Differential Failure

59 posts

• Page 1 of 4 • 1, 2, 3, 4

No photos of my Elan racing at the Winton Historic meeting this year as my diff failed during practice. I packed up early and came home on Saturday and pulled the diff out of the car today.

Getting the diff out was the usual challenge with the diff being a light press fit into the chassis. Fortunately with the hoist i now have, it did not drop on my face like the last time I removed it about 20 years ago!

When I pulled it I could see a large hole in the rear alloy case. No wonder it failed.

Getting one of the output shafts out was a challenge as the splines had jammed in the diff centre. Had to resort to using jacking bolts as I could not drive it out or get it out with a slide hammer puller

It appears the crown wheel to the diff centre bolts had failed in fatigue and 5 of the 6 had lost their heads. One of the 5 was missing so I presume it went out the hole in the case. I don't know why the bolt heads failed but they were the original bolts in the car - the CWP was also the original.

One of the failed bolt heads had been very badly chewed up and I presume this jammed in the gears and led to the final failure and shearing of the pinion gear teeth and the collapse of the pinion bearing.

I now suspect the bangs I had heard a couple of times in the past couple of races that I could not identify had been the bolt heads progressively failing. I think the hole in the diff casing actually occurred when racing at Phillip Island earlier this year as i had a couple of puffs of smoke out the rear of the car that I put down to engine or gear box oil leaks dripping on the exhaust - but it was diff oil as it now turns out. The fact that the diff ran with no noise until it jammed on a loose bolt head and failed and that the diff crown wheel carrier bearings are still perfect having run for some time with not much oil and getting very hot is a testament to Redline gear oil qualities.

Now just a new CWP , new alloy case, new bearings, shims and crush tube and teach myself how to set the Pinion depth correctly as I have never had to do it before and i will have a new diff .

.

I could probably get the alloy case welded up but the output bearing circlip grooves are badly chewed up and to fix them plus the hole plus another cracked area from an internal impact and it would probably cost me more than a new one.

cheers

Rohan

Getting the diff out was the usual challenge with the diff being a light press fit into the chassis. Fortunately with the hoist i now have, it did not drop on my face like the last time I removed it about 20 years ago!

When I pulled it I could see a large hole in the rear alloy case. No wonder it failed.

Getting one of the output shafts out was a challenge as the splines had jammed in the diff centre. Had to resort to using jacking bolts as I could not drive it out or get it out with a slide hammer puller

It appears the crown wheel to the diff centre bolts had failed in fatigue and 5 of the 6 had lost their heads. One of the 5 was missing so I presume it went out the hole in the case. I don't know why the bolt heads failed but they were the original bolts in the car - the CWP was also the original.

One of the failed bolt heads had been very badly chewed up and I presume this jammed in the gears and led to the final failure and shearing of the pinion gear teeth and the collapse of the pinion bearing.

I now suspect the bangs I had heard a couple of times in the past couple of races that I could not identify had been the bolt heads progressively failing. I think the hole in the diff casing actually occurred when racing at Phillip Island earlier this year as i had a couple of puffs of smoke out the rear of the car that I put down to engine or gear box oil leaks dripping on the exhaust - but it was diff oil as it now turns out. The fact that the diff ran with no noise until it jammed on a loose bolt head and failed and that the diff crown wheel carrier bearings are still perfect having run for some time with not much oil and getting very hot is a testament to Redline gear oil qualities.

Now just a new CWP , new alloy case, new bearings, shims and crush tube and teach myself how to set the Pinion depth correctly as I have never had to do it before and i will have a new diff

I could probably get the alloy case welded up but the output bearing circlip grooves are badly chewed up and to fix them plus the hole plus another cracked area from an internal impact and it would probably cost me more than a new one.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

That is a cautionary tale right there. I have heard of some of the longer reproduction crownwheel bolts (used for LSD's as the casing is deeper) actually loosening so I guess they must be stretching more than they should.

