Fiberglass repair

34 posts

• Page 1 of 3 • 1, 2, 3

Folks -

I?m a complete newbie with regards to fiberglass repair. I?ve been watching some videos and reading up on the subject and am willing to give it a go with my S3.

I have a few questions I?ve googled and searched and can?t find the answers I need.

1) What type of resin did Lotus use for the Elan S3? I assume polyester but any specific brand that I should use?

2) What is the thickness of the original glass mat and how many layers were used?

3) My S3 has spider cracking in the paint over the entire vehicle. I assume the underlying gel coat needs a redo. Did Lotus use tissue as a final layer or just gel coat? My car has at least two repaints so don?t know how those were done.

I?m open and welcome recommendations for brands, suppliers, specifics part numbers, etc for materials to use. I haven?t bought the supplies yet.

Thanks

Tom

I?m a complete newbie with regards to fiberglass repair. I?ve been watching some videos and reading up on the subject and am willing to give it a go with my S3.

I have a few questions I?ve googled and searched and can?t find the answers I need.

1) What type of resin did Lotus use for the Elan S3? I assume polyester but any specific brand that I should use?

2) What is the thickness of the original glass mat and how many layers were used?

3) My S3 has spider cracking in the paint over the entire vehicle. I assume the underlying gel coat needs a redo. Did Lotus use tissue as a final layer or just gel coat? My car has at least two repaints so don?t know how those were done.

I?m open and welcome recommendations for brands, suppliers, specifics part numbers, etc for materials to use. I haven?t bought the supplies yet.

Thanks

Tom

- tomjones20194

- Second Gear

- Posts: 64

- Joined: 13 Sep 2018

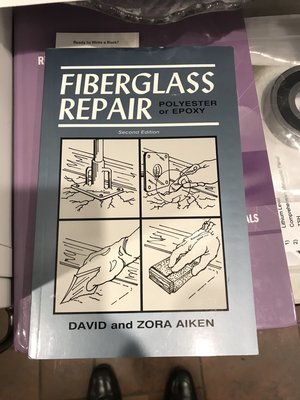

This is what you need .......the answers are all contained within.....

https://www.amazon.co.uk/Restore-Fibreg ... 0850455561

https://www.amazon.co.uk/Restore-Fibreg ... 0850455561

Brian

64 S2 Roadster

72 Sprint FHC

64 S2 Roadster

72 Sprint FHC

-

types26/36 - Coveted Fifth Gear

- Posts: 3408

- Joined: 11 Sep 2003

I doubt you?ll get much in the way of US brands or suppliers from MW?s book but it will give you a good grounding in how to work with glass fibre. I learnt a lot from my copy but that was back long before the advent of YouTube so whether the considerable cost of the book is worth it these days is debatable.

If you?ve not done much with g.f. before the main thing you?ll learn when you start is how messy it all is.

If you?ve not done much with g.f. before the main thing you?ll learn when you start is how messy it all is.

Stuart Holding

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

Thame UK / Alpe D'Huez France

69 S4 FHC

Honda GoldWing 1800

Honda CBX1000

Kawasaki H1 500

Yamaha XS2

- 69S4

- Coveted Fifth Gear

- Posts: 1124

- Joined: 23 Sep 2004

Agree completely that Wilkins book is good, it is extremely thorough; an extensive repair I did in 1985, under the front bumper and using its guidance, now shows just one crack and the inevitable stone chips.

From your description and pictures you really need to grind off the entire surface, repair major cracks and then tissue the whole body before applying filler for the final shape. That is what Wilkins used to do for a living until a few years ago and he hated it! Gel coat is just resin and only used for the original moulding, it doesn't resist cracking as well as tissue does.

From your description and pictures you really need to grind off the entire surface, repair major cracks and then tissue the whole body before applying filler for the final shape. That is what Wilkins used to do for a living until a few years ago and he hated it! Gel coat is just resin and only used for the original moulding, it doesn't resist cracking as well as tissue does.

Meg

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

-

Quart Meg Miles - Coveted Fifth Gear

- Posts: 1170

- Joined: 03 Oct 2012

The bodies were laid up with chopper gun glass - sprayed chopped strands and resin - so just use as many layers of matt as it takes to arrive at the thickness you want. From seeing lots of glass failures of different kinds, when ever I can, I will use biaxial or roving for more strength. If you do that, use matt to cover it or the weave will show. Done right, your hand laid repairs will probably be much stronger than the material it fastens to.

