Pinion oil seal

MarkDa wrote:A pair of SKF bearings c?10 delivered off eBay

Sure those are genuine? There is a lot of fakery about. Also, the sizes are quoted in metric. Will they fit properly onto a shaft machined to an Imperial size?

Example: https://www.ebay.co.uk/itm/222302435128 are SKF 30x62x16mm

-

JonB - Coveted Fifth Gear

- Posts: 2358

- Joined: 14 Nov 2017

I'm sure Rohan is right on the bearing specification.

I must admit that I looked at open bearings and that the sealed variant is a bit more expensive.

There are some very cheap offers out there but if you buy from a bearing specialist then you should get what you're paying for.

I must admit that I looked at open bearings and that the sealed variant is a bit more expensive.

There are some very cheap offers out there but if you buy from a bearing specialist then you should get what you're paying for.

- MarkDa

- Coveted Fifth Gear

- Posts: 1116

- Joined: 15 Apr 2017

JonB wrote:No, but I have a good imagination. On the other hand, my shafts (apart from the one I just replaced) are the safety variety, so they won't flail about even if a doughnut fails completely.

I would not rely on the "failsafe" pins. I had a donut fail on mu Plus 2 many many years ago and the failsafe pin just sheared off and the flailing shaft took a big gouge out of the chassis cross member above it. Been on Cv's since late 1980's without further issues .

cheers

Rohan

-

rgh0 - Coveted Fifth Gear

- Posts: 8413

- Joined: 22 Sep 2003

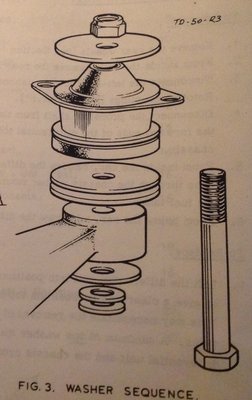

To add to the general confusion, I noticed this diagram in the manual of the top mounting and its washers:

On my car (with Spyder chassis) I have the washer at the very top, a brace bar, then one more washer, very large, with a flat side (so it is D-shaped) that goes under the bolt head. This doesn't seem to be enough! Moreover, i do wonder if the diff is free to move with that enormous D shaped washer in place. I suppose I should check the chassis for witness marks.

I think the D shaped washer is a Spyder part as the service manual doesn't show it. Should I add extra washers?

On my car (with Spyder chassis) I have the washer at the very top, a brace bar, then one more washer, very large, with a flat side (so it is D-shaped) that goes under the bolt head. This doesn't seem to be enough! Moreover, i do wonder if the diff is free to move with that enormous D shaped washer in place. I suppose I should check the chassis for witness marks.

I think the D shaped washer is a Spyder part as the service manual doesn't show it. Should I add extra washers?

-

JonB - Coveted Fifth Gear

- Posts: 2358

- Joined: 14 Nov 2017

Jon,

do you have a photo to show us how it was assembled please with the "Frustacones" in place + Diff Brace.

Alan

do you have a photo to show us how it was assembled please with the "Frustacones" in place + Diff Brace.

Alan

Alan.b Brittany 1972 elan sprint fhc Lagoon Blue 0460E

- alan.barker

- Coveted Fifth Gear

- Posts: 3754

- Joined: 06 Dec 2008

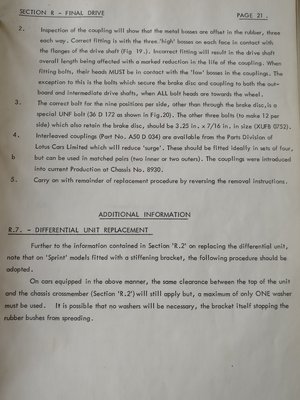

JonB wrote:Should I add extra washers?

Probably not.....this from the 2 seater workshop manual but likely to apply to the Plus 2 also .....

Edit... beat me to it ..too slow on the button

Roger

S4 DHC

S4 DHC

- oldelanman

- Coveted Fifth Gear

- Posts: 1930

- Joined: 02 Jan 2008

If there is no washer between the Frustacone and Diff Brace some people weld extra metal on the sides of the Diff Brace. This is so the Frustacone has full contact across it's contact face.