However I wouldn't expect that with original bolts!

When fitting LSD's now I only use ARP bolts and have not had an issue yet.

Your problem for setting the depth of mesh is selecting the relevant shim, having a supply of shims, and being able to remove the pinion head bearing if the shim you fit doesn't give the correct mesh once the diff is all built.

I've got all the correct diff setting tools - pinion depth of mesh setting tool, pinion head bearing removal tool, cap spread gauge, and pre load gauge and it's still not a straight forward job when trying to ascertain and obtain the correct contact patch.

If you need a second opinion I'm happy to offer my help. I've never had the luxury of fitting a brand new genuine Ford CW&P so don't know how well they respond to changing pinion shims but I can tell you that the Lotus manual (and the Ford manual that Lotus take their settings from) is incorrect in places regarding what needs to be done to rectify a bad contact patch WHEN you have a decent condition CW&P.

Addiitonally it is sometimes impossible to get an acceptable contact patch.

It's best to get as good a CW&P as possible.And make sure you check the runout of the crownwheel mounting face before building the diff as bad runout equals terribly inconsistent backlash.

However I wouldn't expect that with original bolts!

When fitting LSD's now I only use ARP bolts and have not had an issue yet.

Your problem for setting the depth of mesh is selecting the relevant shim, having a supply of shims, and being able to remove the pinion head bearing if the shim you fit doesn't give the correct mesh once the diff is all built.

I've got all the correct diff setting tools - pinion depth of mesh setting tool, pinion head bearing removal tool, cap spread gauge, and pre load gauge and it's still not a straight forward job when trying to ascertain and obtain the correct contact patch.

If you need a second opinion I'm happy to offer my help. I've never had the luxury of fitting a brand new genuine Ford CW&P so don't know how well they respond to changing pinion shims but I can tell you that the Lotus manual (and the Ford manual that Lotus take their settings from) is incorrect in places regarding what needs to be done to rectify a bad contact patch WHEN you have a decent condition CW&P.

Addiitonally it is sometimes impossible to get an acceptable contact patch.

It's best to get as good a CW&P as possible.And make sure you check the runout of the crownwheel mounting face before building the diff as bad runout equals terribly inconsistent backlash.

-

promotor - Fourth Gear

- Posts: 797

- Joined: 16 Mar 2012

Hi Promotor

I have most of what I need i think to do the required measurements and assembly except for the pinion depth

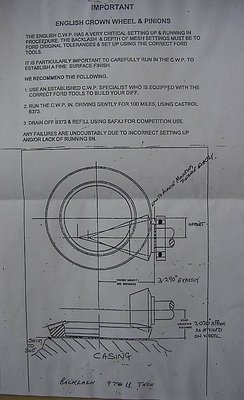

The following diagram from the internet shows a depth of 3.290 inch is required from the centreline of the diff carrier bearings to the face of the shim between the pinion gear and bearing.

If this diagram is correct I can machine up a mount for a depth gauge and measure down to the pinion bearing mounting shoulder. I can then measure the new pinion bearing thickness ( should be the same with the same Timken bearing). i can then calculate the shim thickness needed to get the 3.290 inch dimension.

cheers

Rohan

I have most of what I need i think to do the required measurements and assembly except for the pinion depth

The following diagram from the internet shows a depth of 3.290 inch is required from the centreline of the diff carrier bearings to the face of the shim between the pinion gear and bearing.

If this diagram is correct I can machine up a mount for a depth gauge and measure down to the pinion bearing mounting shoulder. I can then measure the new pinion bearing thickness ( should be the same with the same Timken bearing). i can then calculate the shim thickness needed to get the 3.290 inch dimension.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

Wow - the pictures make my diff woes seem like a walk in the park. My grand plan is to switch from a 3.77 diff to a 3.55. This has so far taken three diff changes in the past 12 months. Once to fit a 3.55 which proved be damaged (a sad story), a second time to refit the original 3.77, and last weekend to refit the newly rebuilt 3.55.