Finishing with tissue will prevent the glass pattern from printing through, and will be a much more stable base for your paint.

Finishing with tissue will prevent the glass pattern from printing through, and will be a much more stable base for your paint.

- webbslinger

- Second Gear

- Posts: 207

- Joined: 23 Jun 2012

Things have moved on a long way since MW's book. There has been a thread recently recommending West system fine woven sheathing and epoxy resin from the boat building world as a cure for pinholes and cracks - instead of tissue mat and polyester resin. Equally, paint technology is now far advanced from the days of MW's book. I would suggest you have a look at alternatives to MW before following his recommendations without question.

68 Elan S3 HSCC Roadsports spec

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

71 Elan Sprint (still being restored)

32 Standard 12

Various modern stuff

- Andy8421

- Coveted Fifth Gear

- Posts: 1227

- Joined: 27 Mar 2011

I was just thinking, are you sure they are gel coat/glass fibre cracks? I don't see why the whole body would show spider cracks unless it's had something really major happen? However several layers of paint can and do react badly and show crazing that might look like gel coat cracks? My car has had terrible abuse/neglect before I got it but cracks are only from damage or stress etc..

- vxah

- Third Gear

- Posts: 380

- Joined: 08 Nov 2012

.if i wuz u i'd get a 10$ repair set which will include some kind of glas fibre weave or cheaper and make a flat sample and a sample which you laminate into (not outside) a 90? angle profile where you'll learn how much resin it takes to get NO air bubbles - you'll see how messy it gets!! good luck sandy thereafter you're almost ready for the goooooooo!

- el-saturn

- Coveted Fifth Gear

- Posts: 1038

- Joined: 27 Jun 2012

Mine has cracks all over the roof, on upper srfaces around where the C-pillarsjoin the body, and several other upward-facing surfaces. I'm away this week and the cracks don't really photograph well, but I'd be interested in an expert opinion of them at some point. Paint is dull and faded too as the car spent decades in Florida then a few years at high altitude in Utah so lots of UV exposure.

1970 Elan Plus 2 (not S) 50/2036

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

2012 BMW R1200GS

"It just wouldn't be a complete day if I didn't forget something!" -Me

-

The Veg - Coveted Fifth Gear

- Posts: 2188

- Joined: 16 Nov 2015

not an expert opinion but a trick of the trade gathered along my way : when you've taken the paint off to the gel coat, you can wet the body in the suspicious area with a rag soaked in acetone and if there are cracks they will show as the sides of the cracks will darken from being wet while the acetone at the surface evaporates quickly (for repair purposes you'll need to consider the cracks extend further from where you see them stop, say an inch or so)

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 2000

- Joined: 02 Sep 2013

Tom,

Avoid woven materials in a cosmetic part, like the body of a car.

If you had start with a mold to create a new part, and put in several layers of matte first, then a layer of woven roving 2-3 layers deep, the weave pattern still eventually, over time, imprint it's weave pattern through to the surface. Yup, 'tis true.

If you?re doing racecar body work, lightness and strength trump cosmetics, and a little weave pattern doesn?t matter. But if you?re making repairs to? or over-restoring a street car to ?show quality?, then you don?t want woven materials involved anywhere. Your best efforts will look good initially, but the weave will eventually imprint through. It may take a very discerning eye to pick up on it, but the fact that you're already going down this road implies that you're looking for a good surface finish... eliminate the weave.

Lotus used chopped strand (ie, like matte sprayed out of a gun) for a reason other than just expediency. They avoided woven fiberglass, and so should you.

Similarly, if you ?fix? stress cracks by applying a fine layer of tissue/ veil over the full body, the hidden cracks or flaws will eventually imprint through. Any crazed paint, stress cracks, repaired fractures, or obvious flaws must be properly repaired first? there?s no easy way around that. Then, and only then, a full overlay of ? oz tissue can be a good final step. But it should never be used as the first, easy step to hide flaws... they'll just come back. Fix them correctly first, then apply your layer of finishing tissue to the now-smooth panel as a surfacing agent, using waxed polyester 'Surfacing' resin.

If you tissue/ veil the body, then to the extent possible, use one large piece to cover the entire surface in one shot. Clearly, you can?t cover the full body with one ?blanket?. But you can do doors, bonnet & boot lids, and major body area in large pieces of veil. That will avoid the need to sand down any overlapping edges between smaller panels. Don't make life harder than it has to be.

