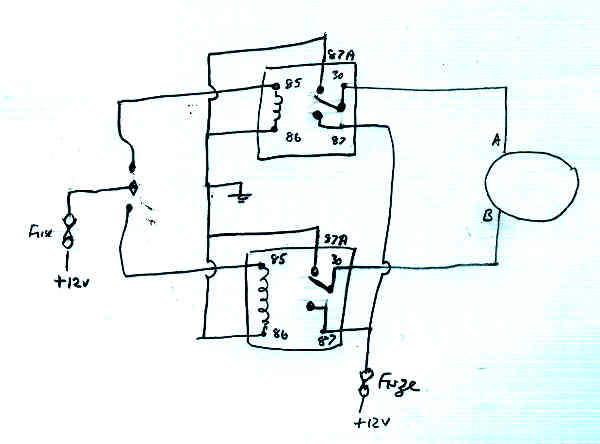

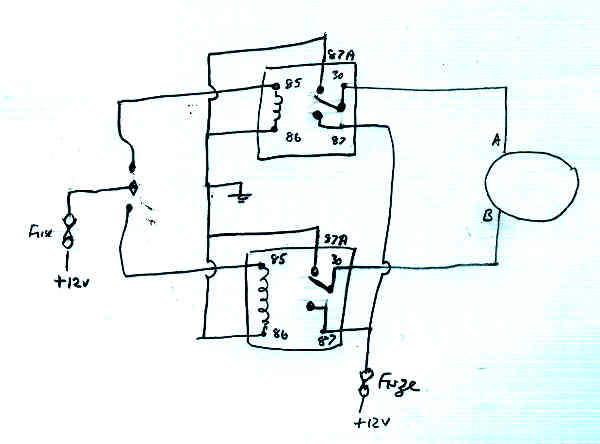

Wiring circuit for relays in the window motor layout

32 posts

• Page 1 of 3 • 1, 2, 3

Hi

Any ideas on this one- I've copied the diagram shown on the picture but testing off the car there appears to be a short somewhere. I'm no expert on wiring although I've fitted relays to quite a few circuits in the past so I'm not a complete novice either but I can't figure out just what the problem is.

As an additional note why is it necessary to use two relays for each side- since these are switchover type whycan't one serve up/down?

All ideas/help gratefully received.

Regards

John

Any ideas on this one- I've copied the diagram shown on the picture but testing off the car there appears to be a short somewhere. I'm no expert on wiring although I've fitted relays to quite a few circuits in the past so I'm not a complete novice either but I can't figure out just what the problem is.

As an additional note why is it necessary to use two relays for each side- since these are switchover type whycan't one serve up/down?

All ideas/help gratefully received.

Regards

John

- worzel

- Fourth Gear

- Posts: 614

- Joined: 13 Jan 2004

This is the thread in which windows relays were discussed. The relevant circuit is the SECOND relay circuit shown as that is much safer than the first one I described.

electrical-instruments-f38/electrical-help-please-t22676.html

The console switches for the windows are not switch-over switches, they are centre off then on one way and on (to a different circuit) the other way. While you could probably find a single relay built to do that, it would be special, rare and expensive. It is simpler and less expensive to use two relays per door.

electrical-instruments-f38/electrical-help-please-t22676.html

The console switches for the windows are not switch-over switches, they are centre off then on one way and on (to a different circuit) the other way. While you could probably find a single relay built to do that, it would be special, rare and expensive. It is simpler and less expensive to use two relays per door.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

Via the other topic, you say that you are using that diagram.

If you are getting a short circuit I suspect that there is an error in the wiring and it is not wired exactly as shown, double-check everything

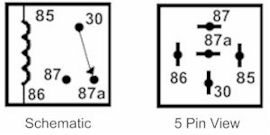

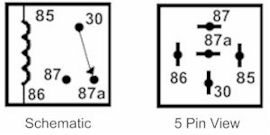

Motor relay pin-out numbers are shown here:

http://www.accessconnect.com/car_relays.htm

and though I have not personally built that circuit, on the basis of those pinouts, the circuit is correct and is drawn from Colin's description of his working system.

If you are getting a short circuit I suspect that there is an error in the wiring and it is not wired exactly as shown, double-check everything

Motor relay pin-out numbers are shown here:

http://www.accessconnect.com/car_relays.htm

and though I have not personally built that circuit, on the basis of those pinouts, the circuit is correct and is drawn from Colin's description of his working system.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

Here's a nice descriptive article about relays for the auto industry.

Really well explained.

http://www.bcae1.com/relays.htm

Have your relays or sockets got protective diodes in them?

If so its possible that pins 85 & 86 are the wrong way around in that diagram above, let me think about it a minute.