The rebuilt 3.55 has a new CWP set from Burton and was installed by the local expert here in Connecticut. It has now done about 150 miles and seems OK, although whining slightly at around 30mph. I hope this will go away as the CWP runs-in.

My question is, how hot should a diff get? I've never checked before, but I'm amazed how hot it gets. Too hot to touch for more than a couple of seconds. I hope that a lot of this is running-in tightness (the new 3.55 was a whole lot tighter than the removed 3.77 when I had them side by side). Burton calls for an oil change after 100 miles, which I did yesterday. The removed oil didn't look too healthy so there's obviously quite a lot of wear going on.

But I never checked the temperature of the 3.77, so I don't have a comparison point.

What's normal?

Nick

The rebuilt 3.55 has a new CWP set from Burton and was installed by the local expert here in Connecticut. It has now done about 150 miles and seems OK, although whining slightly at around 30mph. I hope this will go away as the CWP runs-in.

My question is, how hot should a diff get? I've never checked before, but I'm amazed how hot it gets. Too hot to touch for more than a couple of seconds. I hope that a lot of this is running-in tightness (the new 3.55 was a whole lot tighter than the removed 3.77 when I had them side by side). Burton calls for an oil change after 100 miles, which I did yesterday. The removed oil didn't look too healthy so there's obviously quite a lot of wear going on.

But I never checked the temperature of the 3.77, so I don't have a comparison point.

What's normal?

Nick

-

elanner - Fourth Gear

- Posts: 546

- Joined: 14 Sep 2010

elanner wrote:The rebuilt 3.55 has a new CWP set from Burton and was installed by the local expert here in Connecticut. It has now done about 150 miles and seems OK, although whining slightly at around 30mph. I hope this will go away as the CWP runs-in.

This certainly has been a popular topic over the past few days. I assume that the CWP sets offered by Burton are the same as offered by Tony Thompson Racing (manufactured by Quaife/Tran-X). The TTR folks say the new CWPs are a bit noisy until bedding is complete. The say the REM isotropic finish helps alleviate the initial noise problem.

Russ Newton

Elan +2S (1971)

Elite S2 (1962)

Elan +2S (1971)

Elite S2 (1962)

-

CBUEB1771 - Coveted Fifth Gear

- Posts: 1546

- Joined: 09 Nov 2006

Nick,

Diff's get very hot - not being able to hold one is normal. Some race cars had diff coolers to keep them cool. And an overhauled diff normally feels tighter - as the bearings set in some of the tightness comes off.

Rohan,

I'm not sure about those figures being applicable in all cases - they certainly don't appear to refer to Ford CWP's as the backlash figures are completely different to Ford spec. However, if you fit the CW&P that the information refers to then I can't see there being a problem.

The depth of mesh tools also take into consideration the machining in the differential case and where the pinion bearings themselves seat. When setting a diff up the first job is to fit the new bearing cups into the casing and fit the dummy pinion with cups' relevant bearings.

The relevant pinion shim takes into consideration all aspects of machining tolerances. Some diff casings that can be bought come with either the (manufacturer of the cases) pinion shim figure or the actual shim they have calculated to fit.

I'm not entirely sure how you will get to the pinion shim seating face on the pinion to obtain the correct measurement?

Also don't forget that calculations also need to take into consideration bearing expansion once the pinion head bearing is pressed on and the bearings are preloaded. The book mentions minus 0.001" for this figure (if the book is to be trusted in light of some of the info I mentioned that is not trustworthy!)

Even when these tools are used the shim may need changing due to contact patch being out when using all new parts.

Timken bearings are generally exactly the same in comparison to another Timken (I suppose it depends on how old the two bearings are in comparison to each other) but Koyo and SKF will more often than not give a slightly different reading to a Timken.