*~*~*~*

The original Elan/ Europa bodies were laid-up using polyester resin. Knowing the exact brand and grade won?t help you since now, ~50 years later, it won?t be available.

In a broad generalization, there are two basic types of polyester resin: 1) Laminating resin and 2) Surfacing resin (sometimes called Finishing resin. Polyester won?t fully cure in the presence of air? it needs to be sealed off. For that purpose, surfacing resin contains paraffin wax which floats to the surface, sealing the resin off from the air so it can cure.

But you don?t want wax between layers deep in a multi-layer laminate, so laminating resin contains no wax. Build-up multiple layers with laminating resin, then use surfacing resin for the last layer only. If you?re just resurfacing an old fiberglass part with a single layer of glass, then use surfacing/ finishing resin. However you get to that point, the last layer to go on must use surfacing resin.

If you know what you?re doing, and you?re good at it, there?s another option for external lay-ups (ie, on an existing body, not in a mold). Do all the wet lay-up/ repair work, including the last layer, with laminating resin, keeping the lay-up as dry as possible (excess resin just adds dead weight). Let it go to a ?green cure? state? firm, but with a tacky/ gooey surface. That?s as far as it will go without something to seal if off from the air. Then spray it (or, groan, brush it) with a polyester filler. That will seal the surface, promote a full cure, and provide a nice sandable surface to prep for paint. In the end, you?ll sand most of that off.

Vinylester is similar to polyester, stronger/ better, but different. Don?t mix them in a single part layup or repair. Polyester for boats & cars, vinylester for race cars and homebuilt aircraft.

Epoxy is a huge family of resins, and at the top of the family tree are resins that are superior in all aspects to polyester and vinylester. That?s the stuff that vacuum bagged, autoclaved exotic car and aircraft parts are made of.

However, each resin has a different chemical signature, and will react differently with the other resins, and with any finishing system/ paint that is applied over it. Pick one, and stick with it. Or, Lotus already made the choice for you, polyester, so use it for vintage Lotus repairs.

Epoxy will stick to polyester better than polyester will? so why not use it on a Lotus body?

Like weave imprinting, each resin type has it's own color and chemistry signature that will eventually imprint through to the paint surface as well. The Type 14 Elite in white is a good example. The body was laid up in polyester, and the doors used epoxy. I'm not certain, but I believe the bonnet & boot lids were a third resin. A few years down the road, and a white (or any light color) car become a patchwork of shades of white by body part (epoxy doors gained a pink hue). The effect isn?t bad indoors, but it?s obvious in direct sunlight. For a black or dark color paint, it's less of an issue. But for white and lighter colors, you need to be very careful about what resin you apply before painting. Pick one resin (Lotus already chose polyester for you), and stick with it.

If you want a structural repair as a priority (building a racer?), then a good epoxy is stronger, and actually bonds to polyester better than more polyester does. But, if you're trying to put a quality paint job on the car, and surface cosmetics are a priority, then avoid adding patches of different resins to the body. The original Europa body was molded using polyester resin, so use a polyester resin for your repairs/ resurfacing.

*~*~*~*

There's a 'sizing', or binding agent added to fiberglass matte / tissue that holds all the loose fibers together prior to use. It also makes it a little stiff, like a starched shirt. The solvents that are a normal part of polyester and vinylester resins (mostly ketone or acetone) quickly attack that binder so that the matte / tissue becomes very limp and pliable during lay-up. Epoxy doesn't contain such solvents, and it can be difficult to get matte to conform to convoluted shapes just after wetting it out with epoxy. But give it time to soak, and it will eventually soften and become pliable. If you're using epoxy with matte / tissue, don't mix a 'hot' batch that will cure quickly. Go with a slow cure to give the matte time to soften and follow the contours.

That's important on a convoluted shape. On a broad, mostly flat surface like the bonnet, that's not a big concern, but it's still something to consider. And if you use polyester (as you should on a vintage Lotus body), it's no problem at all.

*~*~*~*

Paint doesn?t stick to paraffin wax, so it?s critical that the surface be thoroughly cleaned ?wax-free? before giving any thought to spraying on anything? filler, primer/ surfacer, paint? ?anything? that you want to stick.

Acetone, Ketone, MEK (methyl-ethyl ketone) and lacquer thinner are all effective at removing wax, finger prints, and any other smudges that might interfere with paint adhesion. However, they will also eat paint. All those solvents can wick down into the fiberglass, following any micro cracks, or even wicking in along exposed glass strands. If you paint over freshly solvent-wiped fiberglass, any trapped solvent will wick up to the surface and attack the paint from below. The result will be paint blisters, usually from small pimples to diameters the size of a quarter or half dollar. And they can cover the entire surface that you wiped-down prior to painting.

