5 Speed gear selector cover improvement

12 posts

• Page 1 of 1

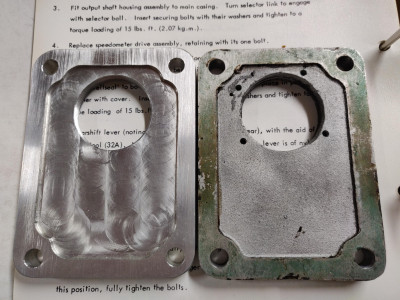

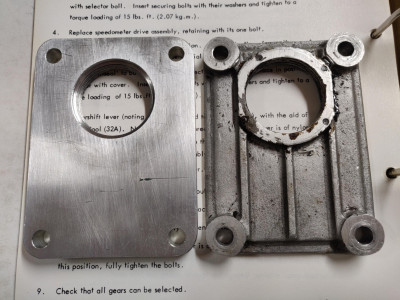

As some of you may recall, around half a year ago I installed a five speed gearbox in my Plus 2. It works a treat overall, but one problem it had was oil leakage from the gear selector cover. Most of the leakage was right past the gasket, which I found to be slightly concave along each side between the corners, probably due to too much bolt-torque over the years. I also found the threads in the big hole on top to have been cross-threaded at some point in the past, making it very difficult to get the lever threaded-in straight so that the base of the lever mated flush with the cover. The cover also had some holes in it where screws had been used to try to secure the old worn plastic lever-base in the hole. In other words, the cover was not in good condition!

I wasn't able to find a replacement cover, so I had a machinist make one for me:

Since its location in the car isn't generally visible, I didn't much care what it looked like, and for strength I had the machinist make it all the same thickness rather than try to replicate the details of the original. I don't know what alloy he used but it does seem much tougher than the original. I also had him add a small chamfer around the hole to allow for an O-ring just to be belt-and-braces about things.

I've done two drives with it so far, a short one of about ten miles and today about 70, and so far so good- I haven't been under the car since the drive, but poking around through the hole in the tunnel and looking underneath at the bits that are visible from aside, no sign yet of any drips. While more drives and closer inspection will be needed to say for sure, I do feel optimistic that the leakage has been sorted.

I wasn't able to find a replacement cover, so I had a machinist make one for me:

Since its location in the car isn't generally visible, I didn't much care what it looked like, and for strength I had the machinist make it all the same thickness rather than try to replicate the details of the original. I don't know what alloy he used but it does seem much tougher than the original. I also had him add a small chamfer around the hole to allow for an O-ring just to be belt-and-braces about things.

I've done two drives with it so far, a short one of about ten miles and today about 70, and so far so good- I haven't been under the car since the drive, but poking around through the hole in the tunnel and looking underneath at the bits that are visible from aside, no sign yet of any drips. While more drives and closer inspection will be needed to say for sure, I do feel optimistic that the leakage has been sorted.

1970 Elan Plus 2 (not S) 50/2036

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

-

The Veg - Coveted Fifth Gear

- Posts: 2188

- Joined: 16 Nov 2015

I've had the gear stick back out on me, then the selector mechanism disconnecting in side the box. Leaving me stranded in neutral.

This was caused by my error in that I fitted a o ring under the stick to make sure it didn't leak and I didn't bent the tabs on the stick to stop it rotating. Looking at your design it looks like you might repeat what I did. Hopefully the new cut thread will avoid this but I wouldn't be comfortable with out something to secure it from rotating.

I thought about doing a similar part but to use the type 9 gear stick. I believe it's the same design just with a different fitting solution. I think they are also a bit more easily available. It might be possible to modify your cover to take a type 9 stick with just adding a few threaded holes.

This was caused by my error in that I fitted a o ring under the stick to make sure it didn't leak and I didn't bent the tabs on the stick to stop it rotating. Looking at your design it looks like you might repeat what I did. Hopefully the new cut thread will avoid this but I wouldn't be comfortable with out something to secure it from rotating.

I thought about doing a similar part but to use the type 9 gear stick. I believe it's the same design just with a different fitting solution. I think they are also a bit more easily available. It might be possible to modify your cover to take a type 9 stick with just adding a few threaded holes.

'73 +2 130/5 RHD, now on the road and very slowly rolling though a "restoration"

- mbell

- Coveted Fifth Gear

- Posts: 2643

- Joined: 07 Jun 2013

mbell wrote:I've had the gear stick back out on me, then the selector mechanism disconnecting in side the box. Leaving me stranded in neutral.