The only crucial tools that are needed for the job are pinion bearing removal tool, cap spread gauge to measure the load on the side bearings, and pre-load/bearing "drag". You could do without the depth of mesh gauge if you have enough shims available, a way to get a new shim in, and plenty of time to progress with trial and error.

Will be interested to see the measuring tool that you intend to make.

Diff's get very hot - not being able to hold one is normal. Some race cars had diff coolers to keep them cool. And an overhauled diff normally feels tighter - as the bearings set in some of the tightness comes off.

Rohan,

I'm not sure about those figures being applicable in all cases - they certainly don't appear to refer to Ford CWP's as the backlash figures are completely different to Ford spec. However, if you fit the CW&P that the information refers to then I can't see there being a problem.

The depth of mesh tools also take into consideration the machining in the differential case and where the pinion bearings themselves seat. When setting a diff up the first job is to fit the new bearing cups into the casing and fit the dummy pinion with cups' relevant bearings.

The relevant pinion shim takes into consideration all aspects of machining tolerances. Some diff casings that can be bought come with either the (manufacturer of the cases) pinion shim figure or the actual shim they have calculated to fit.

I'm not entirely sure how you will get to the pinion shim seating face on the pinion to obtain the correct measurement?

Also don't forget that calculations also need to take into consideration bearing expansion once the pinion head bearing is pressed on and the bearings are preloaded. The book mentions minus 0.001" for this figure (if the book is to be trusted in light of some of the info I mentioned that is not trustworthy!)

Even when these tools are used the shim may need changing due to contact patch being out when using all new parts.

Timken bearings are generally exactly the same in comparison to another Timken (I suppose it depends on how old the two bearings are in comparison to each other) but Koyo and SKF will more often than not give a slightly different reading to a Timken.

The only crucial tools that are needed for the job are pinion bearing removal tool, cap spread gauge to measure the load on the side bearings, and pre-load/bearing "drag". You could do without the depth of mesh gauge if you have enough shims available, a way to get a new shim in, and plenty of time to progress with trial and error.

Will be interested to see the measuring tool that you intend to make.

-

promotor - Fourth Gear

- Posts: 797

- Joined: 16 Mar 2012

Rohan,

I struggled to find a measurement to calculate the thickness of the shim for the pinion bearing. I spoke to several overhaul companies and a couple of gear manufacturers, one of whom advised me of the following.

"The cast iron pinion case is a fairly rough piece of engineering, but the crown wheel and pinion are much more precise. If you fit the original shim it will probably be correct, as the shim is there to compensate for pinion case errors."

I took this advise and it appears to have worked. Of course I could have been lucky, and I was fortunate to find an "old stock" Ford crown wheel and pinion.

Brian Bucklands book shows an involved piece of kit to set the preload torque on the pinion shaft. I improvised with wooden drum rather like a fishing rod reel attached to the pinion flange. A piece of cord wound around the drum, and some wieghts in a two pound jam tin on the other end of the cord. The weight was calculated to produce the correct preload torque while I tigtened the pinion shaft nut.

Richard Hawkins

I struggled to find a measurement to calculate the thickness of the shim for the pinion bearing. I spoke to several overhaul companies and a couple of gear manufacturers, one of whom advised me of the following.

"The cast iron pinion case is a fairly rough piece of engineering, but the crown wheel and pinion are much more precise. If you fit the original shim it will probably be correct, as the shim is there to compensate for pinion case errors."

I took this advise and it appears to have worked. Of course I could have been lucky, and I was fortunate to find an "old stock" Ford crown wheel and pinion.

Brian Bucklands book shows an involved piece of kit to set the preload torque on the pinion shaft. I improvised with wooden drum rather like a fishing rod reel attached to the pinion flange. A piece of cord wound around the drum, and some wieghts in a two pound jam tin on the other end of the cord. The weight was calculated to produce the correct preload torque while I tigtened the pinion shaft nut.

