AX block actual wall thickness

18 posts

• Page 1 of 2 • 1, 2

I have been searching for a while to see if I can find the actual casting wall thickness or outside diameter casting of the bores for an AX block. Lots of people say lots on thing on various forums about the AX block having thicker walls and how they bored it to 85+ mm but no one ever posts real data based on ultrasonic wall thickness measurements. Similar claims are made about L blocks and that is BS from my measurements. I just have never found an AX block here in Australia to measure

From a sand casting technology perspective I cant see how the bore walls can be made much thicker on an AX block at least in the fore / aft direction unless you Siamese the bores (which QED have done with their new blocks) . Maybe you can make the bore walls thicker in the sideways directions and have a thicker thrust face bore wall which may help if you bore it over 85+mm and you can offset the boring to avoid hitting the oil cross passage.

Anyhow.... The question is does anyone have an AX block sitting around as I would happily pay for it to be ultrasonically tested to collect some real data on the bore wall dimensions. Ideally I need to measure 3 or 4 blocks to get an understanding of casting variation as I have found a couple of 120E blocks that could go to 85+mm out of the about 50 I have measured

cheers

Rohan

From a sand casting technology perspective I cant see how the bore walls can be made much thicker on an AX block at least in the fore / aft direction unless you Siamese the bores (which QED have done with their new blocks) . Maybe you can make the bore walls thicker in the sideways directions and have a thicker thrust face bore wall which may help if you bore it over 85+mm and you can offset the boring to avoid hitting the oil cross passage.

Anyhow.... The question is does anyone have an AX block sitting around as I would happily pay for it to be ultrasonically tested to collect some real data on the bore wall dimensions. Ideally I need to measure 3 or 4 blocks to get an understanding of casting variation as I have found a couple of 120E blocks that could go to 85+mm out of the about 50 I have measured

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

rgh0 wrote:From a sand casting technology perspective I cant see how the bore walls can be made much thicker on an AX block at least in the fore / aft direction unless you Siamese the bores (which QED have done with their new blocks)

Rohan

Probably not of much help but I had an AX block that I gave to a friend who used to race Formula Ford when he blew his engine, he weighed it and it was quite a bit heavier then a 711 block but I dont know where the "extra" material was added to the block.

Think I have a copy of a posting I picked up from some Ford forum where a guy who worked at the factory in S.Africa, think he said the extra weight was down to the "mix" of the cast iron that was used on the AX block.

I'll see if I can find the posting.

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3407

- Joined: 11 Sep 2003

rgh0 wrote:I have been searching for a while to see if I can find the actual casting wall thickness or outside diameter casting of the bores for an AX block. Lots of people say lots on thing on various forums about the AX block having thicker walls and how they bored it to 85+ mm but no one ever posts real data based on ultrasonic wall thickness measurements. Similar claims are made about L blocks and that is BS from my measurements. I just have never found an AX block here in Australia to measure

From a sand casting technology perspective I cant see how the bore walls can be made much thicker on an AX block at least in the fore / aft direction unless you Siamese the bores (which QED have done with their new blocks) . Maybe you can make the bore walls thicker in the sideways directions and have a thicker thrust face bore wall which may help if you bore it over 85+mm and you can offset the boring to avoid hitting the oil cross passage.

Anyhow.... The question is does anyone have an AX block sitting around as I would happily pay for it to be ultrasonically tested to collect some real data on the bore wall dimensions. Ideally I need to measure 3 or 4 blocks to get an understanding of casting variation as I have found a couple of 120E blocks that could go to 85+mm out of the about 50 I have measured

cheers

Rohan

I don't have one currently but I've had a few. The bores didn't look any bigger on the outside diameter to 711m blocks I've compared them to (as well as Lotus blocks) when looking inside the water jacket and looking at the gaps between 1&2, 2&3 and 3&4 as well as the distance from the front face to the outside of bore number 1.

I weighed a 711m 1600 block and an AX 1600 block with the same bore sizes and the AX block was something like 5kg heavier. I believe it is down to the type of iron they use that makes them stronger, and thus able to be bored bigger.

I know you will still want to get an AX block checked if possible, just thought this might help you!

-

promotor - Fourth Gear

- Posts: 797

- Joined: 16 Mar 2012

Found the posting,This is a Quote from a forum but I cannot vouch for its authenticity.