Alan

Alan

Alan.b Brittany 1972 elan sprint fhc Lagoon Blue 0460E

- alan.barker

- Coveted Fifth Gear

- Posts: 3754

- Joined: 06 Dec 2008

Hmm, I'm not about to try that, my welding is terrible! That said, I am also thinking of the load spreading capabilities of the brace on the diff ears. When I took the brace off I noticed that the mating surface of the diff was not fully covered by the brace. Then again, it's been like this since 1992 and done ~43,000 miles with no obvious signs of damage.

I have no picture of the parts prior to disassembly and I now realise that I have forgotten which way round it all was. It's possible the big D shaped washer was between the frustacone and brace. I imagine that with a trial fit on reassembly it will become obvious, though.

My main concern is the additional stresses that fitting CV joints will introduce.

I have no picture of the parts prior to disassembly and I now realise that I have forgotten which way round it all was. It's possible the big D shaped washer was between the frustacone and brace. I imagine that with a trial fit on reassembly it will become obvious, though.

My main concern is the additional stresses that fitting CV joints will introduce.

-

JonB - Coveted Fifth Gear

- Posts: 2358

- Joined: 14 Nov 2017

I think it's a good idea if the mating surface with the brace has full width contact.

I imagine you could get someone to weld each side of the brace a half washer. That way you have a nice big contact area to be safe with the CV stresses.

Alan

I imagine you could get someone to weld each side of the brace a half washer. That way you have a nice big contact area to be safe with the CV stresses.

Alan

Alan.b Brittany 1972 elan sprint fhc Lagoon Blue 0460E

- alan.barker

- Coveted Fifth Gear

- Posts: 3754

- Joined: 06 Dec 2008

JonB wrote:MarkDa wrote:A pair of SKF bearings c?10 delivered off eBay

Sure those are genuine? There is a lot of fakery about. Also, the sizes are quoted in metric. Will they fit properly onto a shaft machined to an Imperial size?

Example: https://www.ebay.co.uk/itm/222302435128 are SKF 30x62x16mm

Oddly enough, motor vehicles that generally have imperial sizes elsewhere have METRIC size bearings.

- Craven

- Coveted Fifth Gear

- Posts: 1623

- Joined: 14 Sep 2013

Or the classic thing wheel dia in inches and tyre width in mm.

Alan

Alan

Alan.b Brittany 1972 elan sprint fhc Lagoon Blue 0460E

- alan.barker

- Coveted Fifth Gear

- Posts: 3754

- Joined: 06 Dec 2008

Jon

The diff ear failure mechanism was snapping in the leg back to the housing - in essence 'bending'

The brace reduced that stress in the alloy.

The fact that it doesn't fully cover the ear doesn't matter because the ear is strong enough to take the load.

Having a big washer under the rubber gets the load evenly into the mount and the same goes for the top.

The workshop manual says that the brace is good enough to spread the load but if you're worried and can't get a washer in because of diff to chassis clearance then widening the brace is an option.

How many big (2") washers have you got?

You must have one at the top of the mount, one beneath is optional.

There should be a couple of washers under the bolt head one standard and the other the size of the ear to avoid 'point' loading - All as per the sketch you posted

Mark

The diff ear failure mechanism was snapping in the leg back to the housing - in essence 'bending'

The brace reduced that stress in the alloy.

The fact that it doesn't fully cover the ear doesn't matter because the ear is strong enough to take the load.

Having a big washer under the rubber gets the load evenly into the mount and the same goes for the top.

The workshop manual says that the brace is good enough to spread the load but if you're worried and can't get a washer in because of diff to chassis clearance then widening the brace is an option.

How many big (2") washers have you got?

You must have one at the top of the mount, one beneath is optional.

There should be a couple of washers under the bolt head one standard and the other the size of the ear to avoid 'point' loading - All as per the sketch you posted

Mark

- MarkDa

- Coveted Fifth Gear

- Posts: 1116

- Joined: 15 Apr 2017

I had another look. One washer at the top under the fuel tank, one D shaped washer under the frustacone and one washer under the bolt head, I think.

Meanwhile, I removed one of the circlips had a go at pulling the shaft out of the diff with a home made slide hammer and chains over the ears of the spider. No chance, couldn't budge it, even with heat applied judiciously to the casing. I'm a bit worried that if I go too far I may bend an ear or damage the casing, so I am going to leave it as it is. One seal is OK, the other looks like it is weeping very slightly. Shows as a small amount of oil smeared around the opening of the seal, but there is no evidence of a huge spray under the car, unlike the pinion seal.