ANY use of chemical paint strippers or chemical solvent surface cleaners must be followed by a l-o-n-g rest period, preferably under a hot sun, to allow ALL traces of those chemicals to evaporate before applying paint. A ?long rest? can be a full day or several for ?hot? solvents to weeks for Zip-Strip or similar paint strippers.

I?m paranoid about using chemical paint strippers on fiberglass panels. IMHO, the best paint stripper is sand paper on a ?DA? or orbital sander? or a hand sanding block. Paint stripper is faster and easier, but fixing panel-wide blisters in a painted surface is much harder. Pick your poison.

*~*~*~*

There is a paint flex additive that is mixed with paint that is to be applied over modern flexible bumper covers. Compared to full steel bodies, most... just about all of the vintage Lotus bodies flex enough to cause the paint to crack. It's a good idea to use flex additive in all paint applied to a Lotus body.

*~*~*~*

Off Topic, but...

A friend of mine used to own a Countach. The body was mostly metal, with a few graphite pieces mixed in... like the front bonnet. Over time, the weave would imprint through, and Countach fans consider the weave pattern a badge of honor... proof of the car's originality. One time he had some body work done to the front... nothing that involved the bonnet. The body shop took it upon themselves to do him a favor while they were working on it, and 'fix' the bonnet. It came back looking like a mile deep black mirror. Perfection. Their hearts were in the right place, but they really ticked him off... he pissed & moaned that it would take years for any hint of that weave pattern to come back.

Regards,

Tim Engel

Sorry about the abuse of bandwidth.

Avoid woven materials in a cosmetic part, like the body of a car.

If you had start with a mold to create a new part, and put in several layers of matte first, then a layer of woven roving 2-3 layers deep, the weave pattern still eventually, over time, imprint it's weave pattern through to the surface. Yup, 'tis true.

If you?re doing racecar body work, lightness and strength trump cosmetics, and a little weave pattern doesn?t matter. But if you?re making repairs to? or over-restoring a street car to ?show quality?, then you don?t want woven materials involved anywhere. Your best efforts will look good initially, but the weave will eventually imprint through. It may take a very discerning eye to pick up on it, but the fact that you're already going down this road implies that you're looking for a good surface finish... eliminate the weave.

Lotus used chopped strand (ie, like matte sprayed out of a gun) for a reason other than just expediency. They avoided woven fiberglass, and so should you.

Similarly, if you ?fix? stress cracks by applying a fine layer of tissue/ veil over the full body, the hidden cracks or flaws will eventually imprint through. Any crazed paint, stress cracks, repaired fractures, or obvious flaws must be properly repaired first? there?s no easy way around that. Then, and only then, a full overlay of ? oz tissue can be a good final step. But it should never be used as the first, easy step to hide flaws... they'll just come back. Fix them correctly first, then apply your layer of finishing tissue to the now-smooth panel as a surfacing agent, using waxed polyester 'Surfacing' resin.

If you tissue/ veil the body, then to the extent possible, use one large piece to cover the entire surface in one shot. Clearly, you can?t cover the full body with one ?blanket?. But you can do doors, bonnet & boot lids, and major body area in large pieces of veil. That will avoid the need to sand down any overlapping edges between smaller panels. Don't make life harder than it has to be.

*~*~*~*

The original Elan/ Europa bodies were laid-up using polyester resin. Knowing the exact brand and grade won?t help you since now, ~50 years later, it won?t be available.

In a broad generalization, there are two basic types of polyester resin: 1) Laminating resin and 2) Surfacing resin (sometimes called Finishing resin. Polyester won?t fully cure in the presence of air? it needs to be sealed off. For that purpose, surfacing resin contains paraffin wax which floats to the surface, sealing the resin off from the air so it can cure.

But you don?t want wax between layers deep in a multi-layer laminate, so laminating resin contains no wax. Build-up multiple layers with laminating resin, then use surfacing resin for the last layer only. If you?re just resurfacing an old fiberglass part with a single layer of glass, then use surfacing/ finishing resin. However you get to that point, the last layer to go on must use surfacing resin.