QUOTE:

“Yes, these blocks are manufactured in South Africa and bear the 831C prefix, The large starburst casting marks are also present on the side of the block. I am almost certain the AX designation is merely the spec for the cast iron the foundry used. There is a type A and a type AX. These blocks just had that info cast in which is a sure fire way of identifying one. SA did not use these for Diesels but the UK may have. I was employed by FMC engine plant in Port Elizabeth for a while and got to speak to many people who had spent a lifetime working there. Murray and Roberts foundries, also in Port Elizabeth did the casting job and the block was machined by Ford. Many of these spec blocks were used in local cars until the Kent was discontinued in 1993 or thereabouts. the engine plant struggled on for a few years making 3.0 and 3.4 Essex engines, these kent blocks for Motorsport and customers such as Vegantune and doing remans. + other odd jobs until the RoCam order came through. I managed to fish from the bin a complete set of detailed manufacturing and machining drawings for the Kent engine (the block alone is 6 sheets of A0!). Two months before I arrived they disposed of the tool to cast them which was returned from the foundry, BUMMER! Kent blocks are getting scarce even here but one can occasionally find 831C blocks for good money. Some of them had to be reworked in plant as the pushrod bores were incorrectly machined, they should be at a 4° angle to the vertical (bore), these faulty blocks had the pushrod bores overbored and a sleeve was fitted before remachining. 831C's can still be found on 84 and up 1.6 sierras and sapphires and overboring to 85mm is dead easy. I use one on my 1600 BDA.”

QUOTE:

“Yes, these blocks are manufactured in South Africa and bear the 831C prefix, The large starburst casting marks are also present on the side of the block. I am almost certain the AX designation is merely the spec for the cast iron the foundry used. There is a type A and a type AX. These blocks just had that info cast in which is a sure fire way of identifying one. SA did not use these for Diesels but the UK may have. I was employed by FMC engine plant in Port Elizabeth for a while and got to speak to many people who had spent a lifetime working there. Murray and Roberts foundries, also in Port Elizabeth did the casting job and the block was machined by Ford. Many of these spec blocks were used in local cars until the Kent was discontinued in 1993 or thereabouts. the engine plant struggled on for a few years making 3.0 and 3.4 Essex engines, these kent blocks for Motorsport and customers such as Vegantune and doing remans. + other odd jobs until the RoCam order came through. I managed to fish from the bin a complete set of detailed manufacturing and machining drawings for the Kent engine (the block alone is 6 sheets of A0!). Two months before I arrived they disposed of the tool to cast them which was returned from the foundry, BUMMER! Kent blocks are getting scarce even here but one can occasionally find 831C blocks for good money. Some of them had to be reworked in plant as the pushrod bores were incorrectly machined, they should be at a 4° angle to the vertical (bore), these faulty blocks had the pushrod bores overbored and a sleeve was fitted before remachining. 831C's can still be found on 84 and up 1.6 sierras and sapphires and overboring to 85mm is dead easy. I use one on my 1600 BDA.”

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3407

- Joined: 11 Sep 2003

Just realised I posted in wrong section .... should really be in engine  Not sure if I can move it but sure Jeff could.

Not sure if I can move it but sure Jeff could.

Lots on data on the AX block being heavier and this maybe due to thicker casting in some areas or a denser cast iron being used. When ultrasonically checking the bore walls you need to measure the sound velocity on a section you can measure the thickness of to calibrate the ultrasonic gauge on that actual casting and the sound speed increases with increasing density so that could be checked when its measured

Promotor - The reason I suspect the AX block bore casting O/D are no bigger than on all the previous blocks (120E, 681F, 701M etc) is consistent with your observation that the gaps between the bores in the fore aft direction are about as small as possible with the sand casting technology used and I don't think the South African foundry was using anything better than in the UK at the time. Possible to change the dimension around the rest of the bore circumference more easily and maybe they did that, hence my desire to measure up a block in detail .

The Ford drawings I have seen show that the bore wall casting was not circular in the earlier blocks and maybe they modified this in the AX in some way to further emphasise this non circular design to improve the odds of going to a bigger bore ? Or maybe its really all the same and just normal tolerance variance enable bigger bores in select blocks just as in the earlier block types

cheers

Rohan

Lots on data on the AX block being heavier and this maybe due to thicker casting in some areas or a denser cast iron being used. When ultrasonically checking the bore walls you need to measure the sound velocity on a section you can measure the thickness of to calibrate the ultrasonic gauge on that actual casting and the sound speed increases with increasing density so that could be checked when its measured

Promotor - The reason I suspect the AX block bore casting O/D are no bigger than on all the previous blocks (120E, 681F, 701M etc) is consistent with your observation that the gaps between the bores in the fore aft direction are about as small as possible with the sand casting technology used and I don't think the South African foundry was using anything better than in the UK at the time. Possible to change the dimension around the rest of the bore circumference more easily and maybe they did that, hence my desire to measure up a block in detail .

