Fitting Rear Screen.

10 posts

• Page 1 of 1

Once again Sue Miller exceeded expectations and loaned me a tool for fitting the filler strip.

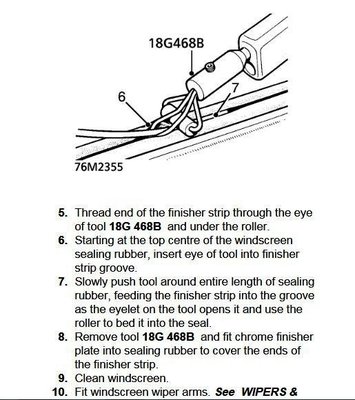

Problem is I don't see how it works. This is the closest I can get to the pic. in the manual.

How is it supposed to work? Is the strip in the right way? I've taken the boot lid off and intend to kneel on the screen whilst attempting this - a form of Lotus position Yoga.

Or perhaps the other way round ?

Or the held wires differently ?

Problem is I don't see how it works. This is the closest I can get to the pic. in the manual.

How is it supposed to work? Is the strip in the right way? I've taken the boot lid off and intend to kneel on the screen whilst attempting this - a form of Lotus position Yoga.

Or perhaps the other way round ?

Or the held wires differently ?

- vincereynard

- Coveted Fifth Gear

- Posts: 1071

- Joined: 12 Jan 2015

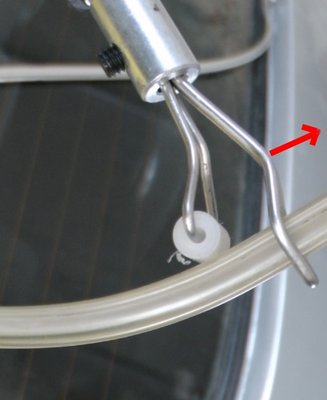

the tool works like on the second photo, the roll maintaining pressure on the shiny side of the strip while the wire opens up the rubber before it.

You don't want to press too much on the wheel or risk getting the strip whitening due to bend angle. You may ease the process with soapy water, warming up the strip etc. Having ample time to complete the task would help keeping one's cool... but it works.

good luck !

You don't want to press too much on the wheel or risk getting the strip whitening due to bend angle. You may ease the process with soapy water, warming up the strip etc. Having ample time to complete the task would help keeping one's cool... but it works.

good luck !

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 2000

- Joined: 02 Sep 2013

Thanks for that. It went in quite easily.

What I found helped was to add a separate (wire) piece that could pull on the guide wire.

It has a tendency to bend back towards the roller. Guide the tool handle with one hand and pull with the other. Went in no problem.

What I found helped was to add a separate (wire) piece that could pull on the guide wire.

It has a tendency to bend back towards the roller. Guide the tool handle with one hand and pull with the other. Went in no problem.

- vincereynard

- Coveted Fifth Gear

- Posts: 1071

- Joined: 12 Jan 2015

alanr wrote:Interesting....

Did you use any lubricant when putting the strip in....Tyre lube, WD40 or similar?

Alan.

Just water / washing liquid in a spray bottle. I also found it helped prevent the mastic (butyl rubber)

from sticking to the paint work!

stuart wrote:Sue Miller.......... probably the nicest parts supplier on the planet !!!!!!

+1 to that. Sue is a gem.

- vincereynard

- Coveted Fifth Gear

- Posts: 1071

- Joined: 12 Jan 2015

vincereynard wrote:What I found helped was to add a separate (wire) piece that could pull on the guide wire.

It has a tendency to bend back towards the roller.

As it was Friday I had a thought this morning.

A cable tie would work better than a separate wire. Tighten it around the "spreader" wire just where it flares out and pull with a mole or similar. Then slip it off when the tool is disassembled! Result.

- vincereynard

- Coveted Fifth Gear

- Posts: 1071

- Joined: 12 Jan 2015

10 posts

• Page 1 of 1

Total Online:

Users browsing this forum: No registered users and 14 guests