<later>

Ah yes, if the relay had a diode inside like this:

then pin 86 needs to be positive and pin 85 the negative. So on an Elan that has been built or modified to negative Earth, you need to swap over the wires on each relay on pins 85 and 86.

I suspect that if a relay with a diode in it was connected the wrong way around there would be loud POP or BANG, magic smoke might be released, and the relay would no longer have a viable diode inside it.

Really well explained.

http://www.bcae1.com/relays.htm

Have your relays or sockets got protective diodes in them?

If so its possible that pins 85 & 86 are the wrong way around in that diagram above, let me think about it a minute.

<later>

Ah yes, if the relay had a diode inside like this:

then pin 86 needs to be positive and pin 85 the negative. So on an Elan that has been built or modified to negative Earth, you need to swap over the wires on each relay on pins 85 and 86.

I suspect that if a relay with a diode in it was connected the wrong way around there would be loud POP or BANG, magic smoke might be released, and the relay would no longer have a viable diode inside it.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

Yes, Bill is correct.

Pin 85 is ground.

Pin 86 is the 12 v power source from the dash switch.

If wired backward the relay is toast, I did in several during my wiring project. The pop and smoke is subtle and can be easily missed.

The pop and smoke is subtle and can be easily missed.  Basically all of the switched current goes through the diode as a direct short and damages the diode, which is there to prevent damage from stray voltage generated when the power is shut off to the relay coil and it's field collapses.

Basically all of the switched current goes through the diode as a direct short and damages the diode, which is there to prevent damage from stray voltage generated when the power is shut off to the relay coil and it's field collapses.

Confusion can be that reversing pins 85 & 86 will work in a relay without the diode, but will damage the diode and relay if the different type is installed. Many of the commonly available changeover relays have the diode, so best to consistently wire for them, although diode type relays are not strictly required in this application.

John, did you get sorted on the question of two relays? Note the pin 87a is Normally Closed (NC), and so these pins provide the ground for the motor to operate. The motor operates in the preferred direction when one relay is powered; the other relay remains grounded. As Bill noted, if both relays are powered at the same time by some fault, the motor sees 12 v on both wires so nothing happens.

Quick note that the Plus 2 uses a different window motor and wiring configuration, so this circuit is Elan only.

Best of luck with the project. HTH.

Pin 85 is ground.

Pin 86 is the 12 v power source from the dash switch.

If wired backward the relay is toast, I did in several during my wiring project.

Confusion can be that reversing pins 85 & 86 will work in a relay without the diode, but will damage the diode and relay if the different type is installed. Many of the commonly available changeover relays have the diode, so best to consistently wire for them, although diode type relays are not strictly required in this application.

John, did you get sorted on the question of two relays? Note the pin 87a is Normally Closed (NC), and so these pins provide the ground for the motor to operate. The motor operates in the preferred direction when one relay is powered; the other relay remains grounded. As Bill noted, if both relays are powered at the same time by some fault, the motor sees 12 v on both wires so nothing happens.

Quick note that the Plus 2 uses a different window motor and wiring configuration, so this circuit is Elan only.

Best of luck with the project. HTH.

Stu

1969 Plus 2 Federal LHD

1969 Plus 2 Federal LHD

-

stugilmour - Coveted Fifth Gear

- Posts: 1942

- Joined: 03 Sep 2007

John

"As an additional note why is it necessary to use two relays for each side- since these are switchover type whycan't one serve up/down?"

how do you stop the widows with a two position relay....one contact up, one contact down?

John

"As an additional note why is it necessary to use two relays for each side- since these are switchover type whycan't one serve up/down?"

how do you stop the widows with a two position relay....one contact up, one contact down?

John

-

john.p.clegg - Coveted Fifth Gear

- Posts: 4533

- Joined: 21 Sep 2003

I did my best to set up the relays as noted in Bill's sketch, but I'm no electrician. (I mounted the relays onto a plastic toilet partition sample chip.) Can anyone in the know review this and let me know if I set it up correctly, before I install it? My car is negative ground.

Thanks,

Gary

'71 Sprint FHC

Miami, Florida

Thanks,

Gary

'71 Sprint FHC

Miami, Florida

-

archigator - Third Gear

- Posts: 447

- Joined: 15 Sep 2003

This is how Colin described it in words for those who prefer them to a circuit diagram:

Now as the further discussion has revealed, this description is correct for the original POSITIVE EARTH arrangement of the Elans, but if your car has been converted to NEGATIVE EARTH it is best to swap over the functions of Pins 85 and 86, in case the relays contain diodes.

This means that for negative earth with diodes Colin's instructions would read as follows instead, with some additional editing by me for clarity.:

You will need two relays per window with the following connections: 30, 85, 86, 87 and 87a.

Follow this procedure per door:

30: Main power out of the relay to power the window motor. One relay pin 30 to the up side of the motor and the other relay pin 30 to the down side. (trial and error will figure that one out).