Richard Hawkins

- RichardHawkins

- Coveted Fifth Gear

- Posts: 1268

- Joined: 05 Jul 2008

Hi Richard

There are 3 variables in manufacture the shim adjusts for

1. the depth of machining for the bearing support shoulder. \

2. The thickness of the bearing

3. The position of the back face of the pinion versus the gear cut in the pinion.

The biggest variable is the depth of machining for the bearing support shoulder as this was not very precise.

The bearing thickness should not change for identical bearings from the same manufacturer. so swapping for a new bearing of the same manufacturer should not affect the shimrequired

The pinion dimensions appear to have been done more precisely and any adjustment to shim thickness used to be etched on the pinion shaft if required. i don't know if this is done with new pinions these days. If you swap for a new pinion that required the same adjustment as the one removed ( most required no adjustment I believe) then the again you would not affect the shim thickness required.

The key question is the 3.290 inch dimension to the shim face written on the drawing I found on the web actually correct ????

cheers

Rohan

There are 3 variables in manufacture the shim adjusts for

1. the depth of machining for the bearing support shoulder. \

2. The thickness of the bearing

3. The position of the back face of the pinion versus the gear cut in the pinion.

The biggest variable is the depth of machining for the bearing support shoulder as this was not very precise.

The bearing thickness should not change for identical bearings from the same manufacturer. so swapping for a new bearing of the same manufacturer should not affect the shimrequired

The pinion dimensions appear to have been done more precisely and any adjustment to shim thickness used to be etched on the pinion shaft if required. i don't know if this is done with new pinions these days. If you swap for a new pinion that required the same adjustment as the one removed ( most required no adjustment I believe) then the again you would not affect the shim thickness required.

The key question is the 3.290 inch dimension to the shim face written on the drawing I found on the web actually correct ????

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

Hi Rohan,

This topic came up a few years ago at this link.

http://www.lotuselan.net/forums/lotus-gearbox-f37/differential-set-t23130.html

Sean Murray posted the following page there from a set of Installation Instructions from Burtons, and it appears to confirm the 3.289 dimension that you identified.

Regards,

Jon

This topic came up a few years ago at this link.

http://www.lotuselan.net/forums/lotus-gearbox-f37/differential-set-t23130.html

Sean Murray posted the following page there from a set of Installation Instructions from Burtons, and it appears to confirm the 3.289 dimension that you identified.

Regards,

Jon

- jpt

- New-tral

- Posts: 14

- Joined: 21 Oct 2009

Completed the diff strip down today - a comprehensive failure if ever i have seen one.

Bearing splitter and hydraulic puller makes getting it apart easy

no teeth left on the pinion. It had +1 marked on in white to indicate the adjustment from standard shim calculation using the standard dummy pinion measurement

and a lot of rubble in the diff - found the 6th crown wheel bolt head - chewed up by the gears also

Ordered all the parts I need from TTR and Burtons. I will need to dismantle, check and clean the Quaiffe LSD as it will be full of metal filings by then I should have all the bits needed to rebuild.

I have measured the depth from the diff bearing centreline to the pinion support bearing shoulder so now just need the new bearing and pinion to calculate the pinion shim needed.

cheers

Rohan

Bearing splitter and hydraulic puller makes getting it apart easy

no teeth left on the pinion. It had +1 marked on in white to indicate the adjustment from standard shim calculation using the standard dummy pinion measurement

and a lot of rubble in the diff - found the 6th crown wheel bolt head - chewed up by the gears also

Ordered all the parts I need from TTR and Burtons. I will need to dismantle, check and clean the Quaiffe LSD as it will be full of metal filings by then I should have all the bits needed to rebuild.

I have measured the depth from the diff bearing centreline to the pinion support bearing shoulder so now just need the new bearing and pinion to calculate the pinion shim needed.

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

Rohan,

A little area of concern for me regarding your diff. When using an LSD the original crownwheel bolts are not long enough. You said you used original bolts? I don't know if that is initial reason the bolts started to fail but I would guess it is the most likely and largest contributing factor.