If you know what you?re doing, and you?re good at it, there?s another option for external lay-ups (ie, on an existing body, not in a mold). Do all the wet lay-up/ repair work, including the last layer, with laminating resin, keeping the lay-up as dry as possible (excess resin just adds dead weight). Let it go to a ?green cure? state? firm, but with a tacky/ gooey surface. That?s as far as it will go without something to seal if off from the air. Then spray it (or, groan, brush it) with a polyester filler. That will seal the surface, promote a full cure, and provide a nice sandable surface to prep for paint. In the end, you?ll sand most of that off.

Vinylester is similar to polyester, stronger/ better, but different. Don?t mix them in a single part layup or repair. Polyester for boats & cars, vinylester for race cars and homebuilt aircraft.

Epoxy is a huge family of resins, and at the top of the family tree are resins that are superior in all aspects to polyester and vinylester. That?s the stuff that vacuum bagged, autoclaved exotic car and aircraft parts are made of.

However, each resin has a different chemical signature, and will react differently with the other resins, and with any finishing system/ paint that is applied over it. Pick one, and stick with it. Or, Lotus already made the choice for you, polyester, so use it for vintage Lotus repairs.

Epoxy will stick to polyester better than polyester will? so why not use it on a Lotus body?

Like weave imprinting, each resin type has it's own color and chemistry signature that will eventually imprint through to the paint surface as well. The Type 14 Elite in white is a good example. The body was laid up in polyester, and the doors used epoxy. I'm not certain, but I believe the bonnet & boot lids were a third resin. A few years down the road, and a white (or any light color) car become a patchwork of shades of white by body part (epoxy doors gained a pink hue). The effect isn?t bad indoors, but it?s obvious in direct sunlight. For a black or dark color paint, it's less of an issue. But for white and lighter colors, you need to be very careful about what resin you apply before painting. Pick one resin (Lotus already chose polyester for you), and stick with it.

If you want a structural repair as a priority (building a racer?), then a good epoxy is stronger, and actually bonds to polyester better than more polyester does. But, if you're trying to put a quality paint job on the car, and surface cosmetics are a priority, then avoid adding patches of different resins to the body. The original Europa body was molded using polyester resin, so use a polyester resin for your repairs/ resurfacing.

*~*~*~*

There's a 'sizing', or binding agent added to fiberglass matte / tissue that holds all the loose fibers together prior to use. It also makes it a little stiff, like a starched shirt. The solvents that are a normal part of polyester and vinylester resins (mostly ketone or acetone) quickly attack that binder so that the matte / tissue becomes very limp and pliable during lay-up. Epoxy doesn't contain such solvents, and it can be difficult to get matte to conform to convoluted shapes just after wetting it out with epoxy. But give it time to soak, and it will eventually soften and become pliable. If you're using epoxy with matte / tissue, don't mix a 'hot' batch that will cure quickly. Go with a slow cure to give the matte time to soften and follow the contours.

That's important on a convoluted shape. On a broad, mostly flat surface like the bonnet, that's not a big concern, but it's still something to consider. And if you use polyester (as you should on a vintage Lotus body), it's no problem at all.

*~*~*~*

Paint doesn?t stick to paraffin wax, so it?s critical that the surface be thoroughly cleaned ?wax-free? before giving any thought to spraying on anything? filler, primer/ surfacer, paint? ?anything? that you want to stick.

Acetone, Ketone, MEK (methyl-ethyl ketone) and lacquer thinner are all effective at removing wax, finger prints, and any other smudges that might interfere with paint adhesion. However, they will also eat paint. All those solvents can wick down into the fiberglass, following any micro cracks, or even wicking in along exposed glass strands. If you paint over freshly solvent-wiped fiberglass, any trapped solvent will wick up to the surface and attack the paint from below. The result will be paint blisters, usually from small pimples to diameters the size of a quarter or half dollar. And they can cover the entire surface that you wiped-down prior to painting.

ANY use of chemical paint strippers or chemical solvent surface cleaners must be followed by a l-o-n-g rest period, preferably under a hot sun, to allow ALL traces of those chemicals to evaporate before applying paint. A ?long rest? can be a full day or several for ?hot? solvents to weeks for Zip-Strip or similar paint strippers.

I?m paranoid about using chemical paint strippers on fiberglass panels. IMHO, the best paint stripper is sand paper on a ?DA? or orbital sander? or a hand sanding block. Paint stripper is faster and easier, but fixing panel-wide blisters in a painted surface is much harder. Pick your poison.