86: The wires from the dash-board window switch. One wire goes to pin 86 on one relay and the other wire goes to pin 86 on the other relay. (These wires are the ones that power the motors pre modification).

85 & 87a: These should all be bussed together and go to earth on both relays, so you make up a lead with 4 connector on the relay end for this. The earth wire that presently goes to the motor case should also be connected to this, and connect it to the chassis or the black earthing wire that earths all the instruments behind the dashboard.

87: +12v Power to the window motors via the relays. Pin 87 of both relays connected together and then the other end connected to a suitable power source via an in-line fuse capsule.

fatboyoz wrote:Tony,

This is how I did the window conversion to relays. You will need two relays per window with the following connections: 30, 85, 86, 87 and 87a.

Follow this procedure per door:

30: Main power out of the relay to power motor. One to the up side of the motor and one to the down. (trial and error will figure that one out).

85: Up control signal from the window switch to the up relay and down control signal from the window switch to the down relay. (These wires are the ones that power the motors pre modification).

86 & 87a: These should all be bussed together and go to earth. The earth wire that presently goes to the motor case should be a suitable earthing point.

87: Power to the relays. I used a thicker wire for this. I took a feed from the main power into the car (thick brown/blue wire, part of main loom where it connects to the interior loom) located above passenger's (L/H seat) knees. This is unswitched and unfused. I then ran this single feed to a fuse box (two fuses) that I attached to the underside of the horizontal part of the firewall above the passenger's knees. Two 10 amp fuses and an individual feed to each door completes the power supply.

My doors have speaker holes cut into them, so I was able to gain access to the inside of the doors to wire up the relays and then mount them inside and up out of any water that might get inside the doors.

Colin.

Now as the further discussion has revealed, this description is correct for the original POSITIVE EARTH arrangement of the Elans, but if your car has been converted to NEGATIVE EARTH it is best to swap over the functions of Pins 85 and 86, in case the relays contain diodes.

This means that for negative earth with diodes Colin's instructions would read as follows instead, with some additional editing by me for clarity.:

You will need two relays per window with the following connections: 30, 85, 86, 87 and 87a.

Follow this procedure per door:

30: Main power out of the relay to power the window motor. One relay pin 30 to the up side of the motor and the other relay pin 30 to the down side. (trial and error will figure that one out).

86: The wires from the dash-board window switch. One wire goes to pin 86 on one relay and the other wire goes to pin 86 on the other relay. (These wires are the ones that power the motors pre modification).

85 & 87a: These should all be bussed together and go to earth on both relays, so you make up a lead with 4 connector on the relay end for this. The earth wire that presently goes to the motor case should also be connected to this, and connect it to the chassis or the black earthing wire that earths all the instruments behind the dashboard.

87: +12v Power to the window motors via the relays. Pin 87 of both relays connected together and then the other end connected to a suitable power source via an in-line fuse capsule.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

In the photos, that does not seem right.

If the pinouts numbers are as shown in my earlier message you have connected 87a to 86 on both relay, presumably for earth, that is as per Colin's original not the later change. Move them all one place right.

The numbers should be engraved/embossed on the bottom of the relay adjacent to each pin. and notice that pins 87 and 87a are at right-angles to the other 3 pins.

If the pinouts numbers are as shown in my earlier message you have connected 87a to 86 on both relay, presumably for earth, that is as per Colin's original not the later change. Move them all one place right.

The numbers should be engraved/embossed on the bottom of the relay adjacent to each pin. and notice that pins 87 and 87a are at right-angles to the other 3 pins.

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

Bill, thanks! That's why I asked...

Gary

'71 Sprint FHC

Miami, Florida

Gary

'71 Sprint FHC

Miami, Florida

-

archigator - Third Gear

- Posts: 447

- Joined: 15 Sep 2003

If you have relays and don't know if they have diodes built in, there is a simple test you can do, which won't damage them.

Obtain either a panel lamp (2.4 watts) or a warning lamp (2 watts).

Connect one side of the lamp to the positive terminal of a 12 volt battery and the other side of the lamp to one of the relay coil terminals (85 or 86). Connect the other relay coil terminal (85 or 86) to the negative battery terminal.

If the lamp lights up there is a diode. If it doesn't, there may be a diode.

Now swap the connections made to 85 and 86. If the lamp now lights, there is a diode. If it still doesn't, there is no diode.

If there is a diode you have to connect 85 & 86 to the car so that when you test it with your small lamp, the lamp does not light.

The purpose of the lamp used for this test is to limit the current to a value which will not damage the diode, so it is important that you use only a very small lamp. Assuming the diode is a 1 amp diode (which is likely, but I don't know) then your absolute maximum is a 12 watt lamp.