Bolts for LSD's need to be as long as flywheel bolts. In fact I have known flywheel bolts to be used. ARP do some bolts for this very job of fitting an LSD to an english diff.

EDIT : bolts need to be longer due to the LSD crownwheel mounting face being thicker than a standard differential unit.

A little area of concern for me regarding your diff. When using an LSD the original crownwheel bolts are not long enough. You said you used original bolts? I don't know if that is initial reason the bolts started to fail but I would guess it is the most likely and largest contributing factor.

Bolts for LSD's need to be as long as flywheel bolts. In fact I have known flywheel bolts to be used. ARP do some bolts for this very job of fitting an LSD to an english diff.

EDIT : bolts need to be longer due to the LSD crownwheel mounting face being thicker than a standard differential unit.

-

promotor - Fourth Gear

- Posts: 797

- Joined: 16 Mar 2012

Thanks and I will check and use longer bolts if there is room in the crown wheel for them to fit. I will also check the thickness of the original open diff flange versus the flange on the Quaiffe diff centre.

The bolt head failure is definitely a fatigue failure under the head but i cant see how the heads of the bolts saw such a high cyclc load. They lasted almost 50 years and perhaps 40 thousand race miles is the expected limit !

There was certainly no damage to the bolt threads or threads in the crown wheel so it does not look like lack of engagement length cause the failure even if i could have fitted a longer bolt

cheers

Rohan

The bolt head failure is definitely a fatigue failure under the head but i cant see how the heads of the bolts saw such a high cyclc load. They lasted almost 50 years and perhaps 40 thousand race miles is the expected limit !

There was certainly no damage to the bolt threads or threads in the crown wheel so it does not look like lack of engagement length cause the failure even if i could have fitted a longer bolt

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

I did some measuring of the various components to check the required CW to diff centre bolt lengths

Original diff centre flange thickness = 7.3 mm

Quaiffe diff centre flange thickness = 10.3 mm

depth of tapped hole in CW = 17.5 mm

depth of tapping in hole = 14.5 mm ( the hole does not appear to be bottom tapped)

Original diff bolt length = 19 mm (3/4 inch)

thus for original bolts

Depth of thread engage with original diff centre = 11.7 mm

Depth of thread engagement with Quaiffe diff centre = 8.7 mm

If you went to the next standard bolt length of 25.4 mm (1 inch) for the Quaiffe diff centre

then depth of engagement would be = 14.1 mm

This is very close to the tapped depth in the crown wheel so you would probable want special bolts about 22.2mm / 7/8 inch long or cut off 3 mm (1/8 inch) from the standard 1 inch bolts.

How long are the special ARP bolts ? Does Burtons stock them ? I could not find them on the ARP or Burtons web site?

cheers

Rohan

Original diff centre flange thickness = 7.3 mm

Quaiffe diff centre flange thickness = 10.3 mm

depth of tapped hole in CW = 17.5 mm

depth of tapping in hole = 14.5 mm ( the hole does not appear to be bottom tapped)

Original diff bolt length = 19 mm (3/4 inch)

thus for original bolts

Depth of thread engage with original diff centre = 11.7 mm

Depth of thread engagement with Quaiffe diff centre = 8.7 mm

If you went to the next standard bolt length of 25.4 mm (1 inch) for the Quaiffe diff centre

then depth of engagement would be = 14.1 mm

This is very close to the tapped depth in the crown wheel so you would probable want special bolts about 22.2mm / 7/8 inch long or cut off 3 mm (1/8 inch) from the standard 1 inch bolts.

How long are the special ARP bolts ? Does Burtons stock them ? I could not find them on the ARP or Burtons web site?

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

59 posts

• Page 1 of 4 • 1, 2, 3, 4

Total Online:

Users browsing this forum: Jason B and 9 guests

Axles.jpg)