The Ford drawings I have seen show that the bore wall casting was not circular in the earlier blocks and maybe they modified this in the AX in some way to further emphasise this non circular design to improve the odds of going to a bigger bore ? Or maybe its really all the same and just normal tolerance variance enable bigger bores in select blocks just as in the earlier block types

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

rgh0 wrote:Just realised I posted in wrong section .... should really be in engineNot sure if I can move it but sure Jeff could.

Lots on data on the AX block being heavier and this maybe due to thicker casting in some areas or a denser cast iron being used. When ultrasonically checking the bore walls you need to measure the sound velocity on a section you can measure the thickness of to calibrate the ultrasonic gauge on that actual casting and the sound speed increases with increasing density so that could be checked when its measured

Promotor - The reason I suspect the AX block bore casting O/D are no bigger than on all the previous blocks (120E, 681F, 701M etc) is consistent with your observation that the gaps between the bores in the fore aft direction are about as small as possible with the sand casting technology used and I don't think the South African foundry was using anything better than in the UK at the time. Possible to change the dimension around the rest of the bore circumference more easily and maybe they did that, hence my desire to measure up a block in detail .

The Ford drawings I have seen show that the bore wall casting was not circular in the earlier blocks and maybe they modified this in the AX in some way to further emphasise this non circular design to improve the odds of going to a bigger bore ? Or maybe its really all the same and just normal tolerance variance enable bigger bores in select blocks just as in the earlier block types

cheers

Rohan

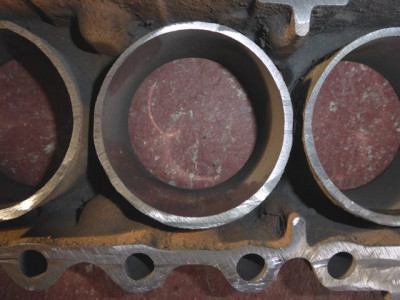

It'd certainly make sense to cast the bores in an oval shape to give more material in the thrust plane. I can't work out whether the outside of these bores are oval or not - the bores not being central is certainly throwing my eye

- I don't know which block this originally was BTW but it's definitely crossflow or pre crossflow!

-

promotor - Fourth Gear

- Posts: 797

- Joined: 16 Mar 2012

promotor wrote: the bores not being central is certainly throwing my eye

quite interesting, thank you : what amount of deviation from original bore axis could be tolerated (without requiring say a crank line bore or other compensating measures) in each direction to make the most of the available material ?

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 1998

- Joined: 02 Sep 2013

It would be interesting to take further sections throughout the height of the block. Sections near the top and bottom may not be reliable indicators of whether the cylinder is cast centrally or not.

I too am curious about the mysteries of the AX block!

I too am curious about the mysteries of the AX block!

1970 Ford Escort Twin Cam

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

- 2cams70

- Coveted Fifth Gear

- Posts: 2162

- Joined: 10 Jun 2015

nmauduit wrote:promotor wrote: the bores not being central is certainly throwing my eye

quite interesting, thank you : what amount of deviation from original bore axis could be tolerated (without requiring say a crank line bore or other compensating measures) in each direction to make the most of the available material ?

I have moved the centreline of the bores a maximum about 0.5 mm in the front / rear direction and about 0.3 mm in the sideways directions to even up wall thickness in blocks when boring them to 83.5mm.

I aim for a minimum of 3.0 mm wall thickness but will accept less down to around 2.5 mm in small areas not on the thrust face if I need to. For an 83.5 mm bore this means a minimum of a 89.5 OD for the bore casting if it can be perfectly centred

Across all the blocks i have measured the minimum bore casting O/D was 88.06 mm, the average 90.34m and the maximum 92..27 mm. Most blocks fall into the 90mm to 90.8 mm range.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

I have 2 AX blocks - one sitting in my race prepared Lotus Cortina (mothballed at the moment) - fitted with DFV pistons and original Ford RS ‘Monte Carlo’ 771M competition crankshaft. Can’t recall rod length - but compression height of DFV pistons required something unusual if I recall correctly. Just under 1800cc. Don’t think we bothered to ultrasonically ‘measure’ the block - have done that before - but there don’t seem to be many places doing that these days. I think Oselli do.