*~*~*~*

There is a paint flex additive that is mixed with paint that is to be applied over modern flexible bumper covers. Compared to full steel bodies, most... just about all of the vintage Lotus bodies flex enough to cause the paint to crack. It's a good idea to use flex additive in all paint applied to a Lotus body.

*~*~*~*

Off Topic, but...

A friend of mine used to own a Countach. The body was mostly metal, with a few graphite pieces mixed in... like the front bonnet. Over time, the weave would imprint through, and Countach fans consider the weave pattern a badge of honor... proof of the car's originality. One time he had some body work done to the front... nothing that involved the bonnet. The body shop took it upon themselves to do him a favor while they were working on it, and 'fix' the bonnet. It came back looking like a mile deep black mirror. Perfection. Their hearts were in the right place, but they really ticked him off... he pissed & moaned that it would take years for any hint of that weave pattern to come back.

Regards,

Tim Engel

Sorry about the abuse of bandwidth.

Last edited by Esprit2 on Mon Jan 21, 2019 2:52 am, edited 3 times in total.

- Esprit2

- Third Gear

- Posts: 355

- Joined: 02 Apr 2008

Wow Tim, I'm going to print that and added it to Miles' book. Thank you, even though I may never use it.

Meg

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

26/4088 1965 S1½ Old and scruffy but in perfect working order; the car too.

________________Put your money where your mouse is, click on "Support LotusElan.net" below.

-

Quart Meg Miles - Coveted Fifth Gear

- Posts: 1170

- Joined: 03 Oct 2012

Tim -

Thank you for the thoughtful and comprehensive response. Very good information there. Admins should pin that post in a how to section. MW book is pricey so I picked up this one instead. Supposed to be very good for beginners. It just arrived so I haven?t had a chance to read it yet.

vxah - see the pics below. It could be be poor paint, crazing or dried out paint - I?m don?t know. Lots of cracking in the paint. There are also sections where the paint is bubbling and chipping off to reveal the original red underneath. Would like to hear folks opinion as to whether this is a paint issue or underlying gelcoat problem.

Thank you for the thoughtful and comprehensive response. Very good information there. Admins should pin that post in a how to section. MW book is pricey so I picked up this one instead. Supposed to be very good for beginners. It just arrived so I haven?t had a chance to read it yet.

vxah - see the pics below. It could be be poor paint, crazing or dried out paint - I?m don?t know. Lots of cracking in the paint. There are also sections where the paint is bubbling and chipping off to reveal the original red underneath. Would like to hear folks opinion as to whether this is a paint issue or underlying gelcoat problem.

- tomjones20194

- Second Gear

- Posts: 64

- Joined: 13 Sep 2018

the last photo shows a crack that most likely extends through the gel coat, while the middle photo does not (more of an preparation issue, e.g. lack of proper sealing/primer on a repair where the gelcoat had been sanded down maybe?)

One element to consider is the amount of defects to fix: is it only a few and localized to a few area, or are there some in many places? Then a second choice to ponder is to fix only defects, or repair the whole car...

The amount of work for the various options varies, but it's likely to count in tens of hours for the localized approach and in hundreds for a complete restoration from the gelcoat (including structural repairs if need be).

The safest and most durable way to go in many cases would be to sand all the paint layers down to the original gelcoat, which would enable to better assess all defects, but due to the duration of the task one needs to make sure to be able to store the car in the dry for the duration of the work - and that is likely to last more than the worst case initial scenario called for...

One element to consider is the amount of defects to fix: is it only a few and localized to a few area, or are there some in many places? Then a second choice to ponder is to fix only defects, or repair the whole car...

The amount of work for the various options varies, but it's likely to count in tens of hours for the localized approach and in hundreds for a complete restoration from the gelcoat (including structural repairs if need be).

The safest and most durable way to go in many cases would be to sand all the paint layers down to the original gelcoat, which would enable to better assess all defects, but due to the duration of the task one needs to make sure to be able to store the car in the dry for the duration of the work - and that is likely to last more than the worst case initial scenario called for...

S4SE 36/8198

-

nmauduit - Coveted Fifth Gear

- Posts: 2000

- Joined: 02 Sep 2013

The second photo is an example of how the paint looks on most of the top sections car. I don?t think it?s a repair section. I think the car spent some significant time sitting in the sun.

- tomjones20194

- Second Gear

- Posts: 64

- Joined: 13 Sep 2018

34 posts

• Page 1 of 3 • 1, 2, 3

Total Online:

Users browsing this forum: No registered users and 26 guests