoon Blue 0460E

- alan.barker

- Coveted Fifth Gear

- Posts: 3800

- Joined: 06 Dec 2008

Alan

I have seen a few of these on eBay and they are aluminium and don't really look the right shape.

I think I may just have to get our little village metal man to make one.

He repaired the anti roll bar on the +2 and made a good job and I have to get him to make the headlamp rod I am anyway. He also made a good job of our gates and external balustrading

Terry

I have seen a few of these on eBay and they are aluminium and don't really look the right shape.

I think I may just have to get our little village metal man to make one.

He repaired the anti roll bar on the +2 and made a good job and I have to get him to make the headlamp rod I am anyway. He also made a good job of our gates and external balustrading

Terry

- terryp

- Coveted Fifth Gear

- Posts: 1264

- Joined: 29 Nov 2007

That bracket style with the arm coming up to connect to the bolt hole in the top of the block was used by Ford for Escorts with Alternators in Australia and I presume elsewhere. The orginals I have sen here were gavlanished steel. You can use it on a twin cam if your block has the upper tapped hole in the square boss just below the cylinder head on the front left but it was never a Lotsu original style as far as i am aware.

regards

Rohan

regards

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8425

- Joined: 22 Sep 2003

terryp wrote: <snip> as I think I could make the dynamo bracket work with a length of threaded rod?

Terry,

Had you seen this wrt threaded rod? I assume so:

http://www.lotuselan.net/publish/elan_a ... conv.shtml

It refers to a Pinto bracket and threaded rod but it isn't clear if the required clearance could have been achieved with a Lucas unit or not...maybe it was just a case of Lucas bashing that lead to a "Chevy" unit.

BTW: This RS2000 bracket appeared on ebay recently...I assume it's "Pintoesque"

Richard

(Vive l'artisans!)

Last edited by ardee_selby on Tue Feb 14, 2012 2:41 pm, edited 1 time in total.

- ardee_selby

- Coveted Fifth Gear

- Posts: 1090

- Joined: 30 Sep 2003

rgh0 wrote:That bracket style with the arm coming up to connect to the bolt hole in the top of the block was used by Ford for Escorts with Alternators in Australia and I presume elsewhere. The orginals I have sen here were gavlanished steel. You can use it on a twin cam if your block has the upper tapped hole in the square boss just below the cylinder head on the front left but it was never a Lotsu original style as far as i am aware.

regards

Rohan

Is this the one Rohan ? Ford also used it on their competition twincam engines in the UK.... Don't know what the additional tapped hole at the top was for though.

Roger

S4 DHC

S4 DHC

- oldelanman

- Coveted Fifth Gear

- Posts: 1928

- Joined: 02 Jan 2008

ardee_selby wrote:terryp wrote: <snip> as I think I could make the dynamo bracket work with a length of threaded rod?

Terry,

Had you see this wrt threaded rod? I assume so:

http://www.lotuselan.net/publish/elan_a ... conv.shtml

It refers to a Pinto bracket and threaded rod but it isn't clear if the required clearance could have been achieved with a Lucas unit or not...maybe it was just a case of Lucas bashing that lead to a "Chevy" unit.

BTW: This RS2000 bracket appeared on ebay recently...I assume it's "Pintoesque"

Richard

(Vive l'artisans!)

Richard

Is the distance between the two bottom holes OK for a twincam? ...or is it a very big bracket?

Thanks

Terry

- terryp

- Coveted Fifth Gear

- Posts: 1264

- Joined: 29 Nov 2007

terryp wrote:ardee_selby wrote:terryp wrote: <snip> as I think I could make the dynamo bracket work with a length of threaded rod?

http://www.lotuselan.net/publish/elan_a ... conv.shtml

Is the distance between the two bottom holes OK for a twincam? ...or is it a very big bracket? Thanks Terry

Ooops!

The "Pinto" reference in the above "Tech Tip" confused me. It's for the US car, not the engine range! As shown here:

Cheers - Richard (Looking for my Muddy Waters CD

- ardee_selby

- Coveted Fifth Gear

- Posts: 1090

- Joined: 30 Sep 2003

oldelanman wrote:rgh0 wrote:That bracket style with the arm coming up to connect to the bolt hole in the top of the block was used by Ford for Escorts with Alternators in Australia and I presume elsewhere. The orginals I have sen here were gavlanished steel. You can use it on a twin cam if your block has the upper tapped hole in the square boss just below the cylinder head on the front left but it was never a Lotsu original style as far as i am aware.

regards

Rohan

Is this the one Rohan ? Ford also used it on their competition twincam engines in the UK.... Don't know what the additional tapped hole at the top was for though.

Yes that is the bracket i was referring to. The square boss at the top of the block was part of the jig arrangements for machining the engine block. At some stage Ford started tapping a hole in it but this hole was being drilled and tapped well before they introduced this alternator bracket. I presume the tapped hole was also part of the engine machining jig arrangements and then Ford adopted it also for the alternstor bracket mounting at a later date just becasue it was there already.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8425

- Joined: 22 Sep 2003

terryp wrote:Found this Crossflow one from Wilcox. What do we think? Will it fit?

Thanks Terry

It's also shown on their Twincam page, so will fit the block. BUT what alternators are they designed for & issue of height of pivot points re LHD clearance??

http://www.wilcoxengines.co.uk/twincam_parts.htm

Interesting to see their note "Rubber mounted alternator bracket kits manufactured"

Richard

Last edited by ardee_selby on Tue Feb 14, 2012 8:00 pm, edited 1 time in total.

- ardee_selby

- Coveted Fifth Gear

- Posts: 1090

- Joined: 30 Sep 2003

42 posts

• Page 2 of 3 • 1, 2, 3

Total Online:

Users browsing this forum: No registered users and 31 guests