Gearbox Selector Fork Rebuilding.

5 posts

• Page 1 of 1

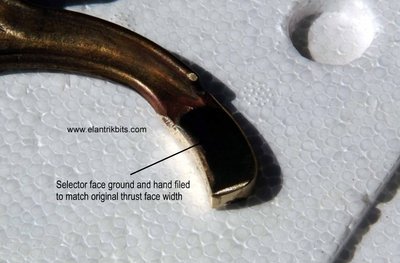

Further to gear box overhaul and rebuild work, pictures

below show 3rd & 4th gear selector, note the amount of wear

on the face.

Re building was done with Oxy and wear resistant

silver braze rod, this is a low melting point braze material

which means the metal deposit can be applied below the

heat point at which bronze will begin to sag.

Gear selector forks are often die cast in Aluminium bronze

which can be tricky to repair with nickel bronze.

With the correct metal preparation & technique the repair

can be done quite easily, the hard part is the careful hand

filing required. These reconditioned selector forks should

last for many more years.

I would not be at all surprised if many elan gearboxes

have badly worn selector forks considering the age

of them now.

Col.

below show 3rd & 4th gear selector, note the amount of wear

on the face.

Re building was done with Oxy and wear resistant

silver braze rod, this is a low melting point braze material

which means the metal deposit can be applied below the

heat point at which bronze will begin to sag.

Gear selector forks are often die cast in Aluminium bronze

which can be tricky to repair with nickel bronze.

With the correct metal preparation & technique the repair

can be done quite easily, the hard part is the careful hand

filing required. These reconditioned selector forks should

last for many more years.

I would not be at all surprised if many elan gearboxes

have badly worn selector forks considering the age

of them now.

Col.

- ceejay

- Fourth Gear

- Posts: 558

- Joined: 27 Mar 2007

Col,

I too have done this repair back in the early 90's when replacement 3-4 forks weren't available. I believe I used EasyFlo 3 silver solder. It is very tough. But rather than hand filing, I made a short stub spindle the same diameter as the shift rail that I could chuck in my lathe and later in the vise of my bench mill. Its a pretty small vertical mill, but easily does that job. the spindle makes sure that the cut surface is perpendicular to the rail which is exactly what is needed. I simply cut down to the original surface that was not touched by wear with the hub. I have a small pile of forks on the shelf waiting their turn under the torch.

Roger

I too have done this repair back in the early 90's when replacement 3-4 forks weren't available. I believe I used EasyFlo 3 silver solder. It is very tough. But rather than hand filing, I made a short stub spindle the same diameter as the shift rail that I could chuck in my lathe and later in the vise of my bench mill. Its a pretty small vertical mill, but easily does that job. the spindle makes sure that the cut surface is perpendicular to the rail which is exactly what is needed. I simply cut down to the original surface that was not touched by wear with the hub. I have a small pile of forks on the shelf waiting their turn under the torch.

Roger

'67 Elan S3 SS DHC

'67 Elan FHC pre-airflow

'67 Elan S3 SE upgrade to 26R by Original owner

'58 Eleven S2 (ex-works)

'62 20/22 FJ (ex-Yamura)

'70 Elan +2S RHD

'61 20 FJ project

'76 Modus M1 F3

'67 Elan FHC pre-airflow

'67 Elan S3 SE upgrade to 26R by Original owner

'58 Eleven S2 (ex-works)

'62 20/22 FJ (ex-Yamura)

'70 Elan +2S RHD

'61 20 FJ project

'76 Modus M1 F3

- Elan45

- Fourth Gear

- Posts: 957

- Joined: 23 Nov 2008

5 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 9 guests