This was caused by my error in that I fitted a o ring under the stick to make sure it didn't leak and I didn't bent the tabs on the stick to stop it rotating. Looking at your design it looks like you might repeat what I did. Hopefully the new cut thread will avoid this but I wouldn't be comfortable with out something to secure it from rotating.

Shouldn't be an issue for a couple of reasons. One is that I had the machinist make a chamfer to accommodate O-ring, and another is that I'm using one of those Burton Power levers for racing Fords, which has a metal threaded base instead of plastic. The metal won't soften and wear-away like the plastic threads on the original Ford levers, and the base has a nice flat surface to mate against the top of the cover, and also flats on opposing sides so I can get a tool on it and torque it in quite securely. After about 90 miles of testing on three different drives I feel pretty confident about it.

I thought about doing a similar part but to use the type 9 gear stick. I believe it's the same design just with a different fitting solution. I think they are also a bit more easily available. It might be possible to modify your cover to take a type 9 stick with just adding a few threaded holes.

That's an interesting idea. The one thing I don't like about the Burton stick is that it has the ball placed a bit higher than that of the Ford lever, making for short shifts (it is intended as a racing part, after all) and requiring high effort. If the fore-aft throws seem short, the lateral movement is proportionally shorter too, making for some trickyness getting the hang of smooth 2-3 shifts. 4-5 Is a little easier, but just a little. I'd love to have a lever that is identical in every respect except for having the ball located lower for more street-friendly throws.

1970 Elan Plus 2 (not S) 50/2036

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

-

The Veg - Coveted Fifth Gear

- Posts: 2188

- Joined: 16 Nov 2015

The Veg wrote:Shouldn't be an issue for a couple of reasons.

Great.

The Veg wrote:The one thing I don't like about the Burton stick is that it has the ball placed a bit higher than that of the Ford lever, making for short shifts (it is intended as a racing part, after all) and requiring high effort.

Interesting. I am seriously thinking about buying one cheap ones of those and likely see if I can mod it to lower the spherical bearing a bit and maybe add some isolation. I had messed with the original gearstick design last time i had the gearbox out and my concussion was a lot of the shift play/vagueness came from the ball arrangement used.

I've got a concept design that keeps the standard stick but replaces the ball and ball holder with plastic spherical bearing with adjustable height in am machined base. But would have to actually fix the design it and get it made. So thinking it might be better to get the off shelf one to se if I can just mod that...

'73 +2 130/5 RHD, now on the road and very slowly rolling though a "restoration"

- mbell

- Coveted Fifth Gear

- Posts: 2643

- Joined: 07 Jun 2013

mbell wrote:Interesting. I am seriously thinking about buying one cheap ones of those and likely see if I can mod it to lower the spherical bearing a bit and maybe add some isolation. I had messed with the original gearstick design last time i had the gearbox out and my concussion was a lot of the shift play/vagueness came from the ball arrangement used.

I've got a concept design that keeps the standard stick but replaces the ball and ball holder with plastic spherical bearing with adjustable height in am machined base. But would have to actually fix the design it and get it made. So thinking it might be better to get the off shelf one to se if I can just mod that...

The Burton lever's bearing is some type of nylon, and I find that it does provide a certain amount of isolation. I have no complaint about it, at least. One other thing I forgot mention was that this lever is made straight, but in a Plus 2 it needs to be bent if you don't want to put your knuckles through the dashboard going into 1,3 & 5. It's made of pretty stout stuff but I have a cute lil' 6-ton benchtop press that handled the job easily.

I've been meaning to talk with Burton to see if they can either make me one with the lower bearing-position or share the CAD file so I can have someone on this side of the world make that change (maybe an engineering-student who'd like to make a little beer-money?) and then I know a shop that can work from that (they could do the CAD-work too but charge a lot for it).

Sounds like we're on similar tracks here.

1970 Elan Plus 2 (not S) 50/2036

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

-

The Veg - Coveted Fifth Gear

- Posts: 2188

- Joined: 16 Nov 2015

I believe it is this one:

https://www.burtonpower.com/quickshift- ... -qs24.html

Personally as planning to hack it around i was going to get a cheap one:

https://mattlewisracing.co.uk/products/ ... gear-lever

The major downside this one that I believe it doesn't have the nylon bearing so more likely to be noisy. Shouldn't be too hard to find a replacement nylon bearing to fit.