Once you have satisfied yourself that everything is correctly connected I suggest the control wire fuse is 1 amp (it should only draw about 65 milliamps with a 'standard' relay). The power line fuse should be 5 amps, as I believe the motor draws about 2 amps, normally. The chosen cable size should of course have a current capacity greater than the fuse selected.

If I was doing this, I think I would put the relays in a sealed box and have all the cables entering the box at the bottom, in an attempt to avoid water problems. I'd use the relay bases that have provision for fuses too, so all the vulnerable bits are safely in the sealed box.

Regards

Richard

Obtain either a panel lamp (2.4 watts) or a warning lamp (2 watts).

Connect one side of the lamp to the positive terminal of a 12 volt battery and the other side of the lamp to one of the relay coil terminals (85 or 86). Connect the other relay coil terminal (85 or 86) to the negative battery terminal.

If the lamp lights up there is a diode. If it doesn't, there may be a diode.

Now swap the connections made to 85 and 86. If the lamp now lights, there is a diode. If it still doesn't, there is no diode.

If there is a diode you have to connect 85 & 86 to the car so that when you test it with your small lamp, the lamp does not light.

The purpose of the lamp used for this test is to limit the current to a value which will not damage the diode, so it is important that you use only a very small lamp. Assuming the diode is a 1 amp diode (which is likely, but I don't know) then your absolute maximum is a 12 watt lamp.

Once you have satisfied yourself that everything is correctly connected I suggest the control wire fuse is 1 amp (it should only draw about 65 milliamps with a 'standard' relay). The power line fuse should be 5 amps, as I believe the motor draws about 2 amps, normally. The chosen cable size should of course have a current capacity greater than the fuse selected.

If I was doing this, I think I would put the relays in a sealed box and have all the cables entering the box at the bottom, in an attempt to avoid water problems. I'd use the relay bases that have provision for fuses too, so all the vulnerable bits are safely in the sealed box.

Regards

Richard

- ricarbo

- Third Gear

- Posts: 264

- Joined: 14 Apr 2010

If a relay has a diode inside it ought to be shown in the symbol on the side or base of the relay, and hopefully the pins marked + plus and - minus.

Richard,

A good method but a bit fiddly, there might be a simpler method.

I don't have a diode-relay on hand to check, but I think if you used a simple multi-meter set to ohms, if you put the probes on pins 85 and 86, if there is a diode inside you will get a different ohms reading if you swap over the probes. If there is no diode it should read the same both ways (the resistance of the coil).

Richard,

A good method but a bit fiddly, there might be a simpler method.

I don't have a diode-relay on hand to check, but I think if you used a simple multi-meter set to ohms, if you put the probes on pins 85 and 86, if there is a diode inside you will get a different ohms reading if you swap over the probes. If there is no diode it should read the same both ways (the resistance of the coil).

Bill Williams

36/6725 S3 Coupe OGU108E Yellow over Black.

36/6725 S3 Coupe OGU108E Yellow over Black.

- billwill

- Coveted Fifth Gear

- Posts: 4417

- Joined: 19 Apr 2008

Hi John,

I am sorry to be picky but crimp tags are colour coded.

Red is for 1mm wire. blue for 2.5mm and the yellow ones which you have used are for 4mm wire and look far too big to me. Also the insulated sleeve should be crimped on the wire insulation for mechanical strength.

The larger type crimping tools do this in one operation. They have a ratchet (all or nothing) mechanism to ensure the correct force is used.

If you use a tag too big you risk having a poor connection in the future as the design tolerances cannot work.

A part of my working life has been spent locating faults in industrial machinery caused by poor tag connections, often caused by the use of the wrong size, so I am a bit sensitive to this.

I hope it all works out OK.

Eric in Burnley

1967 S3SE DHC( still on stands, sorting fuel supply probs.)

I am sorry to be picky but crimp tags are colour coded.

Red is for 1mm wire. blue for 2.5mm and the yellow ones which you have used are for 4mm wire and look far too big to me. Also the insulated sleeve should be crimped on the wire insulation for mechanical strength.

The larger type crimping tools do this in one operation. They have a ratchet (all or nothing) mechanism to ensure the correct force is used.

If you use a tag too big you risk having a poor connection in the future as the design tolerances cannot work.

A part of my working life has been spent locating faults in industrial machinery caused by poor tag connections, often caused by the use of the wrong size, so I am a bit sensitive to this.

I hope it all works out OK.

Eric in Burnley

1967 S3SE DHC( still on stands, sorting fuel supply probs.)

- ericbushby

- Coveted Fifth Gear

- Posts: 1351

- Joined: 13 Jun 2011

32 posts

• Page 1 of 3 • 1, 2, 3

Total Online:

Users browsing this forum: No registered users and 8 guests