The other block is brand new. AX block - not one of the current Ford Motorsport 711M items. Will look into having this measured if I can find somewhere. Anyone know anywhere? I am in Northampton, U.K.

I have heard several times that the ‘thick wall’ theory about AX blocks is nonsense. Some will take a big bore, some won’t - just like any Kent block (unless it’s a Siamesed 701M - but they always were extremely rare and were incredibly expensive).

We bought the first AX block from Burton back in the late 80’s or early 90’s. My recollection is that they said it was made in South Africa where Ford used the crossflow block in a Diesel engine and the blocked needed to be beefier for that reason. We just bored it to 85.67mm for the DFV pistons and it’s been fine - has had some very hard use.

I also have a ‘normal’ old 711M block - would be interesting to get that measured too at the same place/time for a true comparison.

So if anyone knows of a place to ultrasoncially measure reasonably close to me let me know. Would be an interesting exercise.

Am also curious about the current Ford Motorsport blocks. How do they ‘measure up’ in terms of bore thickness/weight?

If an AX block is 5kg heavier than a normal 711M block then I’m surprised the Formula Ford engine builders sold many engines using this block - an extra 5kg is a killer in the back of a Formula Ford - and I’m fairly sure it was Formula Ford engine builders who were importing them.

The other block is brand new. AX block - not one of the current Ford Motorsport 711M items. Will look into having this measured if I can find somewhere. Anyone know anywhere? I am in Northampton, U.K.

I have heard several times that the ‘thick wall’ theory about AX blocks is nonsense. Some will take a big bore, some won’t - just like any Kent block (unless it’s a Siamesed 701M - but they always were extremely rare and were incredibly expensive).

We bought the first AX block from Burton back in the late 80’s or early 90’s. My recollection is that they said it was made in South Africa where Ford used the crossflow block in a Diesel engine and the blocked needed to be beefier for that reason. We just bored it to 85.67mm for the DFV pistons and it’s been fine - has had some very hard use.

I also have a ‘normal’ old 711M block - would be interesting to get that measured too at the same place/time for a true comparison.

So if anyone knows of a place to ultrasoncially measure reasonably close to me let me know. Would be an interesting exercise.

Am also curious about the current Ford Motorsport blocks. How do they ‘measure up’ in terms of bore thickness/weight?

If an AX block is 5kg heavier than a normal 711M block then I’m surprised the Formula Ford engine builders sold many engines using this block - an extra 5kg is a killer in the back of a Formula Ford - and I’m fairly sure it was Formula Ford engine builders who were importing them.

- Jonners

- New-tral

- Posts: 13

- Joined: 07 Jun 2011

I have not weighed the new ford motorsport blocks but have had the opportunity to thickness test a couple.

The wall thicknesses were suitable for a 83.5 mm bore with a 3 mm wall thickness which is what you want especially in a competition block. The tolerances were very tight on the two blocks castings so no more than 83.5 mm bore was possible.

Weight would have been a bit more than original blocks due to more metal in the castings for the main bearing supports

cheers

Rohan

The wall thicknesses were suitable for a 83.5 mm bore with a 3 mm wall thickness which is what you want especially in a competition block. The tolerances were very tight on the two blocks castings so no more than 83.5 mm bore was possible.

Weight would have been a bit more than original blocks due to more metal in the castings for the main bearing supports

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

5kg weight difference is quite a bit. Perhaps the grade of cast iron used was different therefore making the cylinder walls stronger and the weight heavier even if there is no difference in the thickness.

I believe you can buy reasonably priced ultrasonic thickness testers these days and DIY. Not sure of the accuracy.

I believe you can buy reasonably priced ultrasonic thickness testers these days and DIY. Not sure of the accuracy.

1970 Ford Escort Twin Cam

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

1972 Ford Escort GT1600 Twin Cam

1980 Ford Escort 2.0 Ghia

Peugeot 505 GTI Wagons (5spdx1) (Autox1)

2022 Ford Fiesta ST.

- 2cams70

- Coveted Fifth Gear

- Posts: 2162

- Joined: 10 Jun 2015

under A$1000 will get you a very accurate gauge USA made gauge, less for a little less accurate and less reliable Chinese one. You need to calibrate it on the individual casting's sonic velocity being tested by measuring the thickness on a section you can check the thickness with a micrometre as the calibrations changes with every block.

cheers

Rohan

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

18 posts

• Page 1 of 2 • 1, 2

Total Online:

Users browsing this forum: No registered users and 23 guests