Now, someone is going to say that I should do these seals now, but before you do, let me just remind you that the diff on my car isn't that "diff" to remove (geddit??), and if I find it leaking again I can take it out again.

I am left wondering where the lake of oil came from that I found in the battery tray when I cleaned the boot. It was pretty thick stuff. I remember thinking (and saying in a post) that it was from the diff, but I cannot see any way for oil from the pinion end to get into the boot. Maybe the PO had a spill; I'll never know. At that time I had not handled "classic" type engine oil and did not realise it is so stringy. Maybe that's why I thought it was gear oil.

Speaking of which, I marked the nut, shaft and output flange and undid the nut, counting the turns. Harder than it sounds when you can't see the nut.. anyway, the old seal was very poor, rusty and malformed. Although I'd drained the diff, more oil came out of a channel in the nose of the diff, and I was pleased to see that it was very clean. Also noted a Timsen pinion bearing, which may (or may not) be original. Whatever, it's quality.

I cleaned the pinion seal seating out and applied a smear of grease to the new seal, then smeared Wellseal around the seating. Simple matter of drifting the new seal into place (with the spring on the inside), first with a piece of softwood (side on), then carefully with the magic screwdriver and a wooden mallet around the outer edge of the seal to prevent damage. Easy.

Cleaned the nut and shaft threads as well as the splines on the input flange and shaft. Applied Wellseal to the splines and refitted the flange to the shaft, cleaning any excess. Applied Wellseal to the thread on the nut and wound it onto the shaft. "Turns" out (geddit??) that it's not necessary to count the nut revolutions, as you can feel the play in the flange reducing as you tighten the nut. Once there was no play that I could feel, I saw that the nut was half a turn away from its original position as shown by the markings, so I wound it up until they aligned. Checked the play, none, and the action of the diff seems OK.

About Wellseal: I was advised by Miles to use it on the splines and thread, otherwise the oil will worm its way out.

Meanwhile, I removed one of the circlips had a go at pulling the shaft out of the diff with a home made slide hammer and chains over the ears of the spider. No chance, couldn't budge it, even with heat applied judiciously to the casing. I'm a bit worried that if I go too far I may bend an ear or damage the casing, so I am going to leave it as it is. One seal is OK, the other looks like it is weeping very slightly. Shows as a small amount of oil smeared around the opening of the seal, but there is no evidence of a huge spray under the car, unlike the pinion seal.

Now, someone is going to say that I should do these seals now, but before you do, let me just remind you that the diff on my car isn't that "diff" to remove (geddit??), and if I find it leaking again I can take it out again.

I am left wondering where the lake of oil came from that I found in the battery tray when I cleaned the boot. It was pretty thick stuff. I remember thinking (and saying in a post) that it was from the diff, but I cannot see any way for oil from the pinion end to get into the boot. Maybe the PO had a spill; I'll never know. At that time I had not handled "classic" type engine oil and did not realise it is so stringy. Maybe that's why I thought it was gear oil.

Speaking of which, I marked the nut, shaft and output flange and undid the nut, counting the turns. Harder than it sounds when you can't see the nut.. anyway, the old seal was very poor, rusty and malformed. Although I'd drained the diff, more oil came out of a channel in the nose of the diff, and I was pleased to see that it was very clean. Also noted a Timsen pinion bearing, which may (or may not) be original. Whatever, it's quality.

I cleaned the pinion seal seating out and applied a smear of grease to the new seal, then smeared Wellseal around the seating. Simple matter of drifting the new seal into place (with the spring on the inside), first with a piece of softwood (side on), then carefully with the magic screwdriver and a wooden mallet around the outer edge of the seal to prevent damage. Easy.

Cleaned the nut and shaft threads as well as the splines on the input flange and shaft. Applied Wellseal to the splines and refitted the flange to the shaft, cleaning any excess. Applied Wellseal to the thread on the nut and wound it onto the shaft. "Turns" out (geddit??) that it's not necessary to count the nut revolutions, as you can feel the play in the flange reducing as you tighten the nut. Once there was no play that I could feel, I saw that the nut was half a turn away from its original position as shown by the markings, so I wound it up until they aligned. Checked the play, none, and the action of the diff seems OK.

About Wellseal: I was advised by Miles to use it on the splines and thread, otherwise the oil will worm its way out.

-

JonB - Coveted Fifth Gear

- Posts: 2358

- Joined: 14 Nov 2017

Total Online:

Users browsing this forum: DABARTH and 16 guests