Have you adjusted the dome nut on the under side (add an extra washer) to release some of the pretension on the 5th/rev detent?

On box I just finishing repairing I was probably going to drill the dome nut a little so the spring sit further down and removes some pre-tension.

https://www.burtonpower.com/quickshift- ... -qs24.html

Personally as planning to hack it around i was going to get a cheap one:

https://mattlewisracing.co.uk/products/ ... gear-lever

The major downside this one that I believe it doesn't have the nylon bearing so more likely to be noisy. Shouldn't be too hard to find a replacement nylon bearing to fit.

nmauduit wrote:Quite interesting thread (I've still not fully solved my issue with 5th not disengaging smoothly when hot)...

Have you adjusted the dome nut on the under side (add an extra washer) to release some of the pretension on the 5th/rev detent?

On box I just finishing repairing I was probably going to drill the dome nut a little so the spring sit further down and removes some pre-tension.

'73 +2 130/5 RHD, now on the road and very slowly rolling though a "restoration"

- mbell

- Coveted Fifth Gear

- Posts: 2643

- Joined: 07 Jun 2013

mbell wrote:Have you adjusted the dome nut on the under side (add an extra washer) to release some of the pretension on the 5th/rev detent?

thank you for the references.

yes, I now have maxed out that route (3 aluminium washers, 3-4mm I believe, only a bit better - ok for road use but would be unreasonably difficult to disengage during a track session), would have tried a different detent spring next (or grind some of it) but now it looks like third synchro ring needs changing so I'm just mentally preparing to an engine out and to whatever would be done on that occasion (e.g. speedo right angle).

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 1999

- Joined: 02 Sep 2013

nmauduit wrote:yes, I now have maxed out that route

Suspect you had, but thought worth checking. Maybe worth reshaping the detents?

Have a getrag box in a BMW that got hard to get out of 3rd gear. There was a upgrade kit for the detents that replaced ball bearings with a shaped detent to fix that. Might be able to do something similar hear. Luckily it's easily accessible to experiment.

nmauduit wrote:now it looks like third synchro ring needs changing

Same with the box in my car. Had it out to fix 4th gear and then again for new 4th gear syncro. Soon after that it decided to not like down shifts from 5 or 4th to 3rd sometimes.So got a broken eclat box, fixed it and going to fit that while i go through current box and improved/upgrade it.

'73 +2 130/5 RHD, now on the road and very slowly rolling though a "restoration"

- mbell

- Coveted Fifth Gear

- Posts: 2643

- Joined: 07 Jun 2013

Yes, the QS24 is the one I'm using. Externally I see very few differences between it and the Matt Lewis item so I'm guessing that the basic design has been passed-around a bit. I wonder if the nylon bearing in the Burton lever is a standard size and interchangeable with what's in the lower-priced levers?

1970 Elan Plus 2 (not S) 50/2036

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

-

The Veg - Coveted Fifth Gear

- Posts: 2188

- Joined: 16 Nov 2015

I suspect it's either a clone or all made by one factory and the expensive one is just sold as brand one with nice bearing. The cheap one is unbranded with cheap bearing.

My guess is it's a standard metric bearing. So hoping the cheap one with a a few changes might be a good solution.

My guess is it's a standard metric bearing. So hoping the cheap one with a a few changes might be a good solution.

'73 +2 130/5 RHD, now on the road and very slowly rolling though a "restoration"

- mbell

- Coveted Fifth Gear

- Posts: 2643

- Joined: 07 Jun 2013

I bought one of the cheap ones. Not really usable out of the box imo. To higher effort and too close to the dash.

It does use a standard bearing, ge20es-2rs. Looks like it should be possible to lower the bearing by adding a few extra groves to move the bearing position lower and adjusting the stick. Will require a lathe to do that.

The base is also made of steel, so it quite heavy.

Going to see if can mod it but likely take a while as need to get engine and Gearbox out and sorted.

It does use a standard bearing, ge20es-2rs. Looks like it should be possible to lower the bearing by adding a few extra groves to move the bearing position lower and adjusting the stick. Will require a lathe to do that.

The base is also made of steel, so it quite heavy.

Going to see if can mod it but likely take a while as need to get engine and Gearbox out and sorted.

'73 +2 130/5 RHD, now on the road and very slowly rolling though a "restoration"

- mbell

- Coveted Fifth Gear

- Posts: 2643

- Joined: 07 Jun 2013

12 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 17 guests